Liquid tube for electrohydraulic chip

A chip and liquid pipe technology, applied in the field of liquid pipes for electro-hydraulic chips, can solve the problems of difficulty in production and assembly, limit output, increase costs, etc., and achieve simple and easy production and assembly, reduce production costs, and reduce flow resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation.

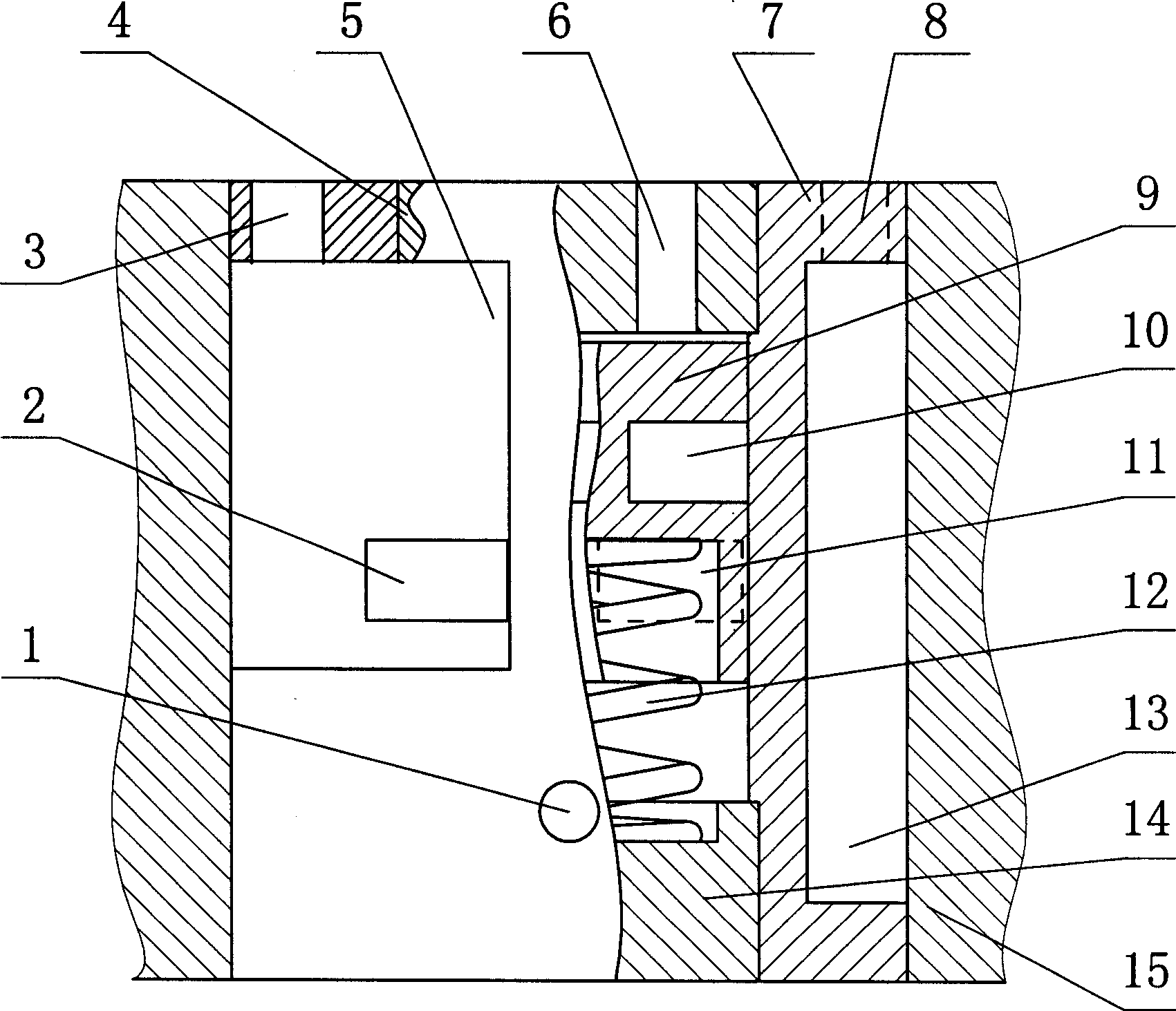

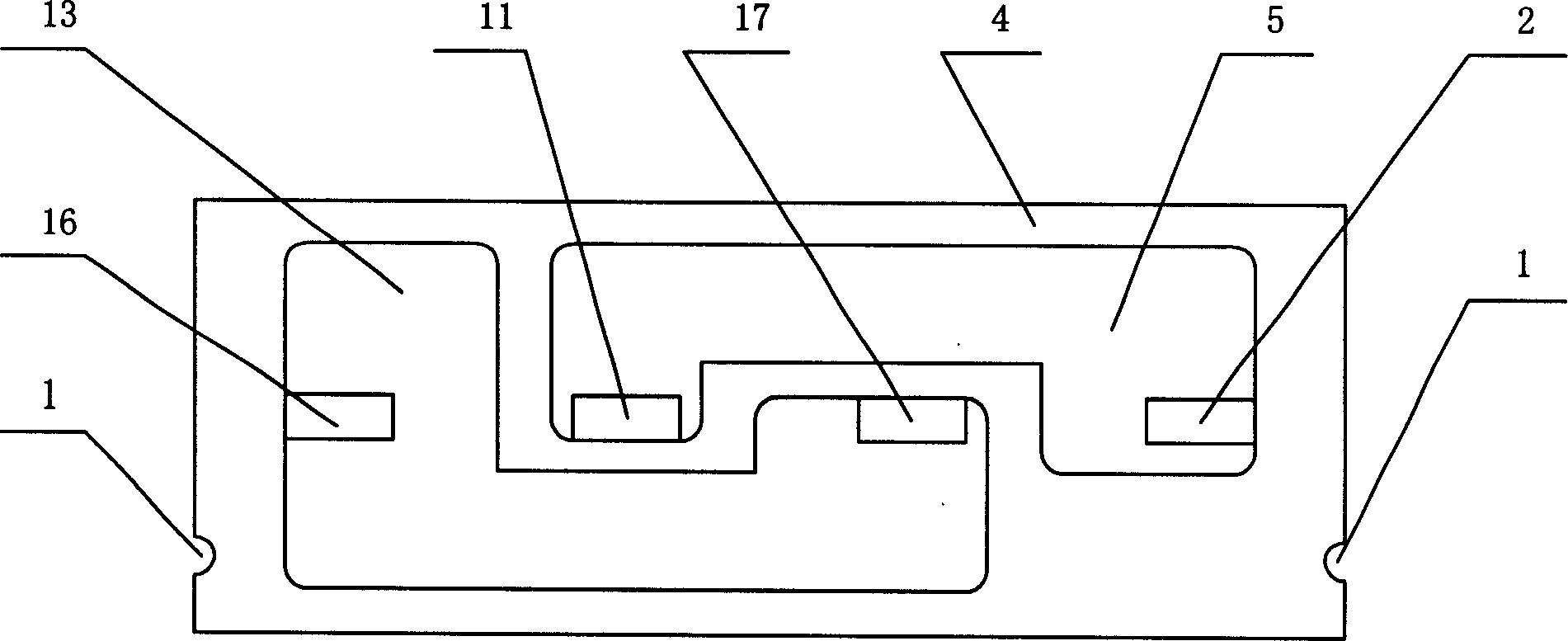

[0010] As can be seen from the accompanying drawings, the liquid pipe for the electro-hydraulic chip of this program has a chip substrate (15), and a cylindrical hollow tube sleeve (7) is arranged in the chip substrate (15), and on the inner cavity of the tube sleeve (7) There is an upper cover plate (4) on the top surface, and a lower cover plate (14) on the lower top surface, and there is a tube core ring groove (10) in the cavity between the upper cover plate (4) and the lower cover plate (14). ) of the die (9). This scheme is that there is an upper control oil passage (6) on the upper cover plate (4), which communicates with the inner cavity of the pipe sleeve (7) on the top of the pipe core (9), and there is a lower control oil passage ( 1) It communicates with the inner cavity of the pipe sleeve (7) at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com