Motor vehicle head light detector and detection method

A detection method and a technology for motor vehicles, which are applied in the direction of testing the alignment of automobile headlights and testing optical performance, etc., can solve the problems of low detection efficiency, long adjustment time, and inability to fully reflect the light distribution characteristics of motor vehicle headlights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

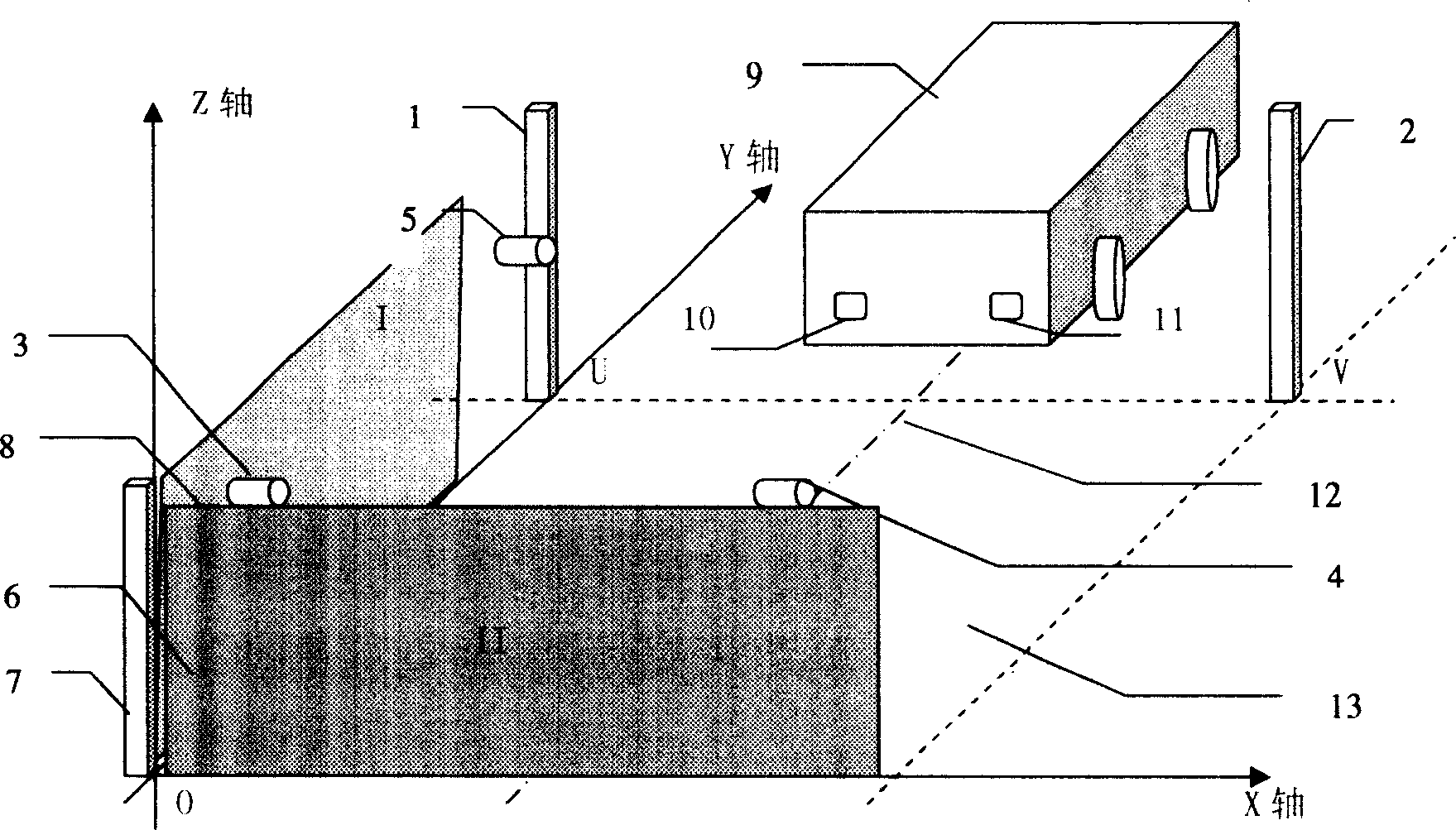

[0083] The principle diagram of the motor vehicle headlamp detector of the present invention is as figure 1 Shown in the figure: 1,2 positioning reference column, 3,4,5 digital camera, 6 detection screen, 7 detection screen driving mechanism, 8 computer, 9 motor vehicle, 10 right headlight of motor vehicle, 11 left front light of motor vehicle Light, the intersection point of U positioning reference column 1 and the installation ground, the intersection point of V positioning reference column 2 and the installation ground, 0 detects the intersection point of the rotation axis centerline of the screen drive mechanism and the installation ground, I detects the initial position of the screen, and II detects the position of the screen.

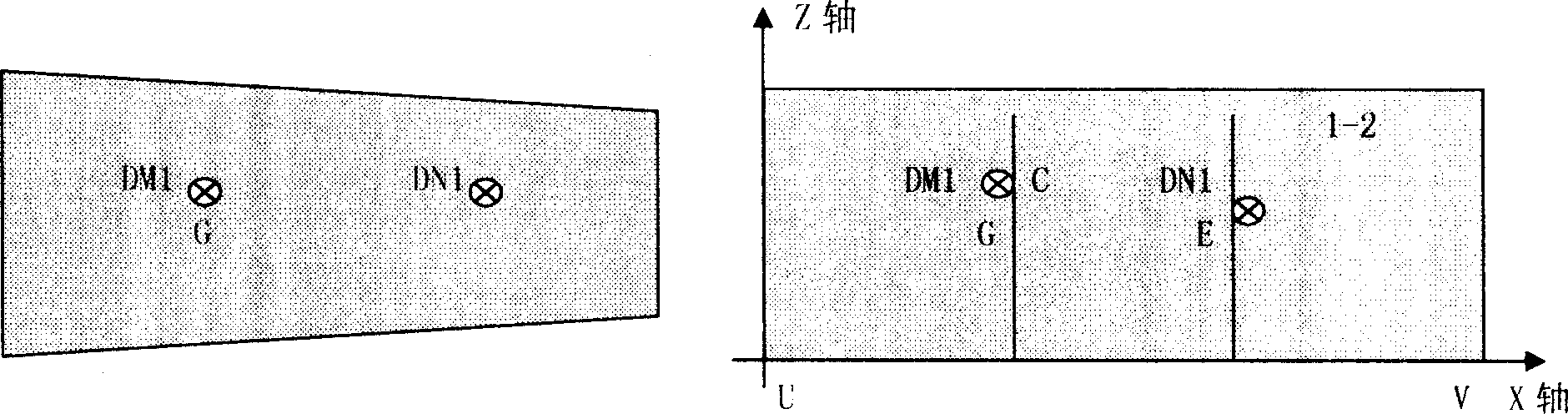

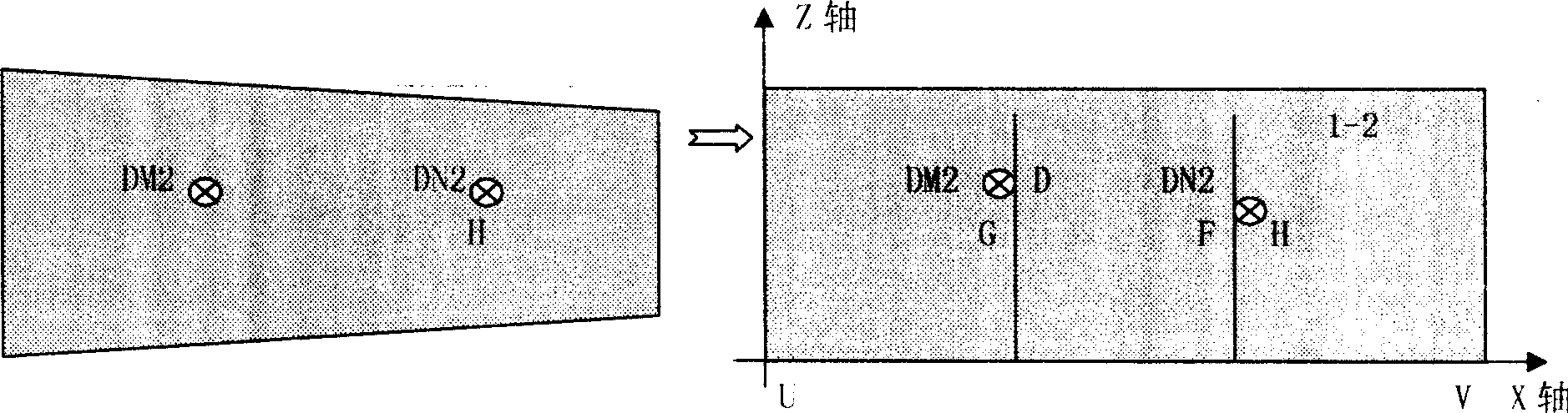

[0084] figure 2 Be digital camera (3) of the present invention to the effect diagram of the digital photo simulation figure that motor vehicle headlamp is taken and the effect figure after geometric stretching; Among the figure: 1-2 is the plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com