Quick connection terminal device

A technology for quick connection and equipment, which is applied in the direction of connection, clamping/spring connection, and parts of the connection device. It can solve the problems of changing the main body of the equipment, increasing the number of parts, and increasing the cost, so as to increase the contact area and touch the operating part. prevent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

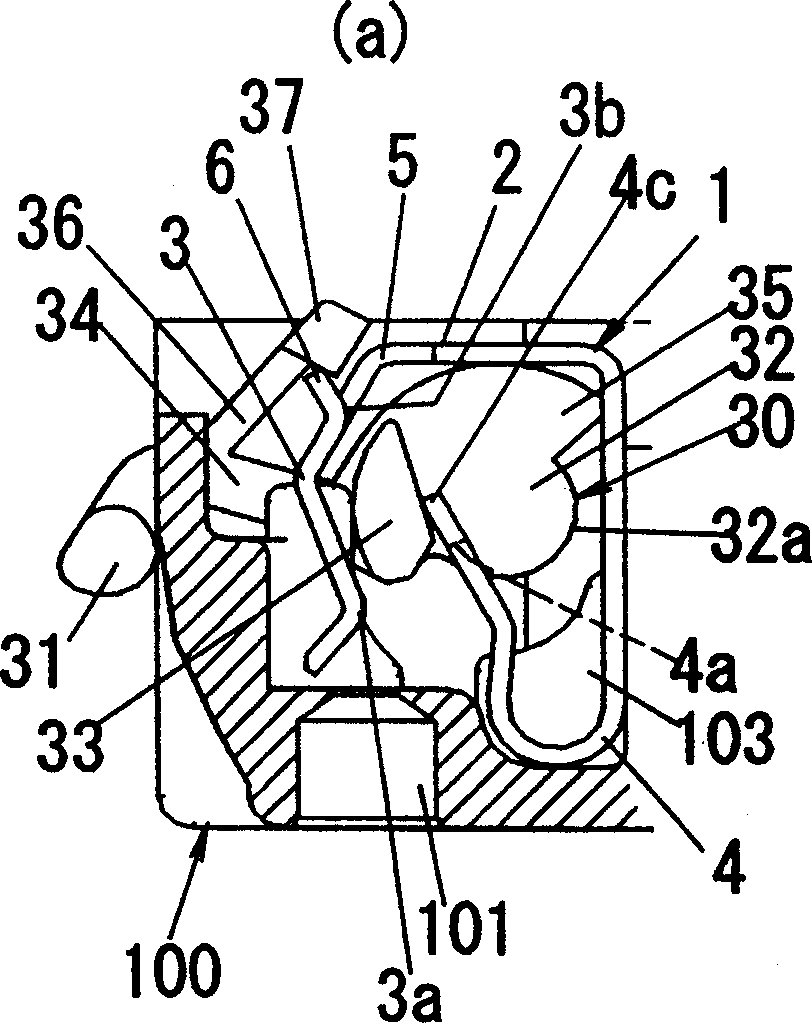

[0097] The quick connect terminal device according to this embodiment includes such as Figure 1 to Figure 3 Terminal strip 1 and release lever 30 are shown. Such as figure 2 As shown, the terminal board 1 has: a rectangular main piece 2; a pair of contact pieces 3 extending vertically downward from one edge of the main piece 2 along its longitudinal direction; A pair of J-shaped locking pieces 4 extending vertically downwards along its longitudinal direction. The main piece 2, the contact piece 3 and the locking piece 4 are integrally formed by processing a strip-shaped elastic metal plate, so that the front ends of the contact piece 3 and the locking piece 4 cross each other. Each contact piece 3 has: a pair of pressing parts 3a and 3b that press the two ends of the wire along the insertion direction of the wire; a hook-shaped part 6 formed by bending the front end of the upper pressing part 3b in the direction away from the locking piece 4; And the opening 5 for passing...

no. 2 approach

[0105] now refer to Figures 5 to 13 The quick connect terminal device according to the present embodiment will be described. Components common to the first embodiment are denoted by the same reference numerals, and description and illustration thereof are appropriately omitted.

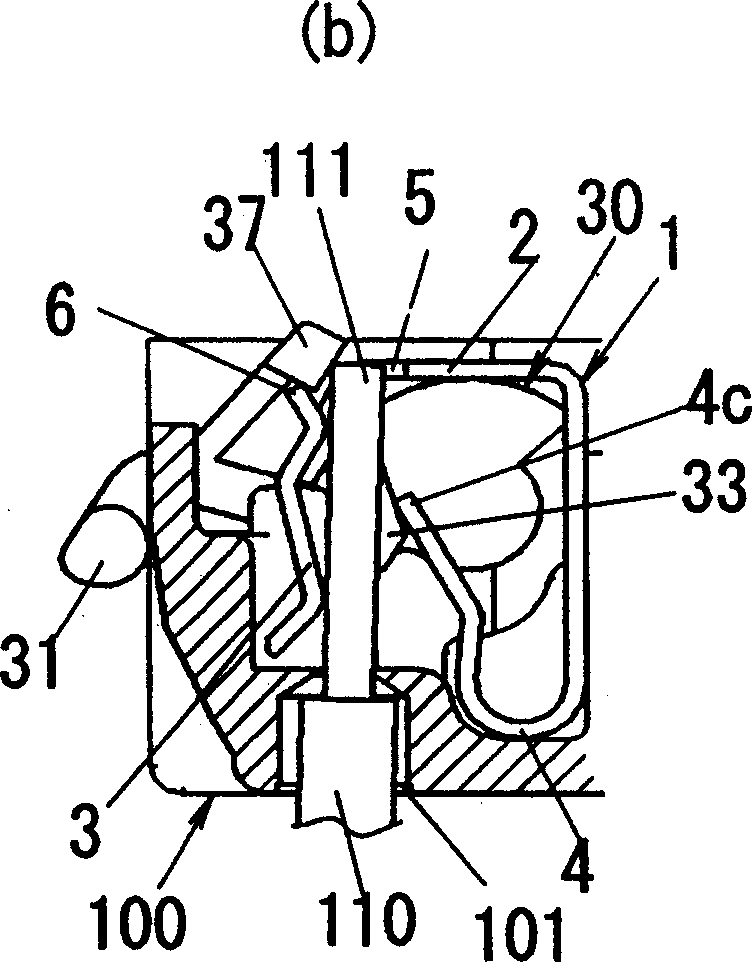

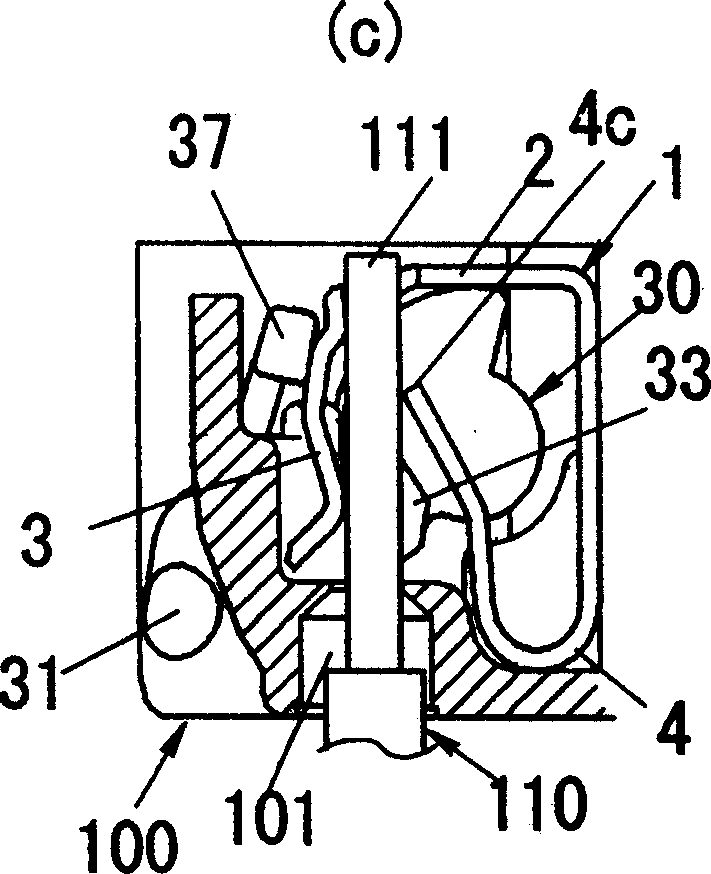

[0106] In the terminal board 1 according to the present embodiment, as Figure 5 and Figure 6 As shown, the contact piece 3 is roughly in the direction perpendicular to the insertion direction of the wire 110 ( Figure 5 centered in the left-right direction) and two parts other than the central part of the locking part 4a are taken as the receiving part 4c.

[0107] On the other hand, if Figure 7 and Figure 8 As shown, the release lever 30 according to this embodiment includes a second pressing and moving portion 38 opposite to the pressing and moving portion 33, wherein the contact piece 3 is interposed between the pressing and moving portion 33 and the second pressing and moving portion 38;...

no. 3 approach

[0112] Although the connection structure between the terminal board 1 and other conductive members (the contact point of the switch or the knife-edge support of the electrical socket) is not particularly described in the first and second embodiments, it is preferable that the terminal board 1 and other conductive members be processed Formed integrally from sheet metal. However, in the first and second embodiments, since the terminal plate and the lock spring are integrally formed, a mold with a very complicated shape is required to integrate the additional conductive member. In order to avoid complicated molds, the terminal board and the other conductive members should be connected using caulking or welding methods.

[0113] Therefore, in this embodiment, if Figure 14 (a) and Figure 15 As shown, the connection device is formed by removing the locking piece 4 from the terminal board 1 and forming a connection device with a locking spring 10 having a U-shaped spring piece 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com