Stepless lifting type six dimension force sensor caliberating device

A six-dimensional force sensor and calibration device technology, which is applied in the field of generalized force loading, can solve the problems of inaccurate calibration of multi-dimensional force sensors in each direction, inapplicability of generalized loading and calibration of large-scale sensors, and unsystematic problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

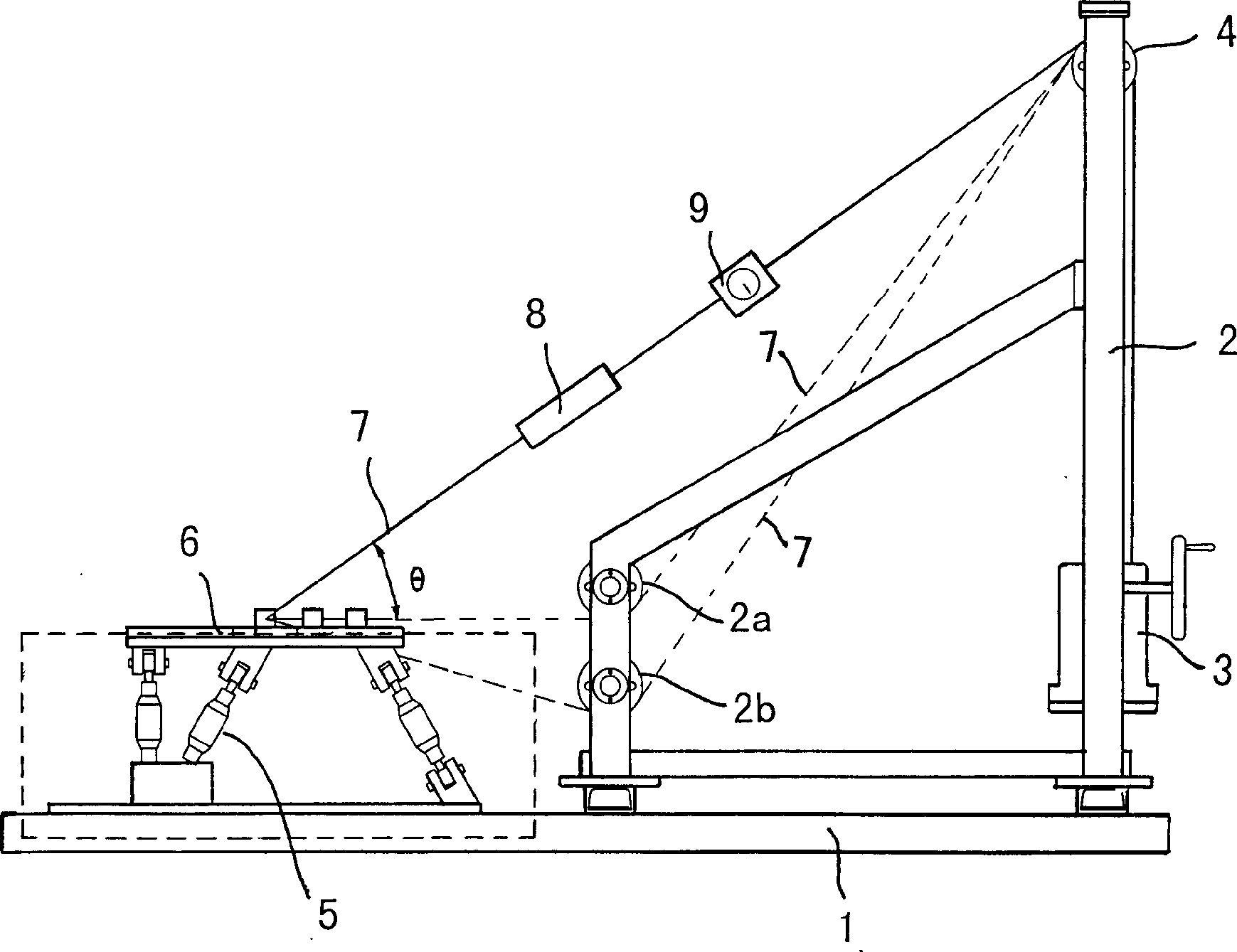

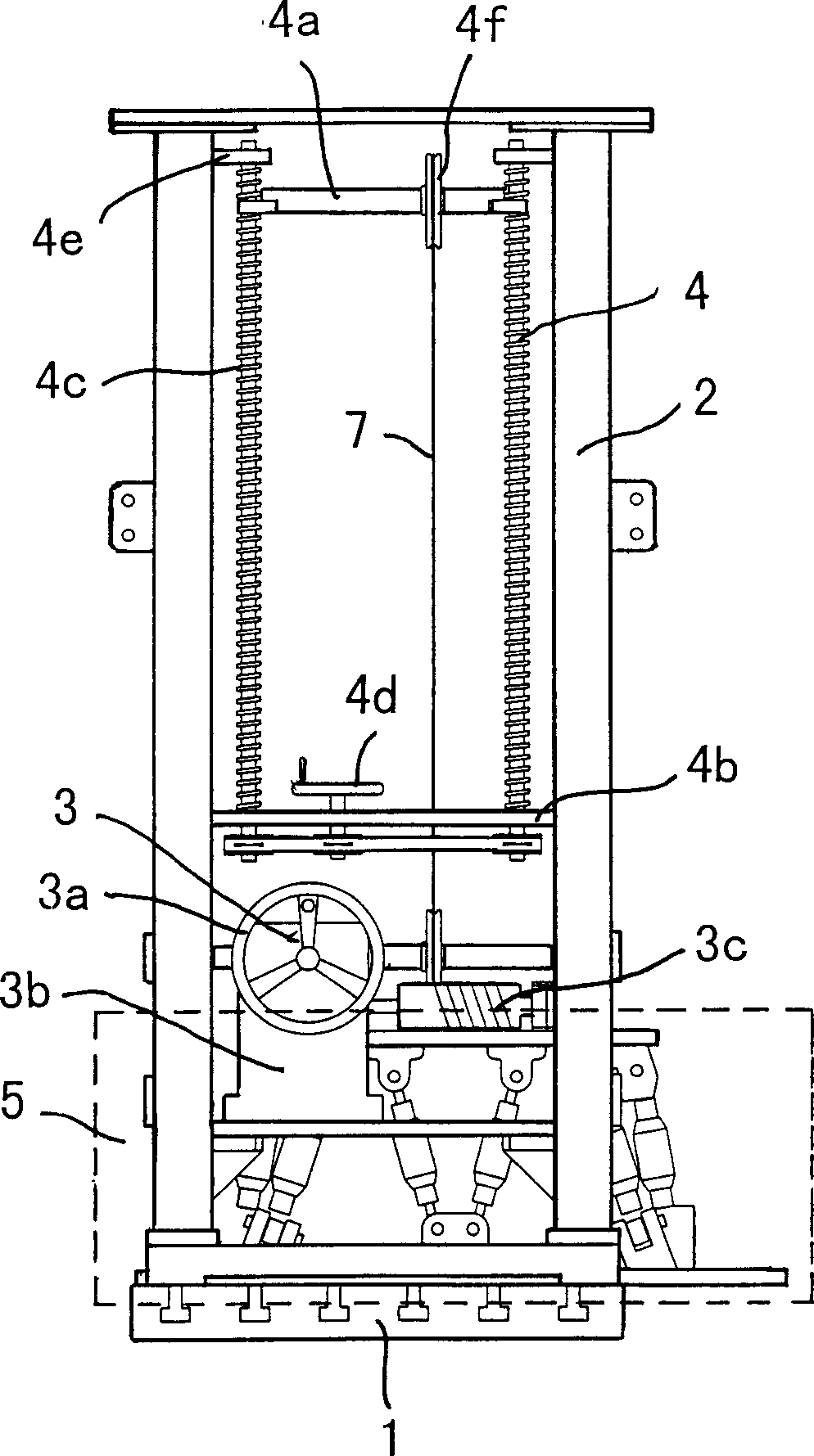

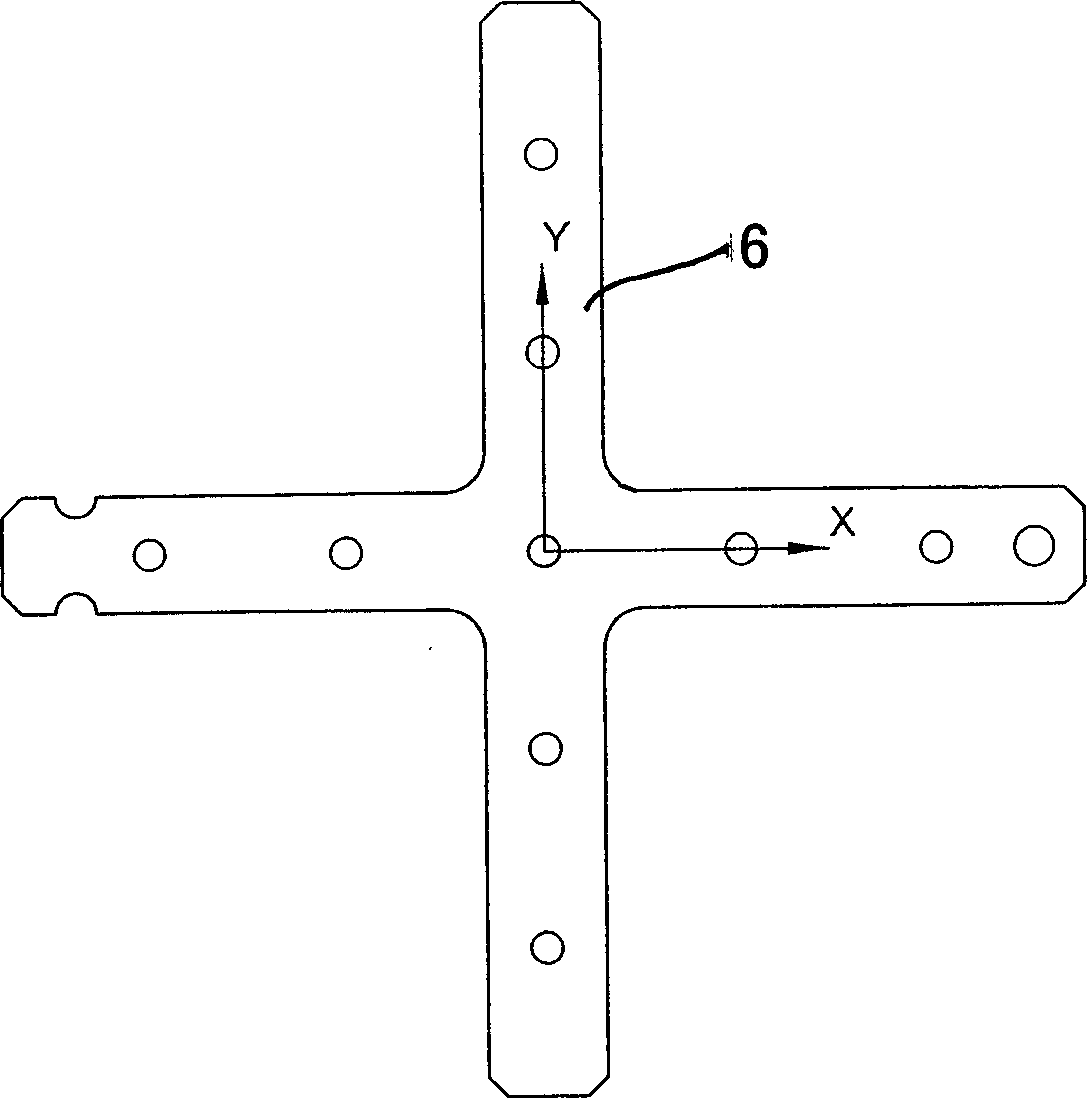

[0010] The working principle of the present invention: the main function of the stepless lifting six-dimensional force sensor calibration device is to provide standard generalized loading, and use the standard generalized load to calibrate the static performance indicators of the six-dimensional force sensor. The lifting pulley is moved to a certain position and fixed by the pulley stepless lifting mechanism 4, and then the loading is started, and the output torque M is generated through the manual loading reducer 3, and the loading rope 7 is wound on the reel of the reducer 3, thereby generating a rope The tension K of the tension force K is proportional to the input torque of the hand crank, and its magnitude is detected by the standard tension sensor 8; the loading rope 7 changes the loading direction through the upper pulley and the lower pulley on the support frame 2, and the loading rope 7 The angle θ with the horizontal plane is detected by the inclination sensor 9; by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com