Resistance and lifting force composite wind pwoer device

A wind power and lift technology, applied in wind turbines, wind turbines at right angles to the wind direction, engines, etc., can solve single problems and achieve the effect of easy starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

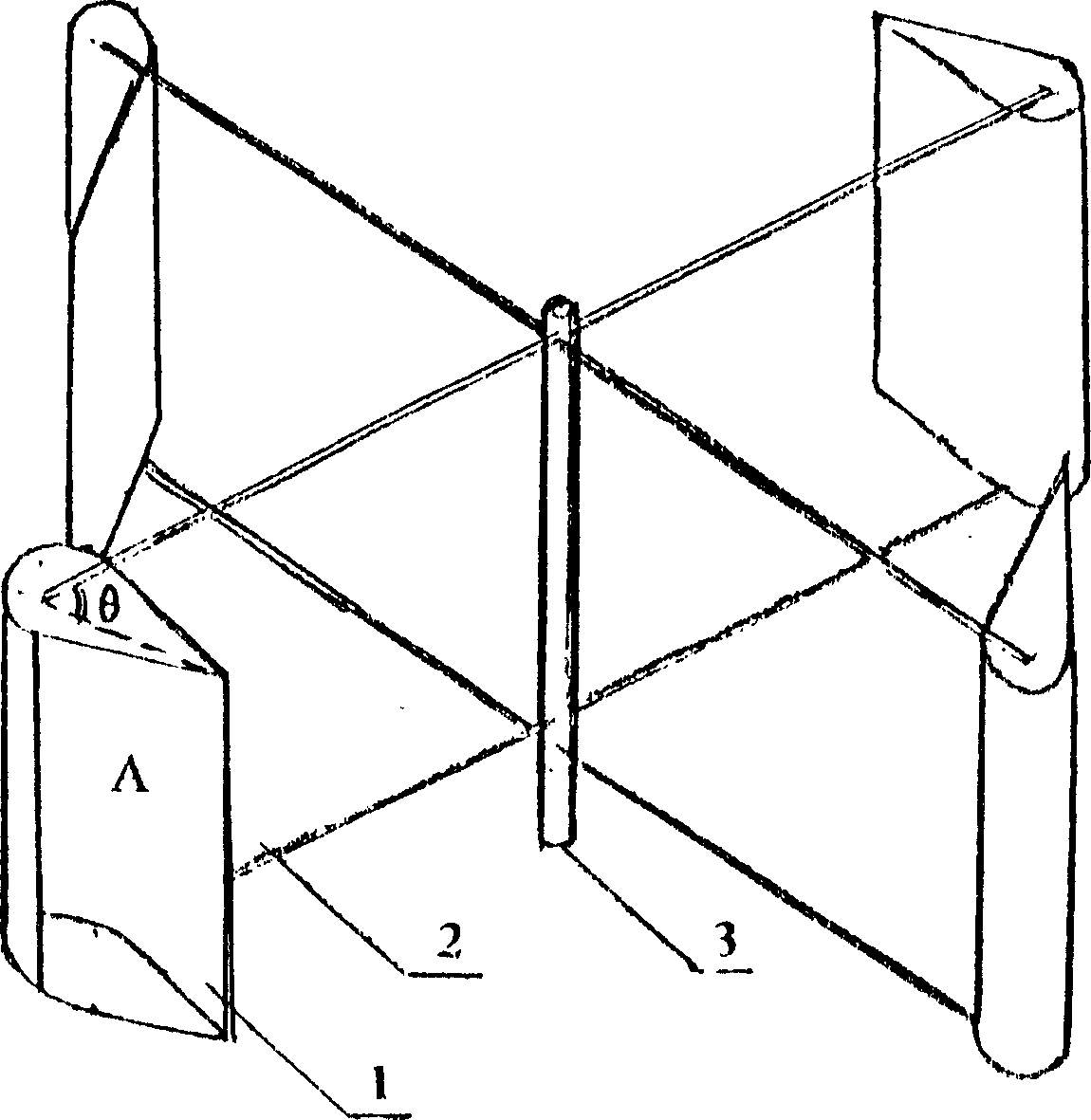

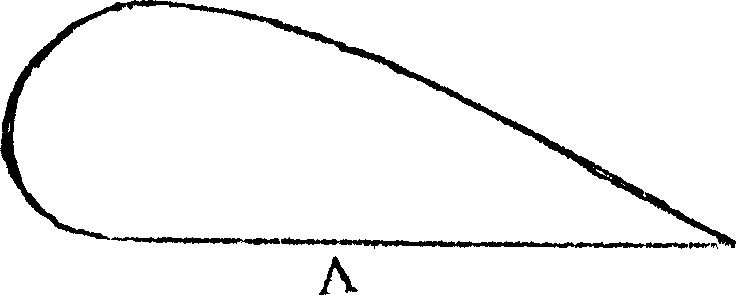

[0013] The airfoil airfoil blade 1 of the wind wheel of the present invention is a special-shaped structure with a concave curved surface made of a thin plate. Rods 2 are uniformly distributed in the axial direction and fixed on the rotating shaft 3 of the wind wheel as the torque output shaft. The included angle θ of pole 2 is 60°-70°. The size of θ angle affects the size and ratio of drag and lift effects. The selection in practical application should be selected according to the local wind conditions. Usually, the annual average wind force is 3 When the level is below 60 days, the θ angle should be larger or close to the upper limit.

[0014] The above-mentioned wind wheel 1 can be an even number of wind blades and is fixed on the wind wheel rotating shaft 3 according to the axial symmetry by means of the connecting rod 2 .

[0015] The above-mentioned thin plate for making the fan blade may be metal or plastic, and the fan blade 1 is an integral structure, which can be ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com