Method and apparatus for operation of a heat engine

一种热力发动机、工作方法的技术,应用在发动机元件、发动机控制、燃烧发动机等方向,能够解决不能考虑颗粒过滤器实际载荷等问题

Inactive Publication Date: 2010-08-11

ROBERT BOSCH GMBH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For other operating points at higher rotational speeds there are rough estimation methods for monitoring the pressure sensor, but they do not especially take into account the actual load of the particle filter in the exhaust tract

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

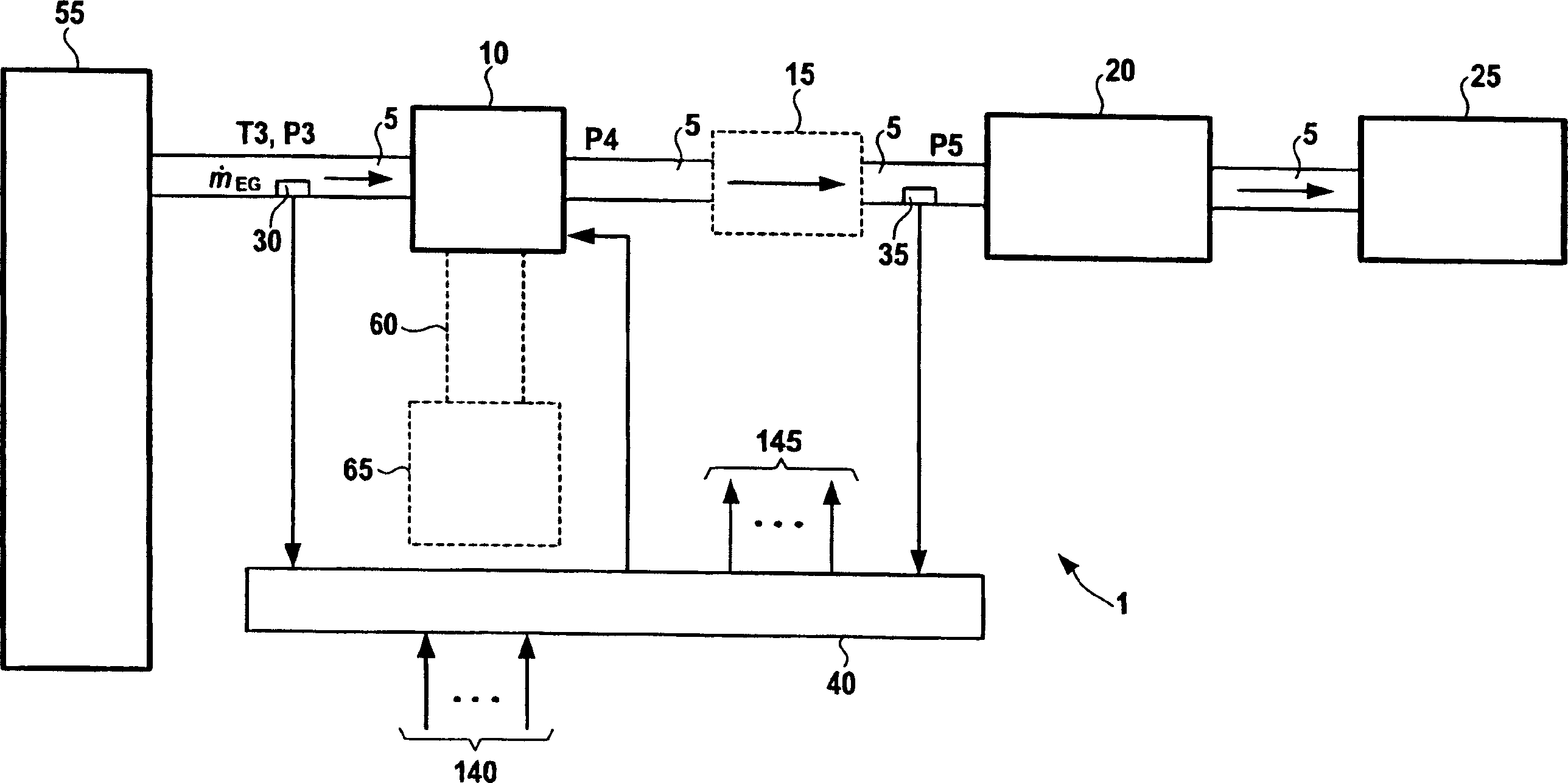

A method and a device for operating a combustion engine(1) allow a plausibility check of two pressure sensors (30,35)in a mass-flow line of the combustion engine(1) in any operating range of the combustion engine. At least one component(10,15) effecting a pressure drop is provided in the mass-flow line(5), and a first pressure is measured upstream from the at least one component with the aid of afirst pressure sensor(30), and a second pressure is measured downstream from the at least one component with the aid of a second pressure sensor(35). The first pressure sensor(30) and the second pressure sensor are checked for plausibility as a function of at least one modeled variable characterizing at least one pressure drop in the mass-flow line between the first pressure sensor and the secondpressure sensor(35).

Description

technical field The invention relates to a method and a device for the operation of a heat engine. Background technique Methods and devices are known for operating a heat engine comprising a mass flow line in the form of an exhaust gas duct and in which at least one component influencing the pressure drop, for example a turbine of an exhaust gas turbocharger, is arranged in the exhaust duct and / or a catalytic converter. It is also known to measure a first pressure in the exhaust gas line downstream of the turbine by a first pressure sensor and to measure a second pressure in the exhaust gas line downstream of the turbine or catalytic converter by a second pressure sensor. Currently only limited measures are known for monitoring two pressure sensors in the exhaust tract. At very low engine speeds or when the engine is switched off, the sensor values of the two pressure sensors can be easily compared with one another, since the pressure difference between the first pressu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02B37/12F01N11/00

CPCF02B77/086F02B39/16F02D41/187F01N3/035F02D2200/0406F02D41/222F01N13/02G01L27/00F02D2200/0812F02B37/00F02D41/1448F02B39/00F01N9/002Y02T10/40G01L27/007F02B77/083F01N13/009

Inventor E·莫泽尔W·埃德尔曼P·萨卡

Owner ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com