Optical bar uniform light device with light-emitting diode as light source

A technology of light emitting diodes and uniform light devices, which is applied in optics, optical components, instruments, etc., can solve problems such as affecting the lighting effect, and achieve the effect of uniform illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

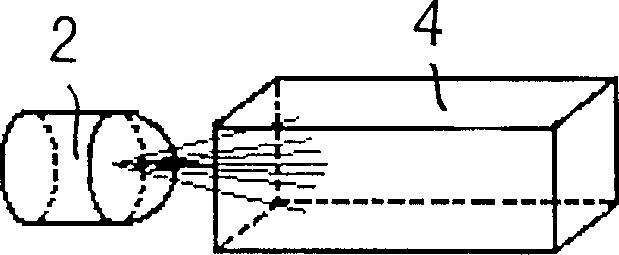

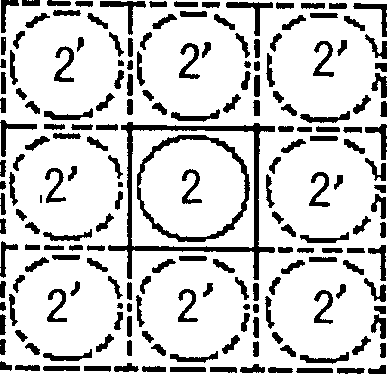

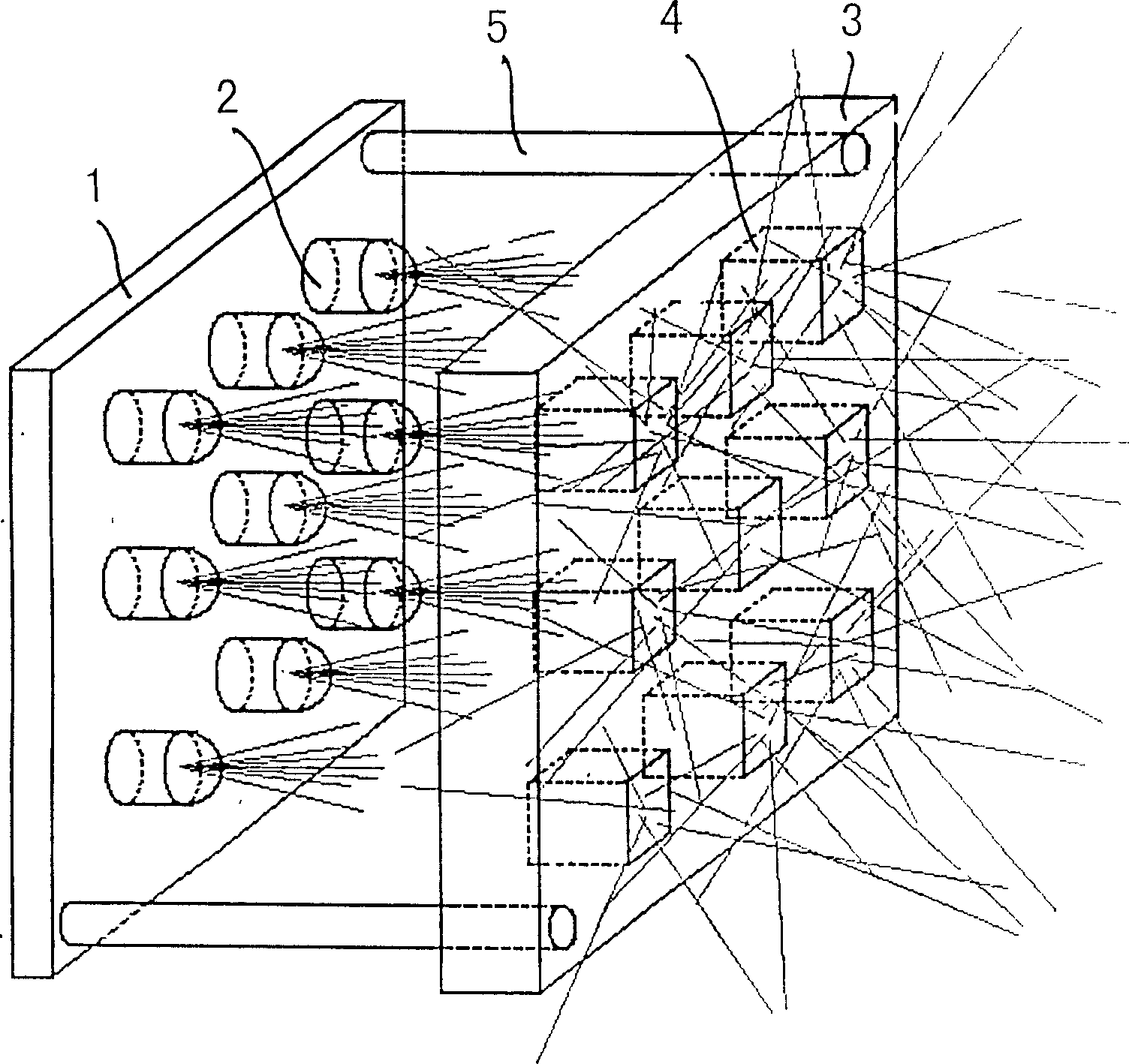

Embodiment 1

[0012] A uniform light device using light-emitting diodes as the light source, an area light source composed of 7 LEDs, the distance between adjacent LEDs is 12mm, and a piece of plexiglass with 7 through holes is arranged in front of the area light source board, the number and position of the through holes correspond to the LED light source, and the organic glass plate 3 and the light source seat 1 are connected together by the connector 5; the thickness of the organic glass plate is 10mm, and the distance between the organic glass plate and the LED light source 2 5mm, the cross-section of the light rod 4 (through hole) is circular, and its aperture is 5mm.

Embodiment 2

[0014] A uniform light device with light-emitting diodes as the light source, an area light source composed of 16 LEDs, the distance between adjacent LEDs is 10mm, and a piece of organic glass with 16 through holes is arranged in front of the area light source board, the number and position of the through holes correspond to the LED light source, and the organic glass plate 3 and the light source seat 1 are connected together by the connector 5; the thickness of the organic glass plate is 15mm, and the distance between the organic glass plate and the LED light source 2 The distance is 10 mm, and the cross-section of the through hole is a regular hexagon with a side length of 5 mm.

Embodiment 3

[0016] A uniform light device using light-emitting diodes as the light source. It is an area light source composed of 32 LEDs. The distance between adjacent LEDs is 10mm. A piece of plexiglass with 32 through holes is arranged in front of the area light source. board, the number and position of the through holes correspond to the LED light source, and the organic glass plate and the light source seat 1 are connected together by the connector 5; the thickness of the organic glass plate is 25mm, and the distance between the organic glass plate and the LED light source 2 20mm, the cross-section of the through hole is circular, and its diameter is 10mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com