Pair circuit substrate operating machine

A technology for circuit substrates and operating machines, which is applied to electrical components, electrical components, etc., and can solve problems such as defective circuit substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

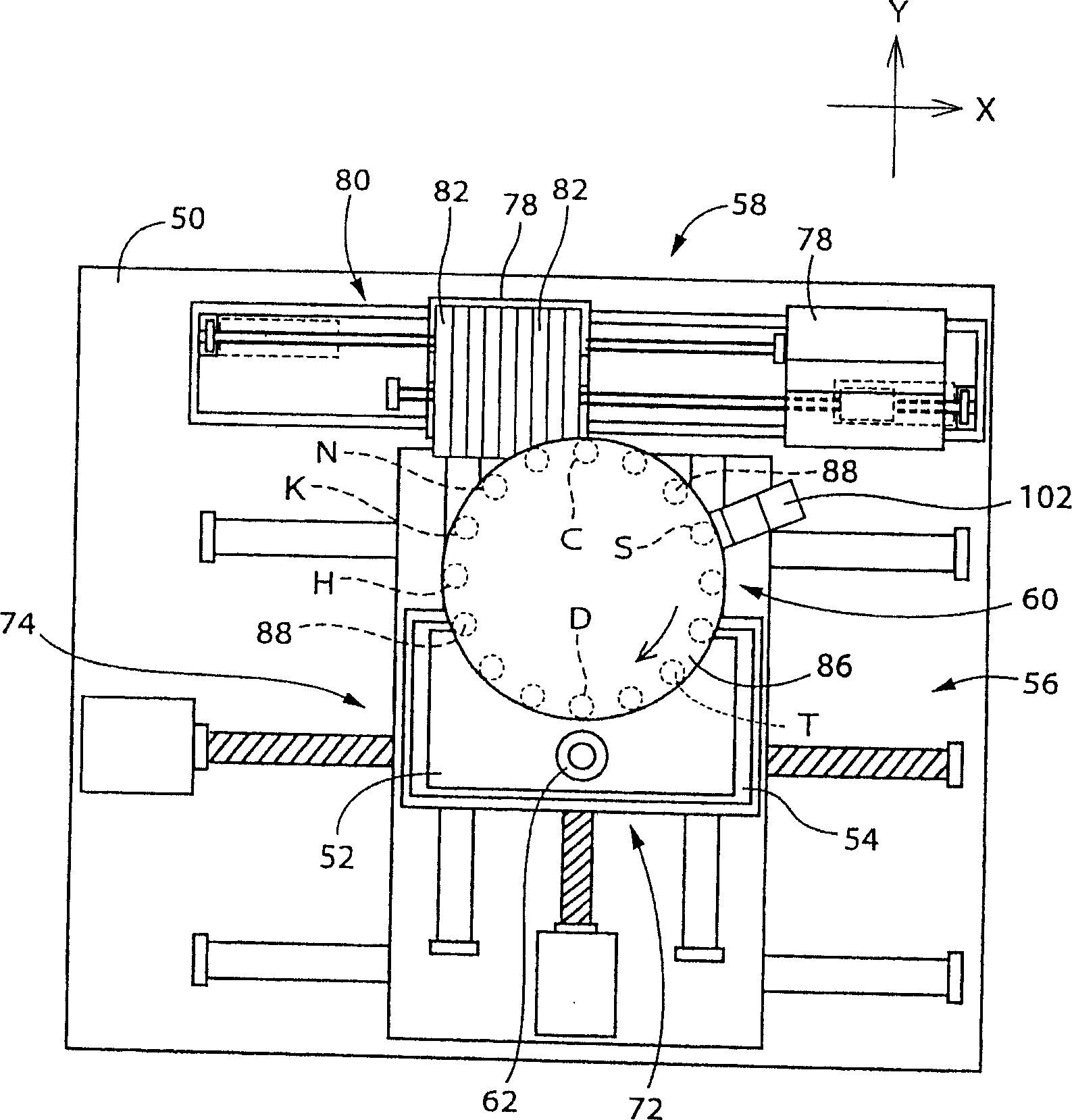

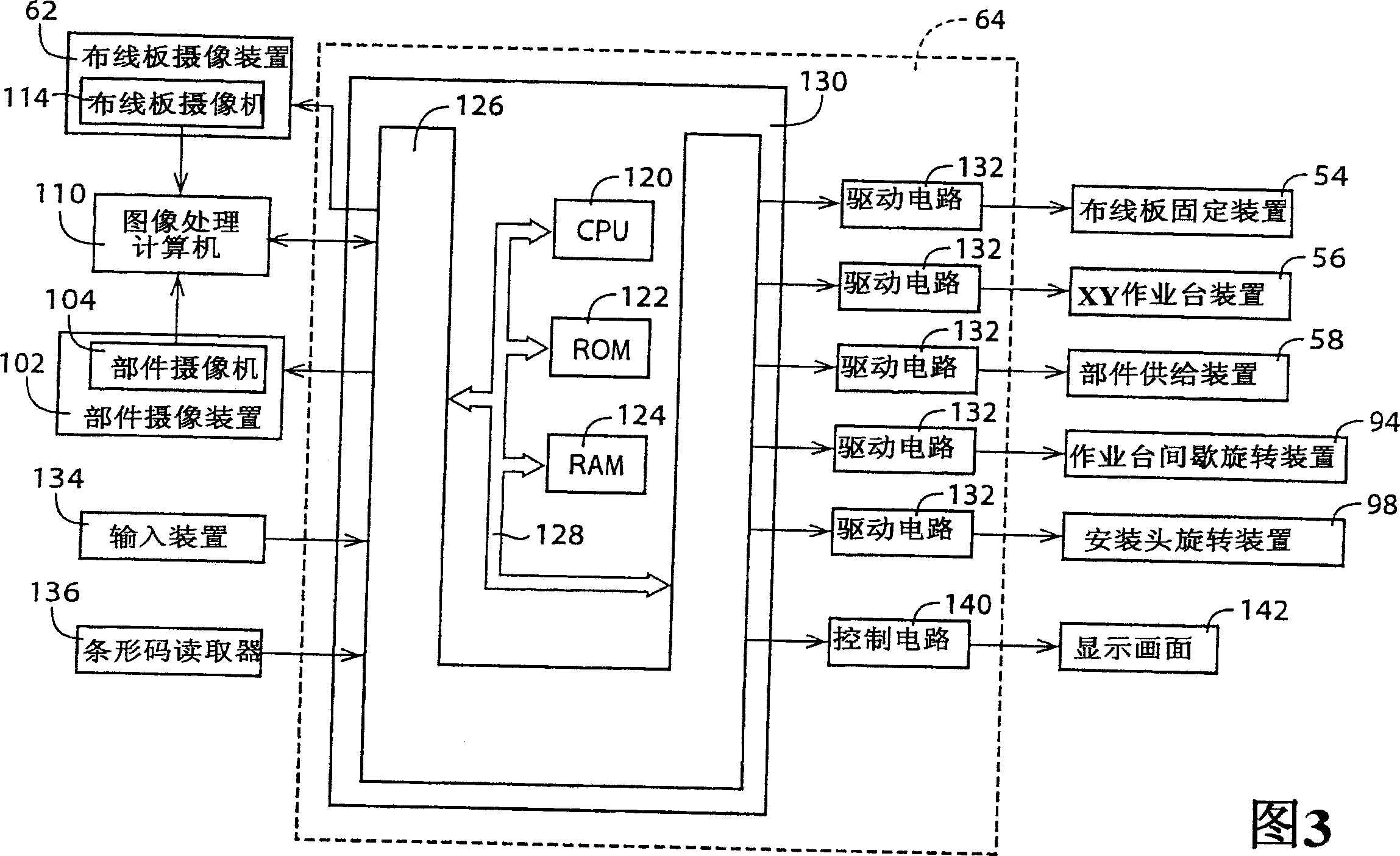

[0091] Hereinafter, an embodiment in which the present invention is applied to an electronic circuit component mounting machine which is a type of circuit board working machine will be described in detail with reference to the drawings.

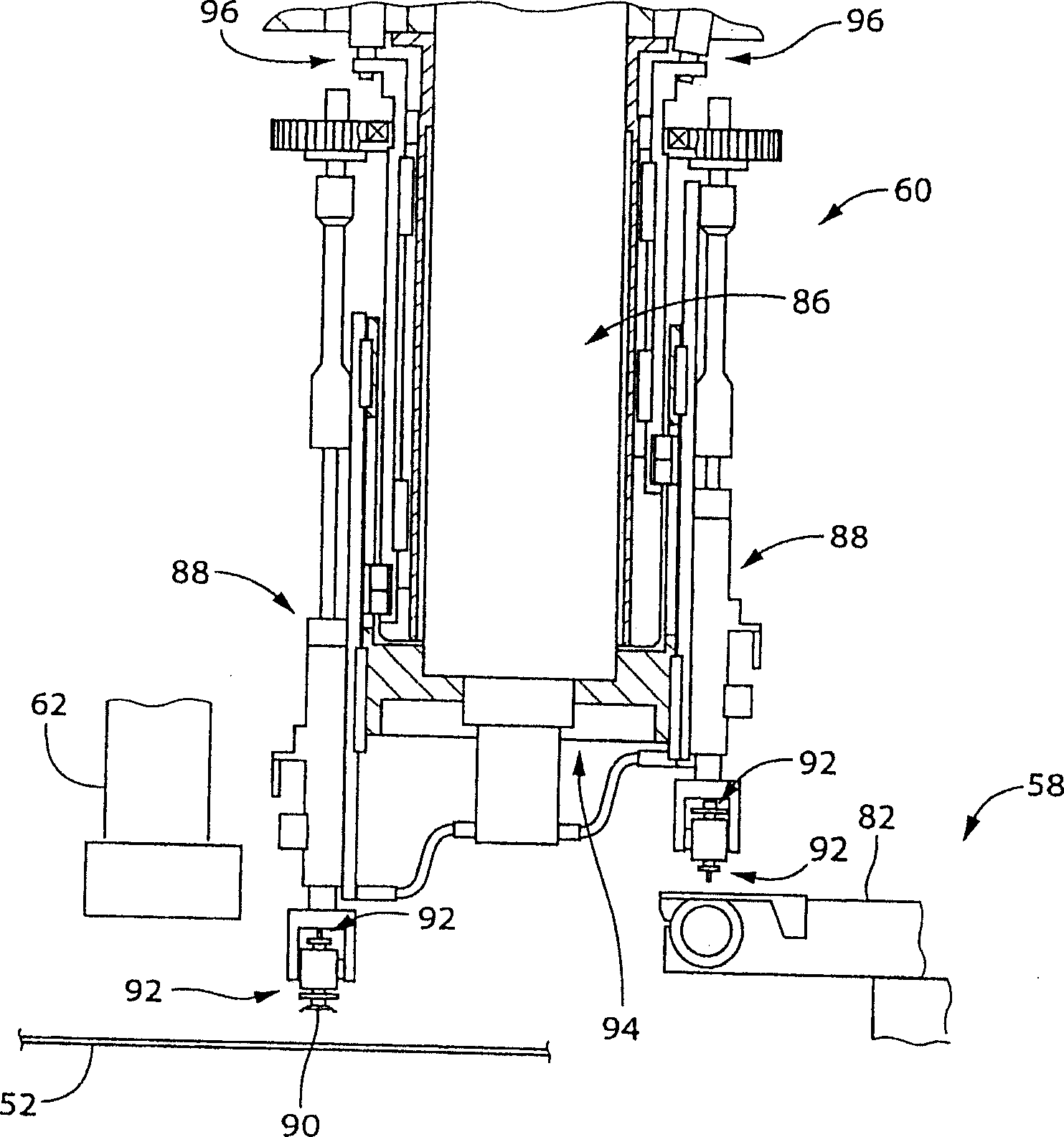

[0092] This electronic circuit component mounting machine is a rotary head type mounting machine having a component mounting device that rotates a plurality of mounting heads around a single rotation axis. figure 1 A plan view showing this electronic circuit component mounting machine, figure 2 It shows a side partial sectional view centering on the component mounting device included in this electronic circuit component mounting machine.

[0093] This electronic circuit component mounting machine, such as figure 1 As shown, it is mainly composed of the following parts: a working machine body 50; a wiring board fixing device 54 arranged on the working machine body 50 to fix a printed wiring board 52 as a circuit substrate as a substrate hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com