Machine for automatically producing disposable over-shoes

An automatic production, one-time technology, applied in the direction of shoe-making machinery, footwear, clothing, etc., can solve the problems of cumbersome transmission, unreasonable process, complicated process, etc., to ensure neutrality, improve product qualification rate, Reasonable effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation, structure, features and functions of the embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

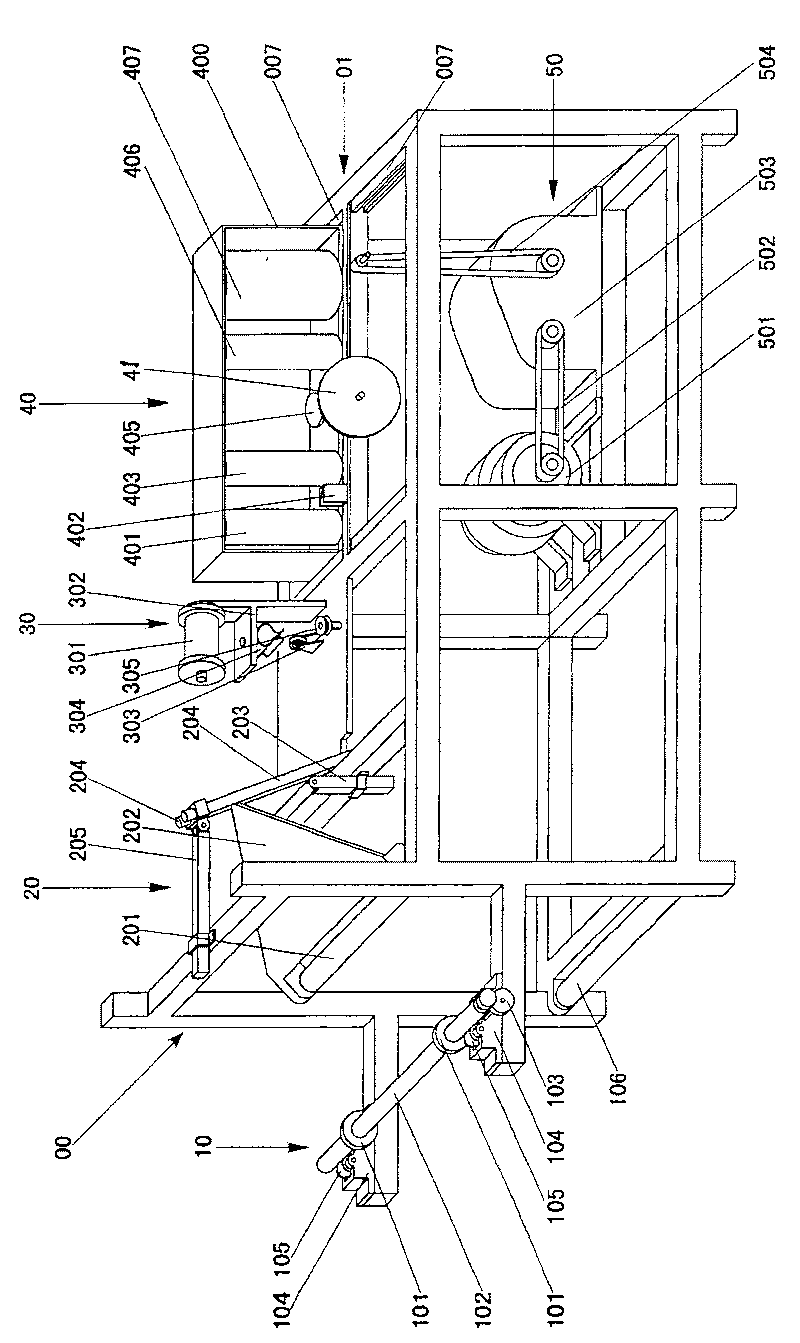

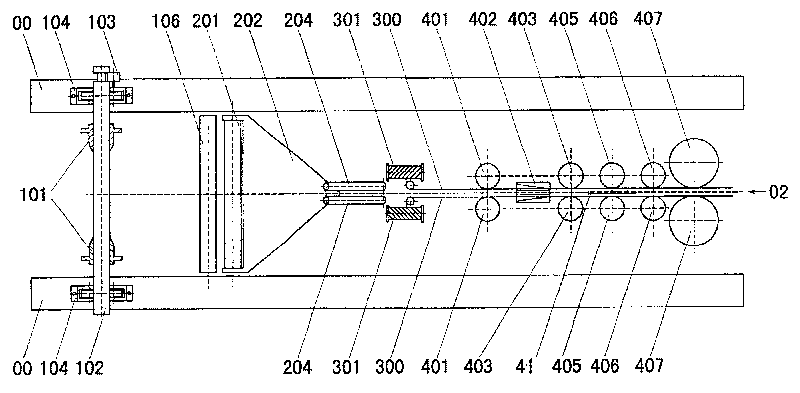

[0037] Such as figure 1 , 2 Shown: the film material feeding device 10 of the present invention is arranged on one end of the frame 00, and the film material folding device 20, the elastic band feeding device 30 and the processing device 40 are sequentially arranged on the processing surface 01 of the frame 00 immediately thereafter , the transmission device 50 is installed below the processing surface 01 .

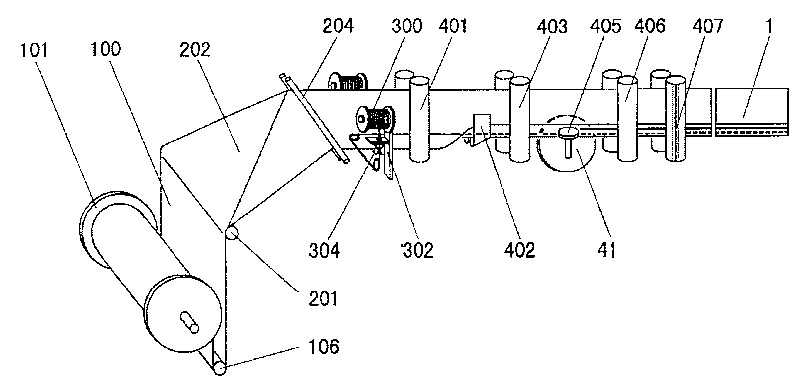

[0038] Such as image 3 , 4 As shown, the mold material feeding device 10 has a positioning ring 101, a material rod 102, an adjusting ring 103, a bearing seat 104, a bearing 105 and a guide roller 106, wherein a pair of bearing seats 104 are respectively fixed on the left and right sides of one end of the frame 00, A pair of bearings 105 are arranged in parallel in each bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com