Side shaft powder feeding apparatus based on laser powder filling welding and powder feeding method

A technology of powder feeding device and laser powder, which is applied in the direction of laser welding equipment, welding equipment, heating inorganic powder coating, etc., which can solve the problems of inability to weld and process, and no occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] A side-axis powder feeding device and powder feeding method based on laser powder filling welding of the present invention will be described in detail below in conjunction with a specific embodiment.

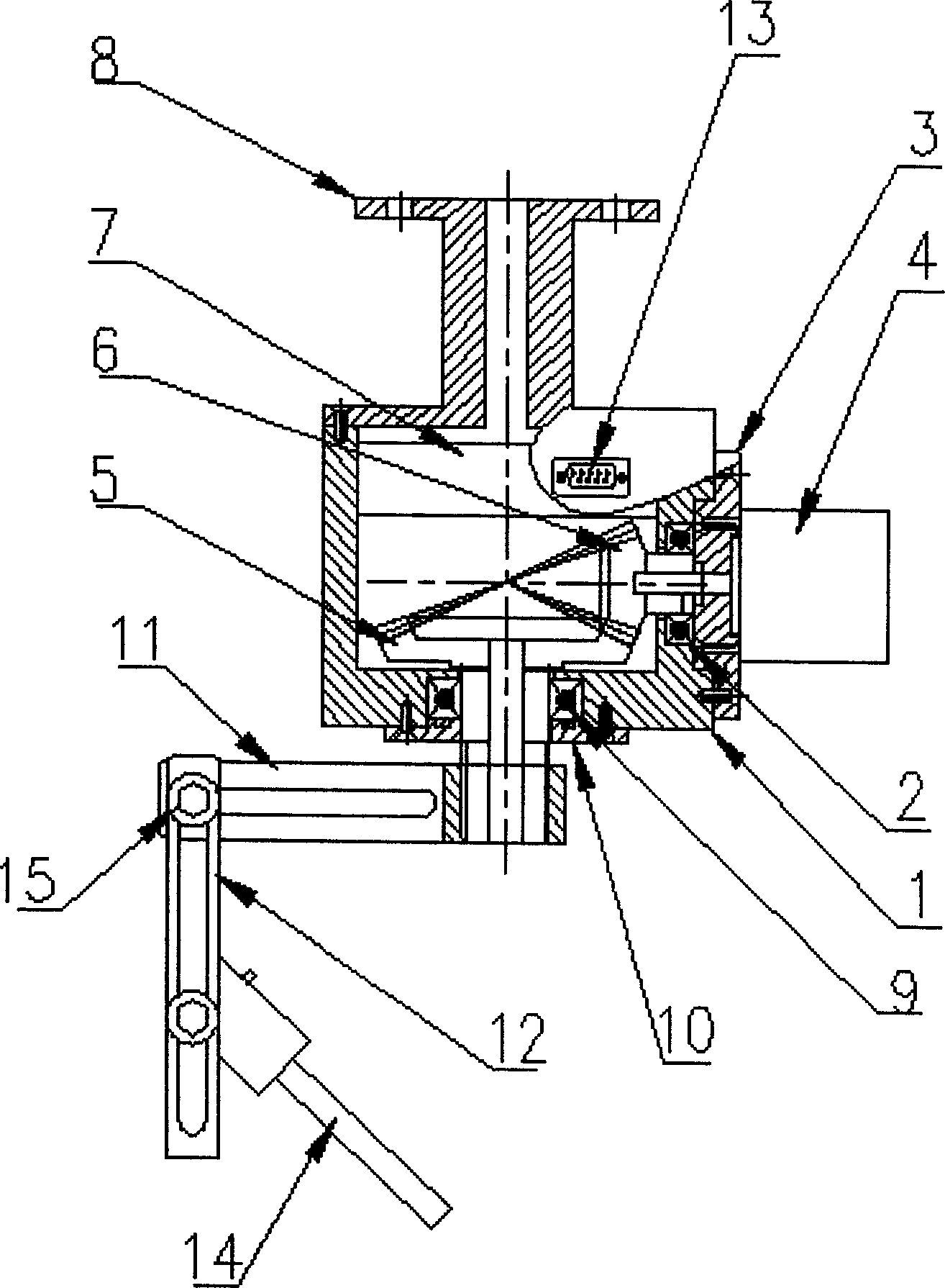

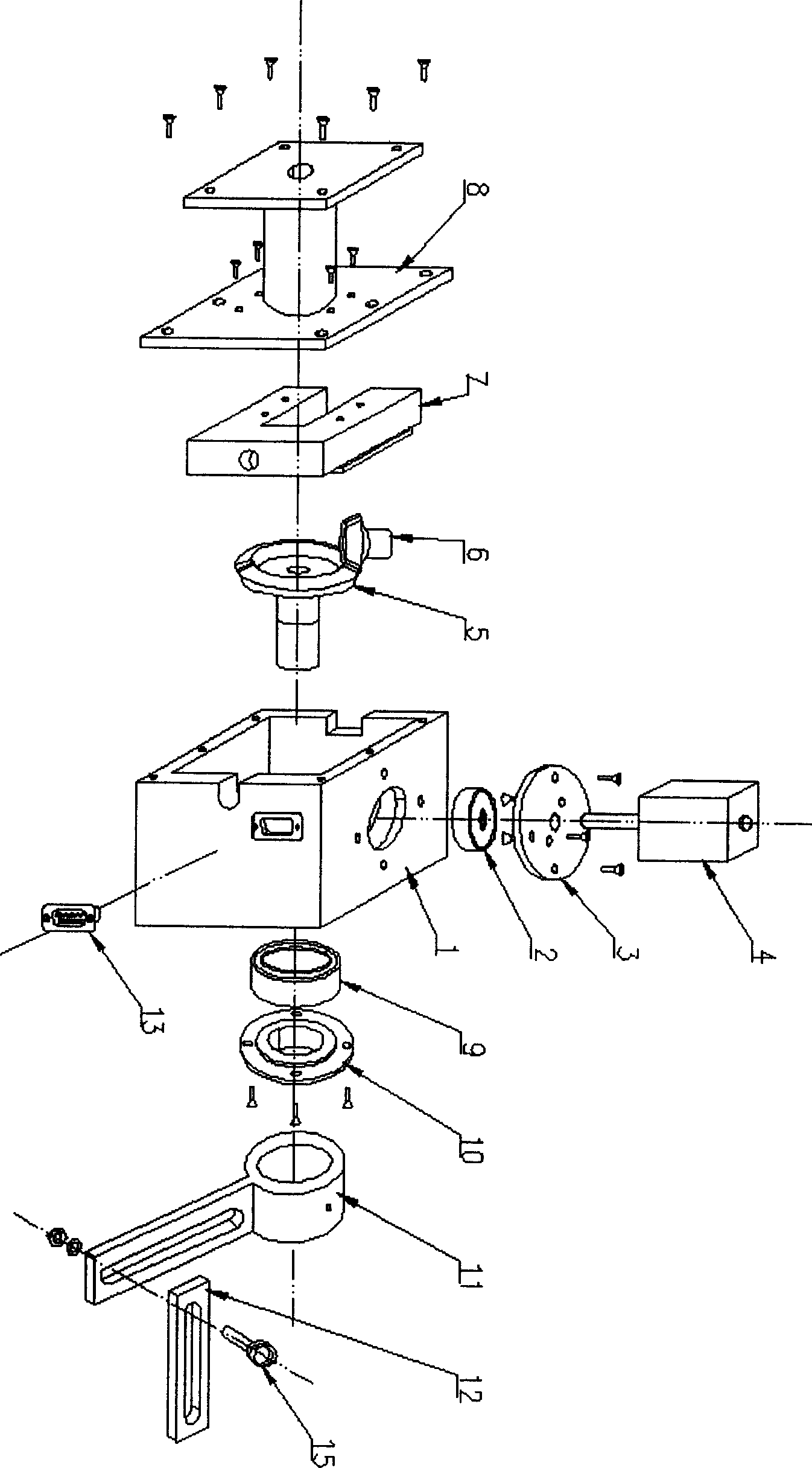

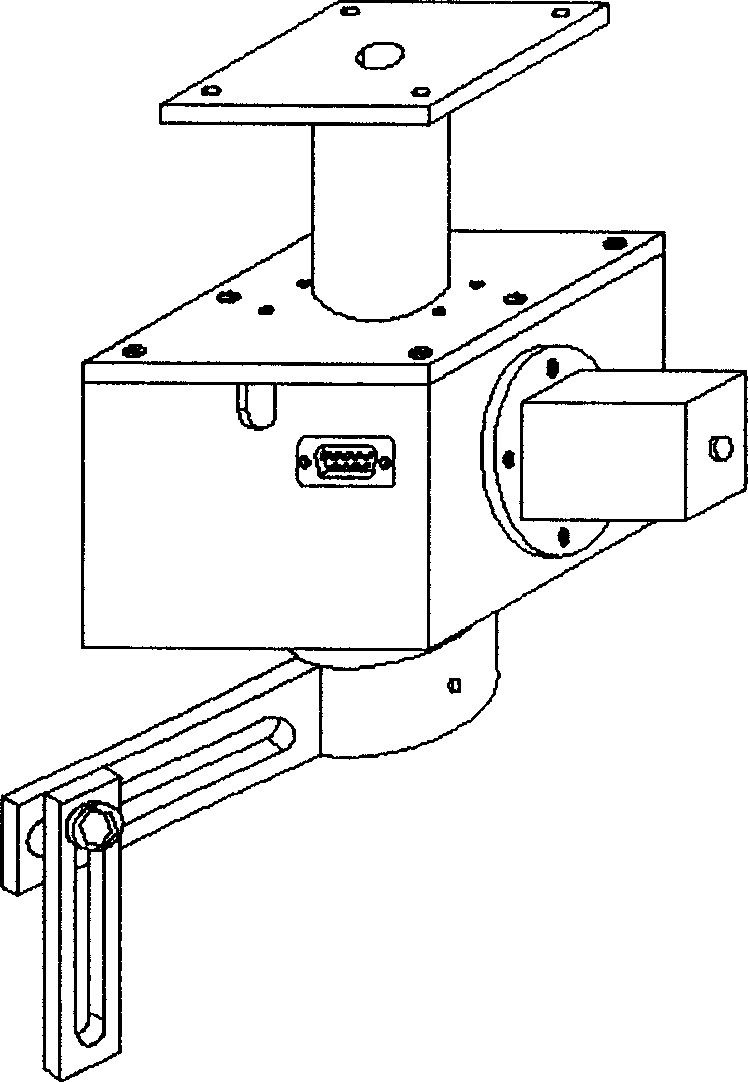

[0048] Refer to attached figure 1 and attached figure 2 . A side-axis powder feeding device based on laser powder filling and welding is composed of three parts: an upper body, an intermediate body and a lower body connected in sequence; the upper body mainly includes a cavity 1, a cavity cover 8 and an air curtain device 7, and the intermediate The long-arm bevel gear 5 and the short-arm bevel gear 6 are composed of a gear pair and a motor 4. The lower body is composed of an angular displacement adjustment mechanism and a powder feeding nozzle 14. The angular displacement adjustment mechanism is mainly composed of a horizontal support 11 and a vertical support 12.

[0049] Wherein, the chamber cover 8 is arranged on the top of the device of the present invention, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com