Glass thin layer optic disk structure and process

A disc structure and glass technology, which is applied in optical recording/reproduction, instrumentation, data recording, etc., can solve problems such as vibration, poor wear resistance, recording errors, etc., to achieve less vibration, improve disc rigidity, and long life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

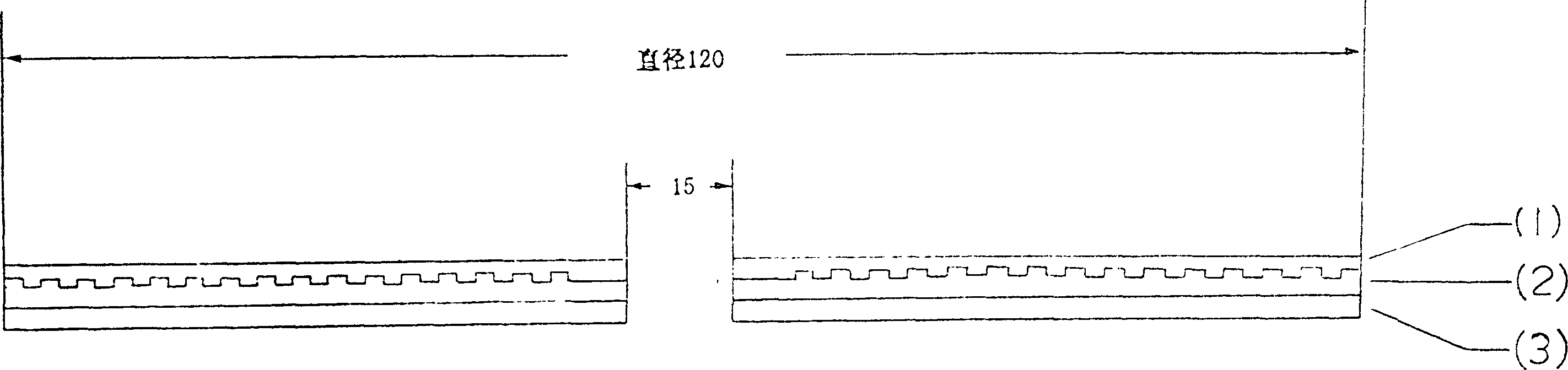

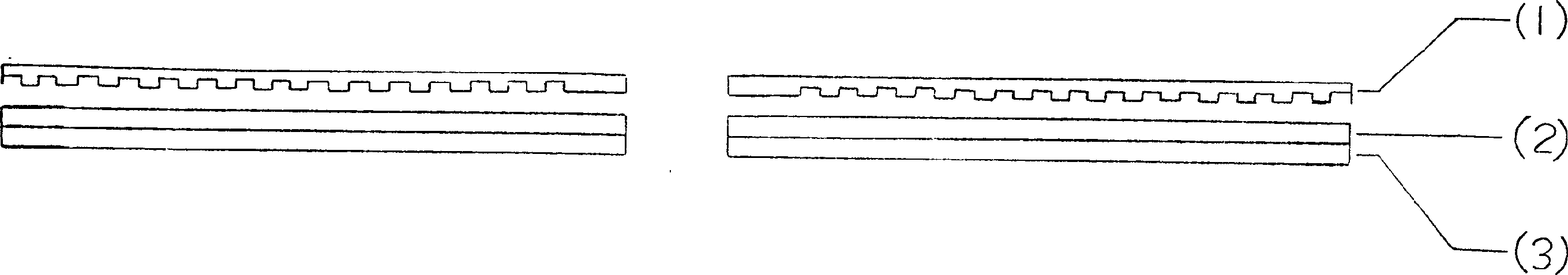

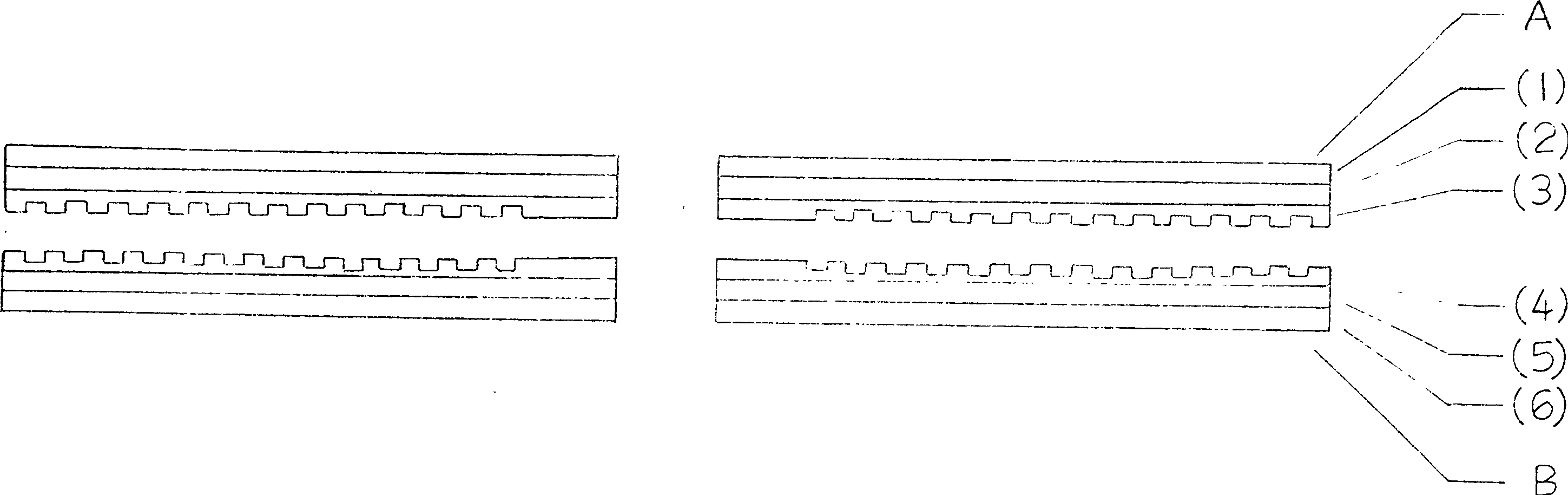

[0015] exist Figure 4 (1)-(4) are traditional optical disc technology, Figure 4 -(1) is die-cast, Figure 4 -(2) for copying, Figure 4 -(3) is a gold or aluminum layer, Figure 4 -(4) is the protection of the marking signal surface. After this process, another process is added. Figure 4 -(5) is to add a thin layer of quartz glass on the surface of the resin disc such as Figure 4 -(A). The thin layer of quartz glass and the traditional resin disc are bonded with an epoxy resin adhesive, wherein the thickness of the resin disc is reduced from the original 1.2mm to 1.0mm, and the thickness of the thin layer of quartz glass is 0.2mm, which just realizes the manufacturing process of the present invention .

[0016] exist figure 2 Middle: The manufacturing process of DVD-5 quartz glass layer disc and Figure 4 The same as described in (1)-(5) optical disk manufacturing process, but the parameters are changed, such as reducing the thickness of the resin optical disk fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com