Vertical set control box for pneumatic bipipeline commodity flow transfer

A double-pipeline, control box technology, applied to conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as slow speed, low efficiency, and space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following is a specific description with examples:

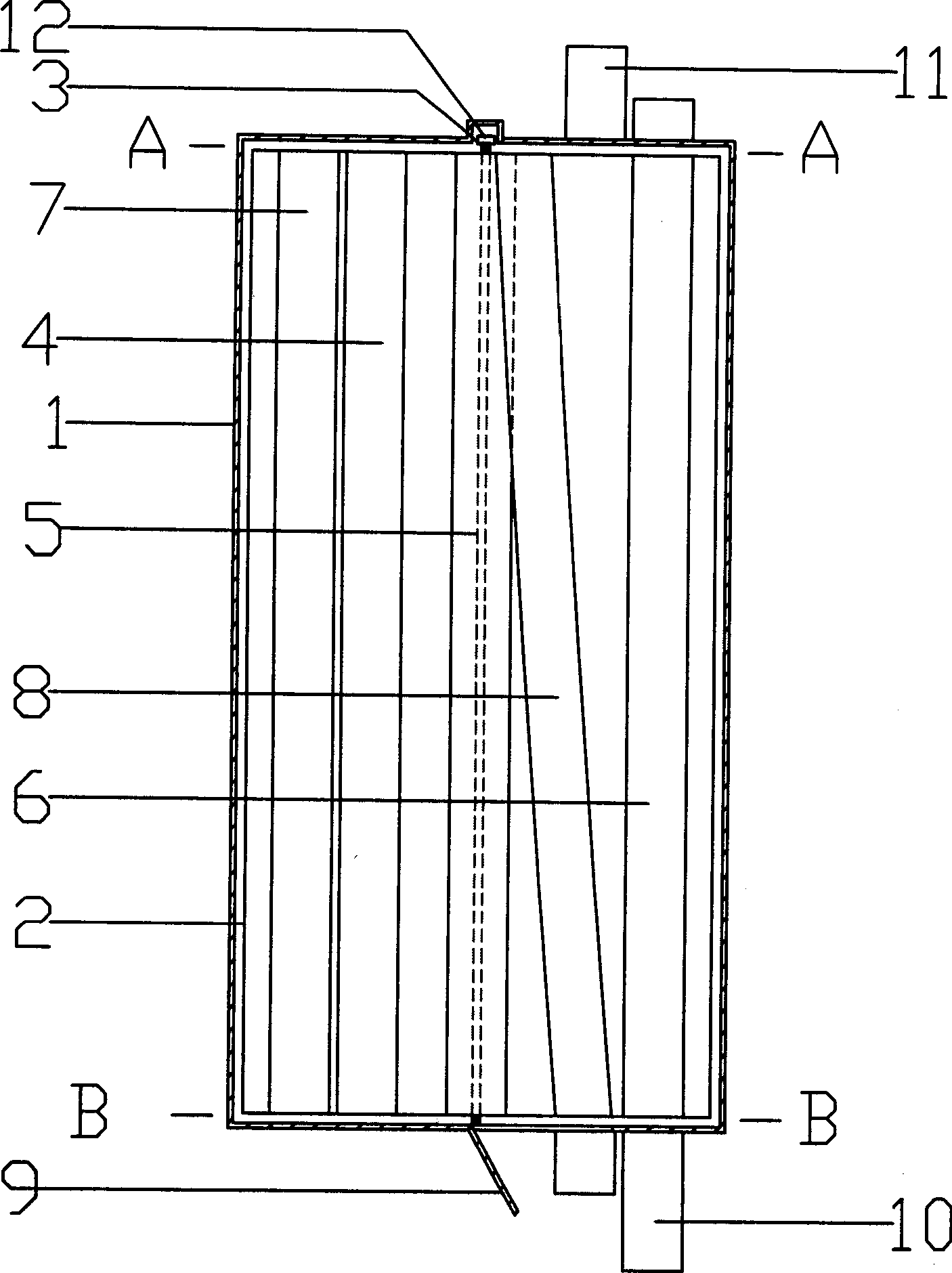

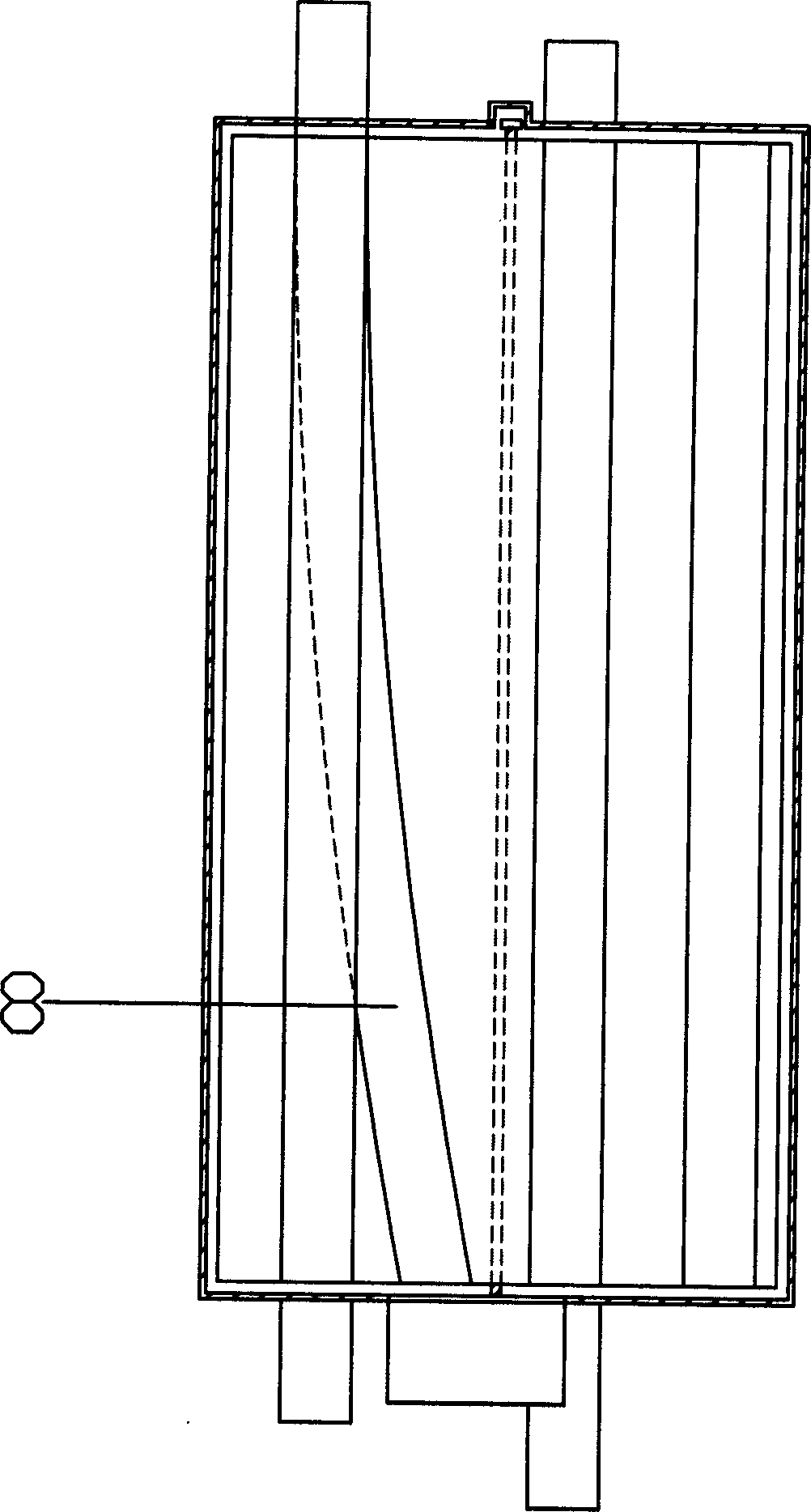

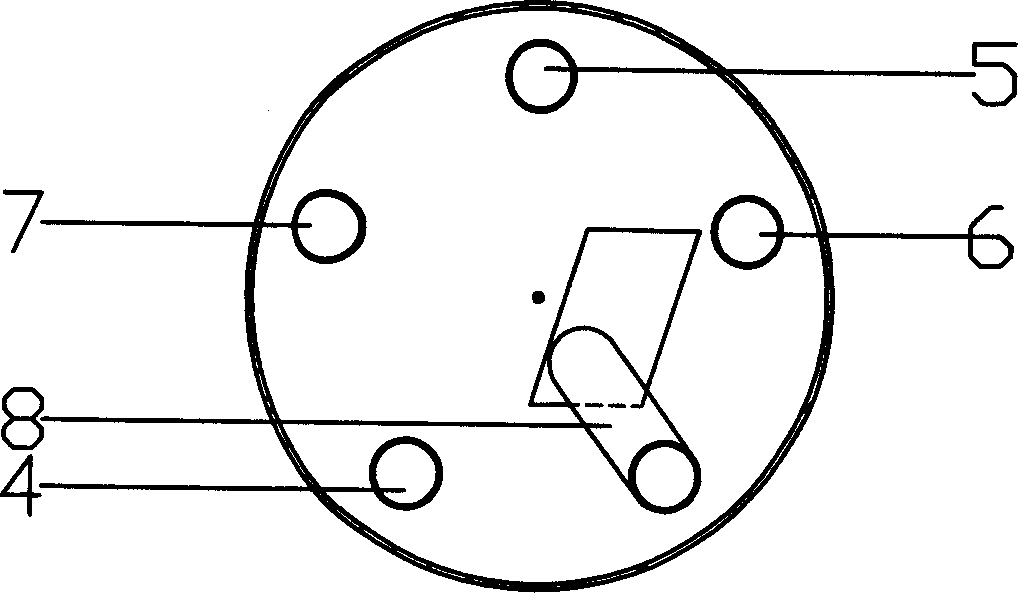

[0011] Such as figure 1 2 is the rotor inside the control box; 3 is the fixed shaft fixed between the rotor and the control box shell; 4, 5, 6 are the three conduction cabins on the rotor; 7 is the sending cabin on the rotor; 8 is the rotor 9 is the release door; 10,11 are two pipelines for conveying objects; 12 is the driving motor of the fixed shaft 3.

[0012] Using the existing software technology, the rotor (2) can be rotated and transposed around the fixed shaft (3) under the drive of the drive motor (12), so as to realize the three conduction cabins 4, 5, and 6 of the rotor (2), and the transmission cabin (7), the receiving cabin (8) is respectively connected with the pipeline 10 and the pipeline 11 outside the casing, so as to realize the purpose of conducting, sending and receiving.

[0013] When sending, put the transmission tube into the sending cabin (7), the sensor informs the circuit, and the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com