Rotary compressor

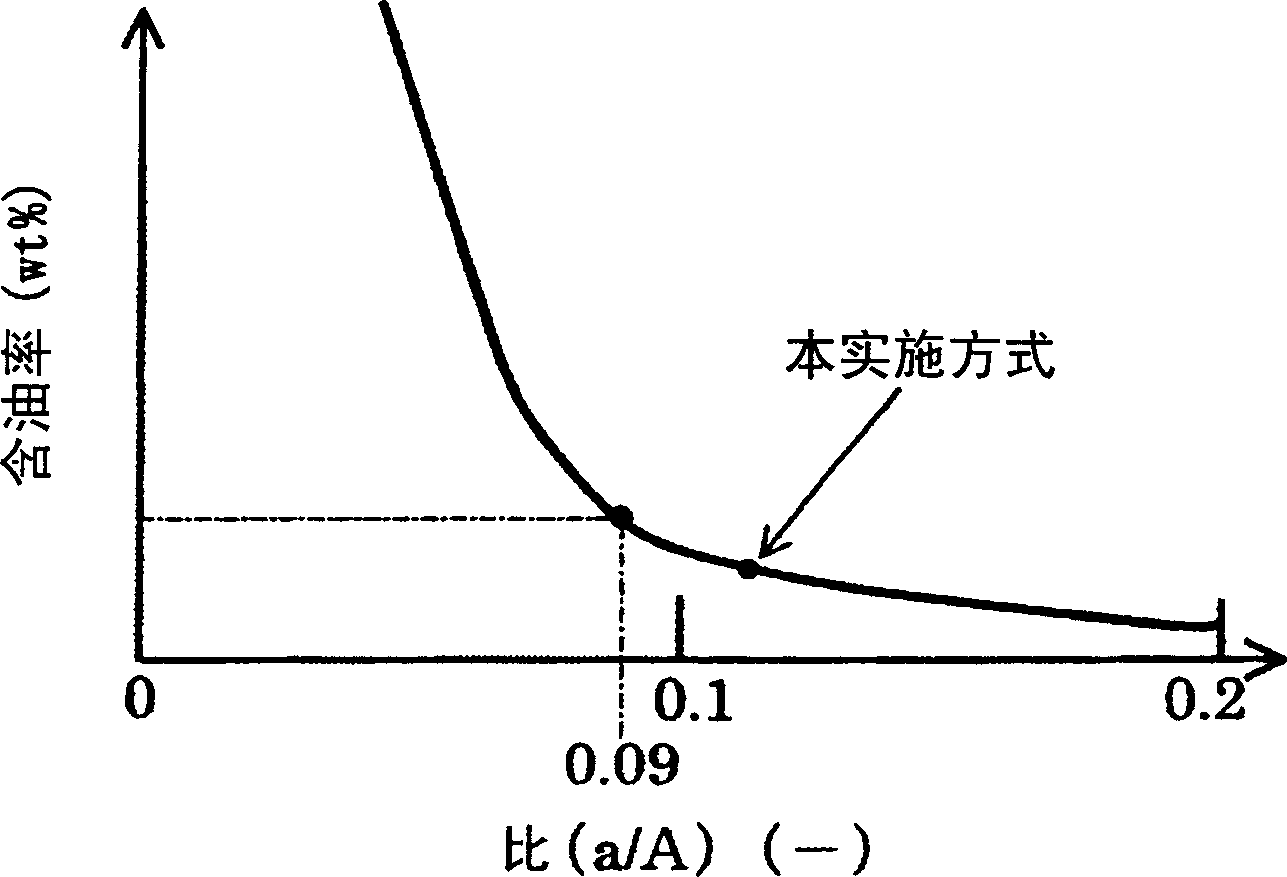

A rotary and compressor technology, applied in rotary piston machines, rotary piston pumps, pump combinations for elastic fluid rotary piston/oscillating piston, etc., can solve the unclear relationship between passage cross-sectional area and oil content , difficulties in the design of confined spaces, etc., to achieve the effect of reducing oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

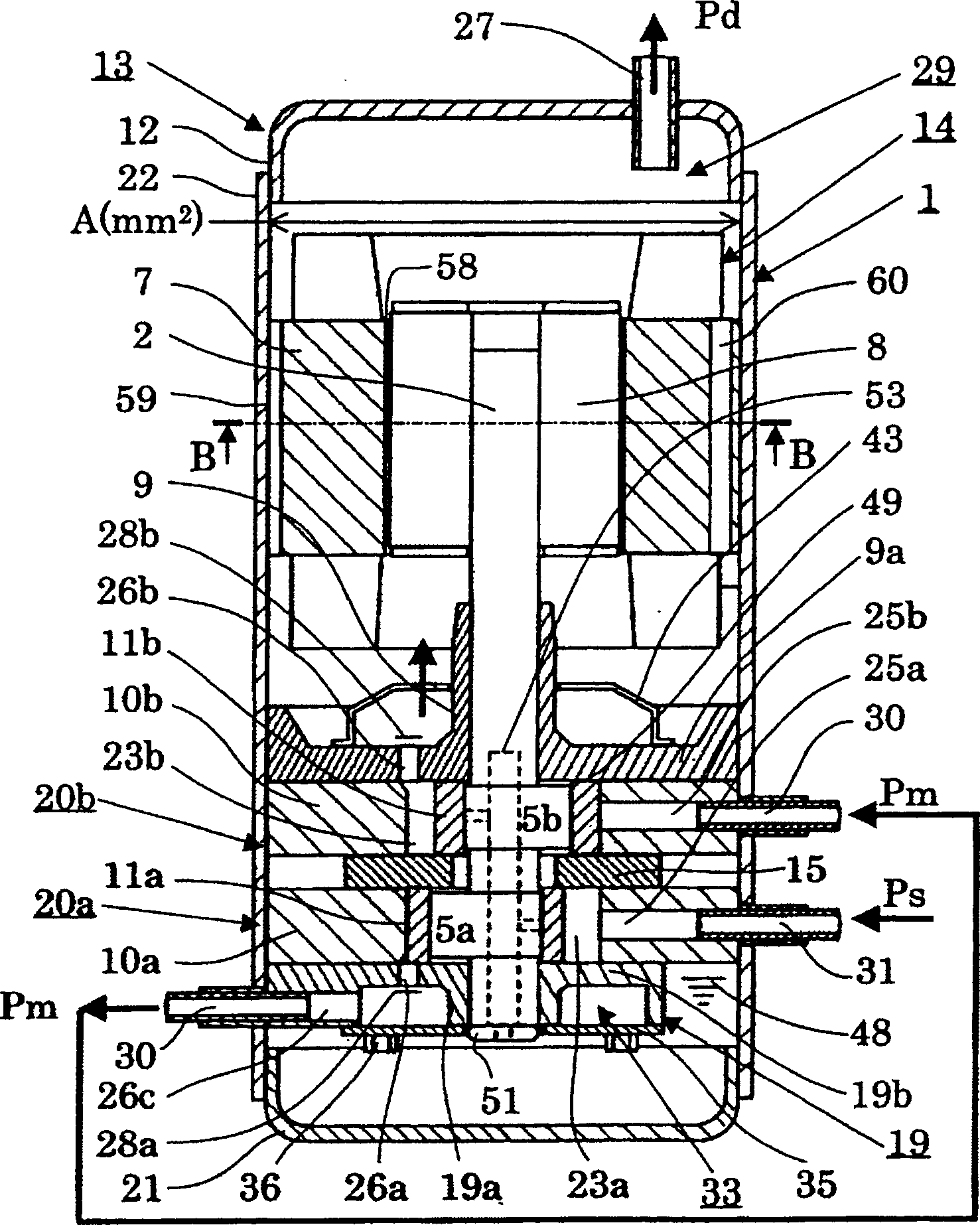

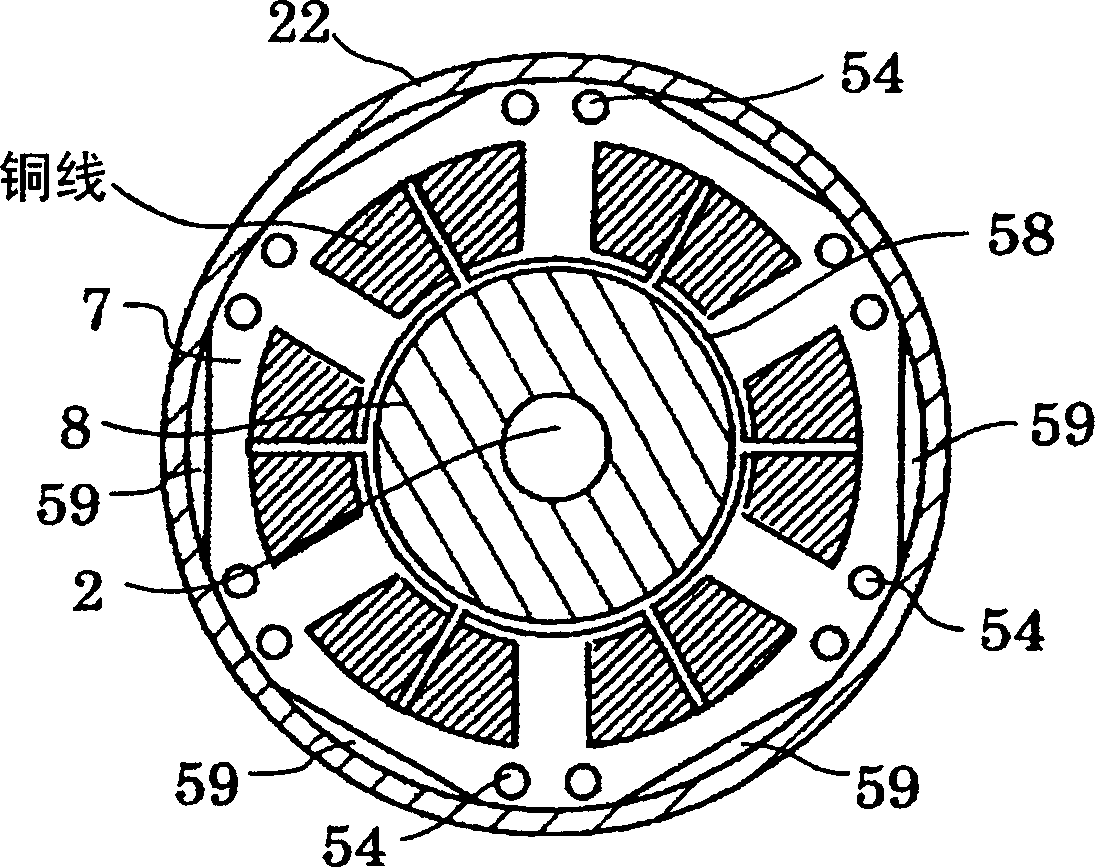

[0021] Embodiments of the present invention are described using drawings. exist figure 1 A vertical cross-sectional view of the rotary two-stage compressor 1 of this embodiment is shown in . The compressor 1 has an airtight container 13 composed of a bottom 21 , a cover 12 , and a body 22 . Below the inside of the airtight container 13, a motor 14 having a stator 7 and a rotor 8 is provided. The rotary shaft 2 to which the motor 14 is connected has two eccentric portions 5, and the main bearing 9 is pivotally supported by the sub bearing 19a. Corresponding to the rotary shaft 2, stacked in order from the motor 14: the main bearing 9 having the end plate portion 9a, the high-pressure compression element 20b, the intermediate partition plate 15, the low-pressure compression element 20a, the end plate portion 19b, and the sub-bearing 19a. The container 19 is integrated with connecting elements 36 such as bolts.

[0022] The end plate portion 9 a is fixed by being welded to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap