Standardised hinge for flatrack container

A hinge and flat-frame technology, applied in the field of foldable flat-frame containers, can solve problems such as extending the production cycle of hinges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

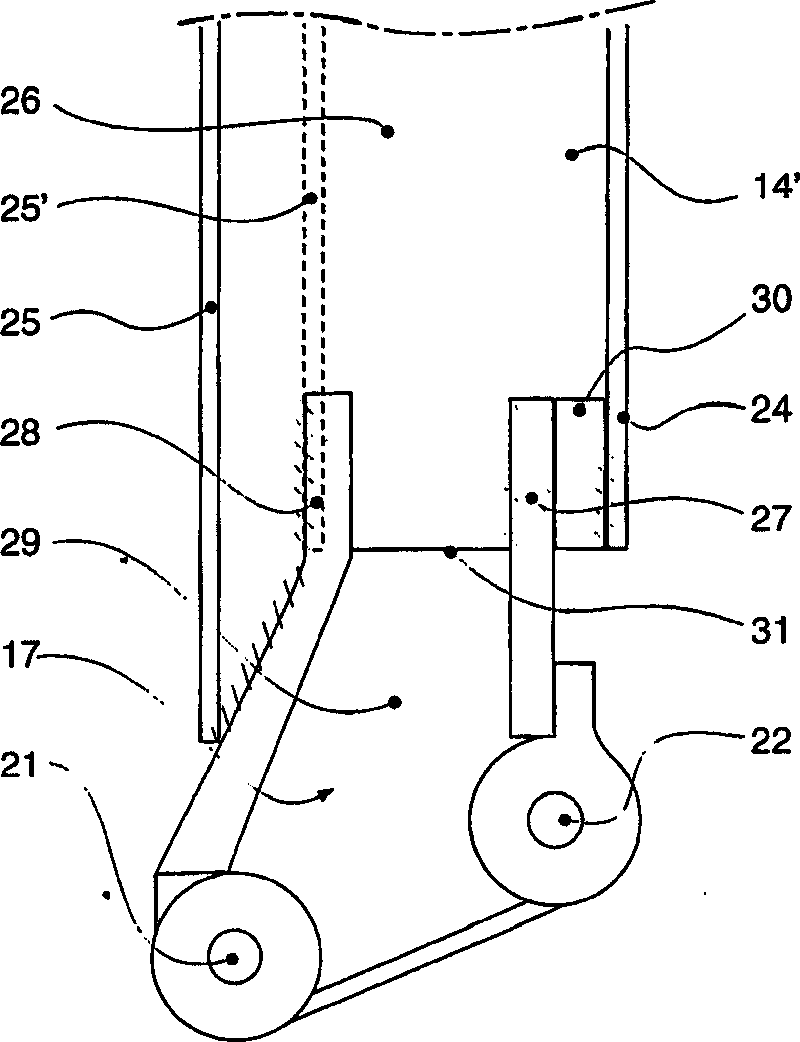

[0121] Refer to attached picture.

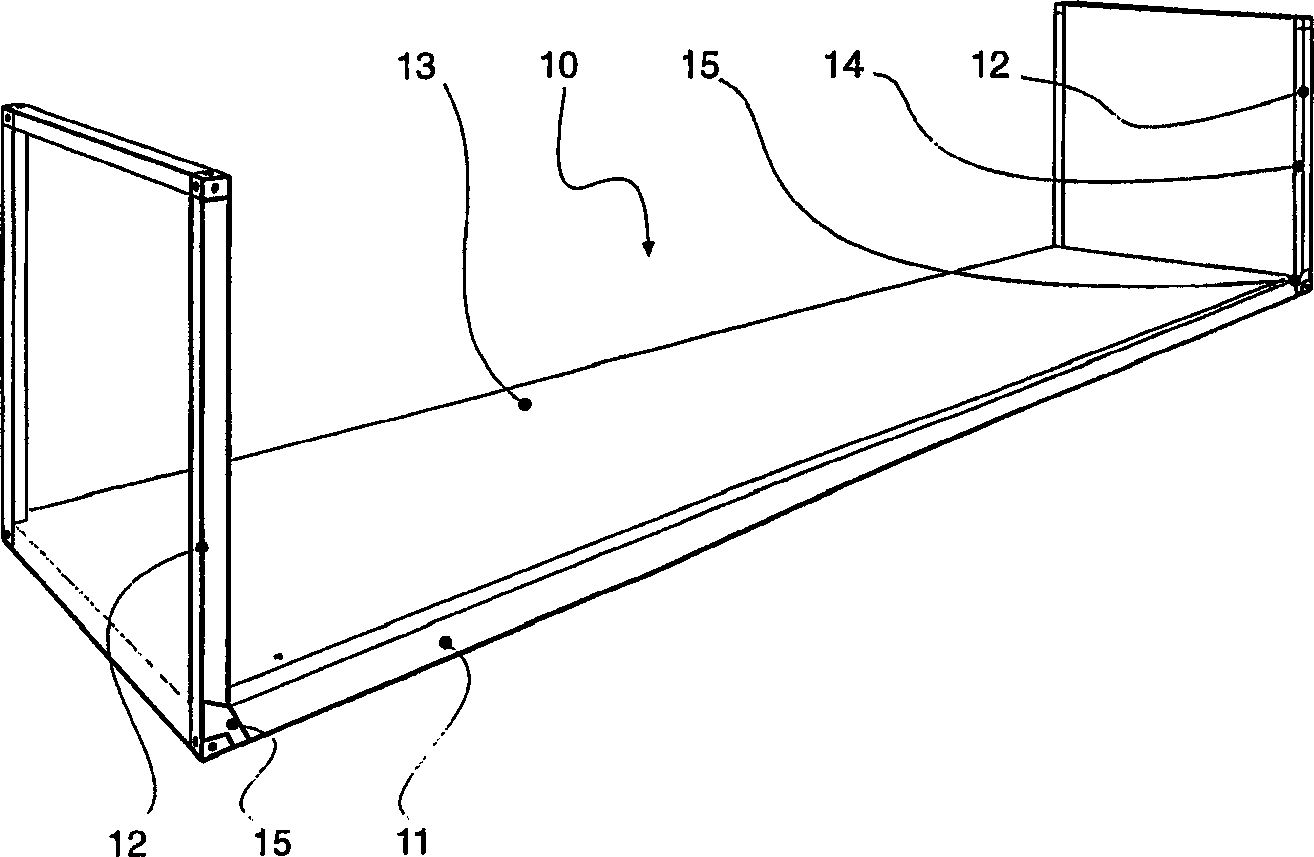

[0122] figure 1 A perspective view is shown of a typical collapsible flat frame 10, comprising a platform base 11 having infill panels or base panels 13 (such as timber supports) with inwardly folded end frames or walls 12 at their opposite ends.

[0123] Each end frame 12 has, or is arranged between, a pair of corner end posts 14 mounted on the platform base plate 11 by hinges 15 .

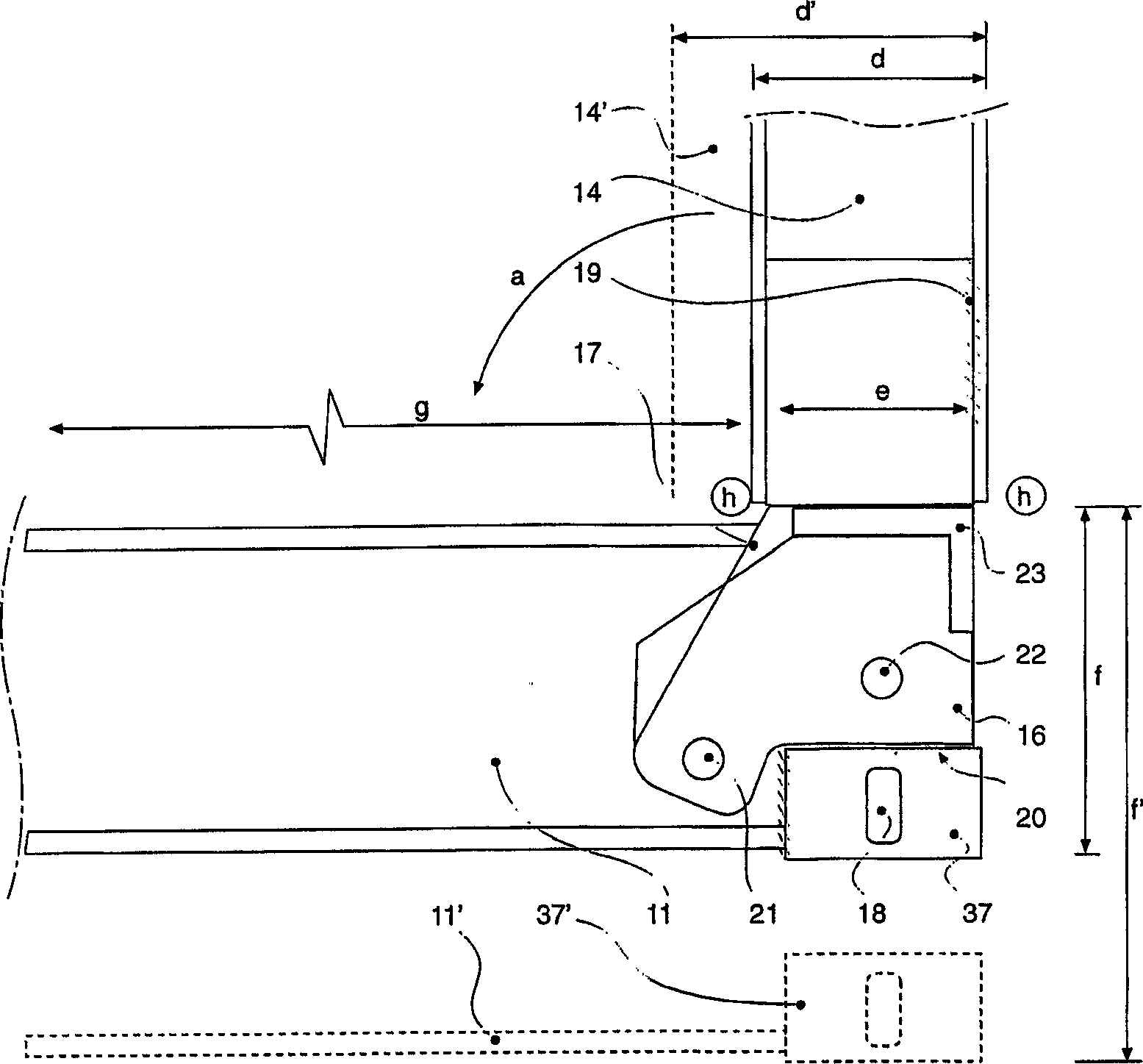

[0124] figure 2 A detailed side sectional view showing a conventional hinge 15 with posts 14 locked vertically.

[0125] This is a conventional hinge made by known manufacturing methods and has an inner hinge element 17 attached to the post 14 and an outer hinge element 16 attached to the base plate 11 .

[0126] At the bottom corner (drawn on the right-hand side) a corner fitting 37 is mounted, which is of standard form for container acquisition, handling and centering stacking.

[0127] The corner fitting 37 comprises a cast iron cuboid box with a handli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com