Labor-saving high-speed jinrick-shaw

A rickshaw, high-speed technology, applied to labor-saving high-speed rickshaws. It can solve the problems of strenuous speed and difficulty in further improvement, and achieve the effects of easy manufacture, reduced physical exertion, and large work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

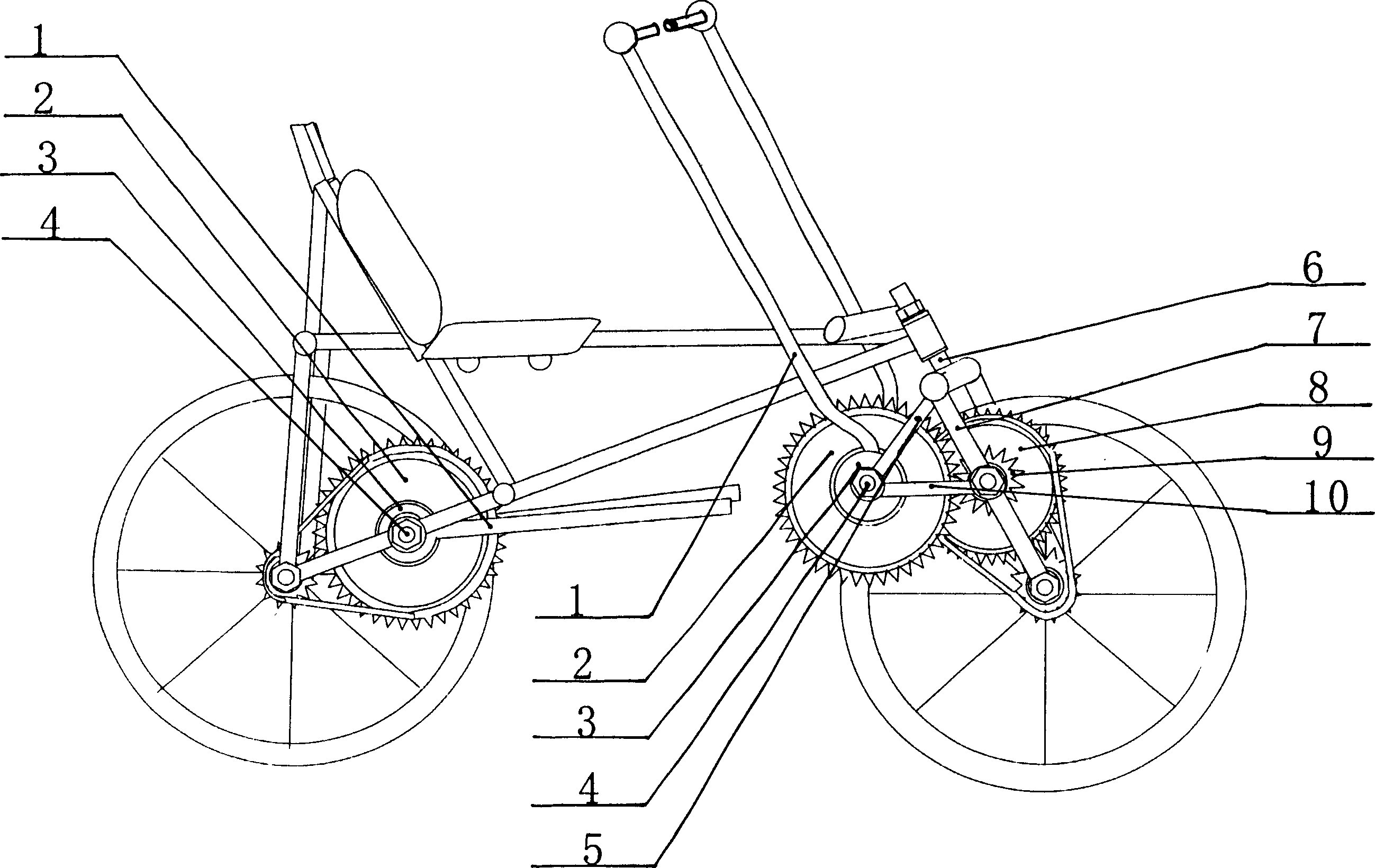

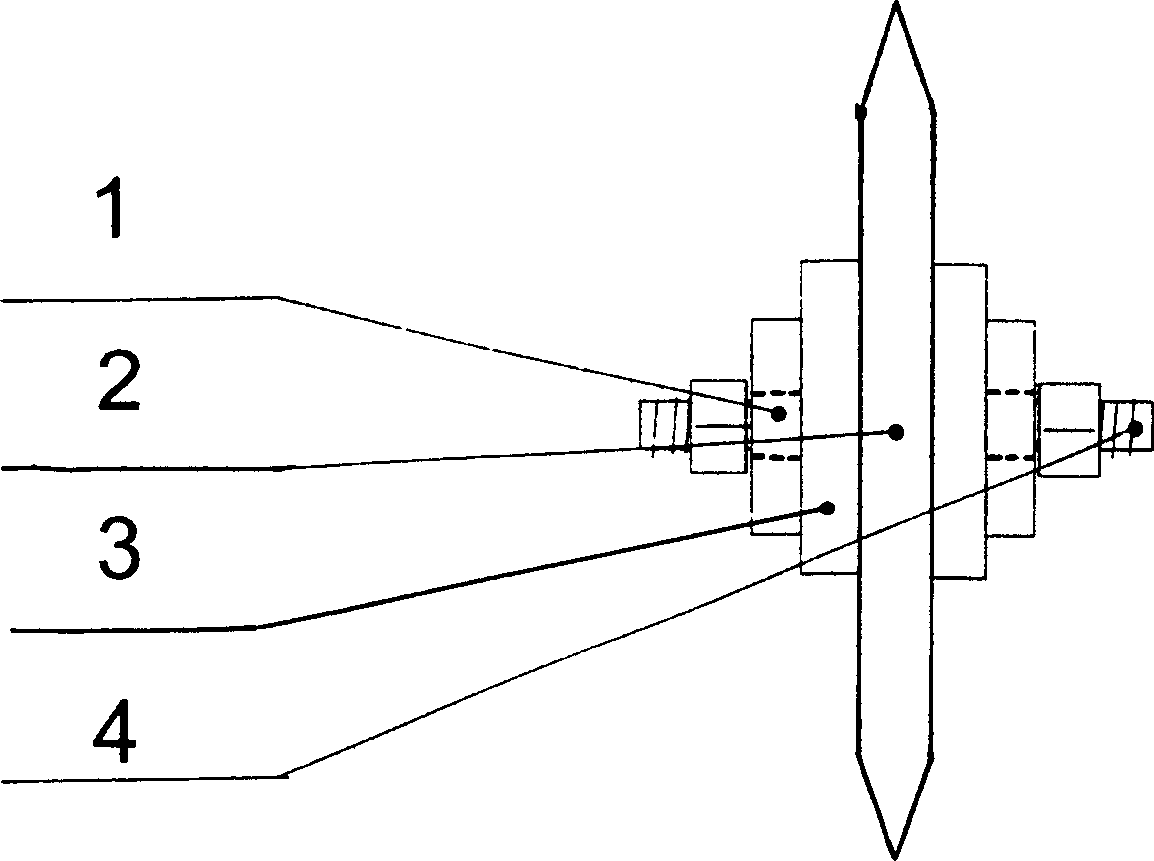

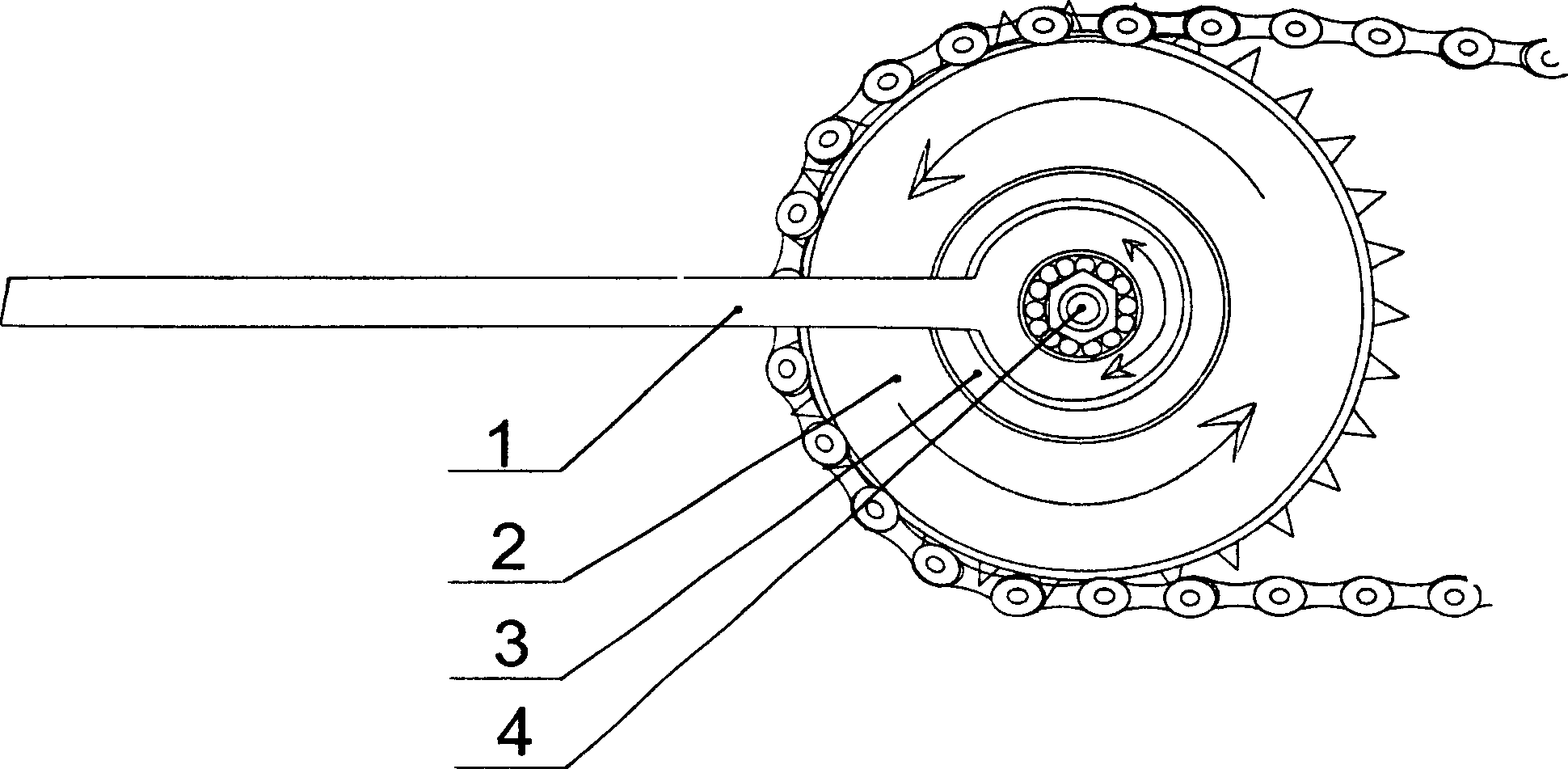

[0018] see figure 1 , figure 2 and image 3 , a bicycle comprising a head control mechanism, a vehicle frame, a front drive mechanism and a rear drive mechanism. Said driving mechanism comprises a chain disc 2, two one-way flywheels 3, two power arms 1 and a central shaft 4, said power arm 1 is more than twice as long as the length of a common pedal power arm 1, and the central shaft 4 Two one-way flywheels 3 are symmetrically arranged on both sides of the upper chain disc 2, and a power arm 1 is arranged on the outside of the two one-way flywheels 3. The said chain disc 2 is connected to the inner layer of the two one-way flywheels 3, One end of said power arm 1 is fixedly connected to the outer layers of two corresponding one-way flywheels 3 . In the front drive mechanism, the central axis 4 is horizontally arranged, and vertically intersects with the vertical shaft 6 space, and the power arm 1 is arranged upward and backward, and the upper part of the power arm 1 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com