Pressing safety power supply socket

A safe power supply, push-type technology, applied in the direction of circuits, electrical components, coupling devices, etc., can solve problems such as plug influence, power failure of electrical equipment, poor contact, etc., to achieve easy processing and production, avoid safety hazards, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

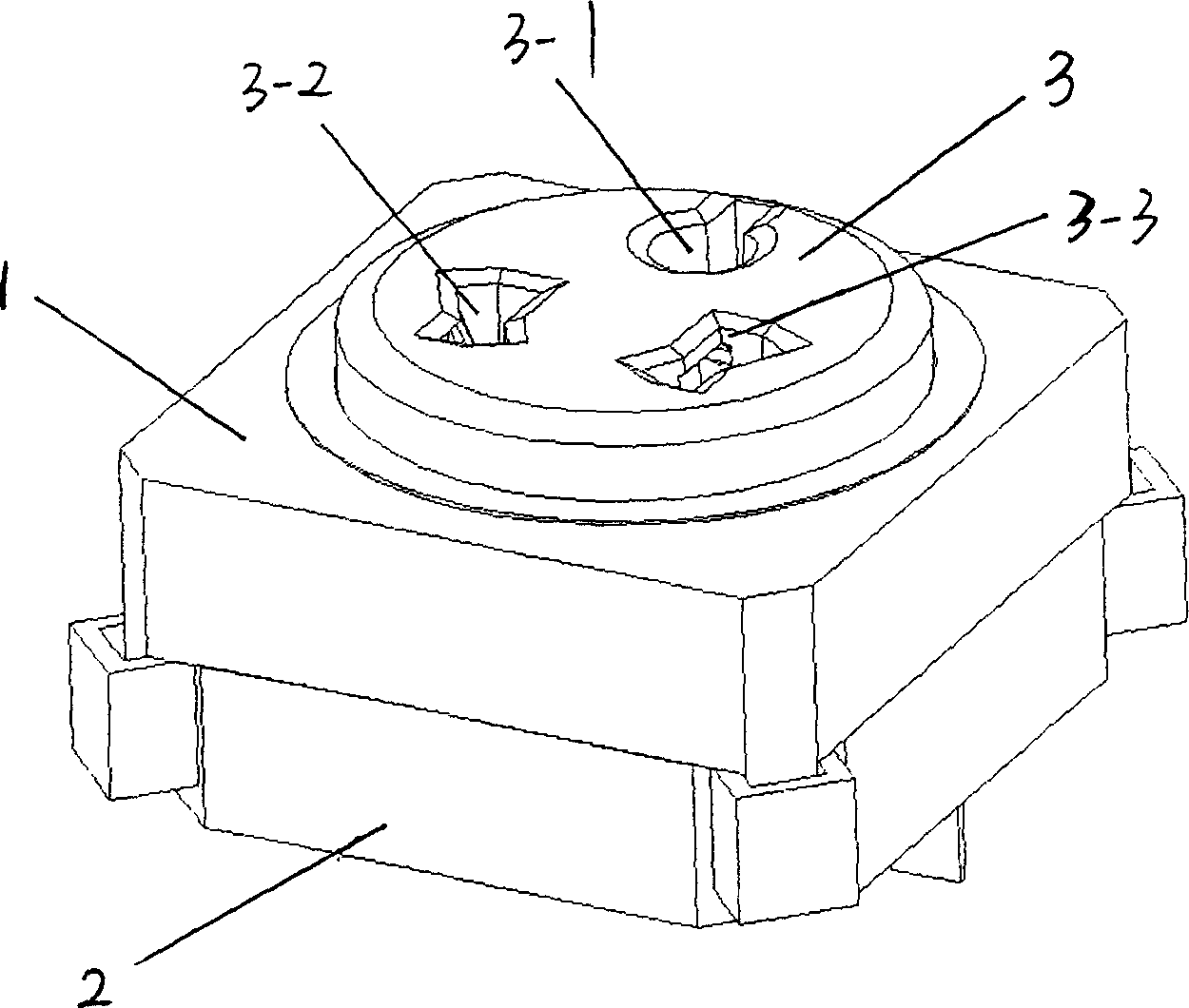

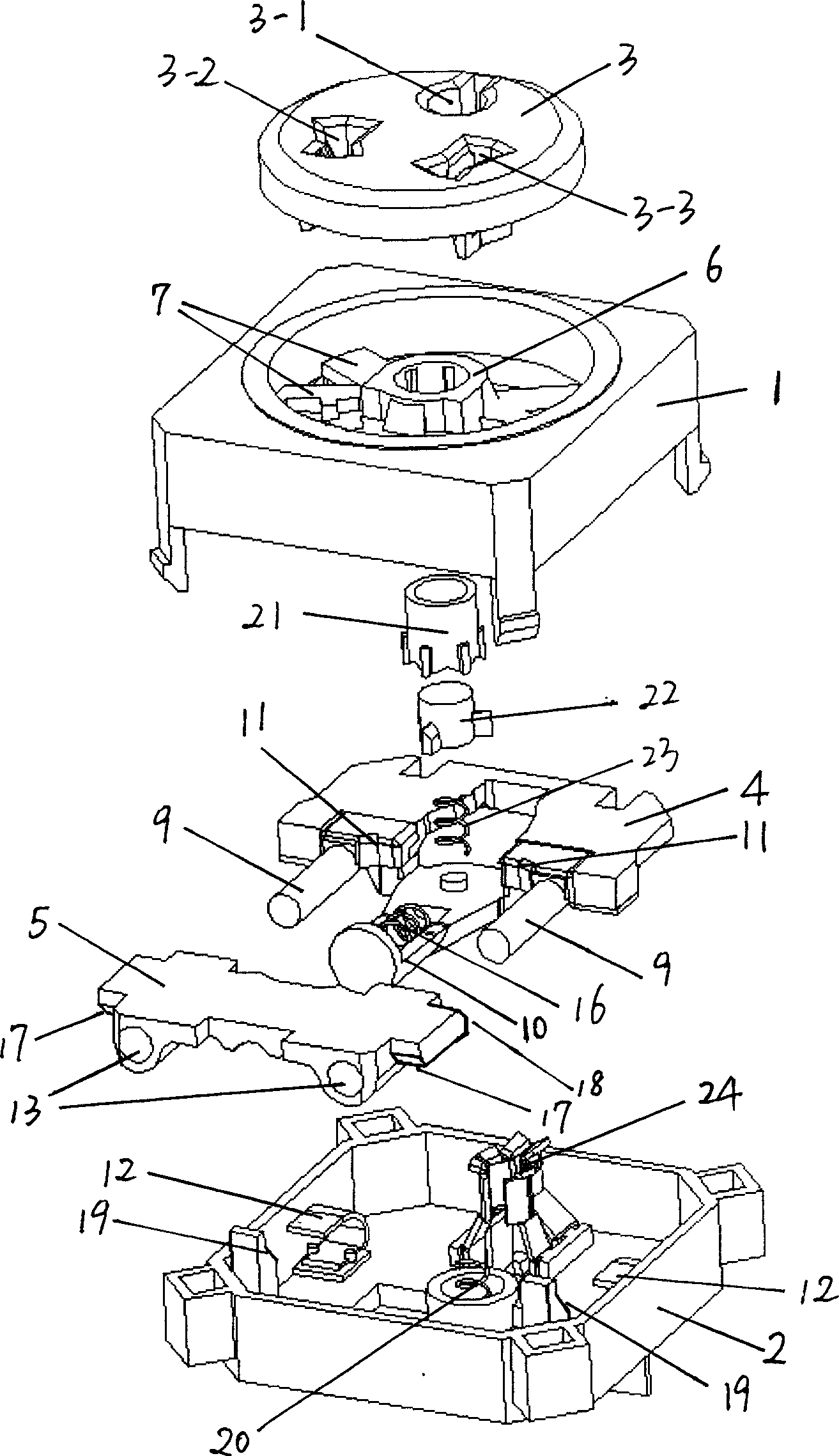

[0016] The present invention mainly includes: a plug cap 3, an upper cover 1, a base 2, a transmission block 4 and a side slider 5. The upper cover 1 is fixedly connected to the base 2, and a plug cap 3 for plugging in the power plug is embedded in the center of the upper cover 1 to form a complete shell; the transmission block 4 and the side slider 5 are arranged In the above housing.

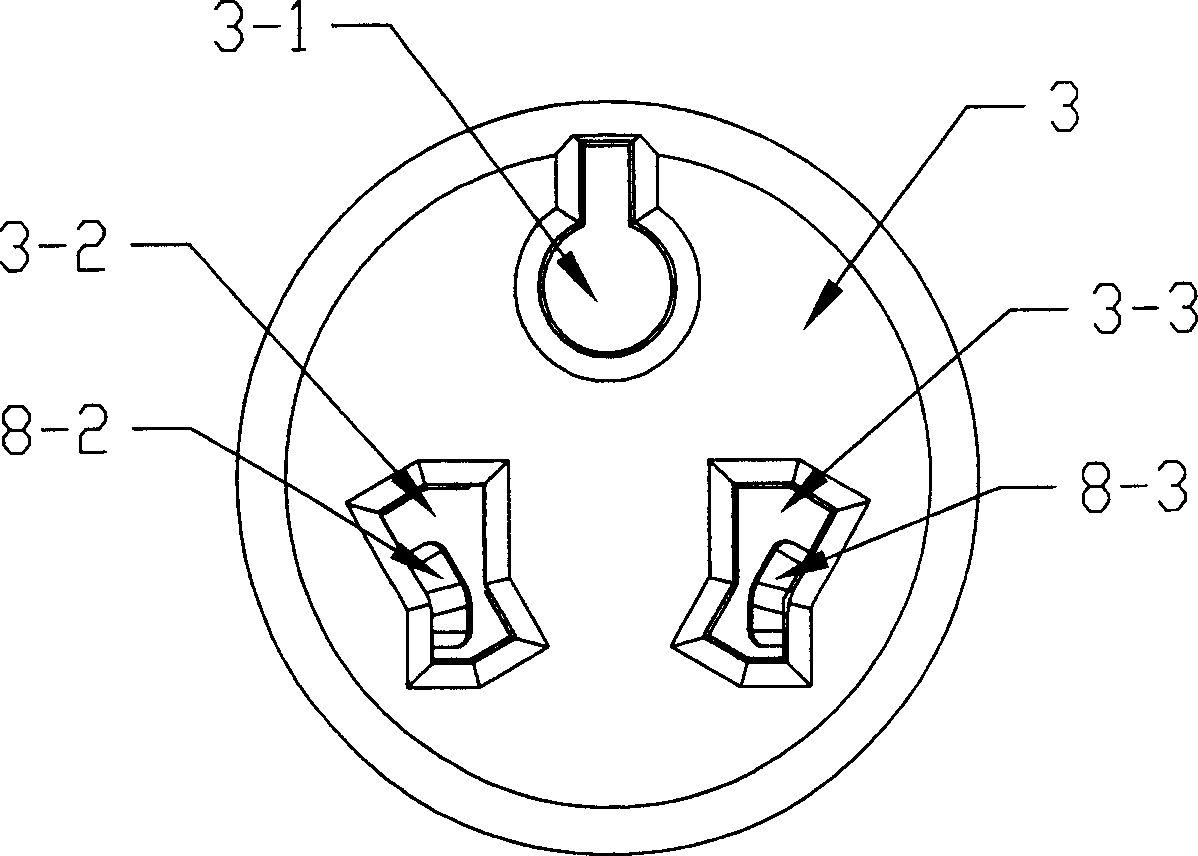

[0017] The plug cap 3 is provided with three sockets, namely the ground wire socket 3-1, the live wire socket 3-2, and the neutral wire socket 3-3; the bottom end of the ground wire socket 3-1 is The shape of the live wire jack 3-2 and the neutral wire jack 3-3 are exactly the same, and they are symmetrical with respect to the center line of the ground wire jack 3-1. The live wire receptacle 3-2 and the neutral wire receptacle 3-3 are respectively formed by overlapping a pair of long rectangular holes arranged in parallel with the center line and a pair of long rectangular holes arranged in a V sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com