Loading structure of back light module

A backlight module and load-carrying structure technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as increasing the thickness and increasing the thickness of the backlight module assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

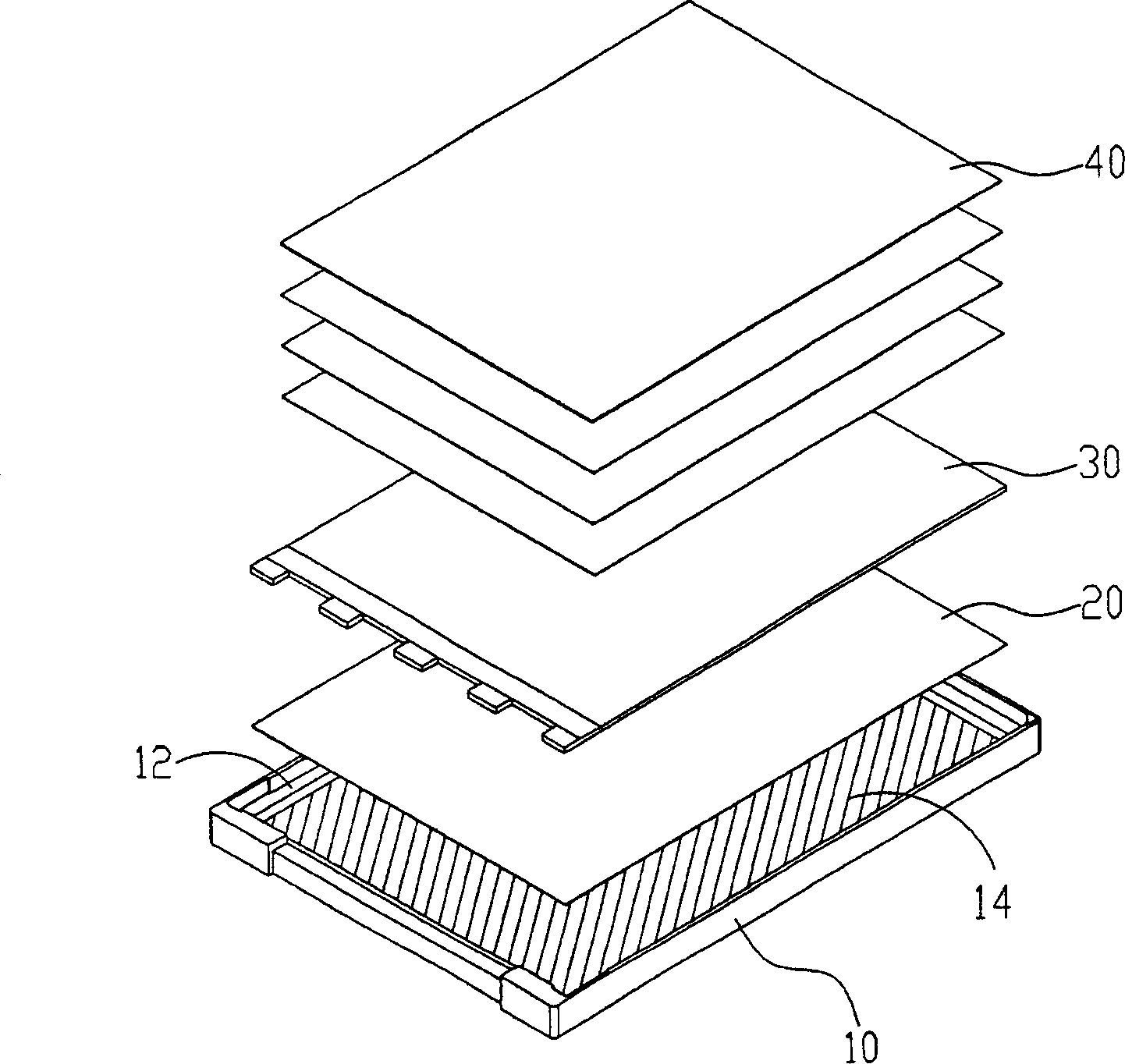

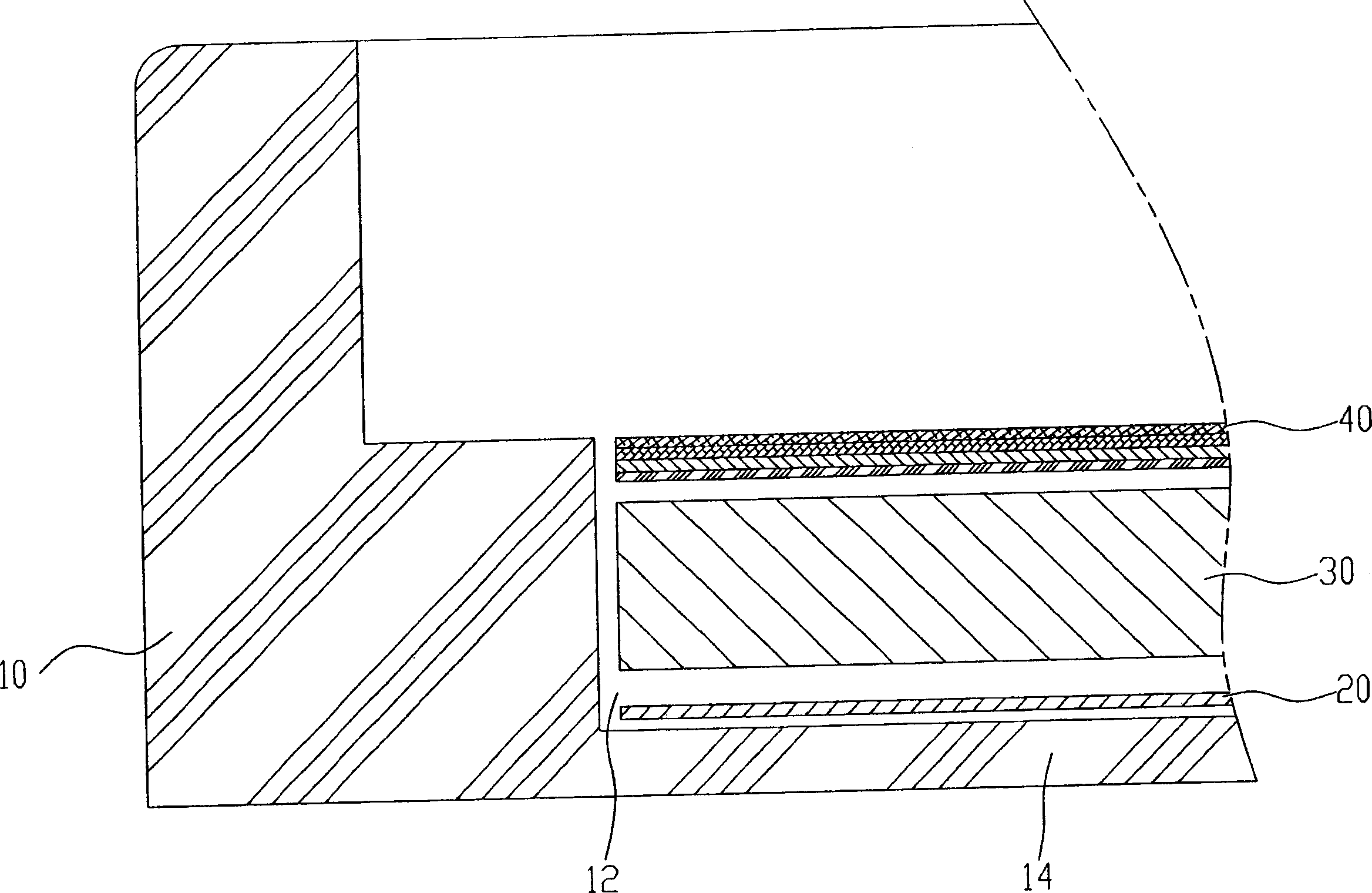

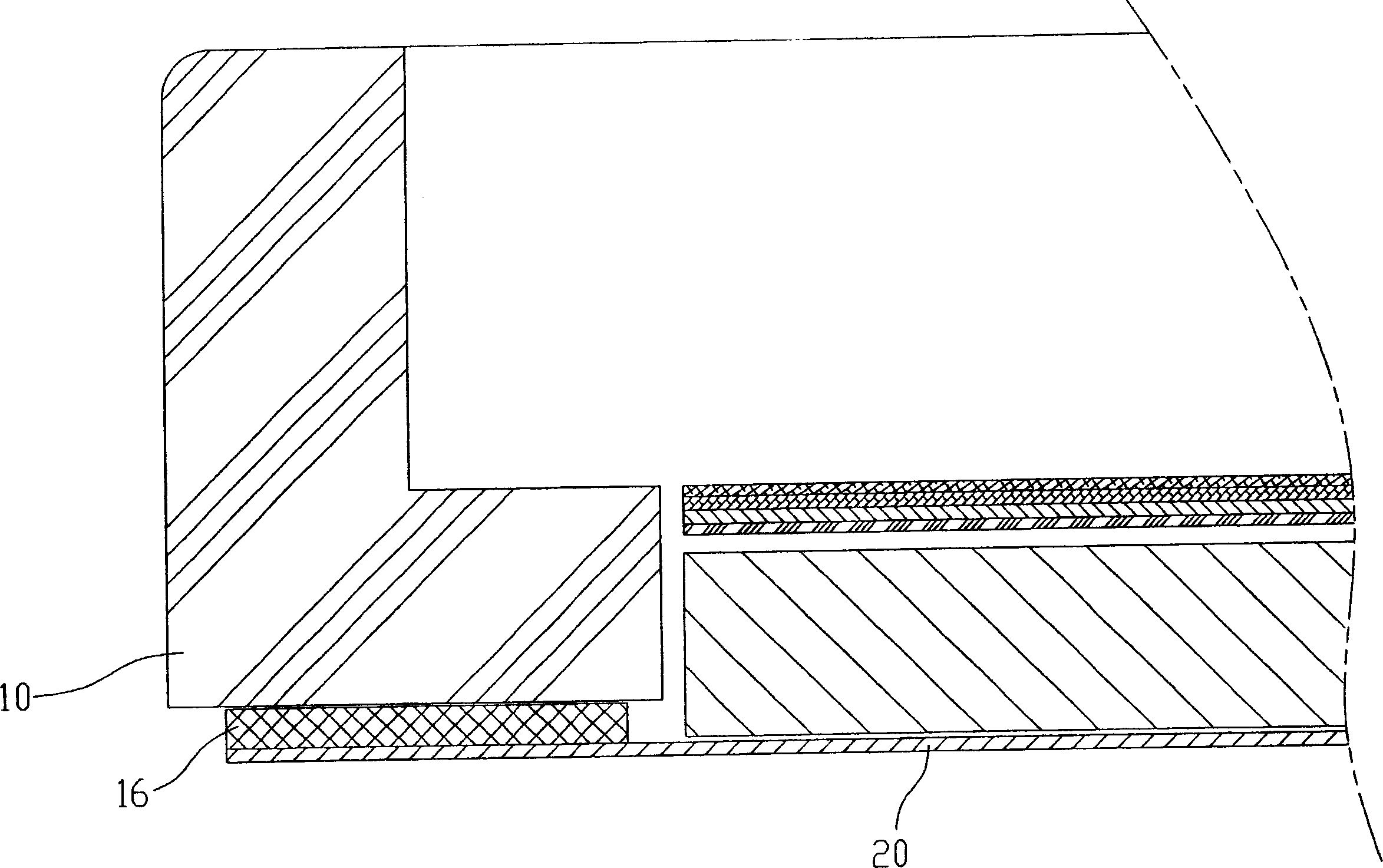

[0030] In order to have a further understanding and recognition of the structural features and achieved effects of the present invention, the preferred embodiments will be described in detail below with accompanying drawings.

[0031] refer to Figure 7 with Figure 8 , which is an exploded view and a cross-sectional view of a frame assembly disposed on a substrate according to an embodiment of the present invention. As shown in the figure, the present invention includes a frame 60 and a base plate 70, the material of the frame 60 includes plastic material, and the material of the base plate 70 includes metal material. The bottom of one side of the frame 60 is provided with a housing portion 61, the base plate 70 has an insert 71, the insert 71 is an edge portion of the base plate, the position of the insert 71 is opposite to the housing portion 61, and the housing portion 61 and the insert An adhesive body 62 is arranged between 71 , the insert 71 is arranged on the accommo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com