Full automatic sausage segment binding machine

A fully automatic, sausage technology, applied to the equipment for ligating sausage casings, etc., can solve the problems of different lengths of sausages, slippage, etc., and achieve the effects of simple operation, consistent knot length and high knot efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

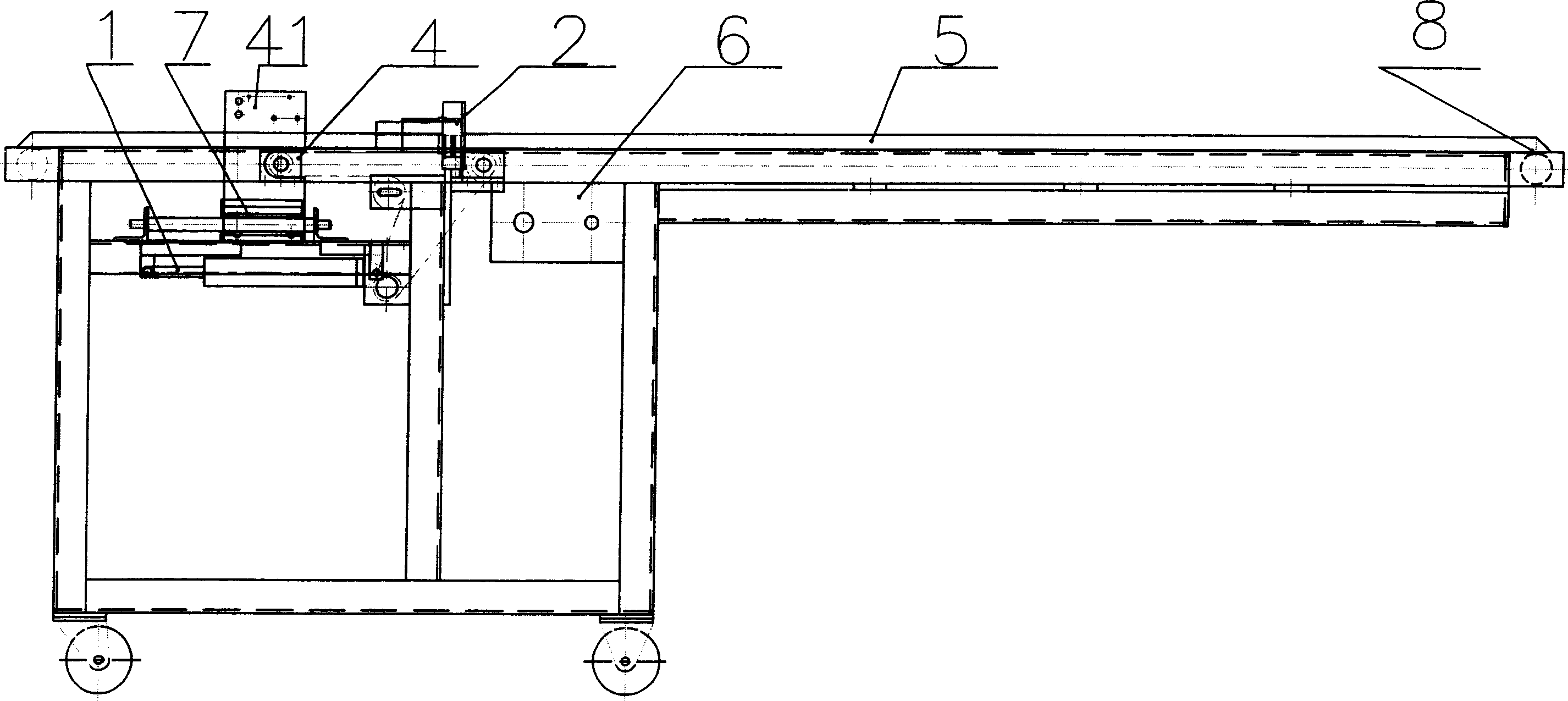

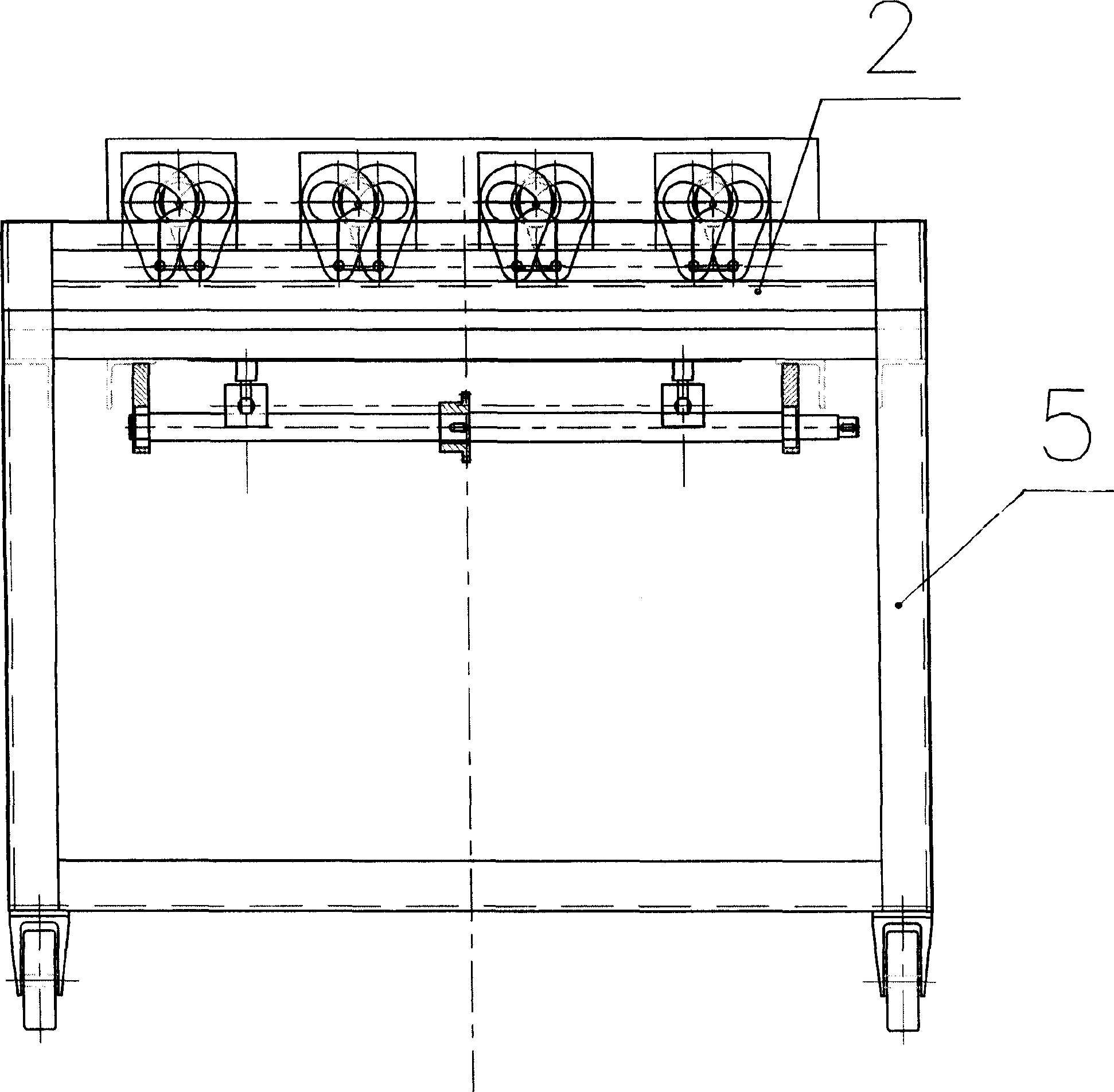

[0019] Such as Figure 1 to Figure 6 As shown, the present invention is mainly made up of frame 5 and feeding mechanism, and described feeding mechanism is made up of conveyer belt 8 and a jaw device 4 that is provided with jaw 48 and jaw bottom plate 41, and this jaw bottom plate 41 passes through a The sliding assembly 7 is connected with the piston rod 1 of the air cylinder, and the 6 is a control panel.

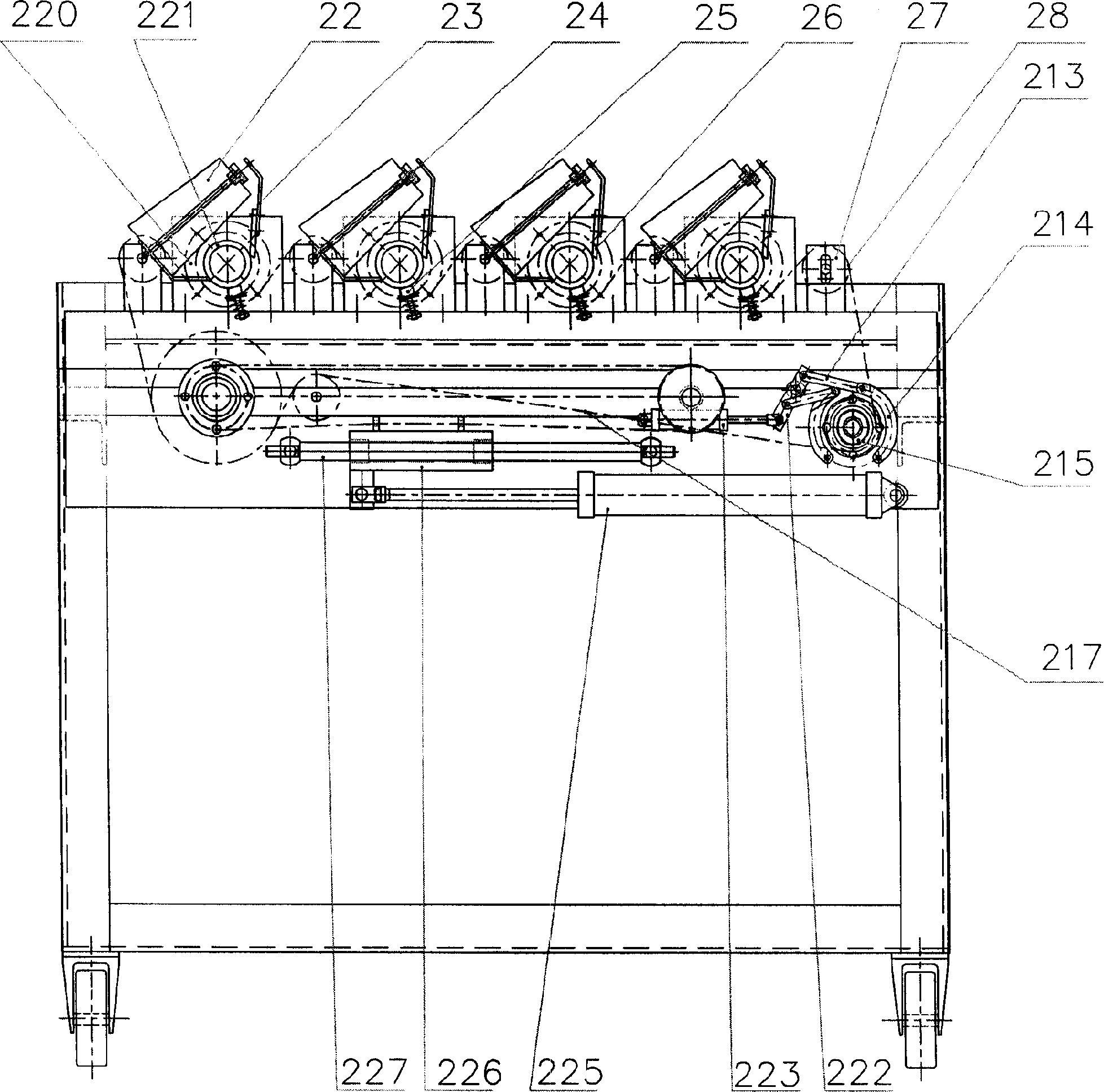

[0020] The frame is also provided with a necking device 3 which constricts the neck at the joint and a winding device 2 which winds the wire at the necking.

[0021] The jaw device includes a pair of jaws 48, the jaws 48 are fixed on the jaw fixing block 47 and are respectively hinged with the air jaw pressure plate 410 and the synchronous connecting rod 44, and the synchronous connecting rod 44 passes through a three-link mechanism Connect with the piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com