Device and method for producing powder-air mixture

A technology of air mixture and air pre-mixture, applied in mixing methods, chemical instruments and methods, gas/steam and solid mixing, etc., can solve problems such as insufficient reliability, unsuitability for industrial use, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

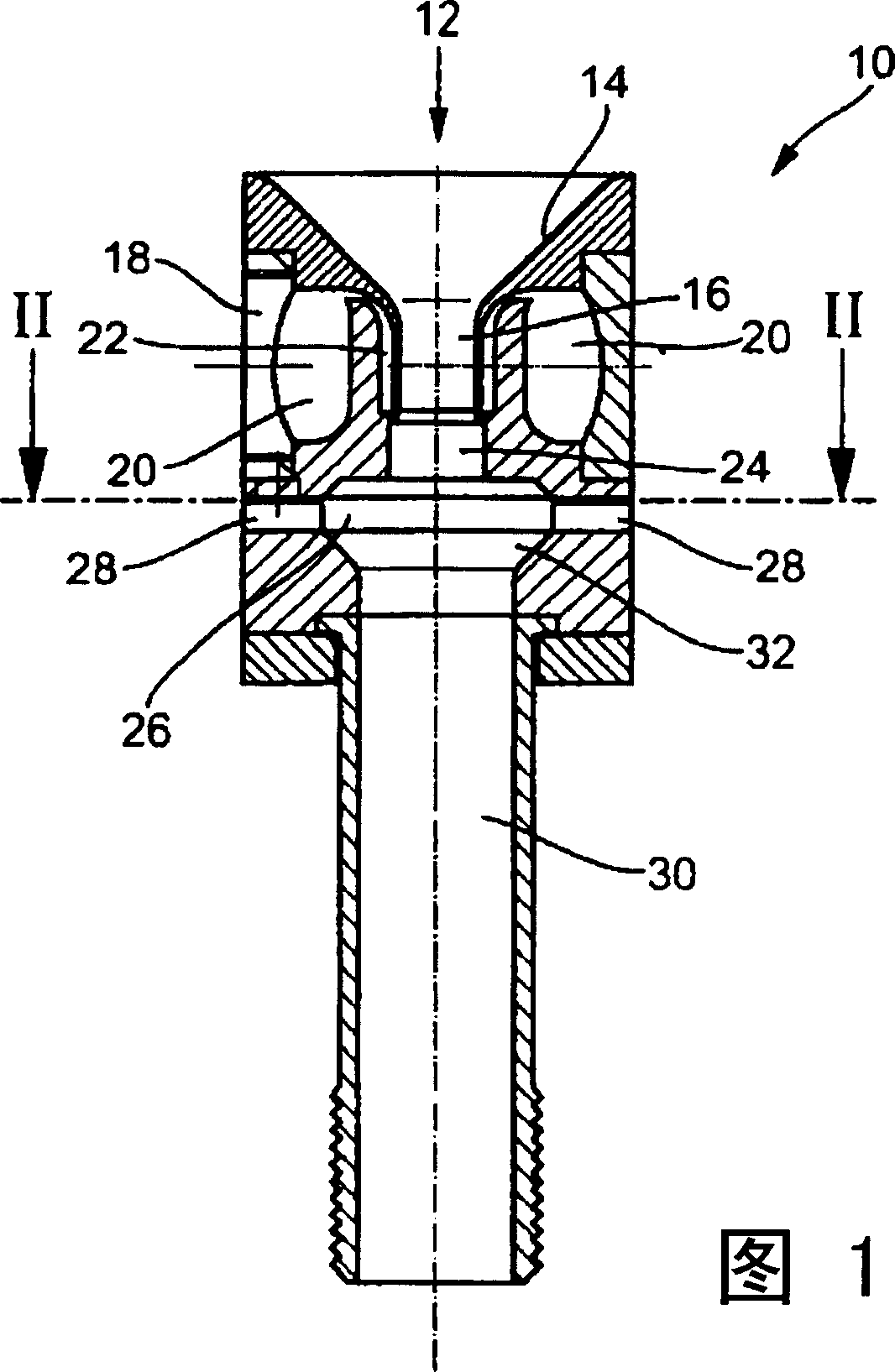

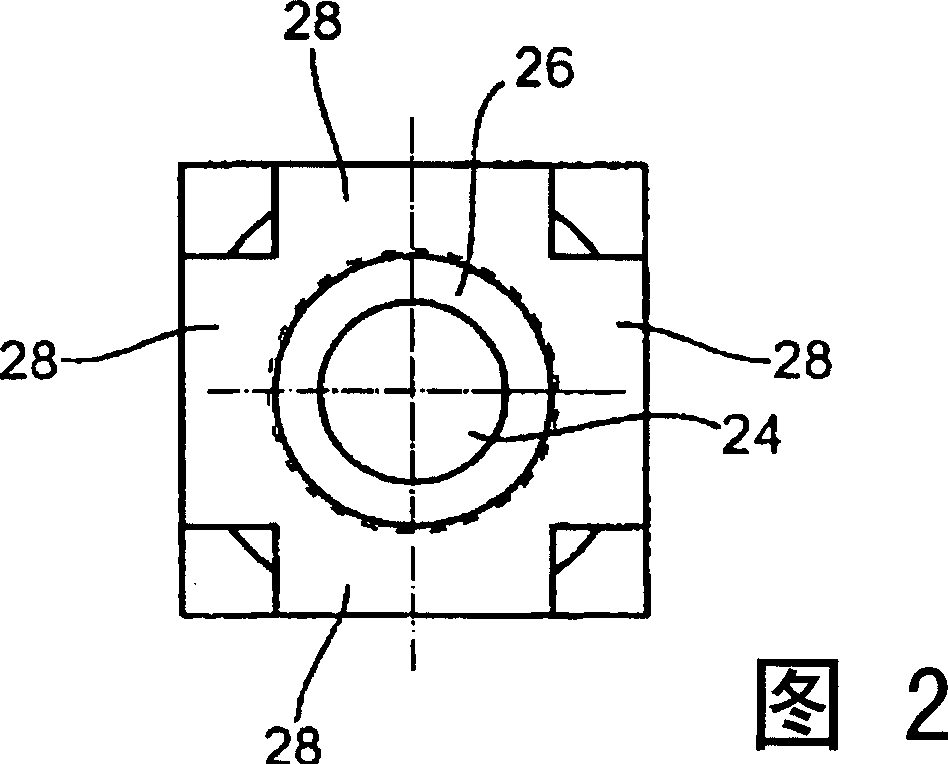

[0019] FIG. 1 shows a device for producing a homogeneous powder-air mixture, indicated generally at 10 , which can be used, for example, in a powder spraying device for powdering printing paper in a printing press. The powder will thus be fed from a supply container (not shown) by means of a dosing device (not shown) in the direction of arrow 12 . The powder falls into a funnel 14 terminating in a suction line 16 . Reference numeral 18 denotes a line nozzle for supplying compressed air. The line nozzles 18 terminate in an annular distribution space 20 in which the compressed air is uniformly introduced into an annular space 22 . The compressed air in the annular space 22 is deflected downwards around the suction line 16 so that an enveloping jet is formed. The suction line 16 terminates in said envelope jet, whereby powder from the funnel 14 and suction line 16 is entrained by said envelope jet.

[0020] The above mixture of powder and air has a flow rate, but is still inho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com