Intelligent repair method of injection molding during plastic injection process and injection molding machine

A technology of injection process and injection parts, applied in electrical components, systems based on fuzzy logic, logic circuits, etc., can solve problems such as not fully reflecting the real situation of the injection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0051] A pair of molds, the injection plastic is ABS, the defect type is "under-injection", and the process parameter is "injection pressure".

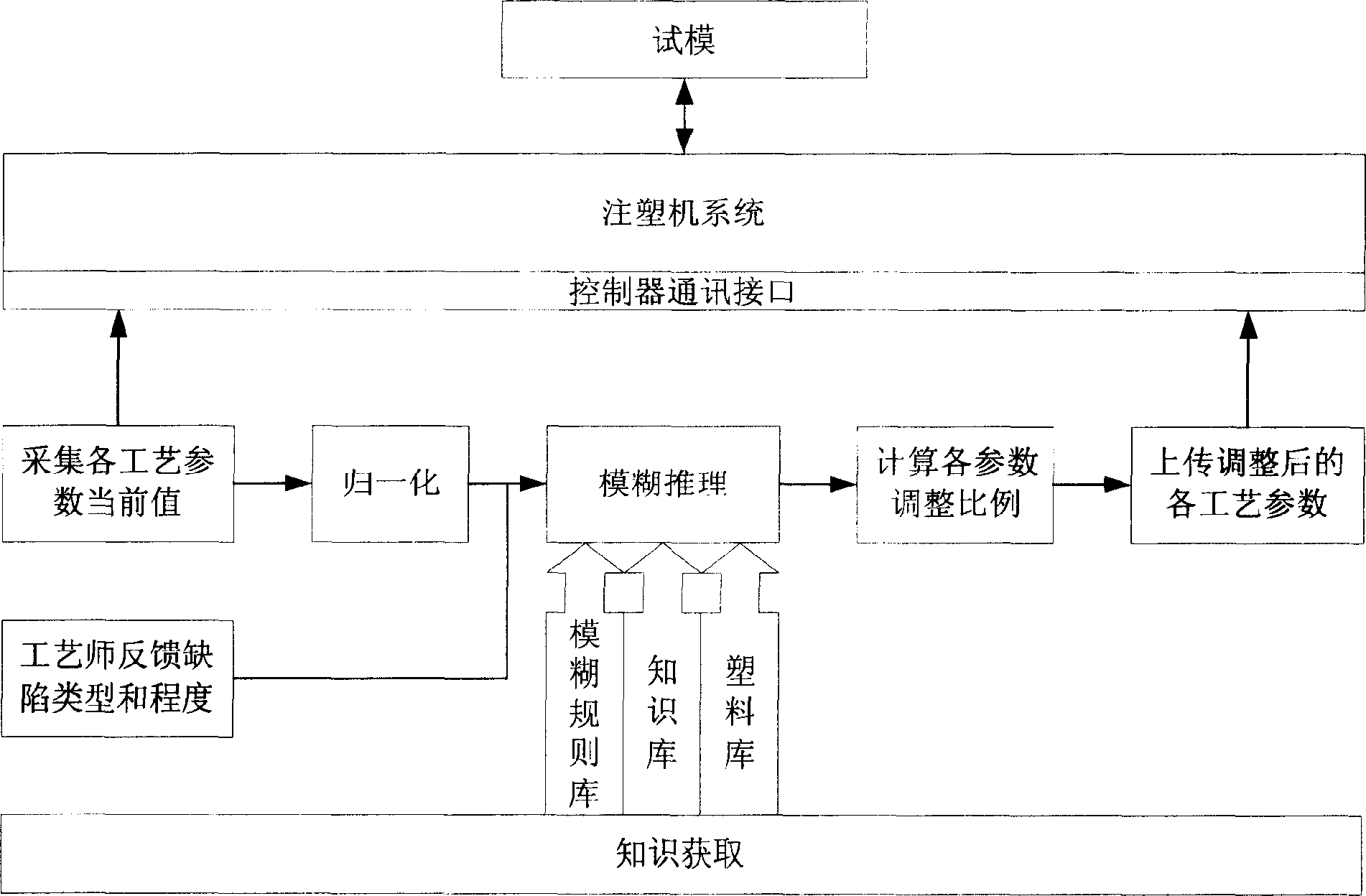

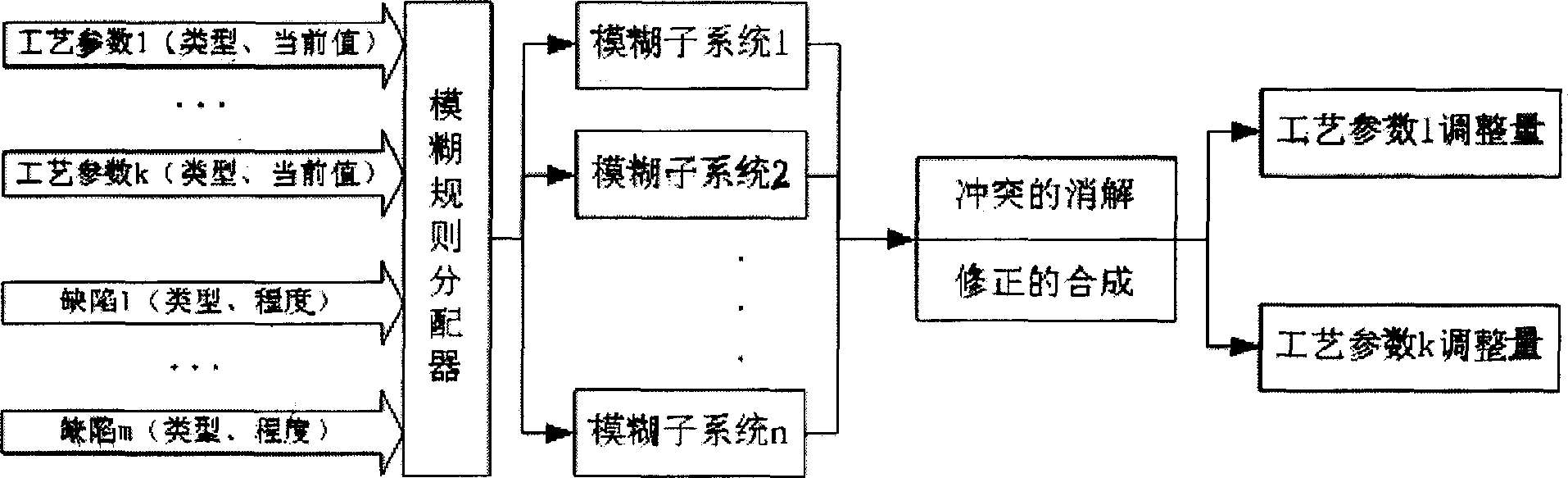

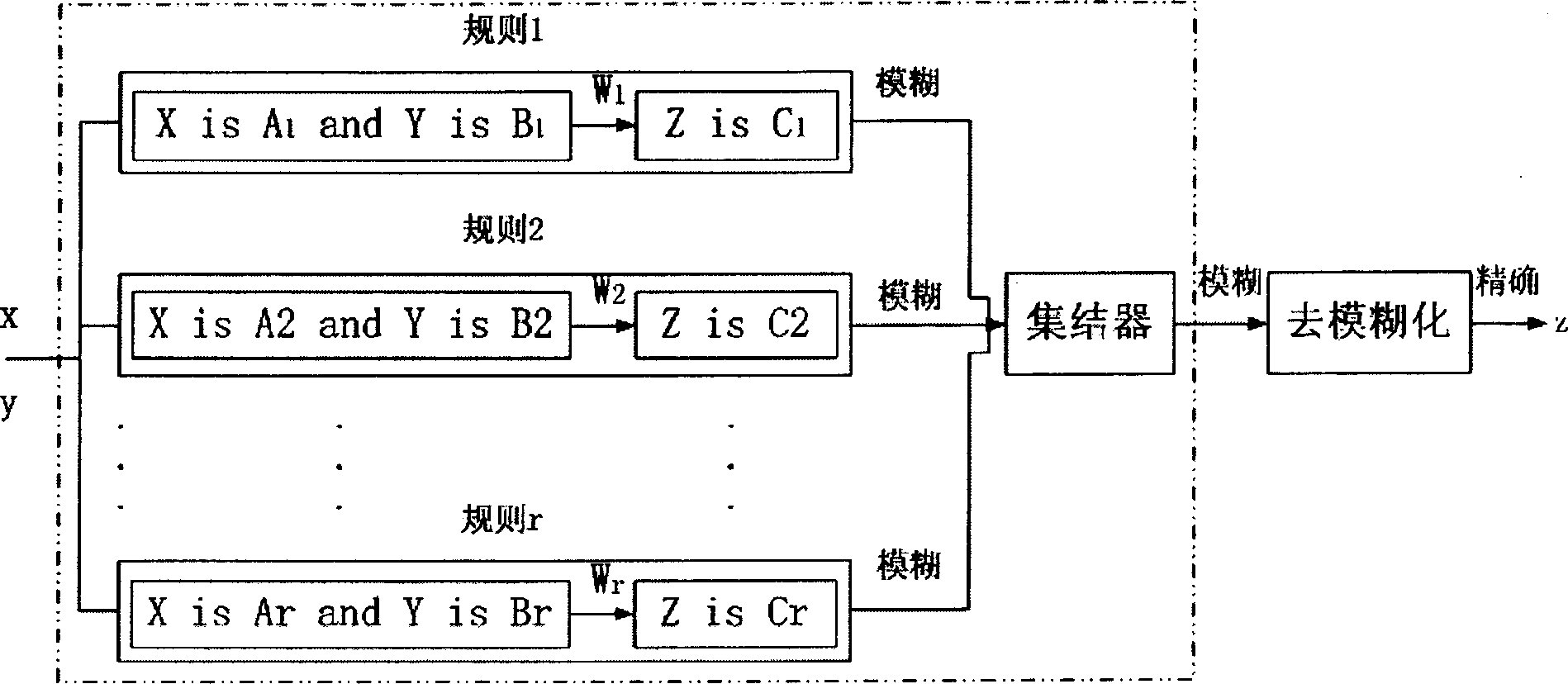

[0052] figure 1 It is an overall block diagram of the embodiment of the present invention, illustrating the overall implementation method and process of the present invention. In the part of knowledge acquisition, the expert knowledge of plastic injection is collected and sorted out by the method of knowledge engineering, and the fuzzy if-then rule set of "under-injection" and "injection pressure" correction is formed, and its form is as shown in the example of fuzzy if-then rules in the content of the invention At the same time, a knowledge base of defect priority is formed to determine which defect should be corrected first when multiple defects appear at the same time. Both the fuzzy rule base an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com