A valve for a drinking receptacle

A drinking container and valve seat technology, applied in the field of low pressure start-up and outflow mechanism, can solve the problems of valve surface damage, strong deformation, increased cost and complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

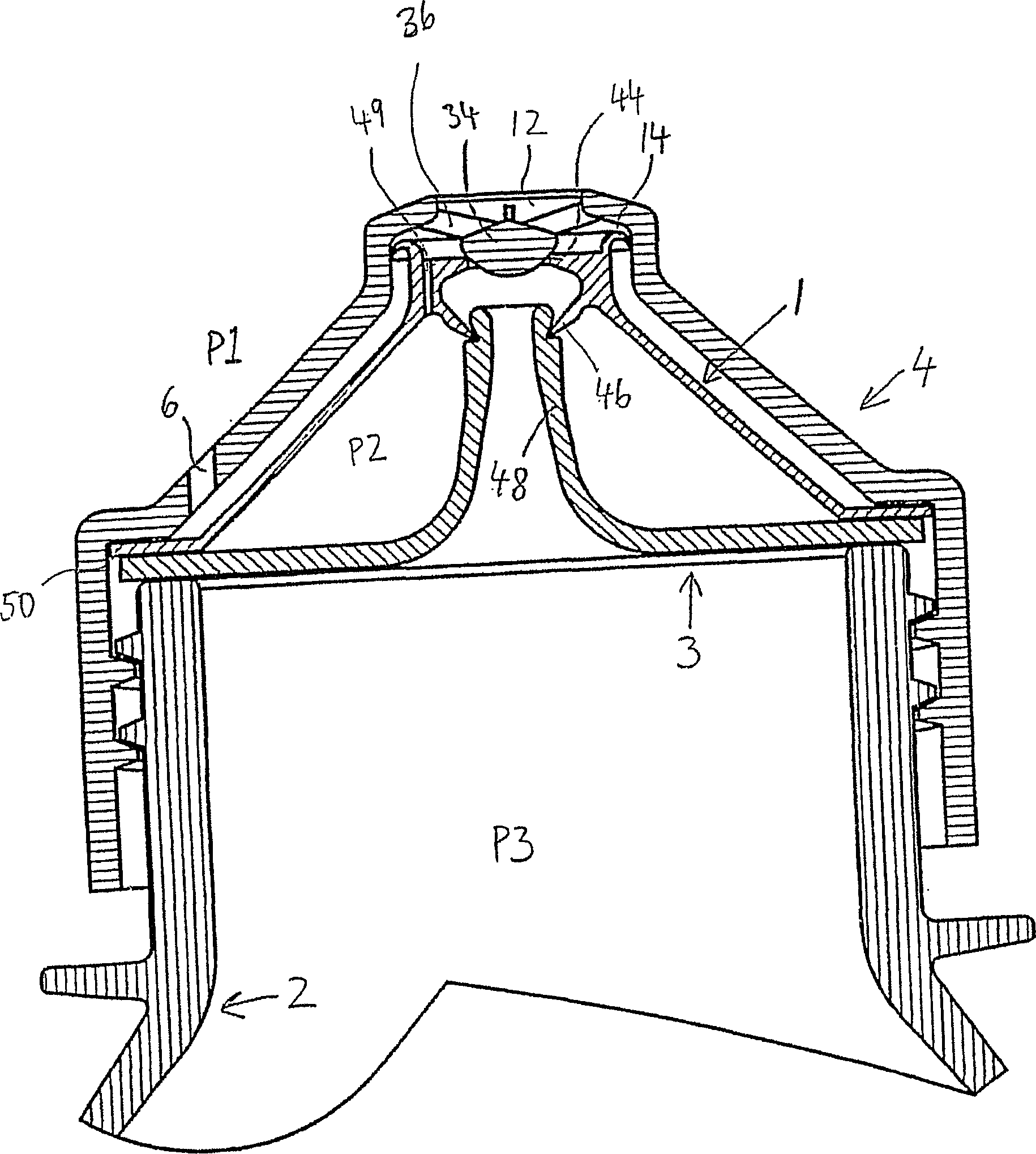

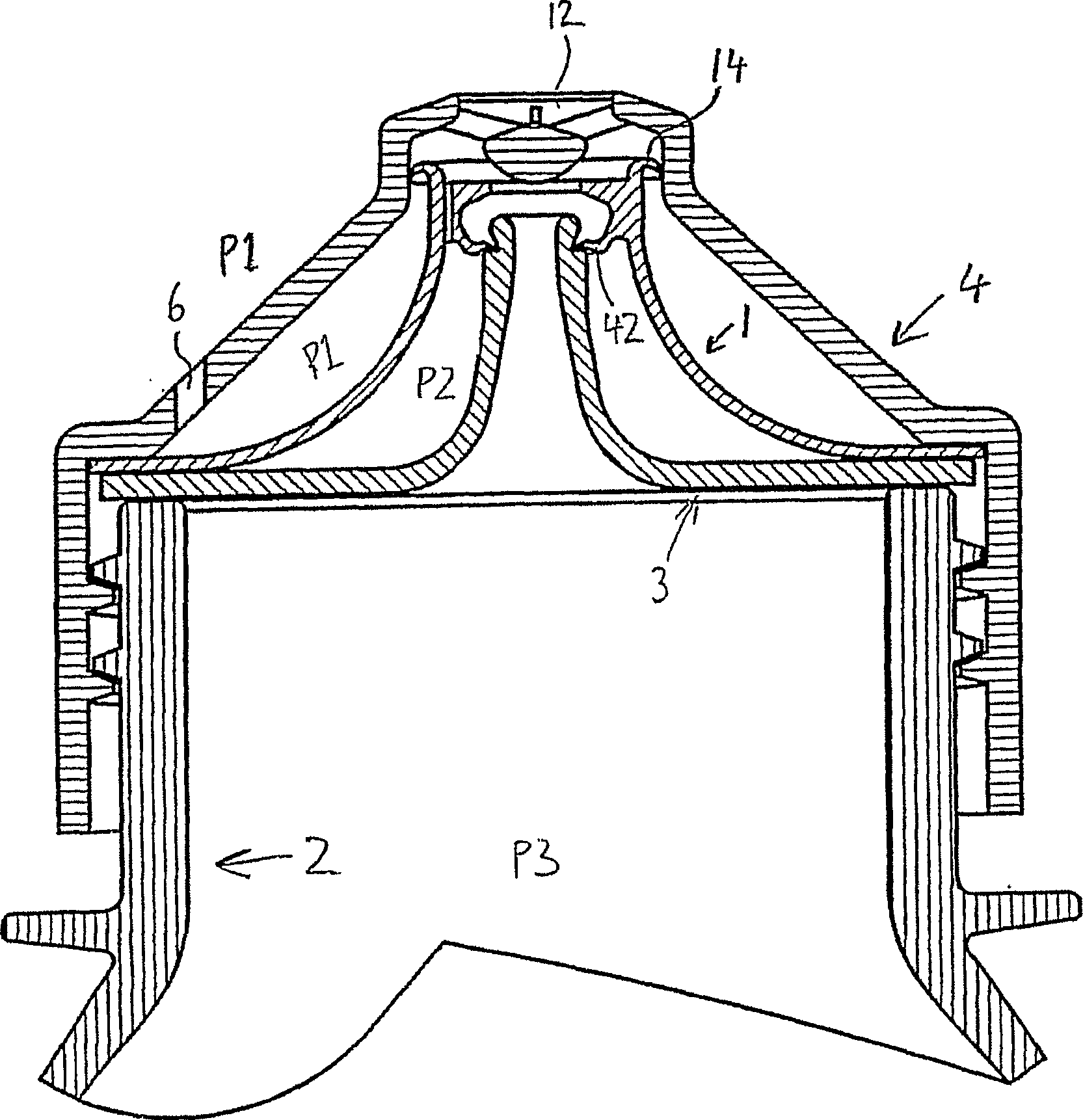

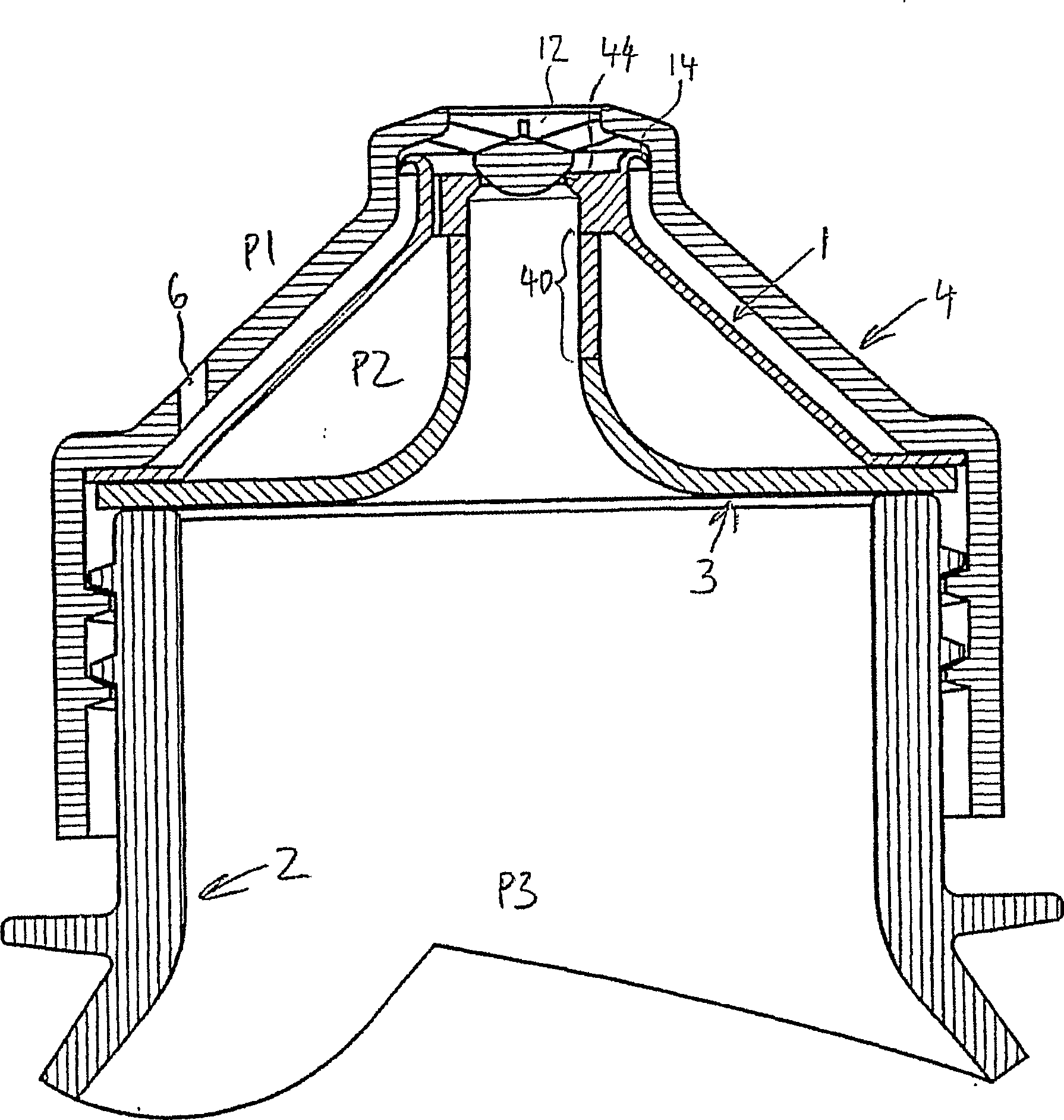

[0014] Figure 1a An embodiment of a valve device according to the invention is shown wherein said device is connected to a drinking container 2, in this example a bottle. In its rest position, the valve seat 44 will be in pressure-tight contact with the valve head 34 . The valve head 34 is secured within the cover and / or to the remainder by one or more stays 36 . When a low pressure P2 is applied to the inside of the membrane 1 through the suction channel 49, the radial shape of the membrane 1 changes and becomes shorter axially. As the membrane 1 is secured at its lower end 50, the resulting suction force moves the valve seat 44 away from the valve head 34, which is downwards in the drawing, and opens the valve for outflow. The seal 46 is also connected in a pressure-tight manner to the valve seat 44 and is directed towards the drinking container 2 against a projecting, tubular channel 48 on the pressure-tight partition 3 . A movable and / or flexible flange 14 in pressure-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com