A new push-type faucet

A faucet and push-type technology, applied in the field of new push-type faucets, can solve the problems of inflexible overall structure and laborious pressing, and achieve the effects of unique structure, improved opening speed, and reduced opening force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

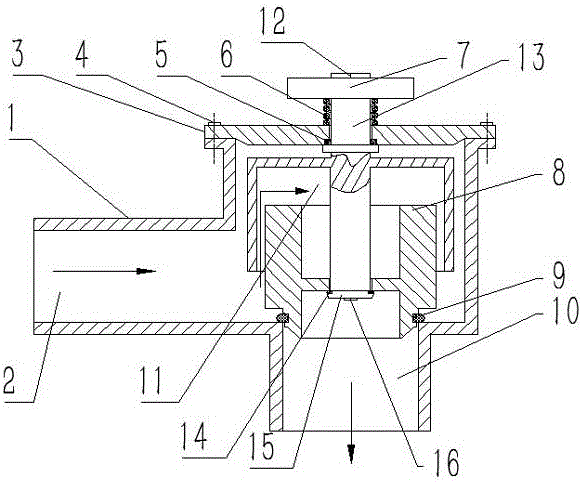

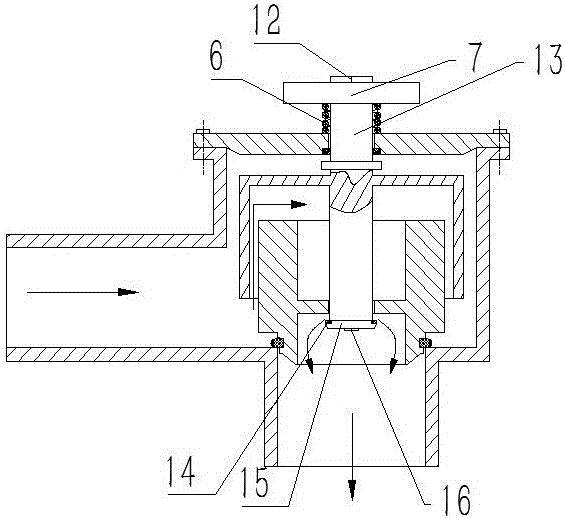

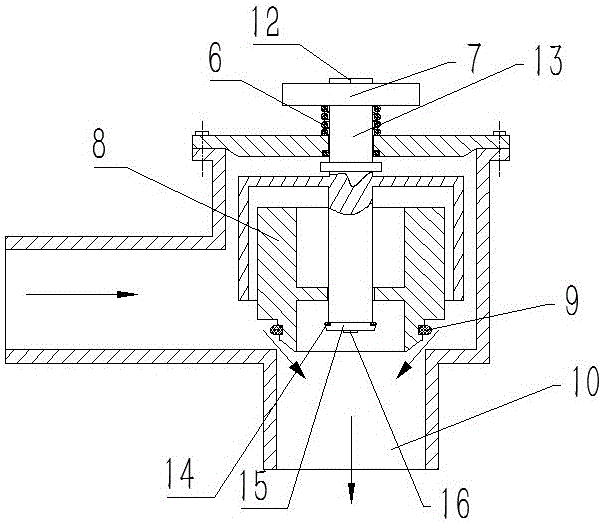

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, this embodiment includes a body 1, a water inlet 2 is provided on the left end of the body 1, and a water outlet 10 is provided on the lower end of the body 1; The pilot rod 13 is provided with a threaded hole A on the upper surface of the pilot rod 13, and the threaded hole A is provided with a pressing plate 7 through the pressing plate fixing screw 12, and a return spring 6 is arranged between the lower surface of the pressing plate 7 and the upper surface of the body cover 3, The pilot rod 13 and the body cover 3 are equipped with a sealing ring 5, a limit stop ring is provided on the pilot rod 13, a pilot cylinder is fixedly connected to the pilot rod 13, and a sealing cavity 11 is formed inside the pilot cylinder, and the internal gap of the sealing cavity 11 Cooperate with a large piston 8, the gap between the large piston 8 and the sealing chamber 11 is 2-4mm, a large pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com