Patents

Literature

35results about How to "Poor sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

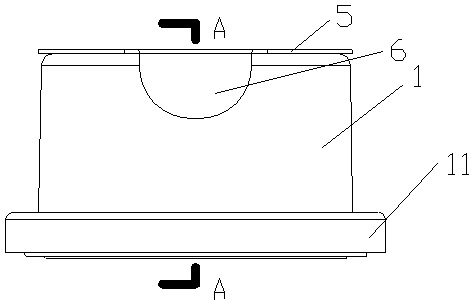

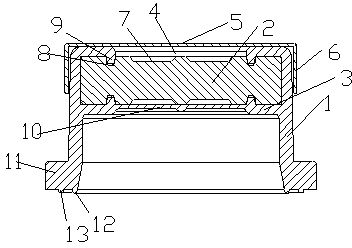

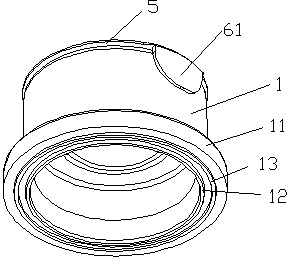

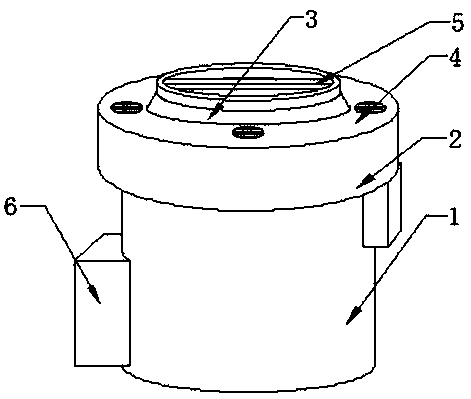

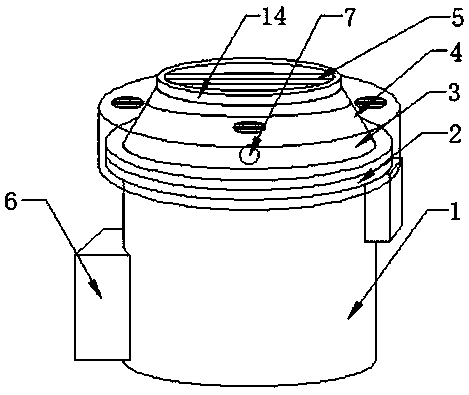

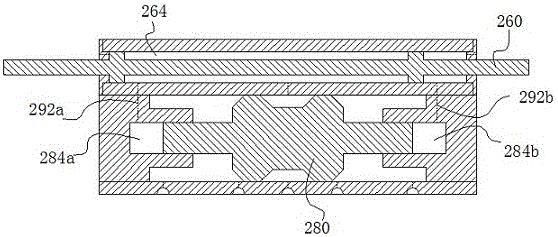

Novel polypropylene film-coated cover for infusion package

InactiveCN104306154APoor sealingImprove sealingInfusion devicesPharmaceutical containersEngineeringPolypropylene

The invention discloses a novel polypropylene film-coated cover for infusion package. The novel polypropylene film-coated cover for infusion package polypropylene film-coated cover for infusion package comprises a cover body and a rubber plug installed in the cover body, wherein the cover body is of an integral structure, a horizontal supporting interlayer is arranged at the middle position of the inner side of the cover body, the rubber plug is installed between the supporting interlayer and the top of the cover body, a hole is formed in the middle of the top of the cover body, an opening sealing film is arranged above the top of the cover body, and two symmetrical outwards-extending side wings are arranged on the opening sealing film. The cover body of the novel polypropylene film-coated cover for infusion package polypropylene film-coated cover for infusion package is designed to be integral, sealing performance is good, the upper portion of the cover body is sealed by the opening sealing film, and the cover is convenient to open.

Owner:江苏金扬子包装科技有限公司

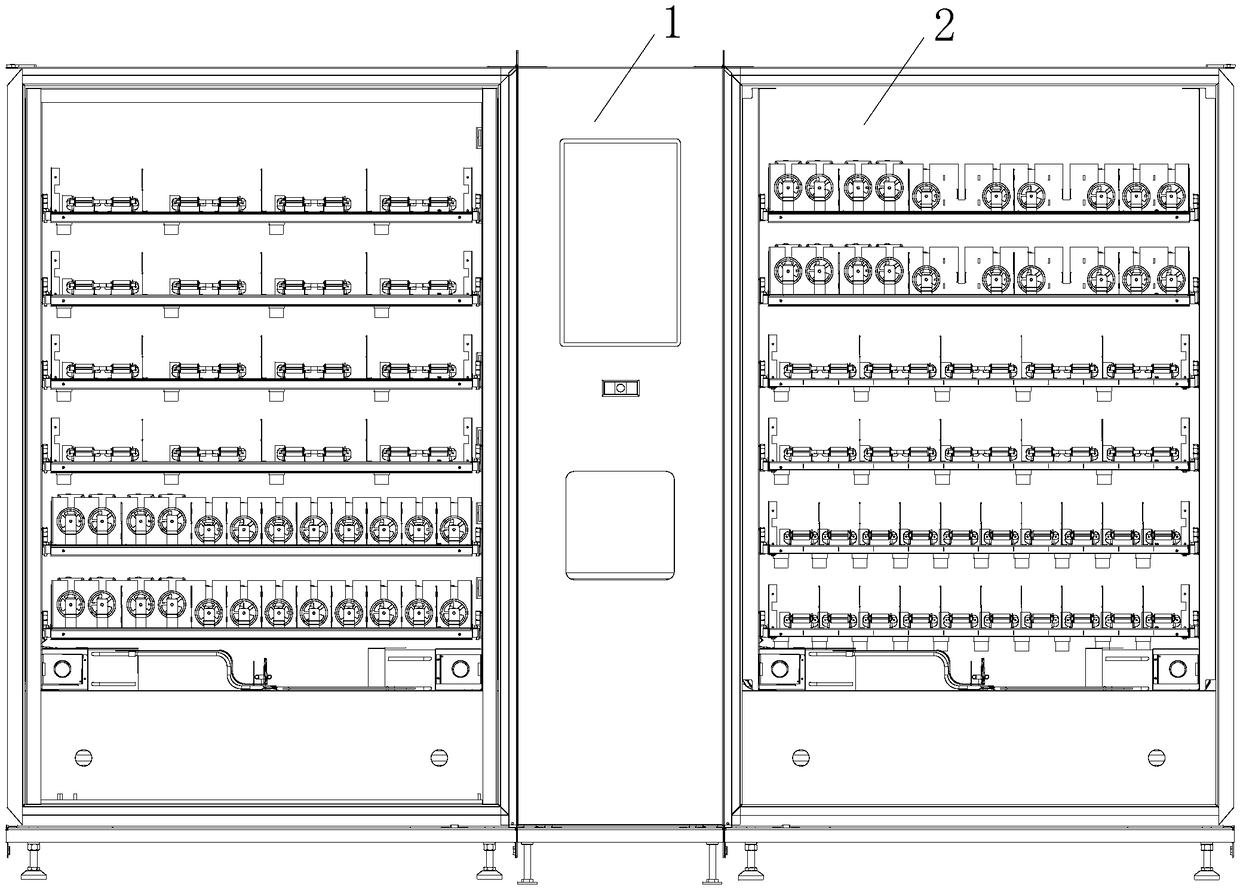

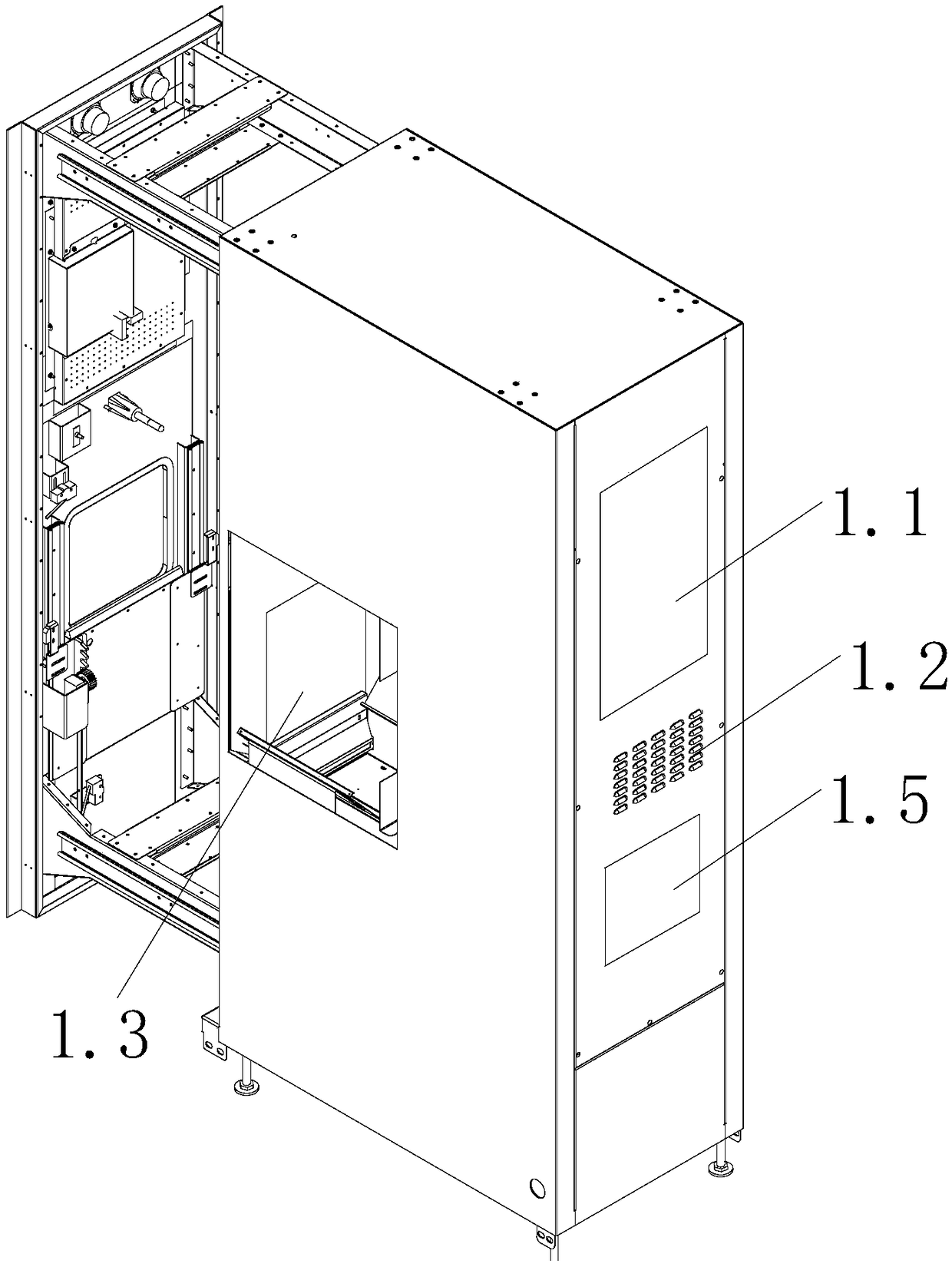

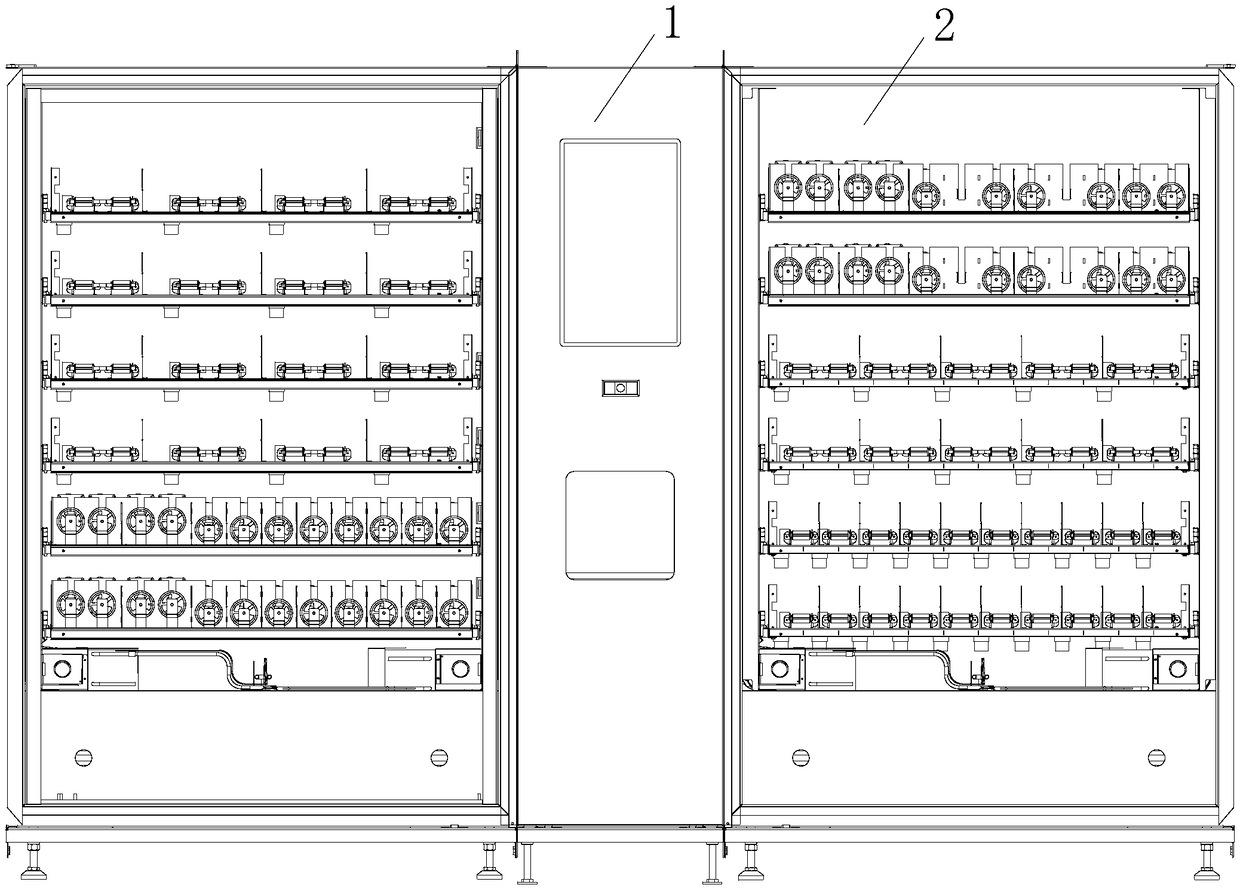

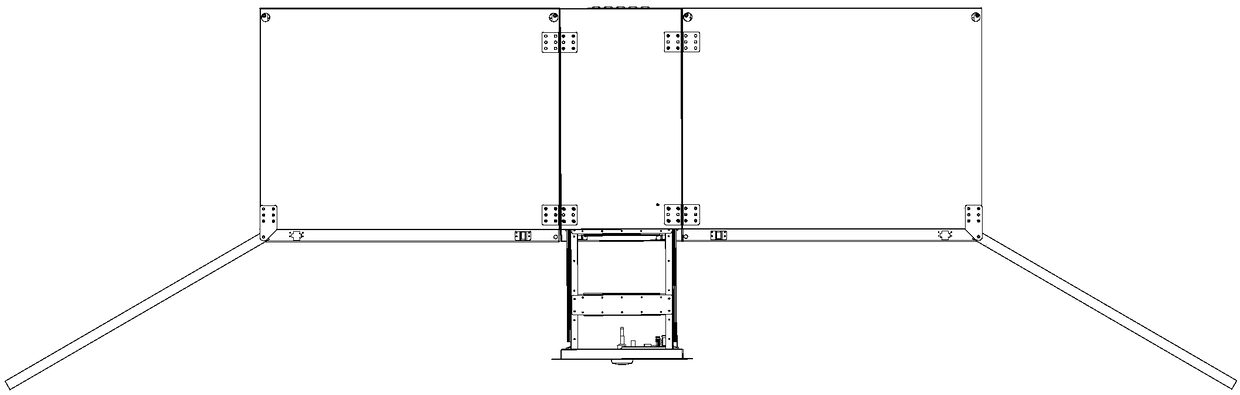

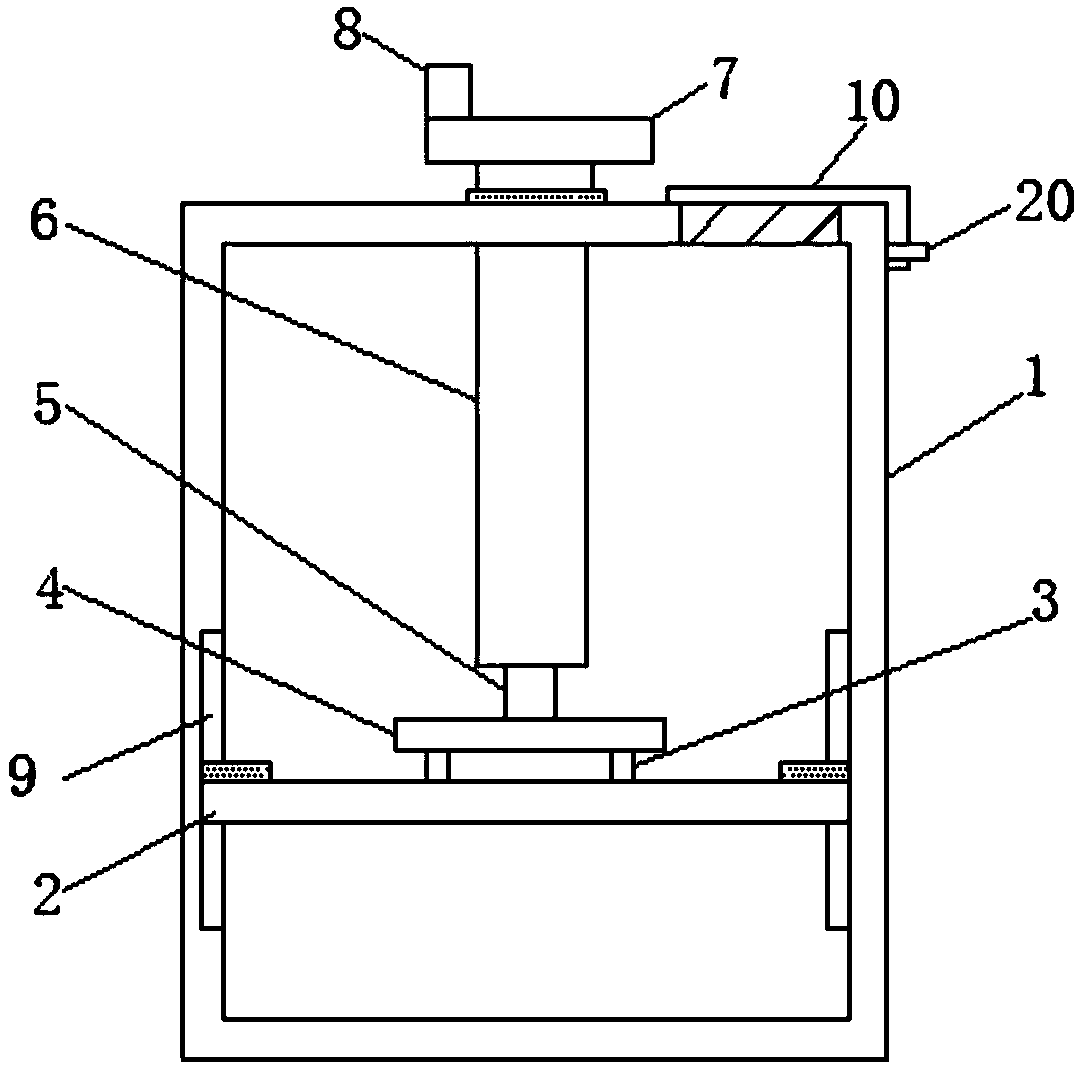

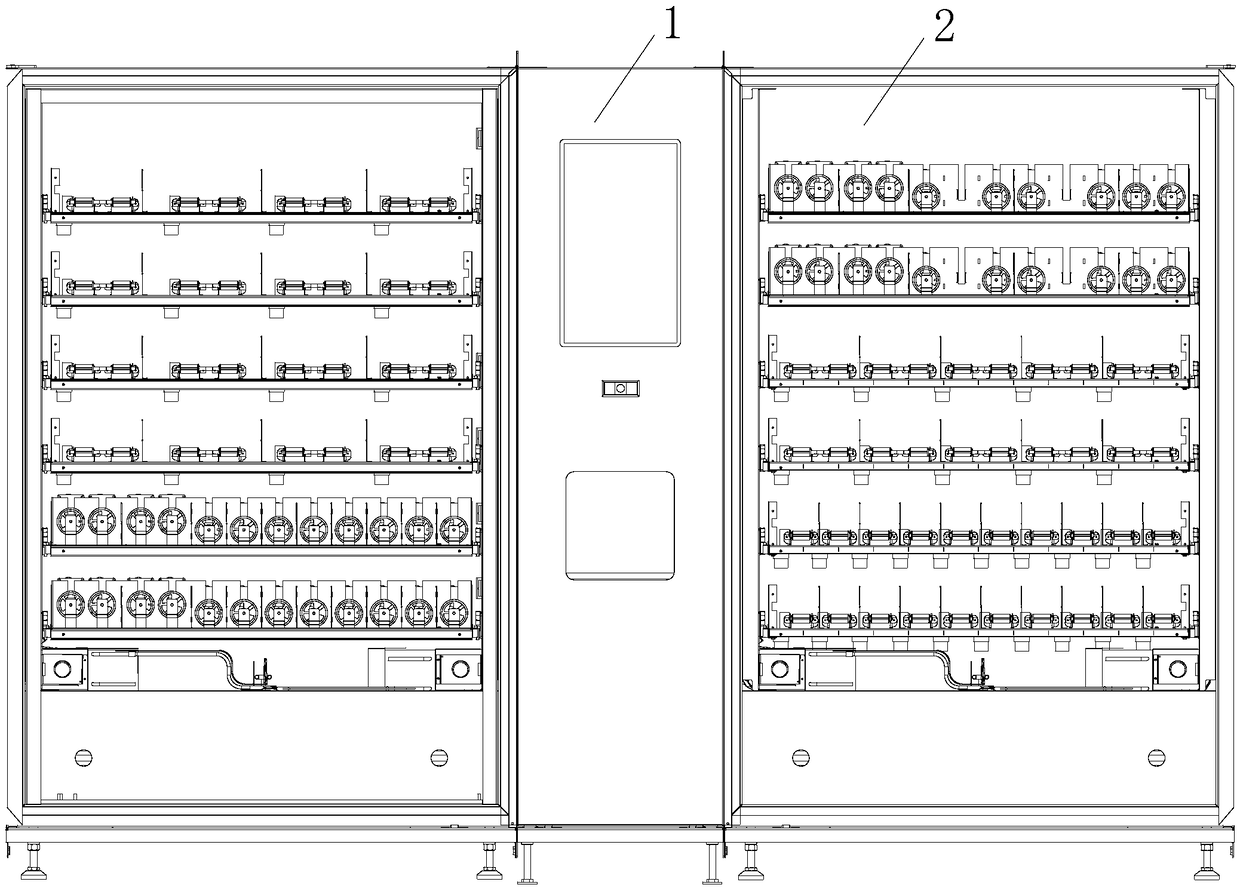

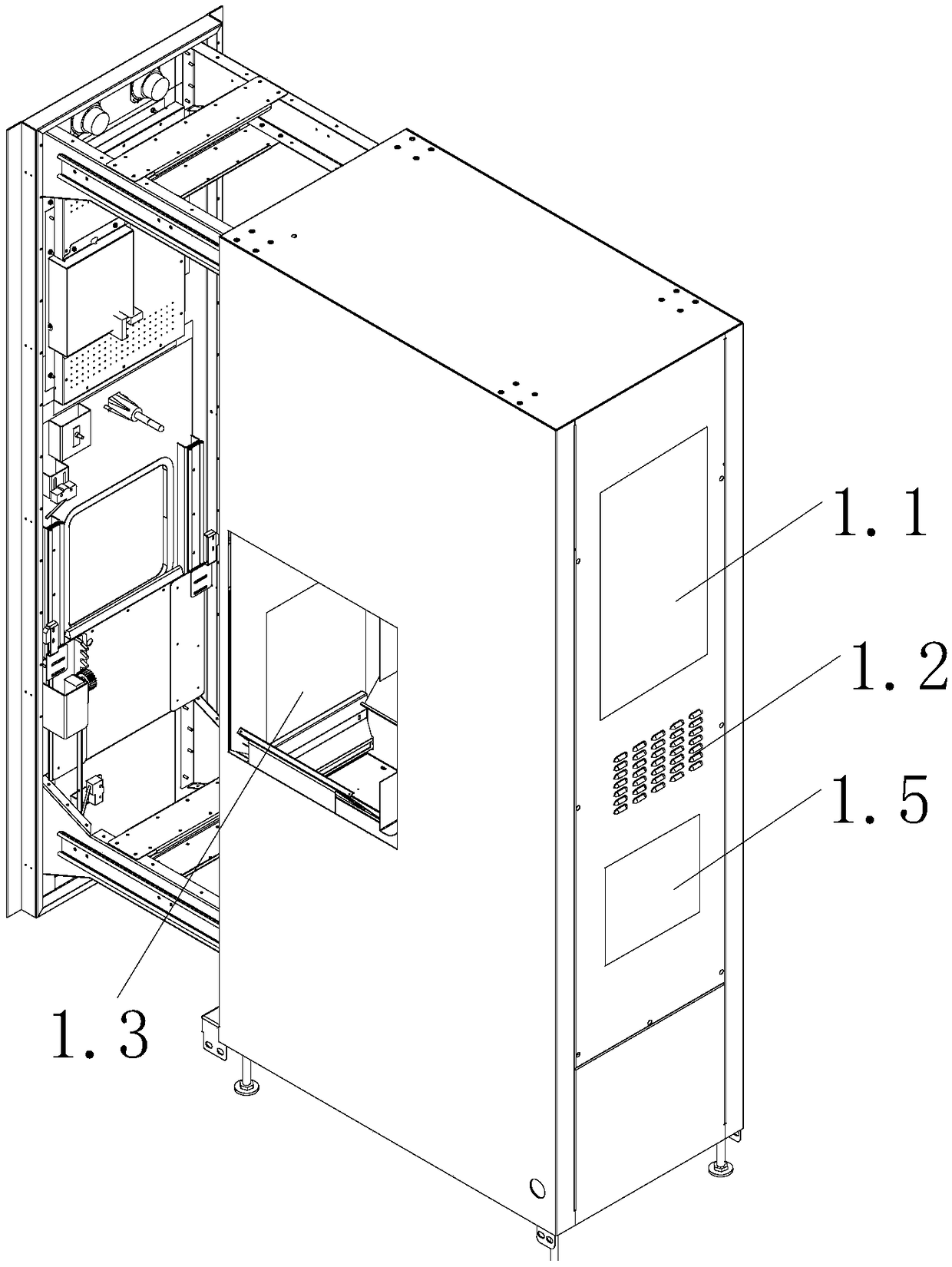

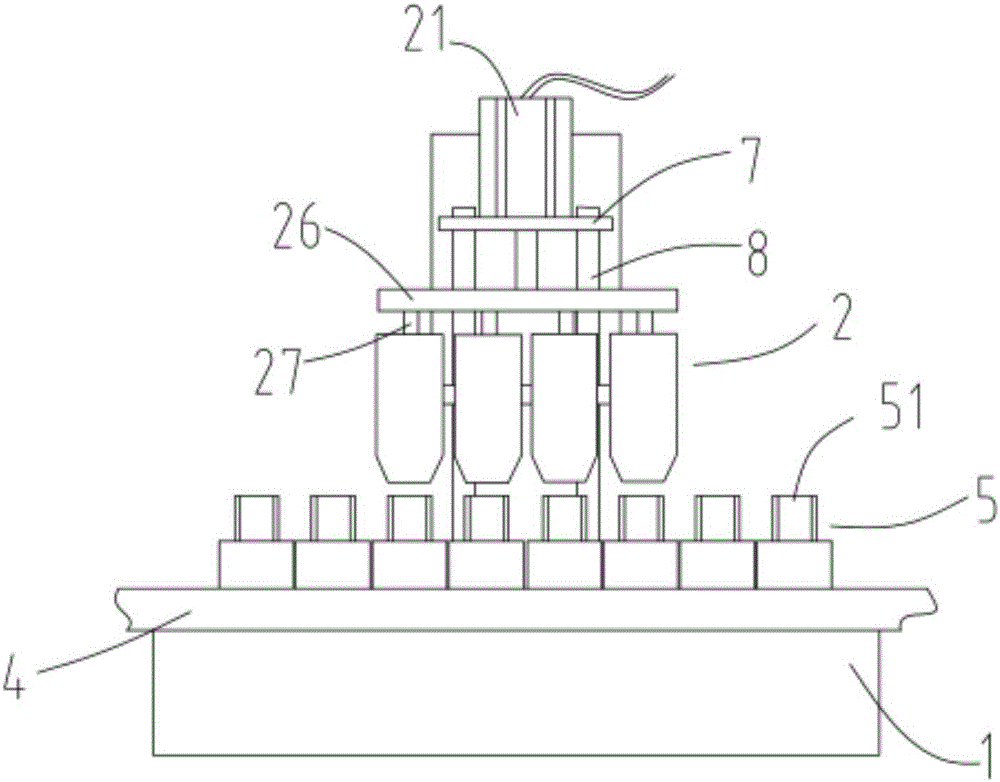

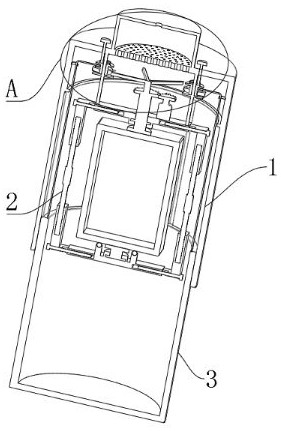

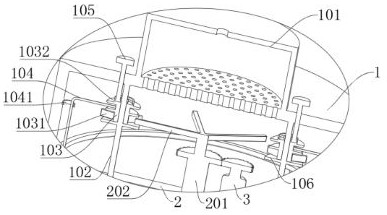

Two-driven-by-one comprehensive automatic vending machine

InactiveCN108806079ASmall footprintIncrease productivityCoin-freed apparatus detailsApparatus for dispensing discrete articlesElectric machineryEngineering

The invention relates to a two-driven-by-one comprehensive automatic vending machine. A vending machine body is integrally molded into a U-shaped shell box through a rolling manner, the production isconvenient, the production efficiency of the machine body is improved, besides, polyurethane is injected into a U-shaped shell, foaming is carried out to form hard foams, therefore, polyurethane is taken as a framework for support, the thickness of the box is reduced, the total weight of the whole machine body is reduced, the airtightness of the polyurethane hard foams of the U-shaped shell is notstrong, the heat-preservation performance is strong, the quality of the automatic vending machine can be guaranteed, and one central control box can simultaneously control the work of two vending machines, so that the occupying space of the vending machines is saved, more commodities can be sold; besides, a motor is transversely fixed at one side of a caterpillar band aisle, and the vertical space in the automatic vending machine can be saved through a horizontal fixing manner, so that more caterpillar band aisles can be arranged in the automatic vending machine.

Owner:JIANGYIN WANYUAN ELECTRONICS TECH CO LTD

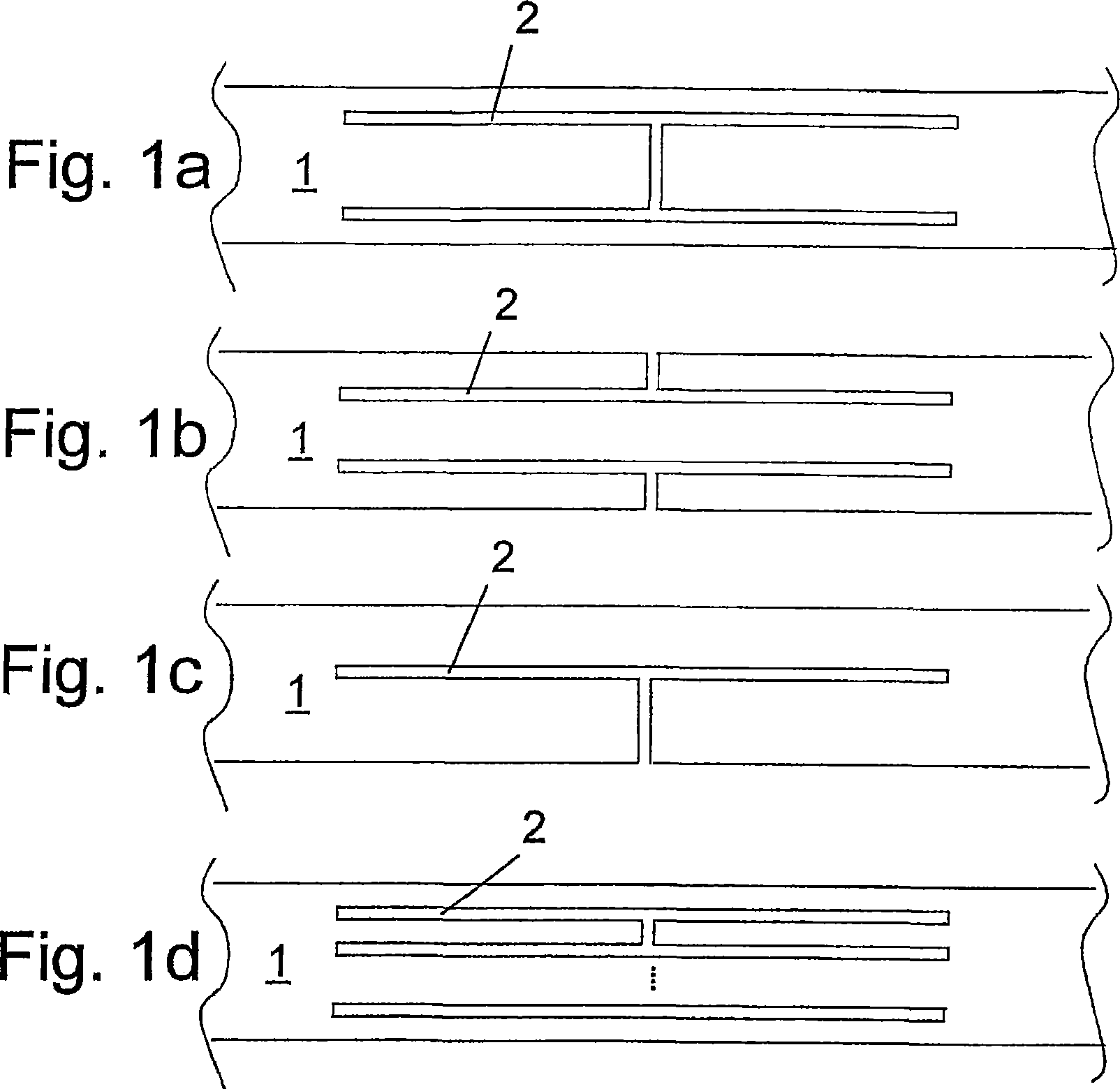

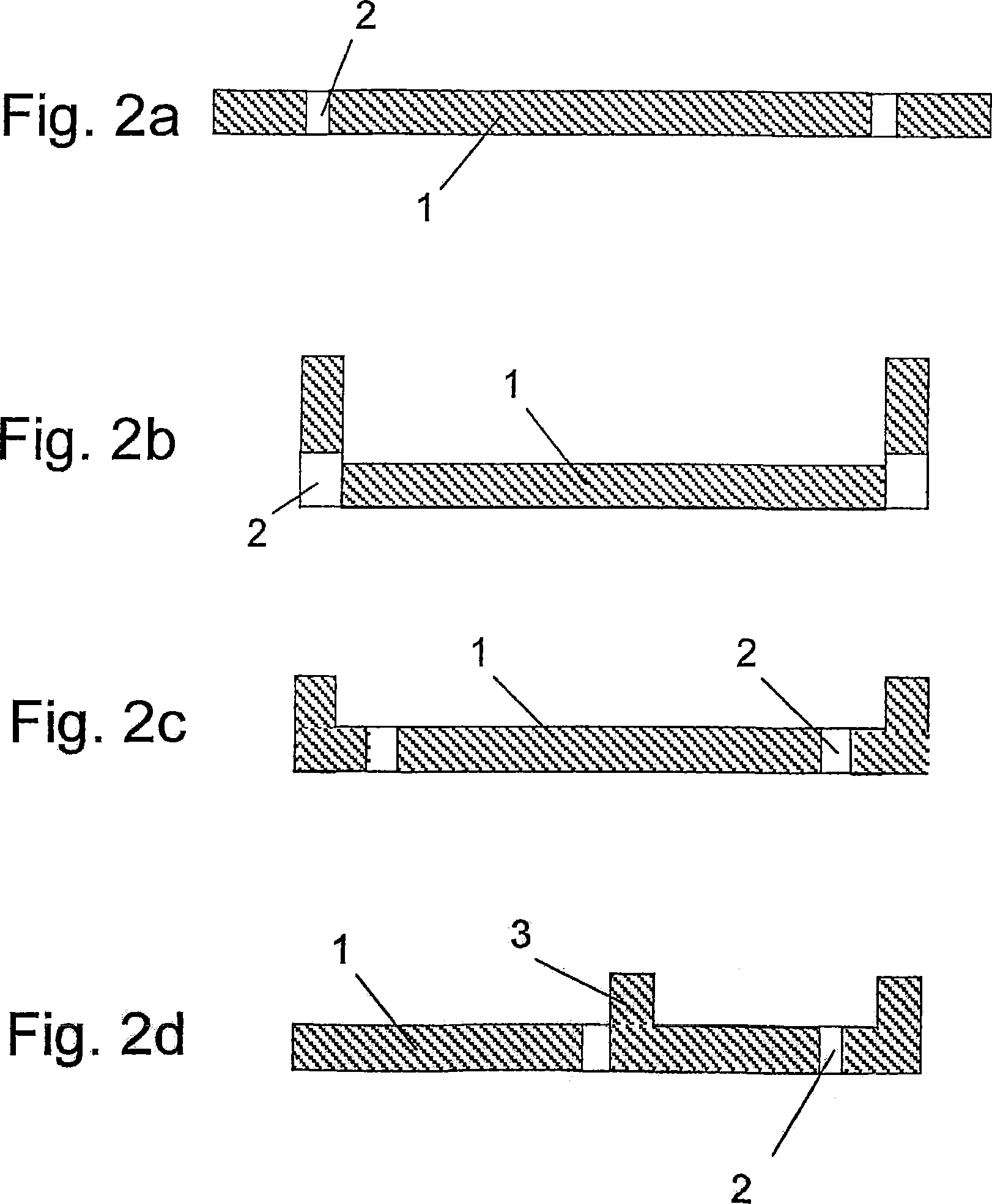

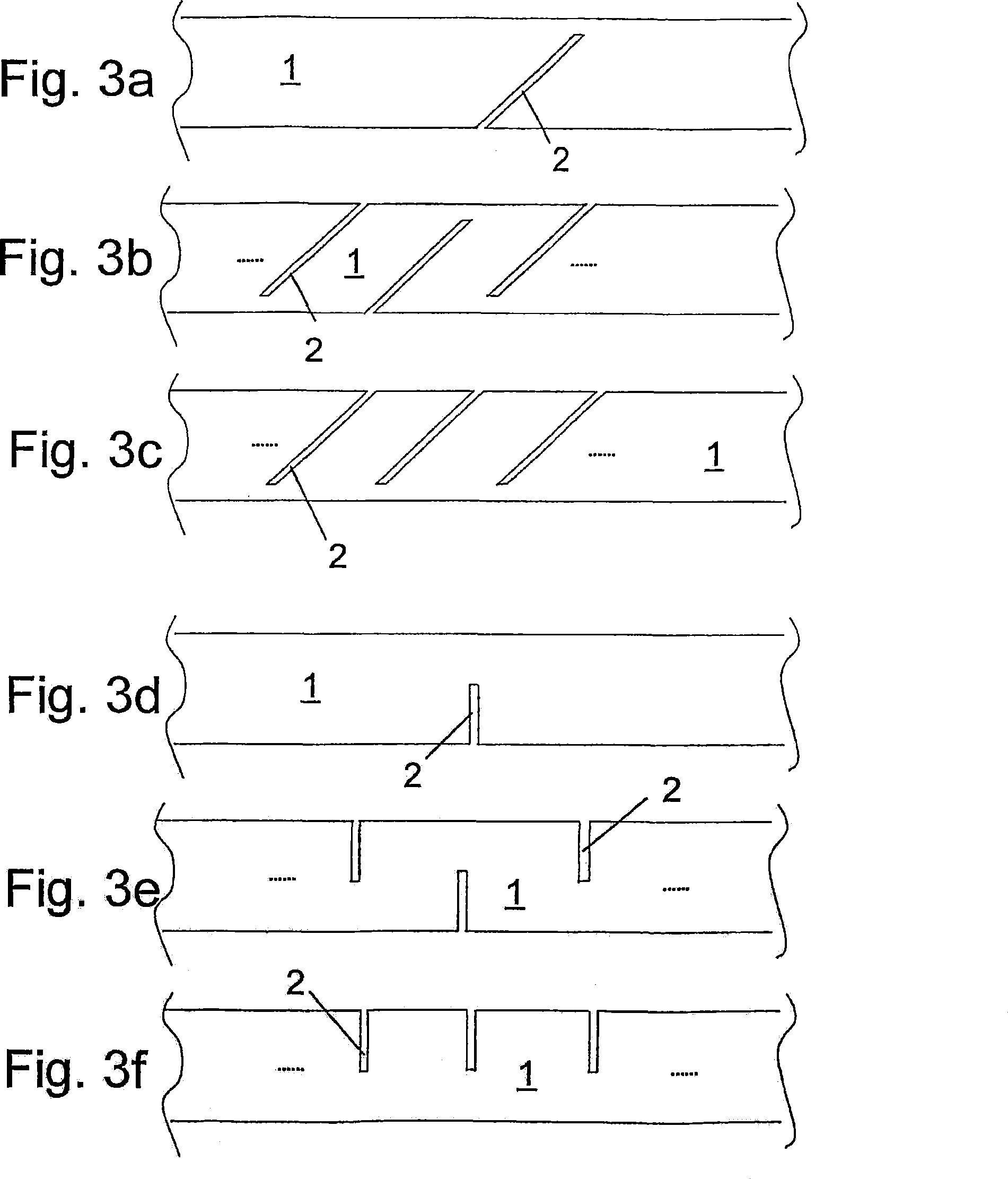

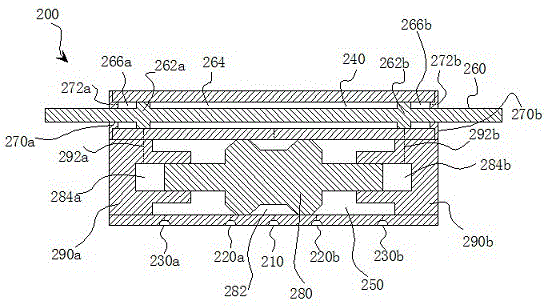

Heat exchanger for a motor vehicle

InactiveCN101166945APoor sealingFree from overloadSafety devices for heat exchange apparatusIndirect heat exchangersThermal expansionMicro heat exchanger

The invention relates to a heat exchanger, in particular for a motor vehicle, having tubes and if appropriate corrugated fins through which a first, hot medium can flow and which are arranged between collecting boxes, and having at least one side part ( 1 ) which is arranged laterally between two collecting boxes, a second medium which flows around the tubes and if appropriate corrugated fins being colder than the first, hot medium during operation, the side part ( 1 ) absorbing at least some of the tensile stresses which act at least on the outermost tube as a result of different thermal expansions of the tubes and if appropriate corrugated fins, and the side part ( 1 ) having slots ( 2 ) and / or openings ( 4 ) which change the spring constant of the side part ( 1 ) in relation to a side part without slots and / or openings such that, in the event of a different longitudinal expansion of the central tubes relative to the outermost tube which is arranged adjacent to the side part ( 1 ), the tensile stress which acts on the outermost tube is reduced.

Owner:BEHR GMBH & CO KG

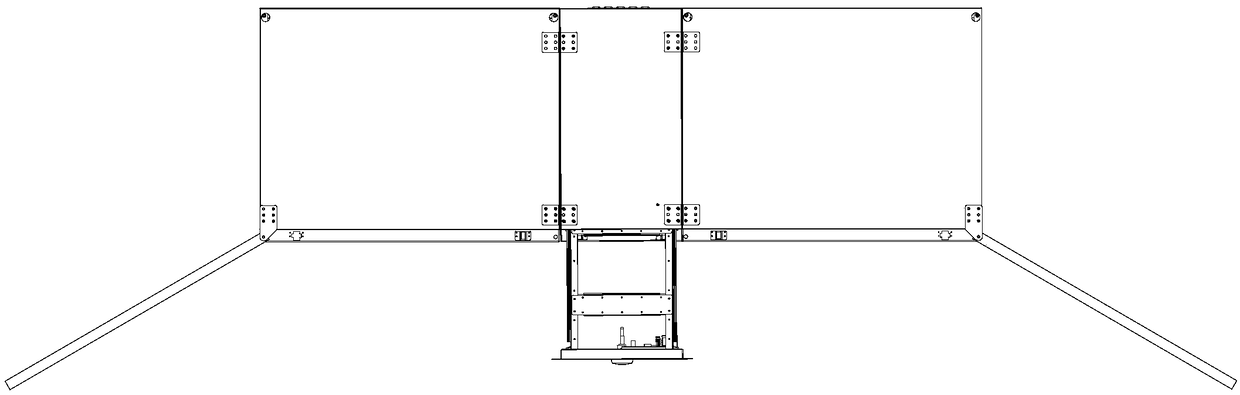

Comprehensive vending machine and working mode thereof

InactiveCN109191689AIncrease productivityReduce thicknessCoin-freed apparatus detailsApparatus for dispensing discrete articlesMotor driveElectric machine

The invention relates to a comprehensive vending machine. One central control box simultaneously controls two vending machines, so that the space occupied by the vending machines can be reduced, and more goods can be sold; one motor drives two conveyer racks to move, so that the left and right spaces of racks can be saved, the left and right spaces of the two conveyer racks can be adjusted, and goods of different sizes can be put into; the motor is transversely fixed on one side of the conveyer rack, so that up and down spaces in the vending machine can be saved, and more conveyer racks can beplaced in the vending machine; a lifting platform is formed by splicing a horizontal plate and vertical plates on the inner and outer sides, a plurality of through holes are formed in the horizontalplate to reduce the total weight of the lifting platform; a plurality of connecting rods are arranged from left to right between the vertical plates to play a role of reinforcing strength; the two vertical plates are respectively provided with a mounting opening near an outlet of the vending machine; a sensor can be conveniently arranged at the mounting opening, which can sense that goods are transferred to a tray of the central control box component through the outlet of the vending machine.

Owner:JIANGYIN WANYUAN ELECTRONICS TECH CO LTD

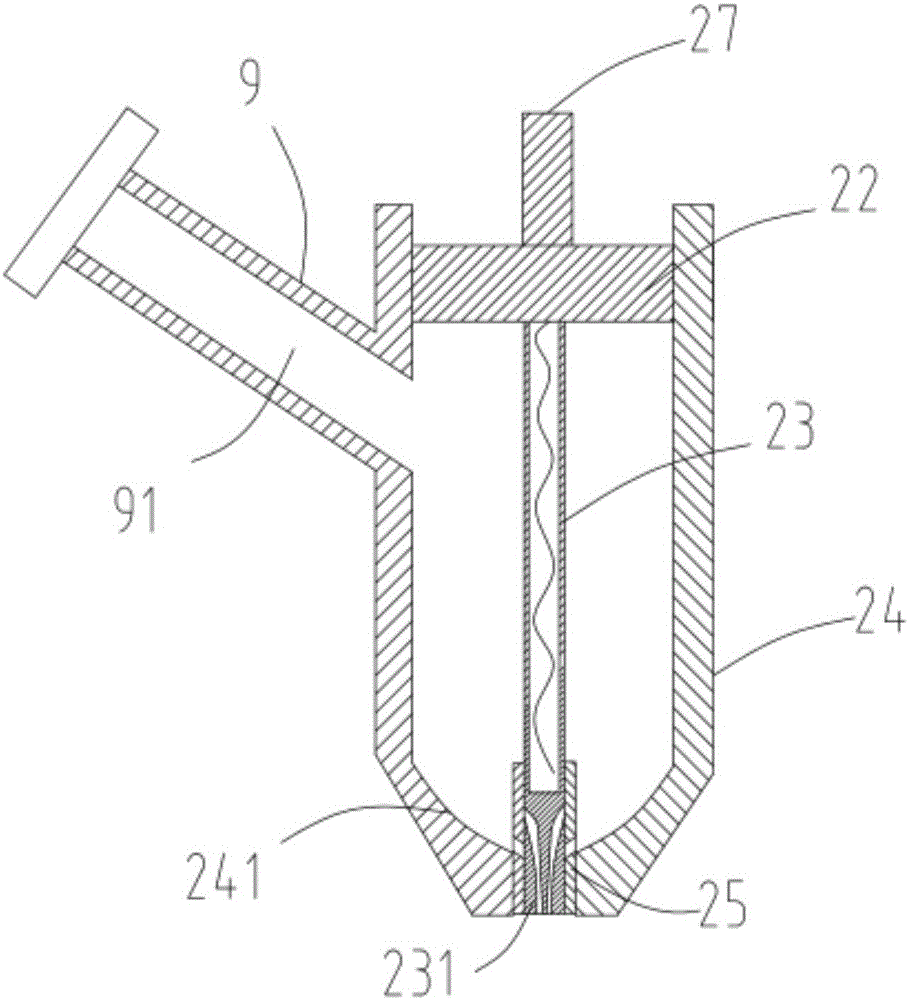

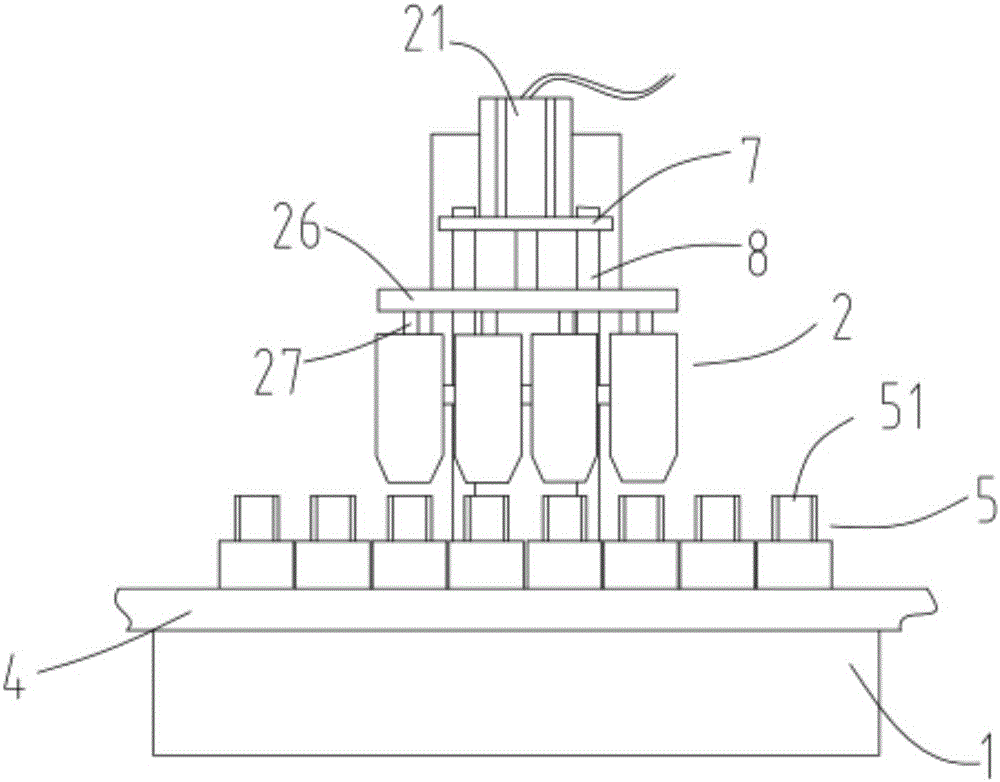

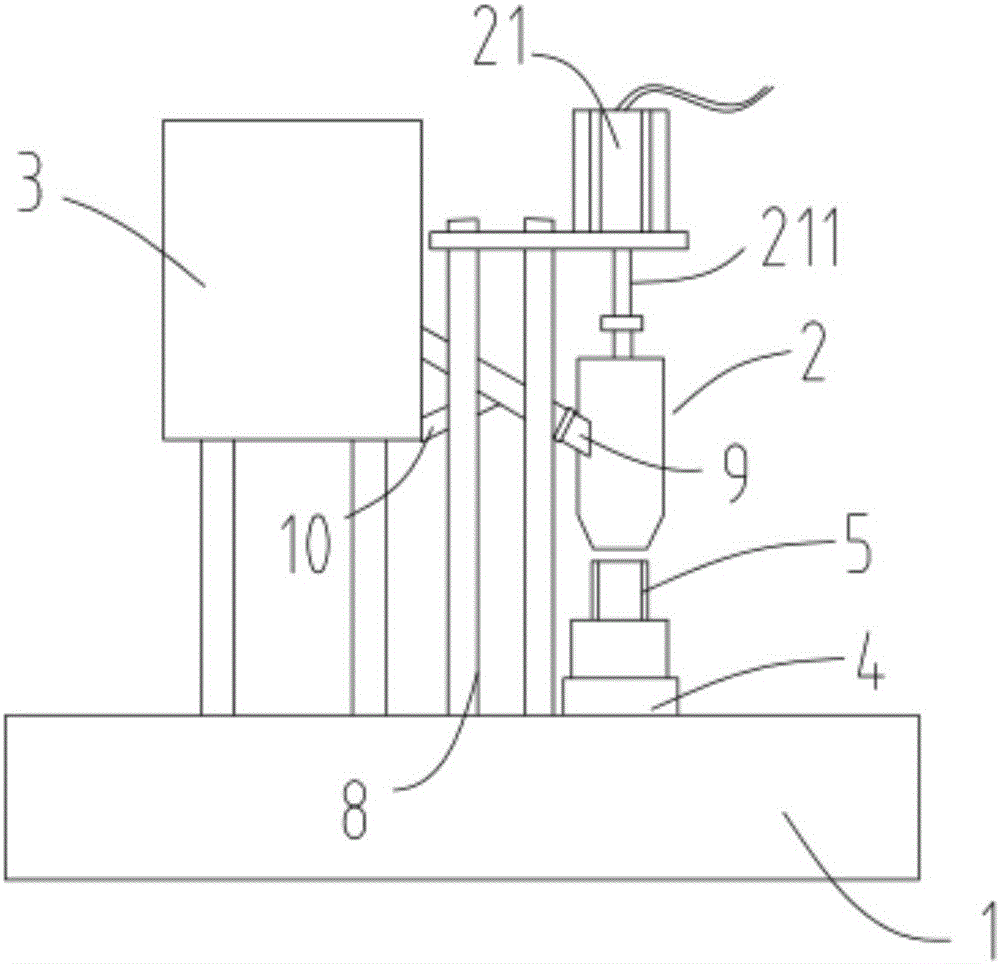

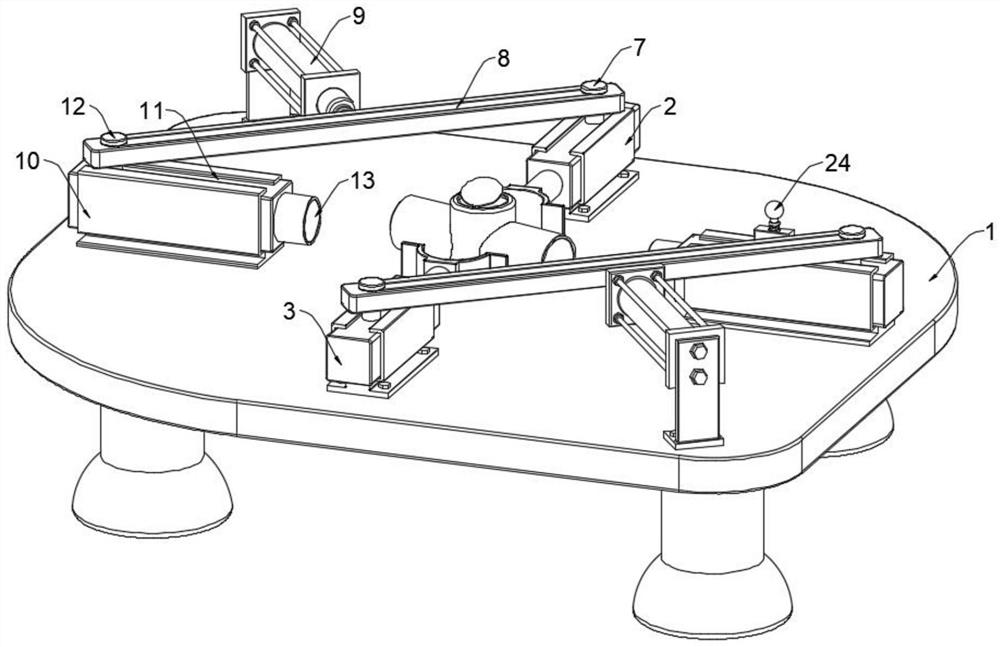

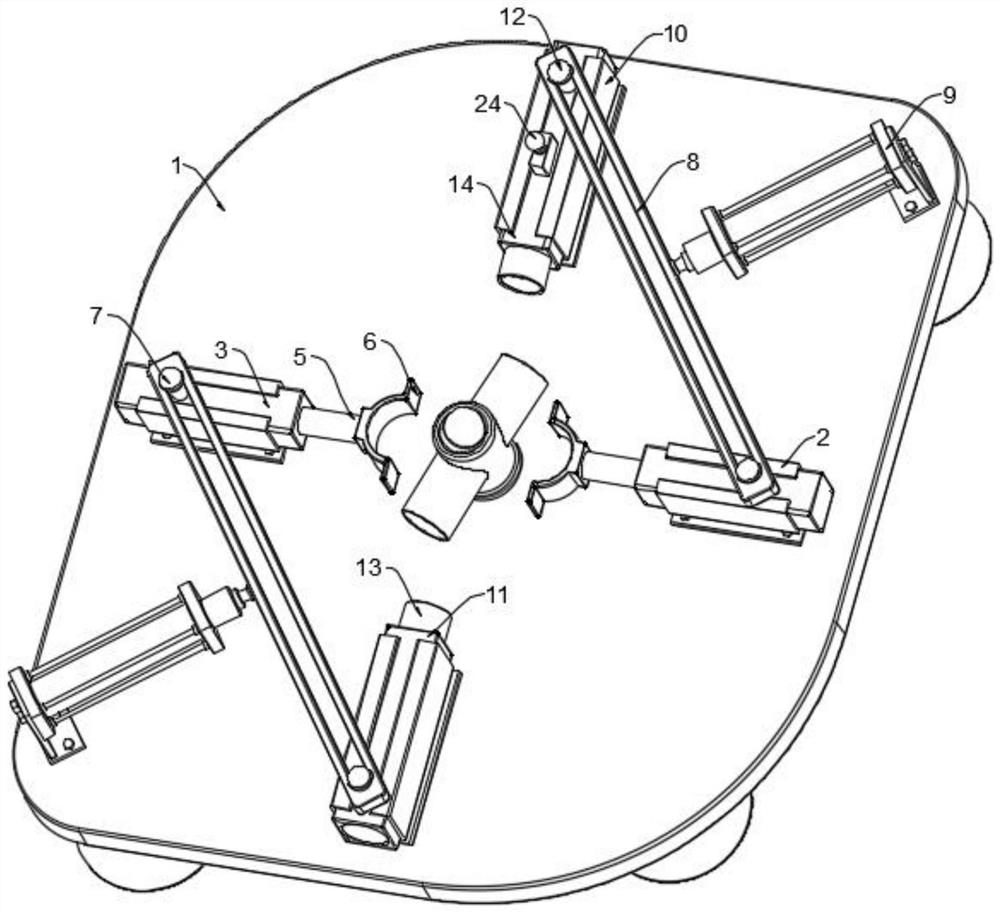

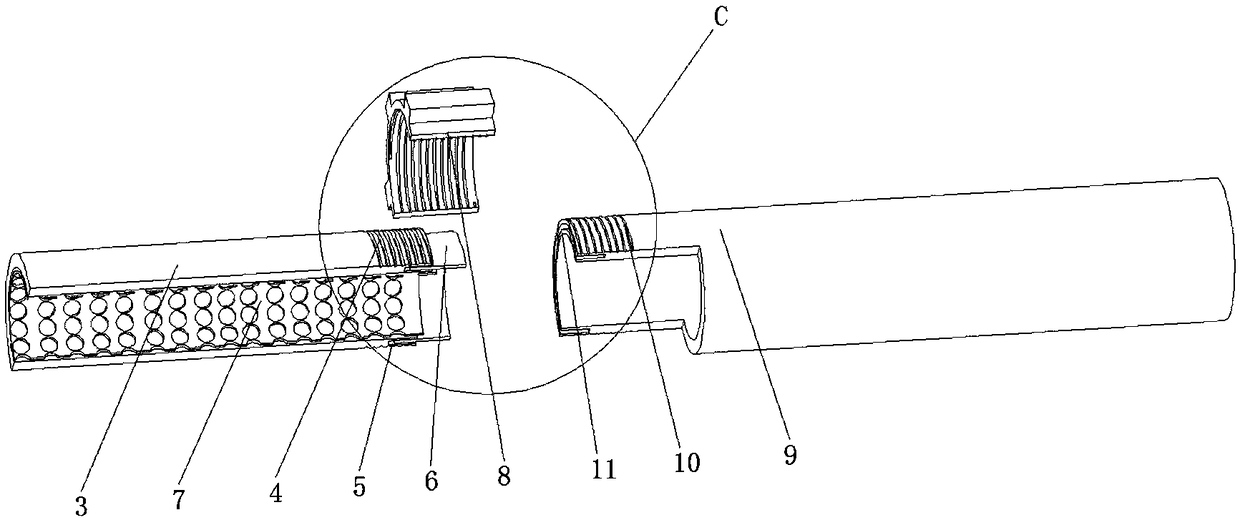

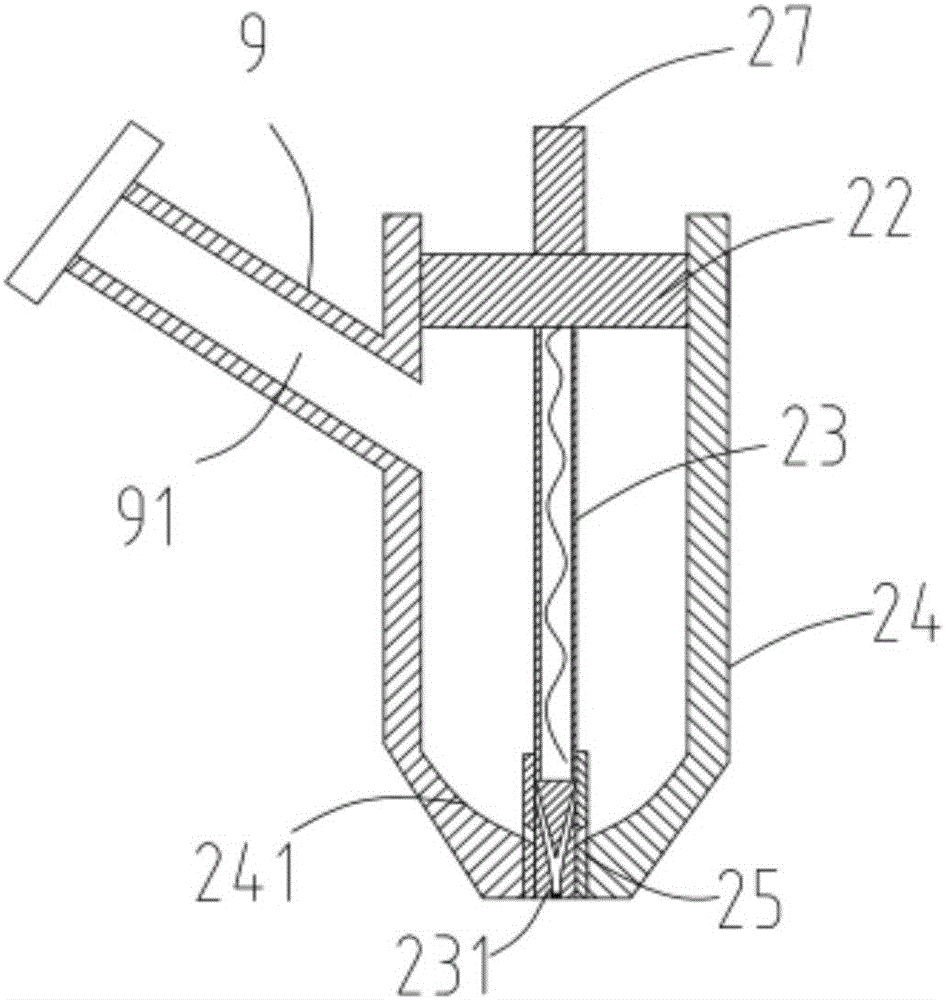

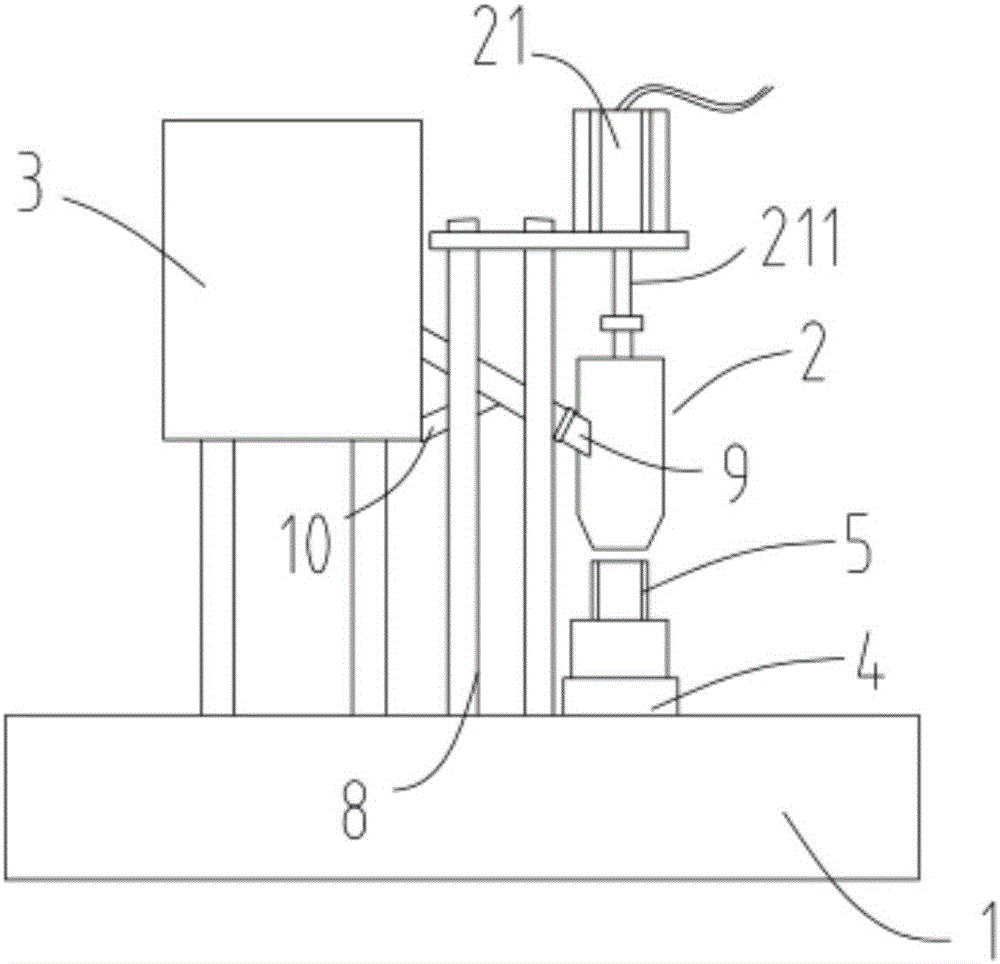

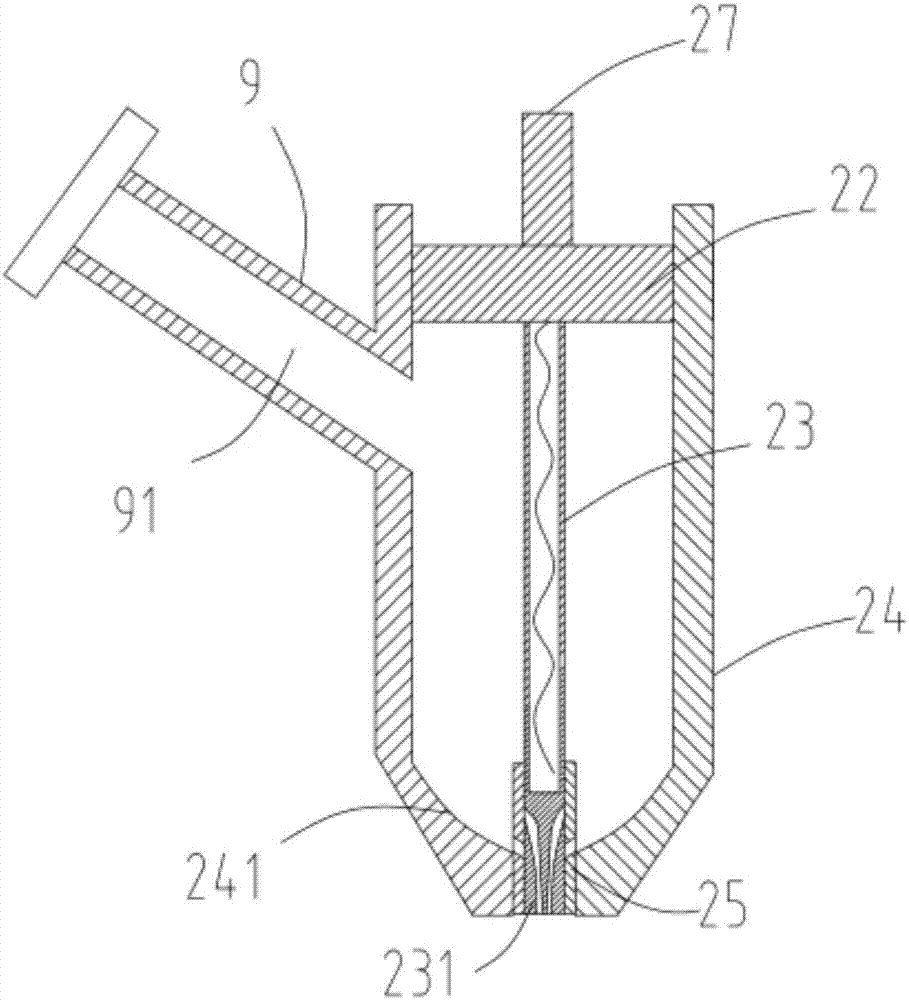

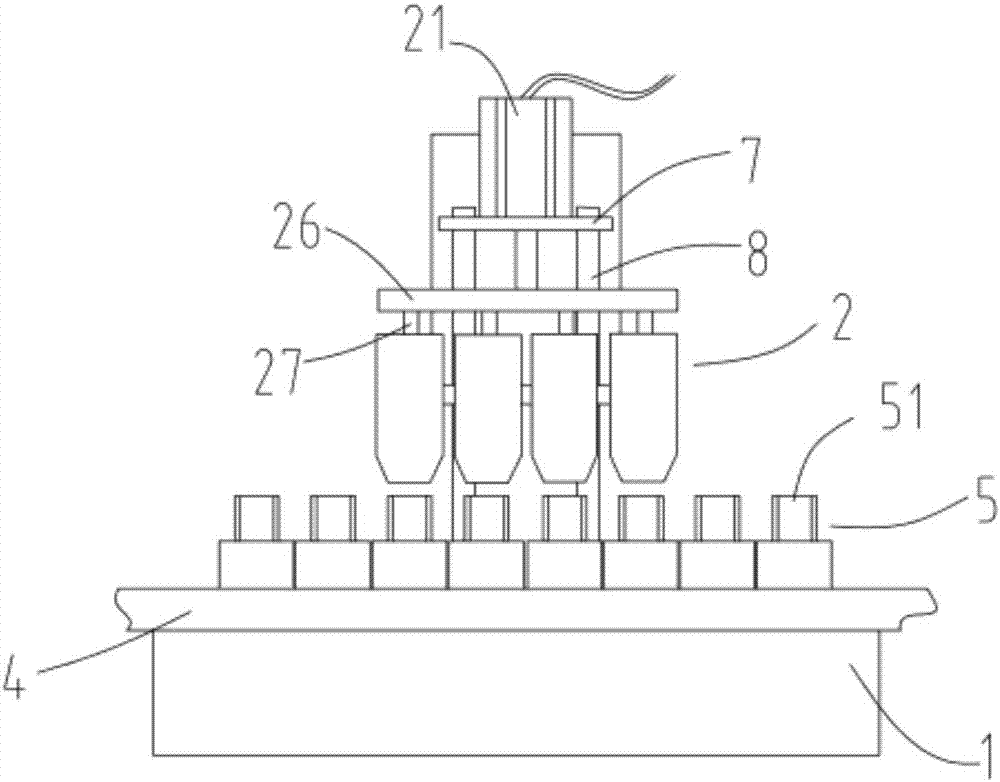

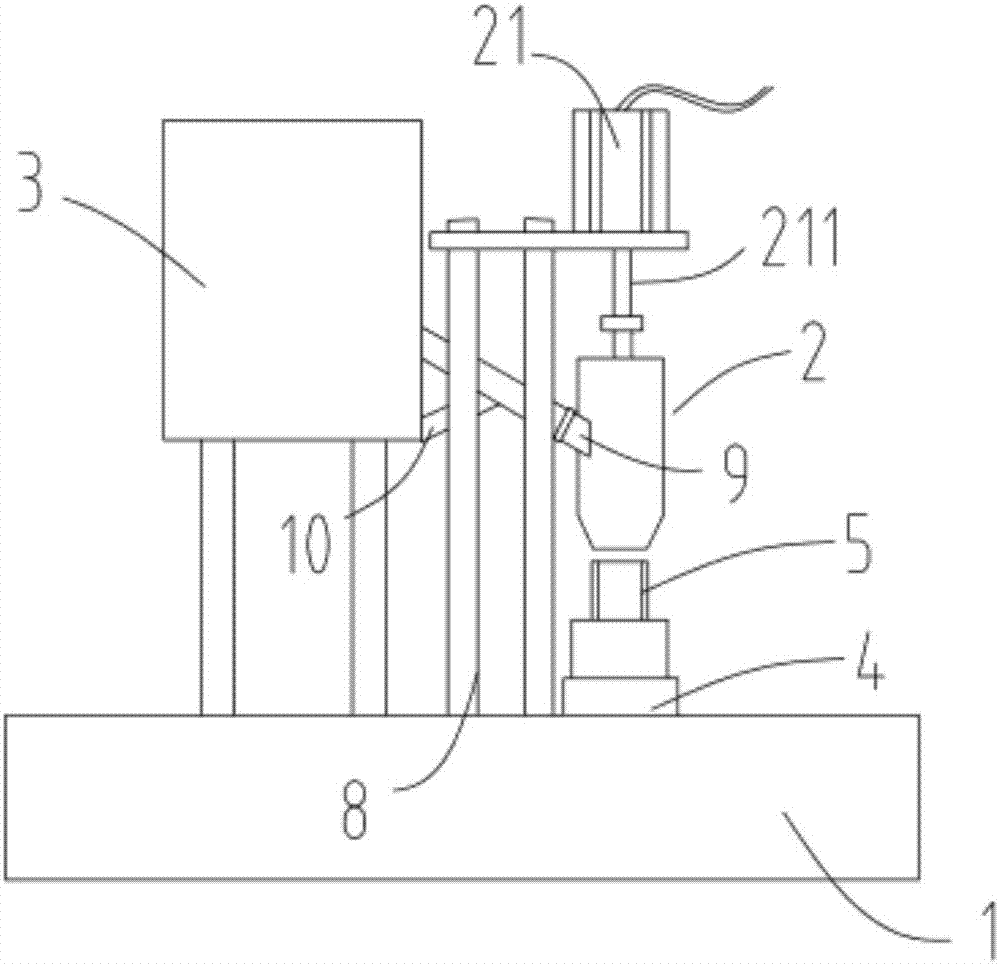

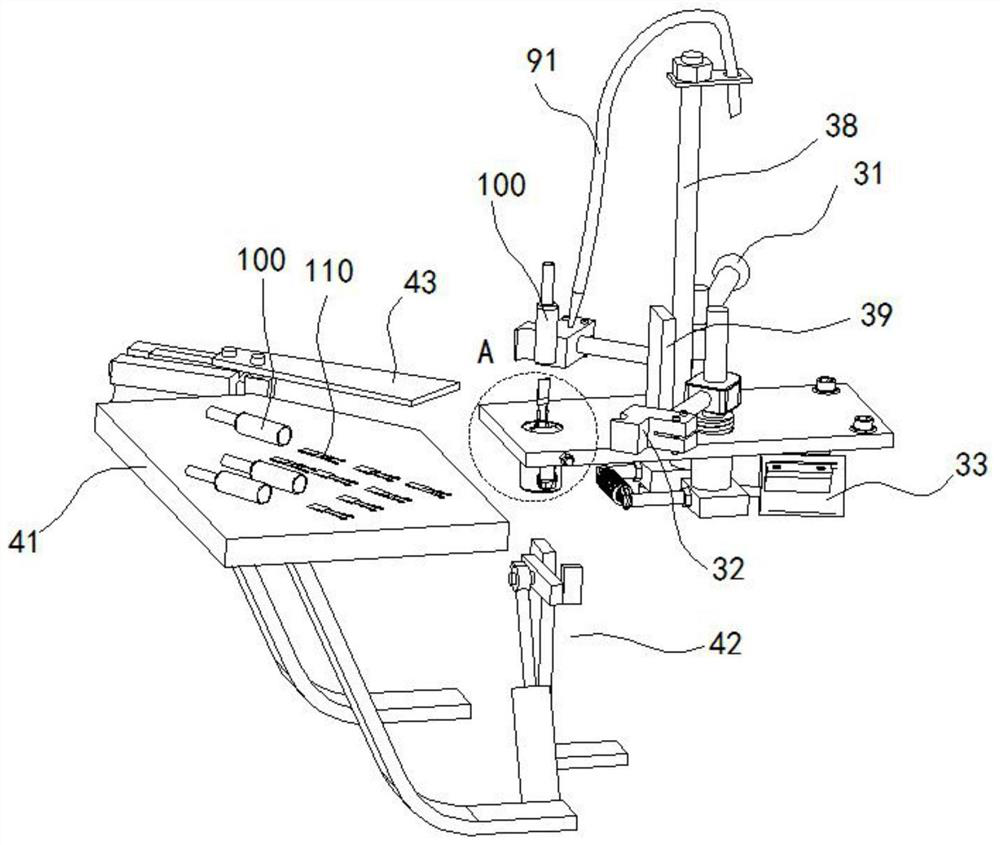

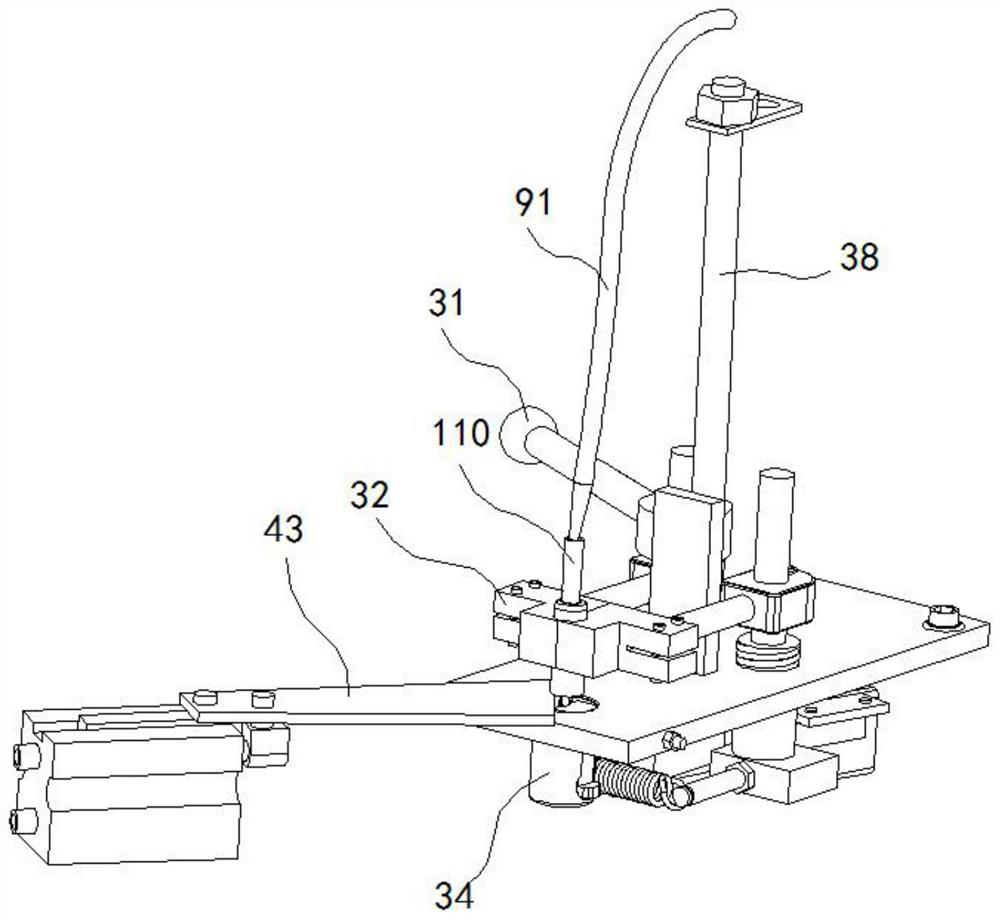

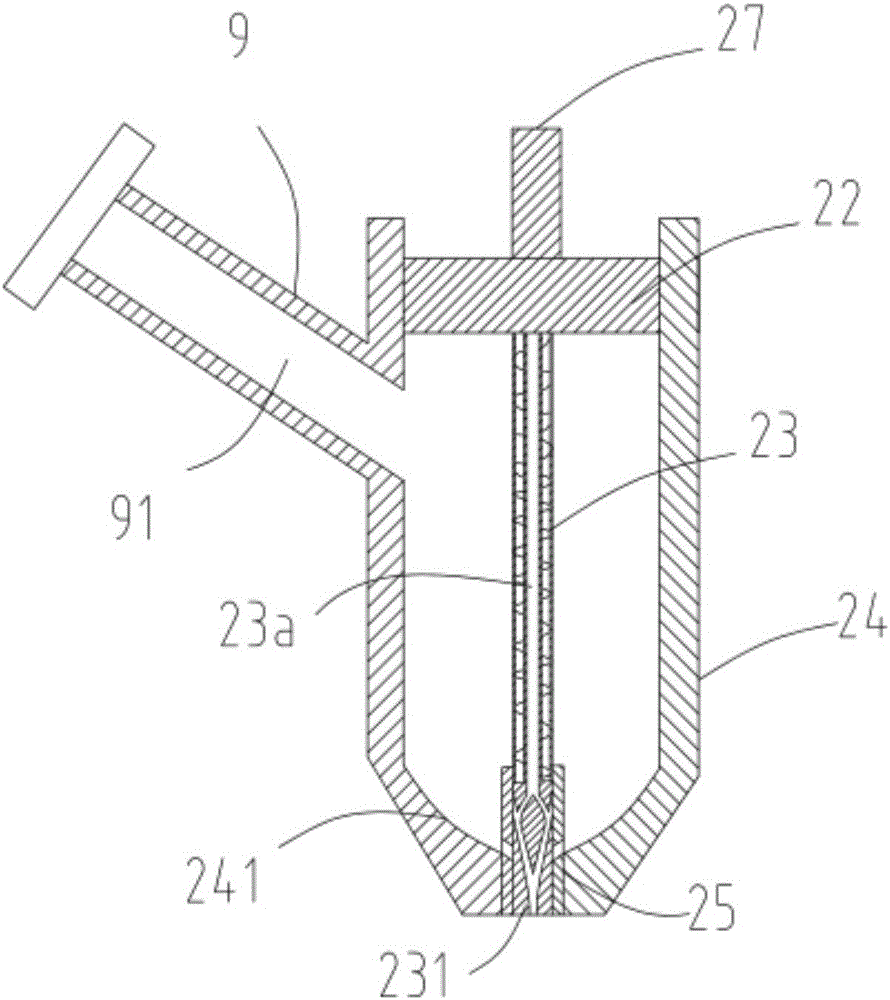

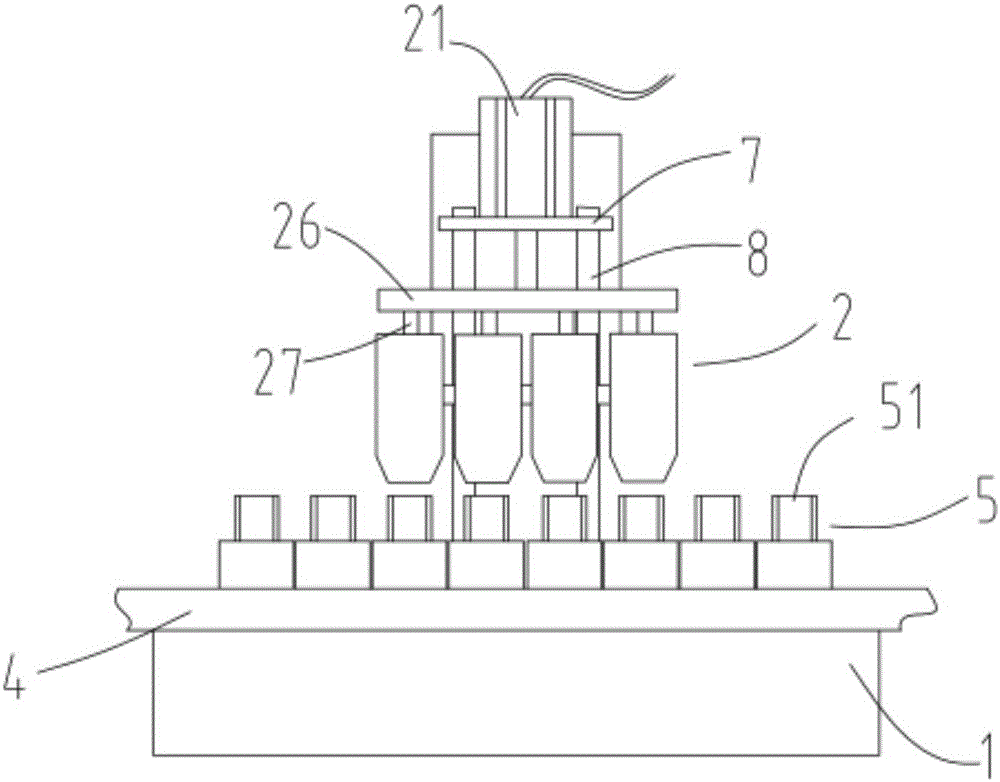

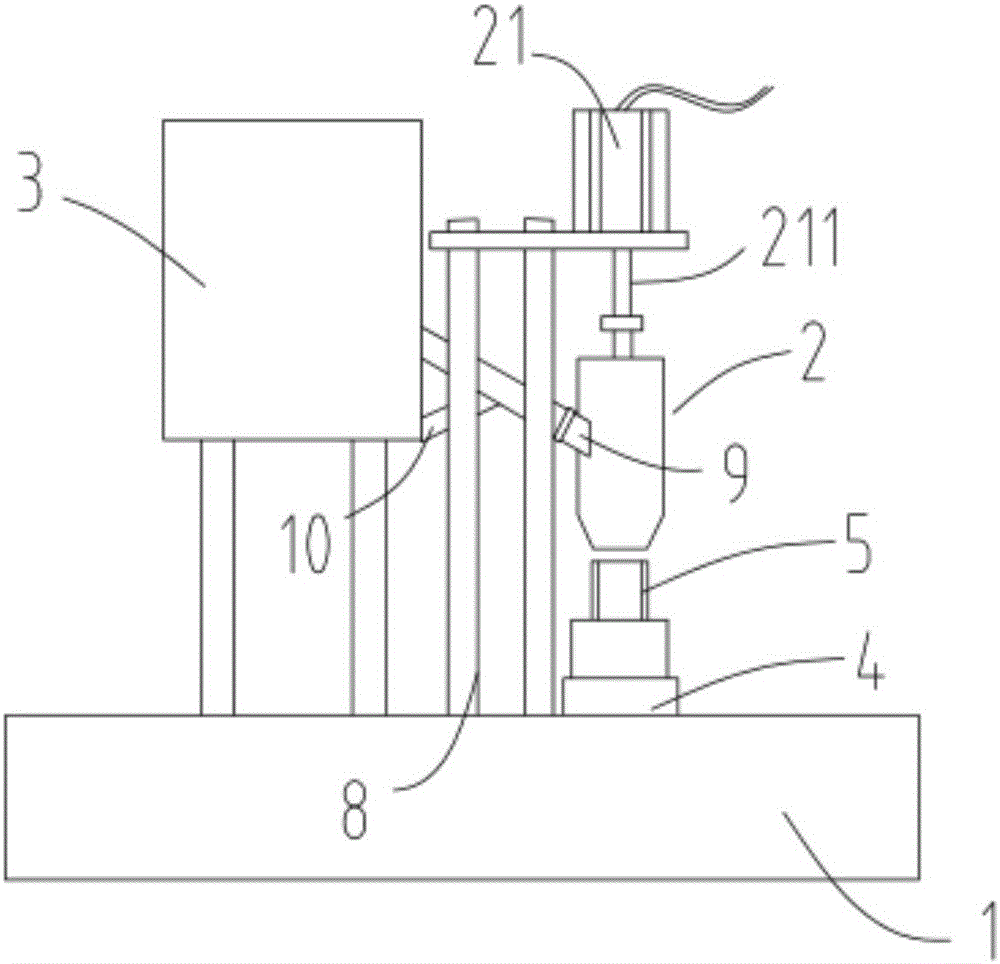

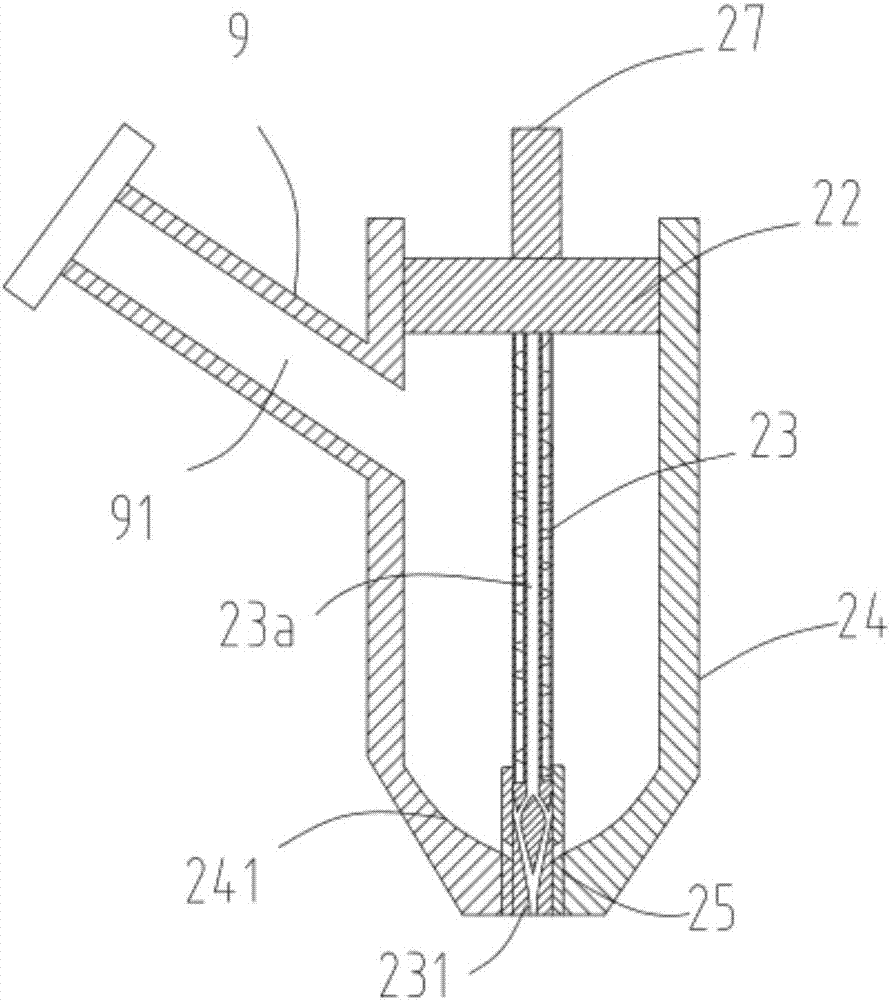

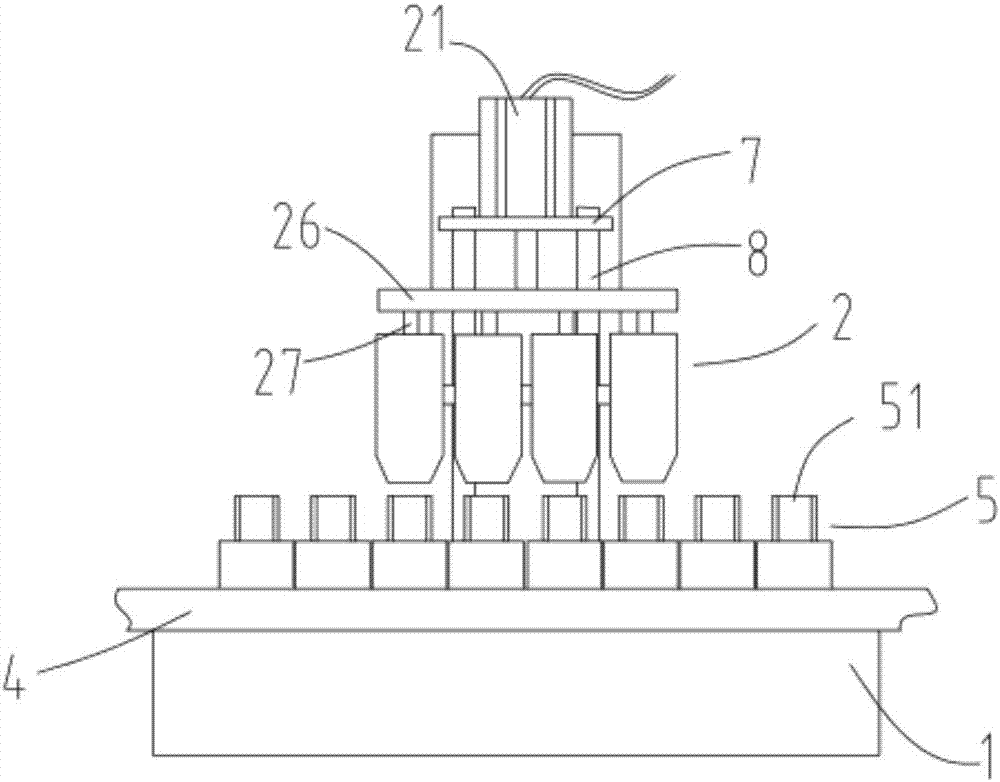

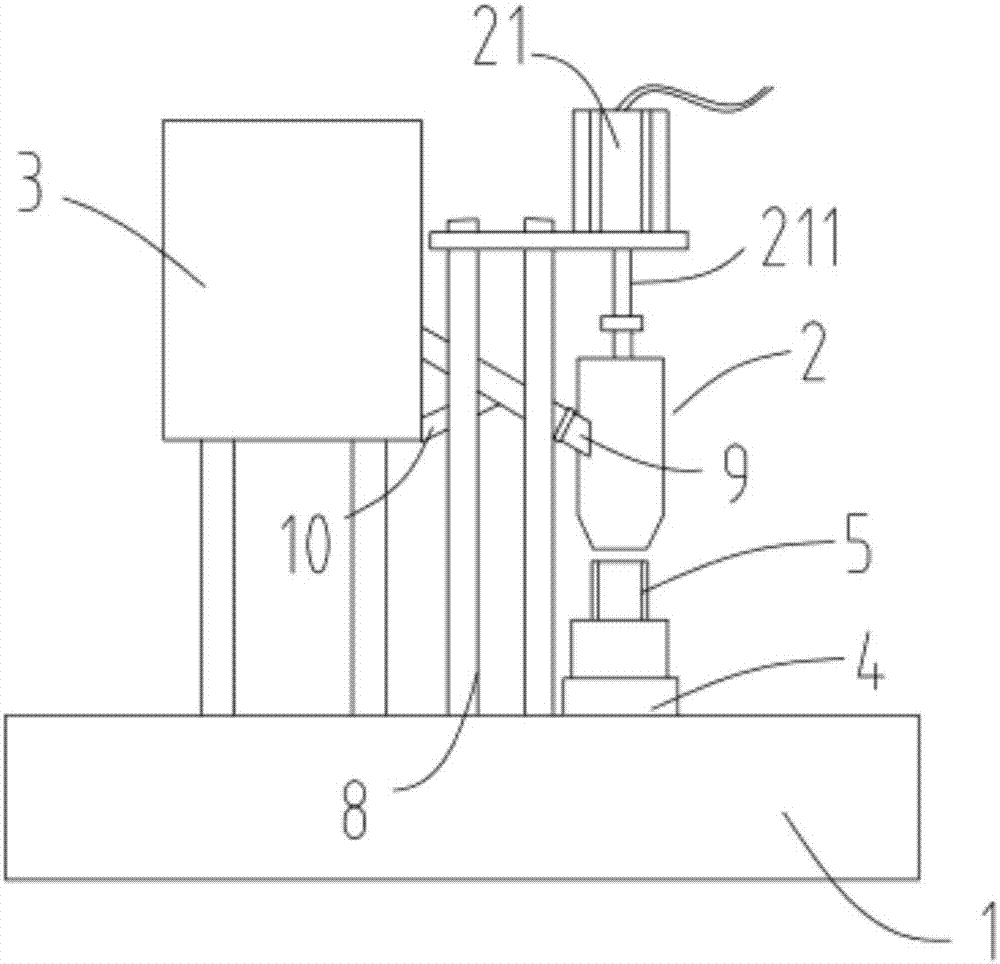

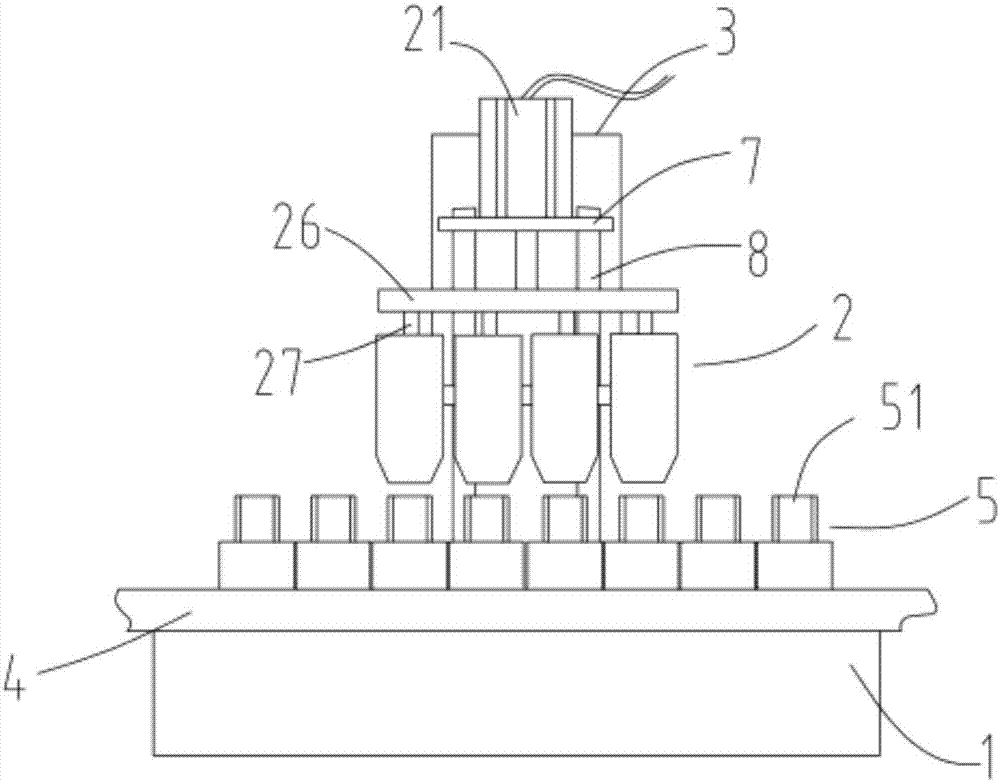

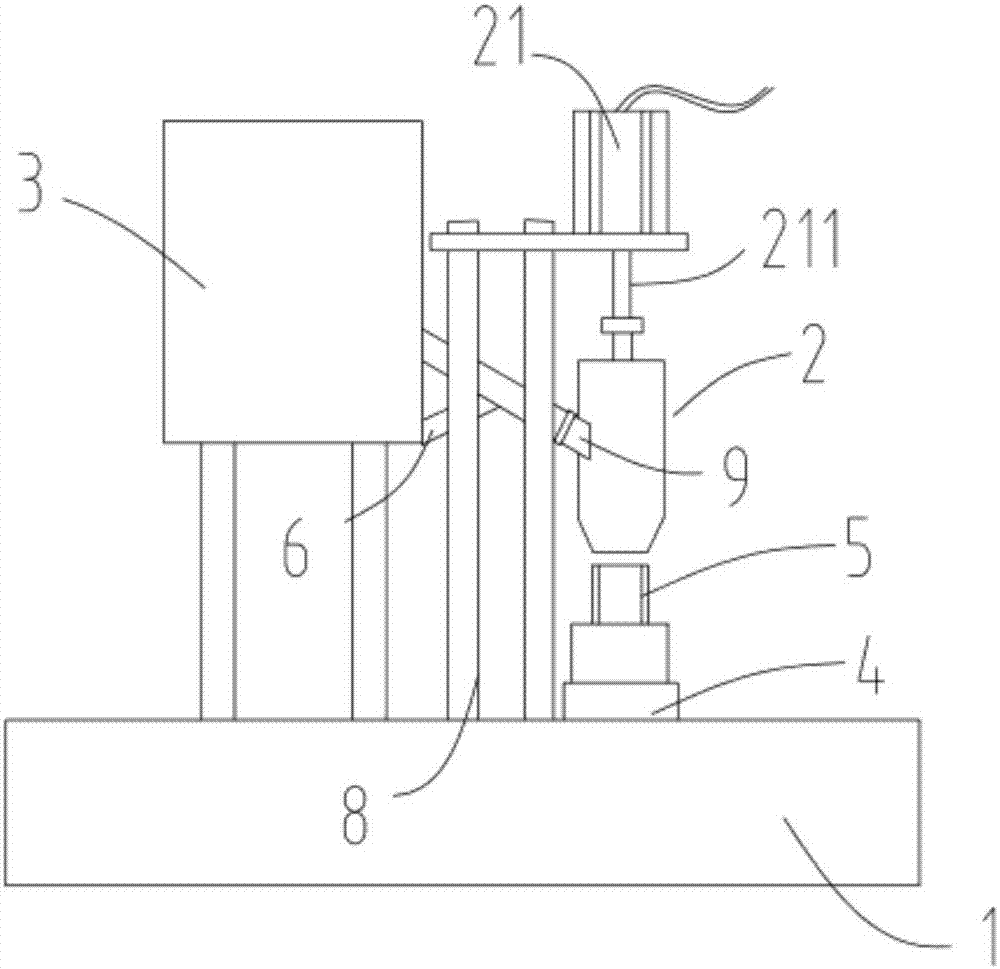

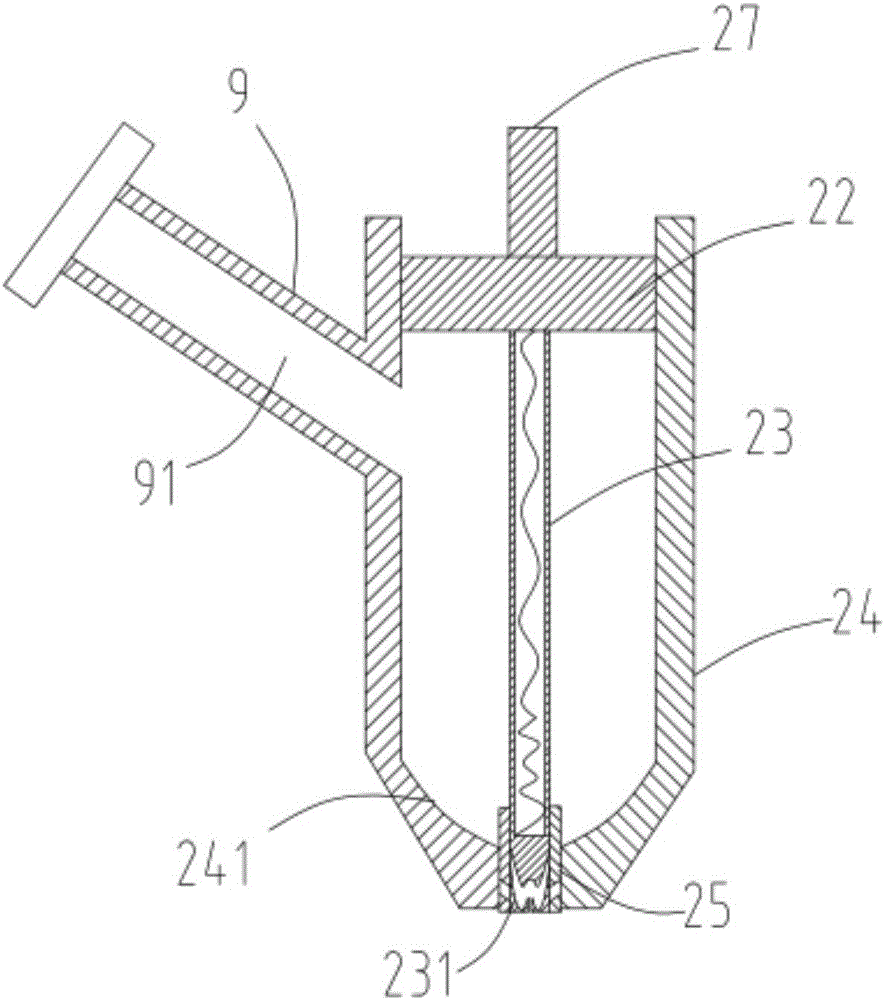

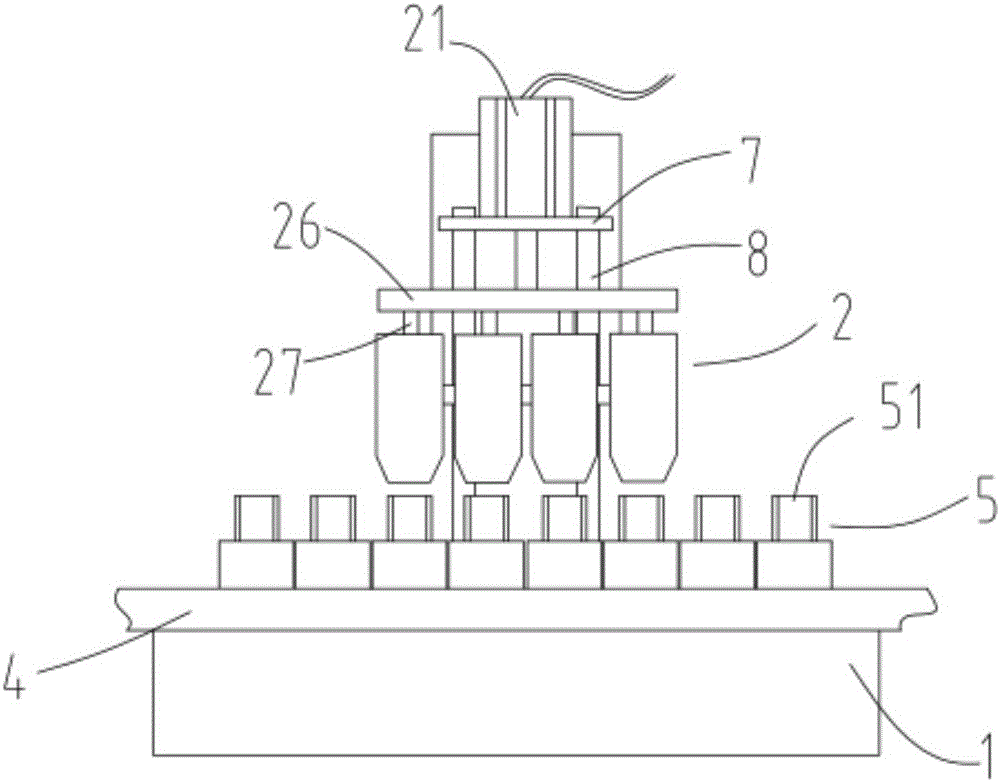

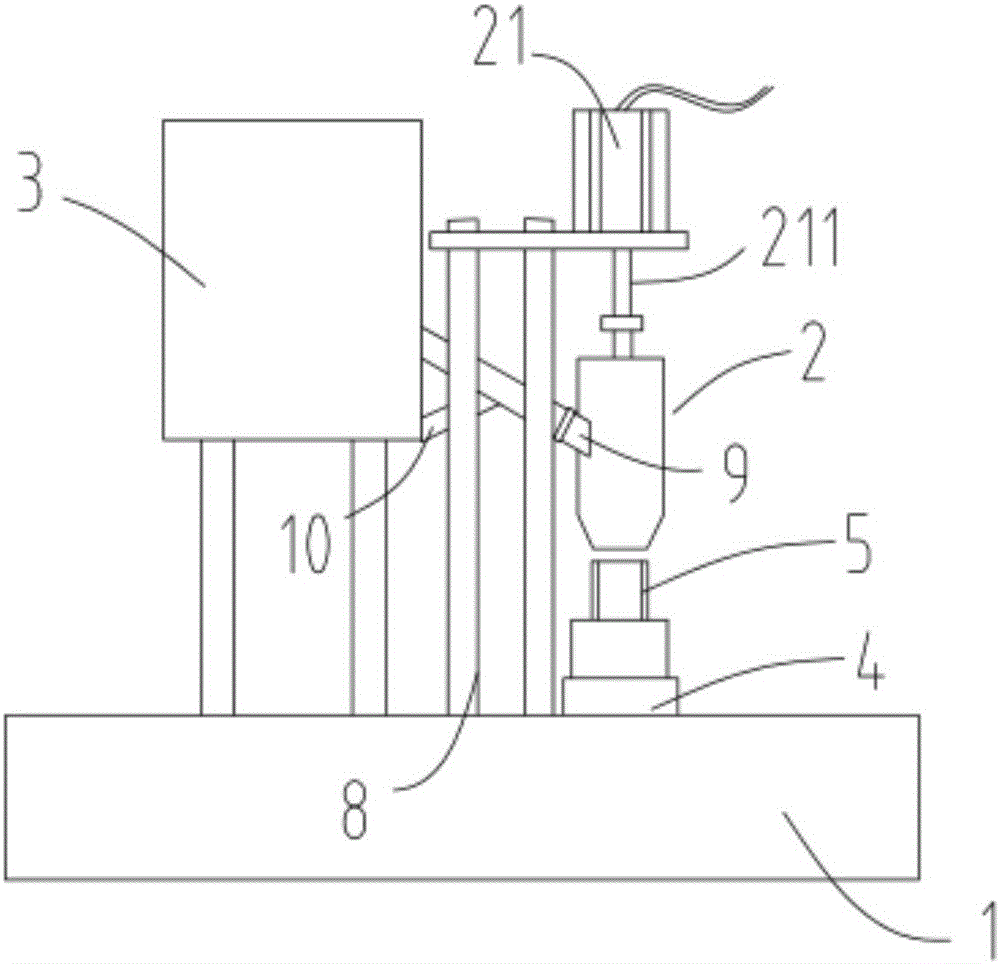

Equipment for uniformly injecting glue into battery

ActiveCN105789649AAvoid drippingReduce length of stayPrimary cell manufactureCell sealing materialsInjectorEngineering

The invention relates to equipment for uniformly injecting glue into a battery. The equipment comprises a bearing platform, a plurality of glue injecting components, a tank and an incoming material component, wherein the plurality of glue injecting components are arranged in parallel at equal intervals; the tank is used for storing glue; the incoming material component carries a plurality of battery steel shells; the glue injecting components vertically correspond to glue injecting openings of the battery steel shells; each of the glue injecting components comprise a power part, a pressing plate, a discharge rod, a glue injecting bucket and a material guide column; the pressing plates are arranged on top rods of the power parts; the discharge rods are arranged on the pressing plates; the material guide columns are arranged at the end parts of the discharge rods in a sleeving manner; the discharge rods can slide upwards and downwards relative to the inner walls of the material guide columns; the material guide columns are fixed on the glue injecting buckets; a semicircular material guide hole is formed in the end part of each discharge rod; a discharge hole is formed in each material guide column. By adopting the equipment, the problems that in the battery glue injecting process, the sealing property of a battery can be affected as the flowability is poorer as glue can be relatively greatly affected by the external environment, the glue injecting process is slow, the glue cannot be uniformly injected and distributed, and an injector can be easily blocked, are overcome.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

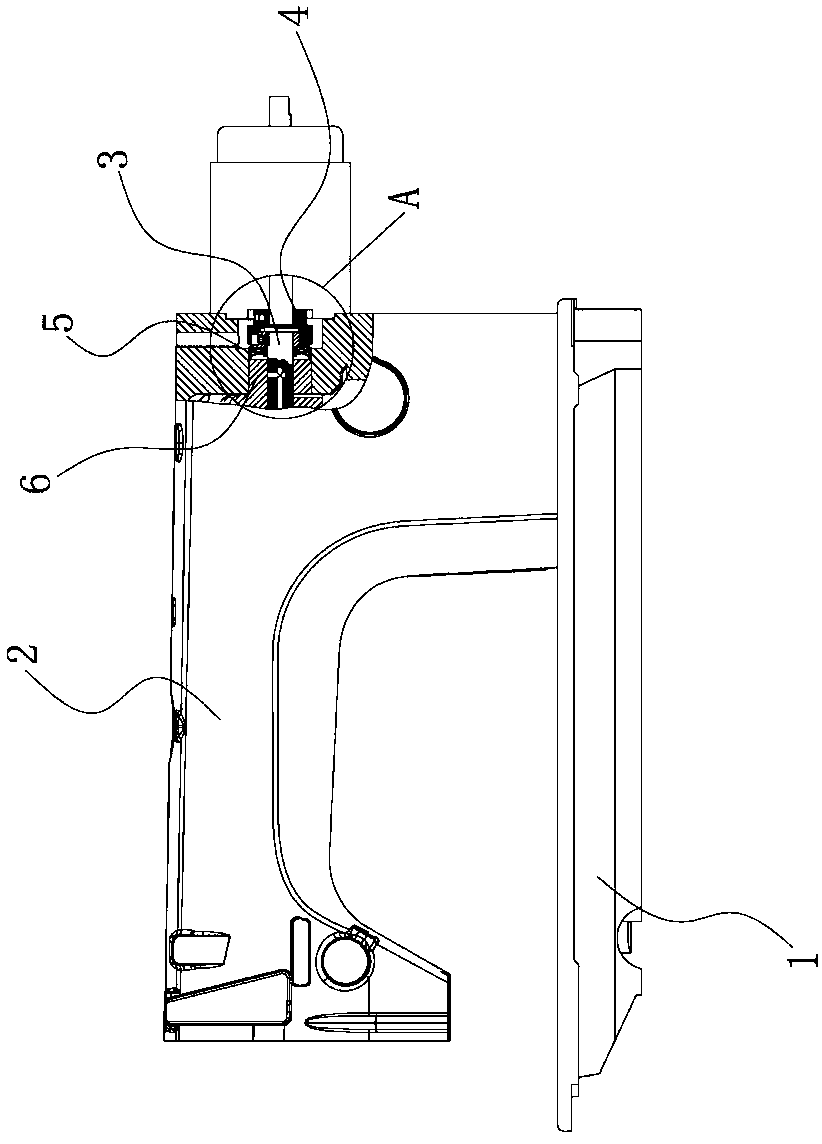

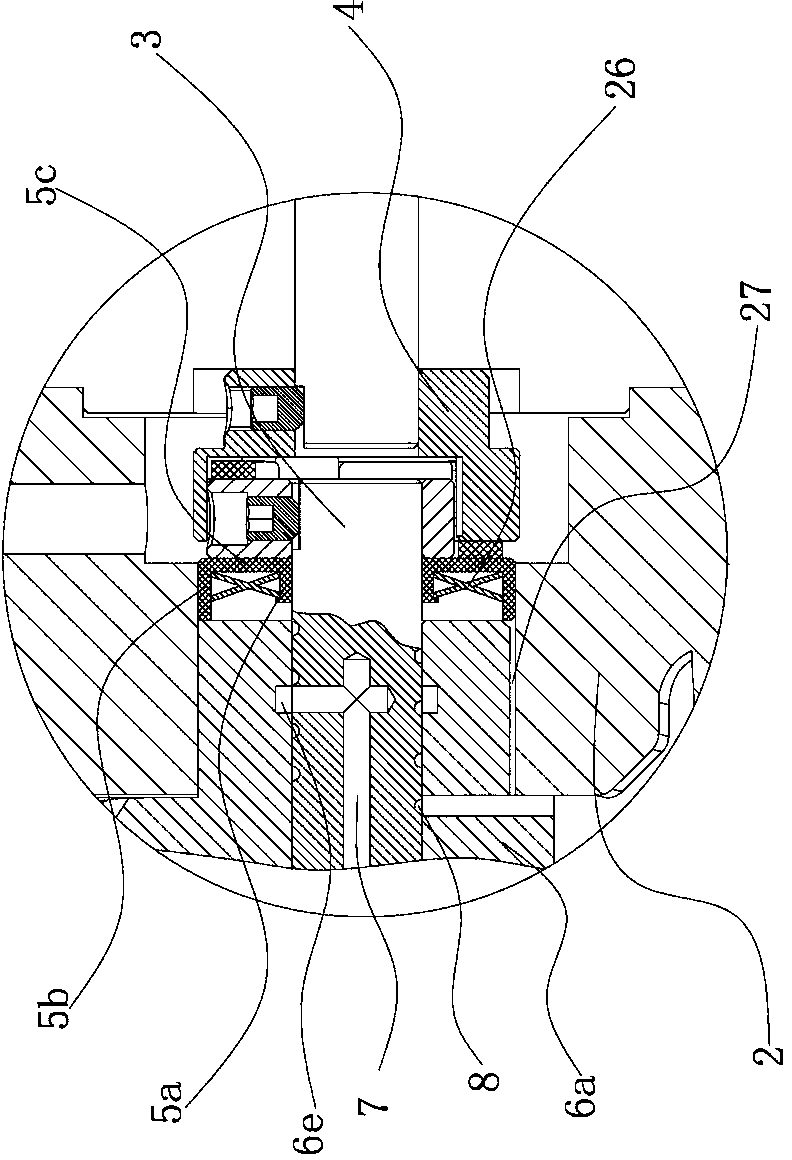

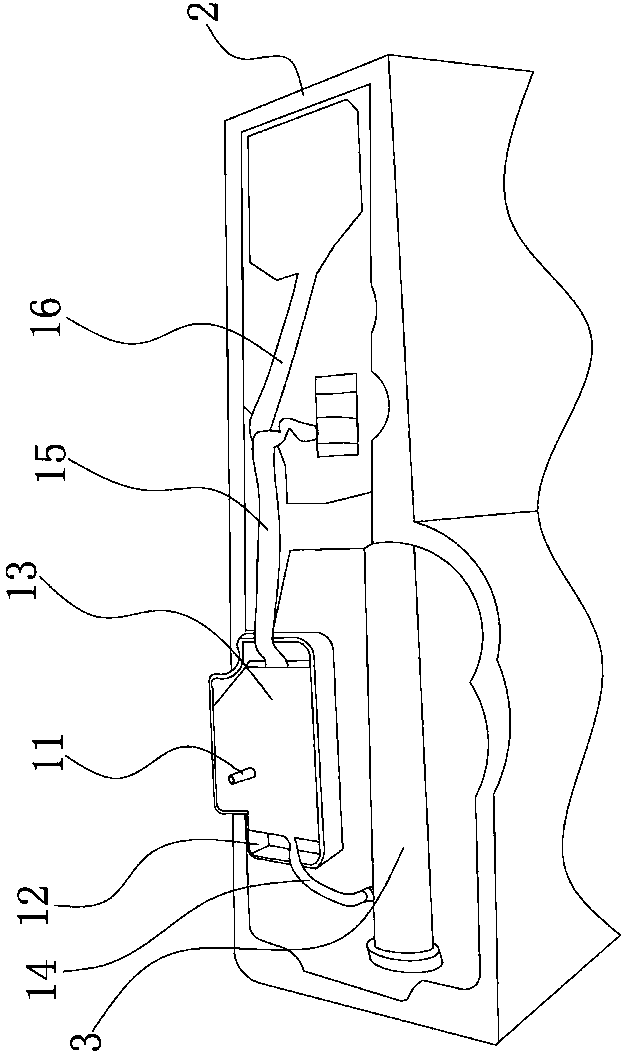

Main shaft lubricating mechanism of straight buttonhole machine

InactiveCN103290628AIdeal sealingExtended service lifeLubrication/cooling devicesOil canMechanical equipment

The invention provides a main shaft lubricating mechanism of a straight buttonhole machine and belongs to the technical field of mechanical equipment. The main shaft lubricating mechanism solves the problems that lubricating oil needs to be supplied manually and the lubricating oil can not be reused in an existing main shaft lubricating structure. The main shaft lubricating mechanism of the straight buttonhole machine is characterized in that a main shaft is fixedly arranged in a machine head shell, an oil seal is arranged between the main shaft and the machine head shell, an oil supply sleeve which is integrally formed by an eccentric wheel and an oil supply sleeve body is connected to the portion, located at the inner end of the oil seal, of the main shaft in a sleeved mode, an oil drive structure which absorbs oil from an oil inlet and supplies the oil to an oil outlet through vacuum is arranged between the main shaft and the eccentric wheel, an oil outlet channel is formed in the main shaft, an annular oil storage chute is formed in the inner wall of the eccentric wheel, the opening of an oil return chute is attached to the inner wall of the eccentric wheel, and the oil return chute is communicated with an inner cavity of the machine head shell. The main shaft lubricating mechanism of the straight buttonhole machine has the advantages of being low in work noise, simple in structure, long in service life and the like.

Owner:浙江银工缝制设备有限公司

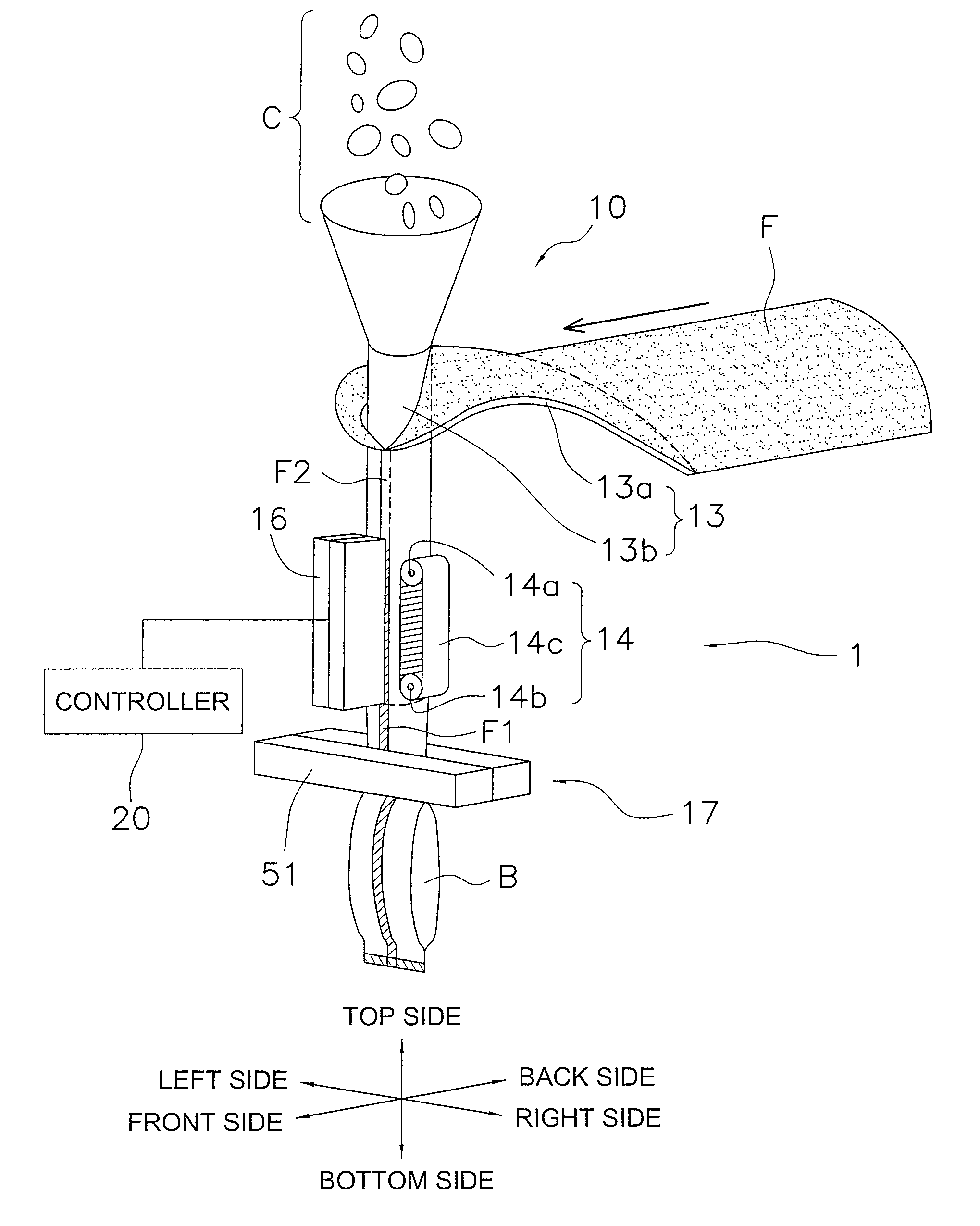

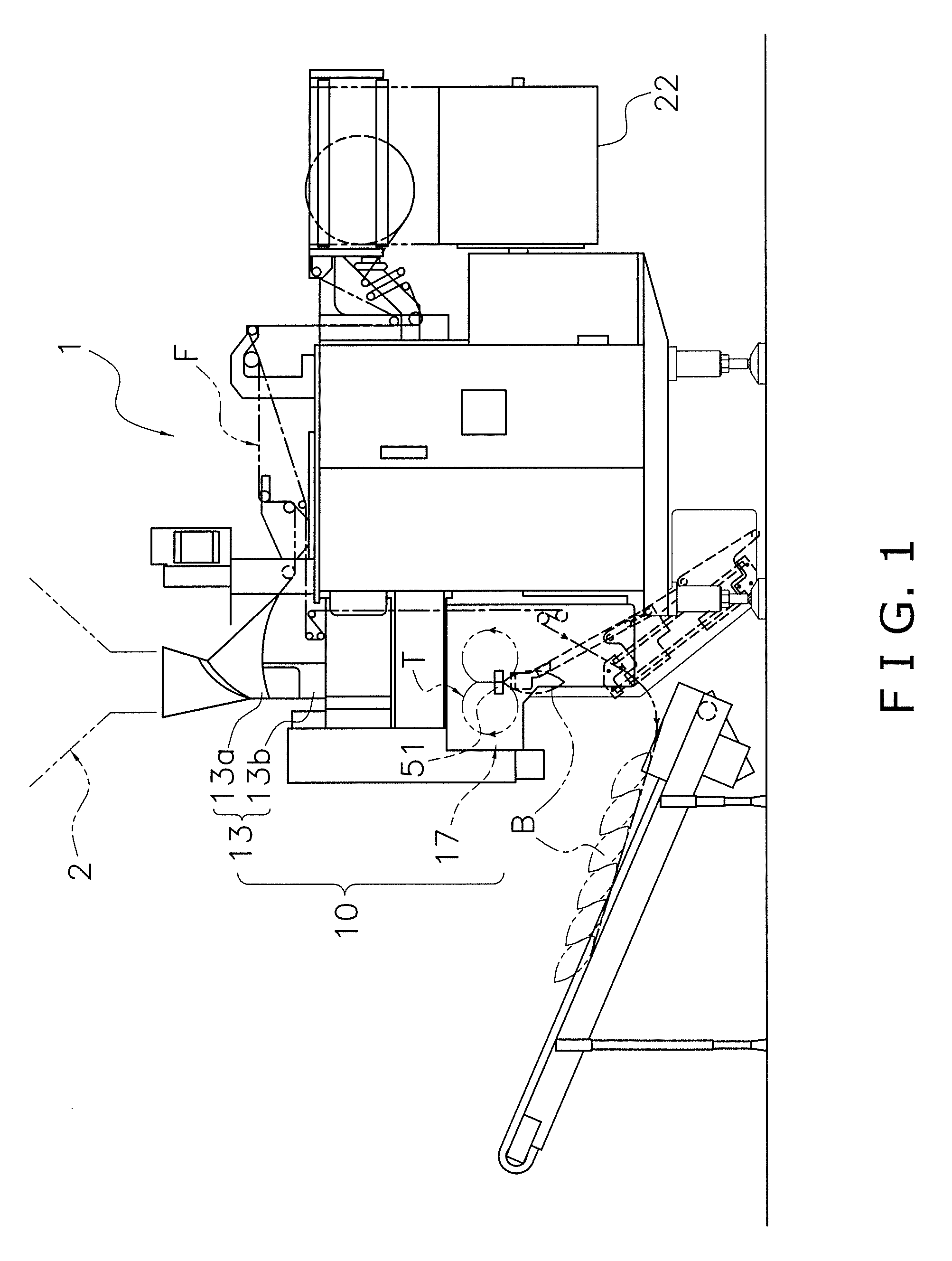

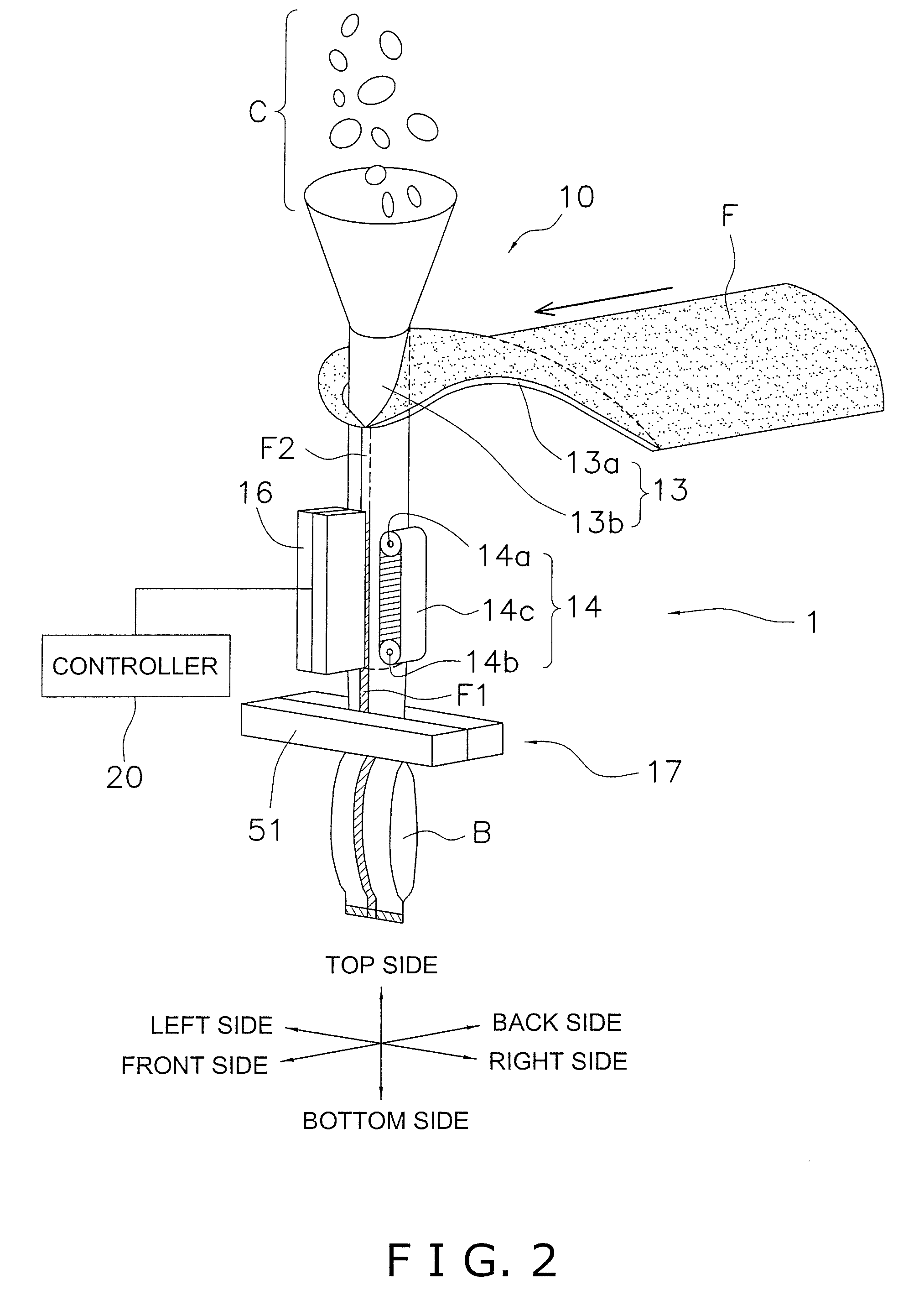

Bag-making and packaging machine

InactiveUS20100115894A1Poor sealingReduced sealing performanceWrapper twisting/gatheringSuccessive articlesEngineeringPackaging machine

A bag-making and packaging machine includes a forming mechanism, a vertical sealing mechanism, a transverse sealing mechanism and a receiving member. The forming mechanism is configured to roll a sheet-shaped packaging material into a cylindrical shape to form a cylindrical packaging material. The vertical sealing mechanism is configured and arranged to seal an overlapping portion of the cylindrical packaging material with heat vertically along a direction in which the cylindrical packaging material extends. The receiving member is attached to the forming mechanism in a position facing the vertical sealing mechanism, and configured and arranged to sandwich the overlapping portion together with the vertical sealing mechanism. The receiving member has elasticity with which the receiving member presses the overlapping portion toward the vertical sealing mechanism.

Owner:ISHIDA CO LTD

Wine bucket convenient for taking wine

The invention provides a wine bucket convenient for taking wine, relating to the technical field of wine buckets. The wine bucket convenient for taking wine comprises a wine box, wherein a movement plate is arranged inside the wine box in a sliding mode, two sides at the top of the movement plate are both fixedly provided with connecting rods, the tops of the two connecting rods are fixedly provided with a connecting plate, the top of the connecting plate is fixedly provided with a threaded rod, the outer surface of the threaded rod is in threaded connection with a thread bushing, the top of the thread bushing is are provided with a bearing, the top of the bearing is fixedly provided with a handle, the top of the wine box is fixedly provided with a hinged ring, and the top of the hinged ring is hinged to a sealing device. According to the wine bucket convenient for taking wine, the movement plate can move inside a limiting groove by rotating the handle, the movement plate moves upwardsto enable a liquid level in the inner cavity of the wine box to rise, and in conclusion, the effect that the liquid level of wine can rise so that the wine is conveniently taken is achieved.

Owner:房乾良

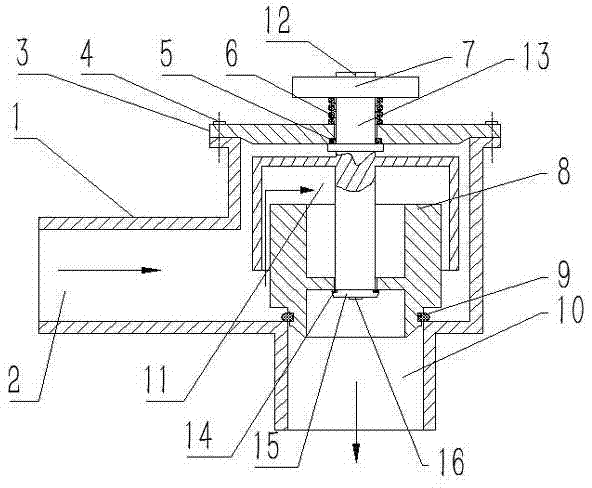

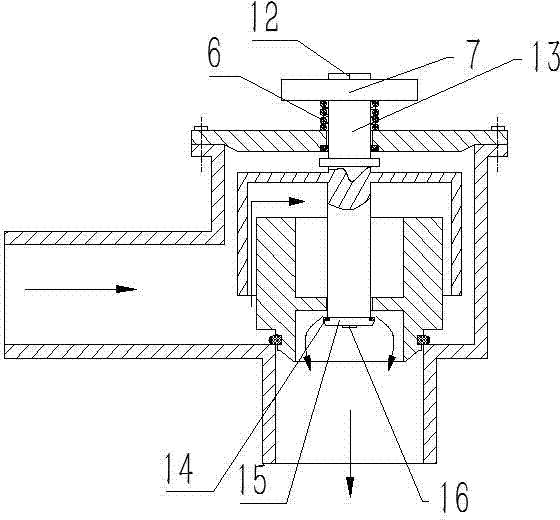

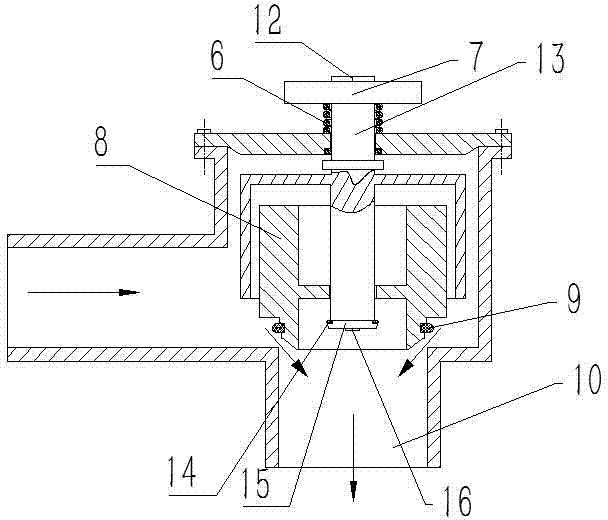

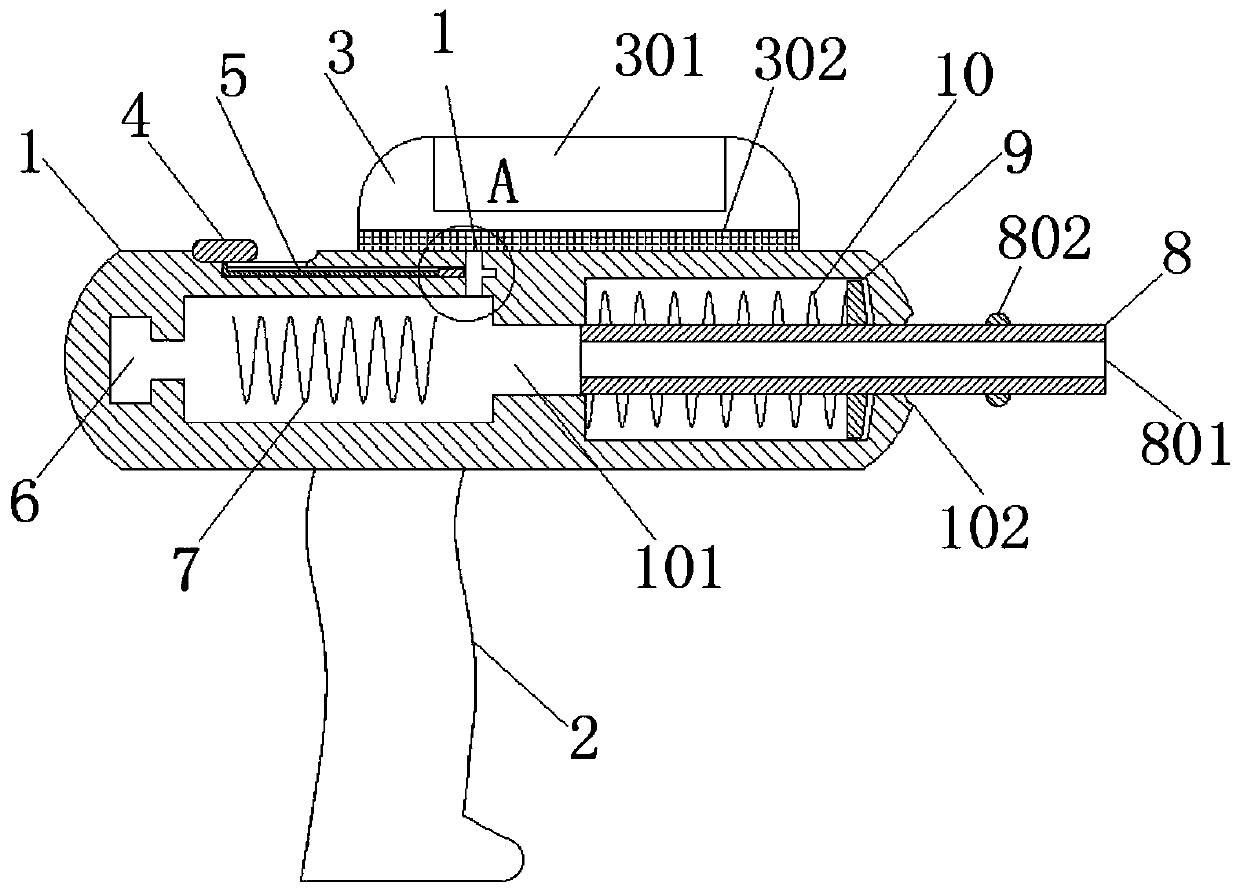

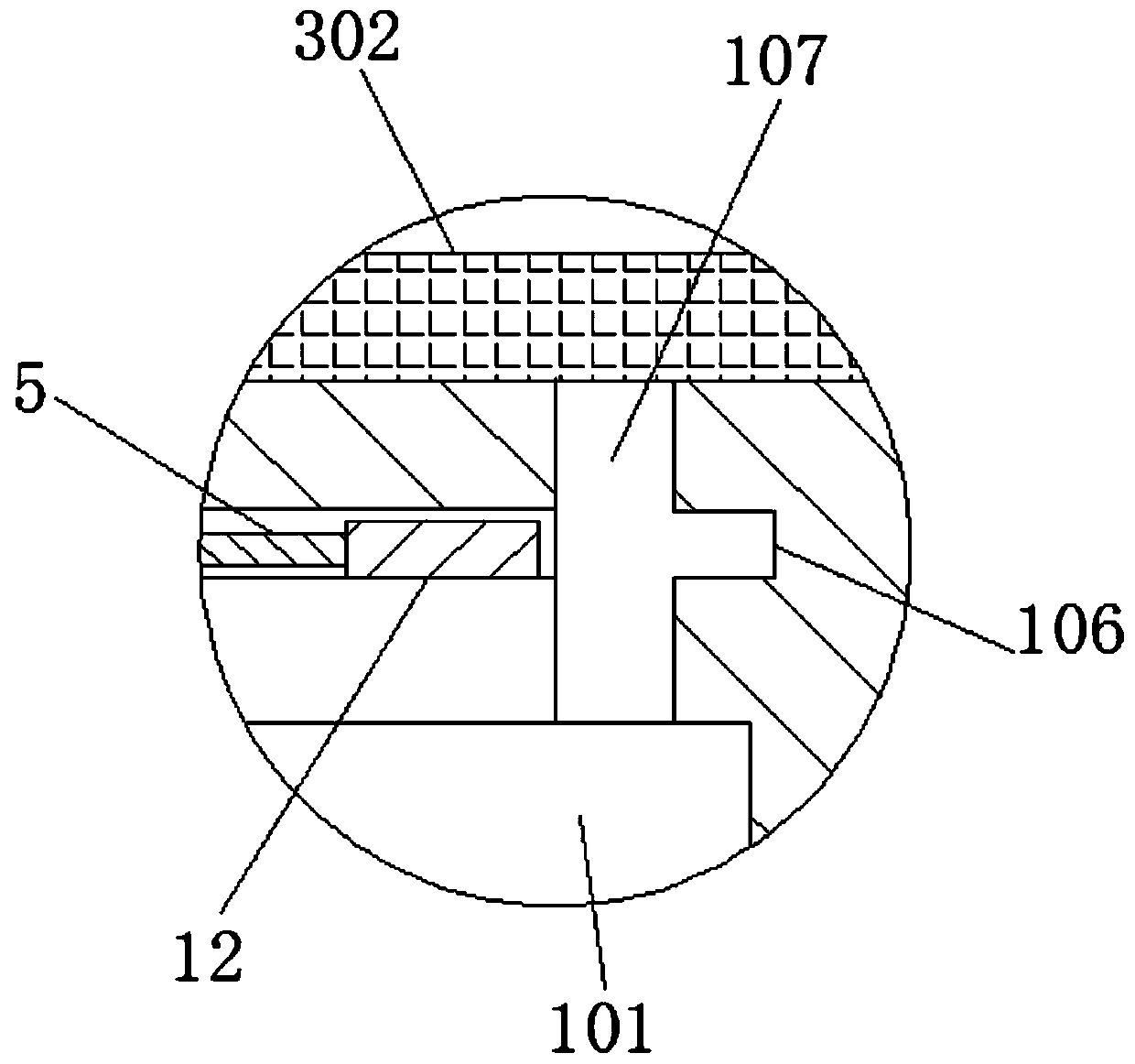

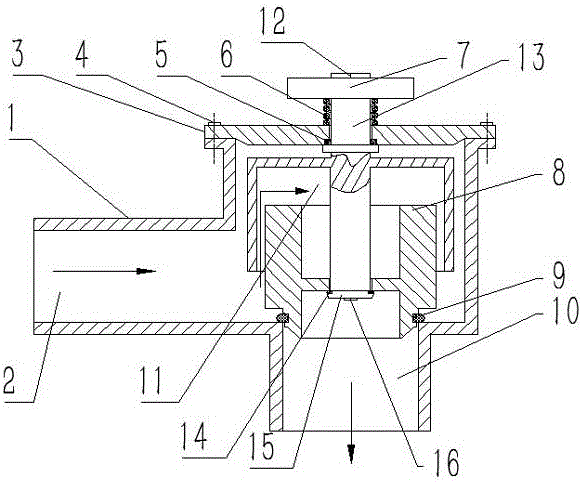

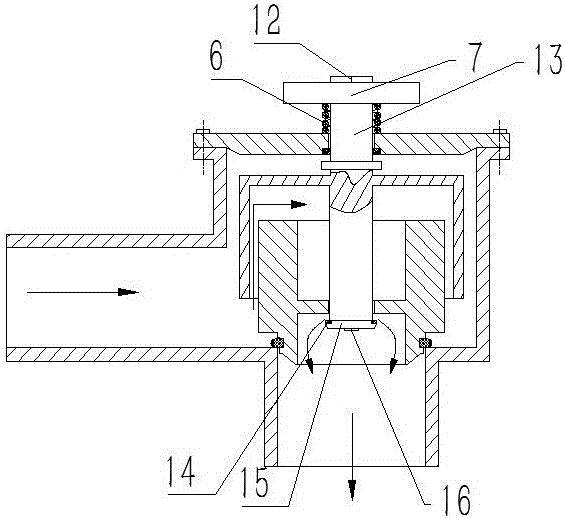

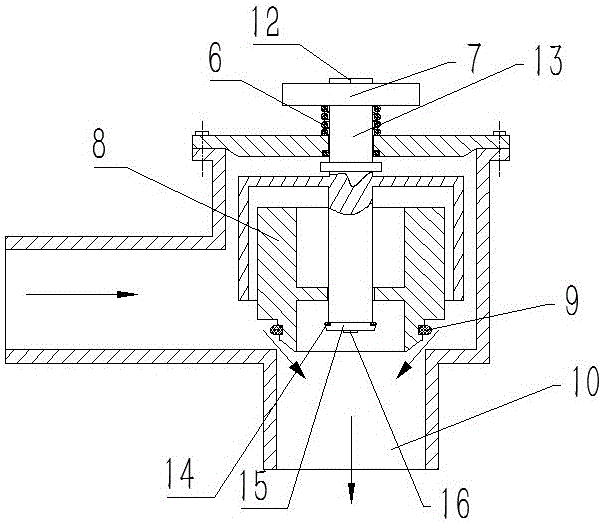

Novel press type water faucet

InactiveCN104728490AExtended service lifeOpen quicklySpindle sealingsFluid-delivery valvesPilot holeEngineering

The invention belongs to the technical field of water faucet equipment, and in particular relates to a novel press type water faucet. The water faucet comprises a water faucet body, a water faucet body cover is fixedly connected with the water faucet body, a pilot rod is in clearance fit with the middle of the water faucet body, a threaded hole A is formed in the upper end face of the pilot rod, a press plate is arranged on the threaded hole A through a press plate fixing screw, and a reset spring is arranged between the lower surface of the press plate and the upper surface of the water faucet body cover; the pilot rod is fixedly connected with a pilot cylinder, a sealing cavity is formed inside the pilot cylinder, the interior of the sealing cavity is in clearance fit with a big piston, a big piston sealing ring is arranged between the big piston and a water outlet in a matched mode, the interior of the big piston is provided with a big piston inner cavity, and the big piston inner cavity is provided with a pilot hole; the lower end face of the pilot rod is provided with a threaded hole B, a pilot piston is arranged on the threaded hole B through a pilot piston fixing screw, and a pilot piston sealing ring is arranged between the pilot piston and the pilot hole in a matched mode.

Owner:UNIV OF JINAN

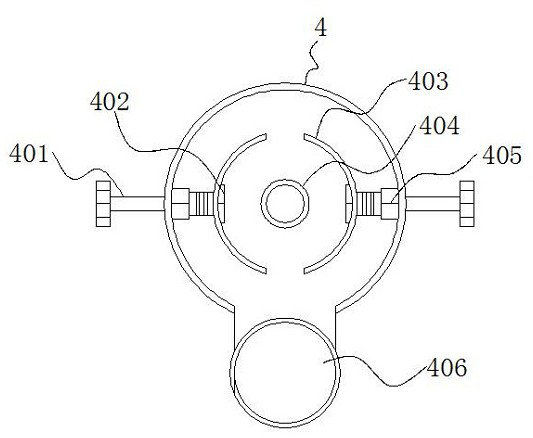

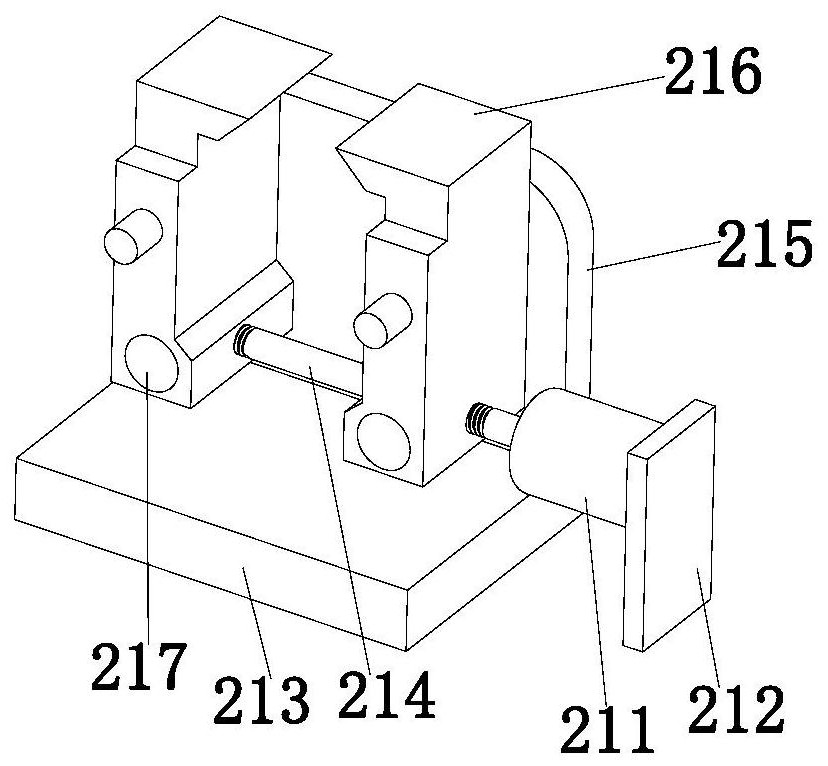

Three-way valve anti-leakage detection device with limiting performance

InactiveCN112051011ALimitedEasy to operateDetection of fluid at leakage pointUsing optical meansEngineeringMechanical engineering

The invention discloses a three-way valve anti-leakage detection device with limiting performance, and relates to three-way valve anti-leakage detection, the three-way valve anti-leakage detection device comprises a detection piece and a bottom groove, a fixing device is arranged at one end of the outer portion of the detection piece, a separation groove is formed in one end of the outer portion of the fixing device, and a separation plate is arranged outside the separation groove; a connection post is arranged at one end of the outside of the partition board; and a detection area is arrangedat the outside part of the connecting post. According to the present invention, with the arrangement of the second detection assembly, the proper anti-leakage detection manner can be selected according to the actual use rotation, and the user can inject the colored liquid into the stirring frame, and the stirring frame is connected with a connecting hose in the second detection assembly, the connecting hose can be fixedly connected into the detection piece through threaded connection, and the other end of the detection piece can be sealed through a middle groove in a threaded mode, so that colored objects are injected into the detection piece to judge whether the detection piece leaks or not, the structure is simple, and it is convenient for users to operate.

Owner:深圳市辉迪机电科技有限公司

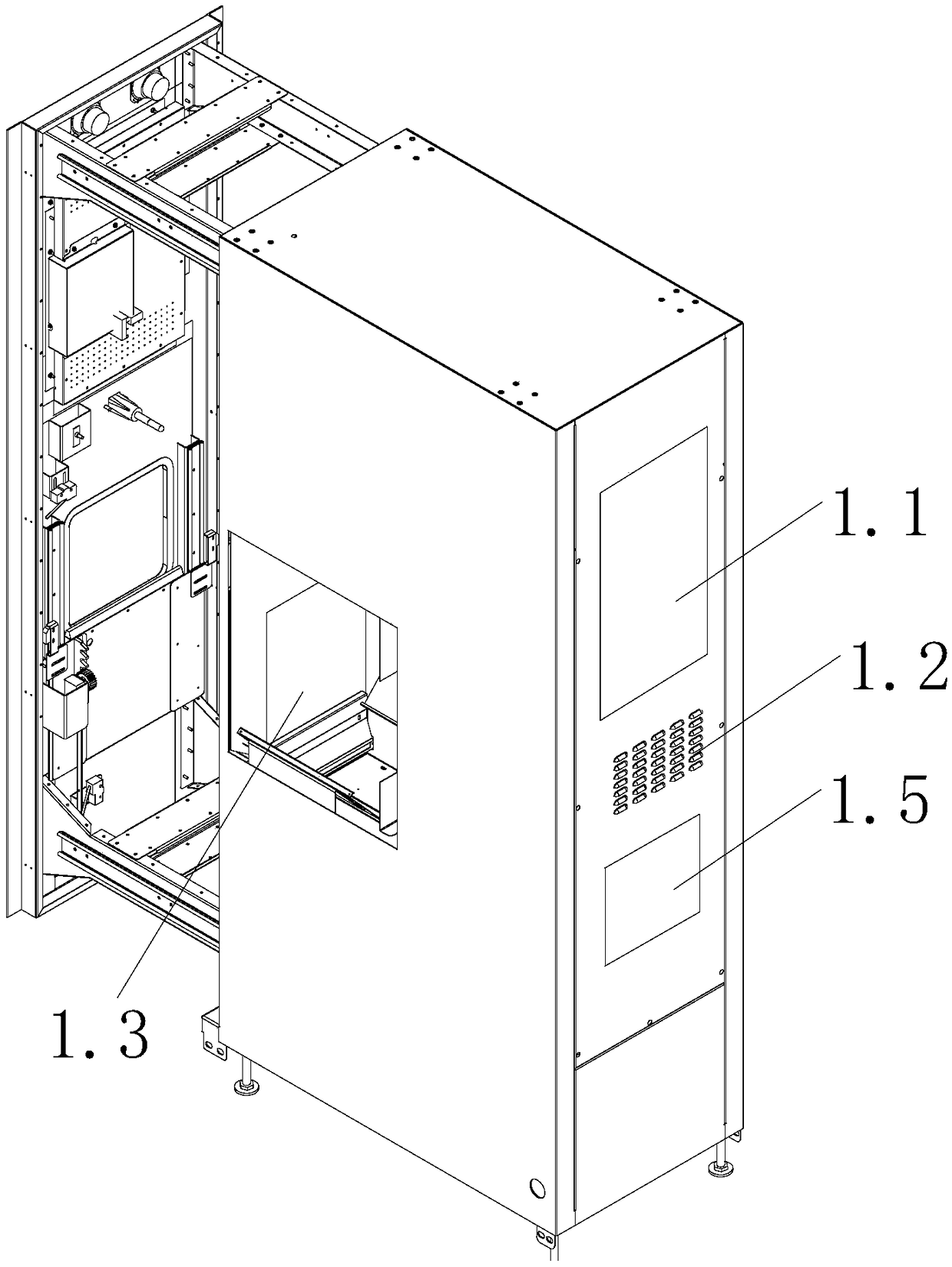

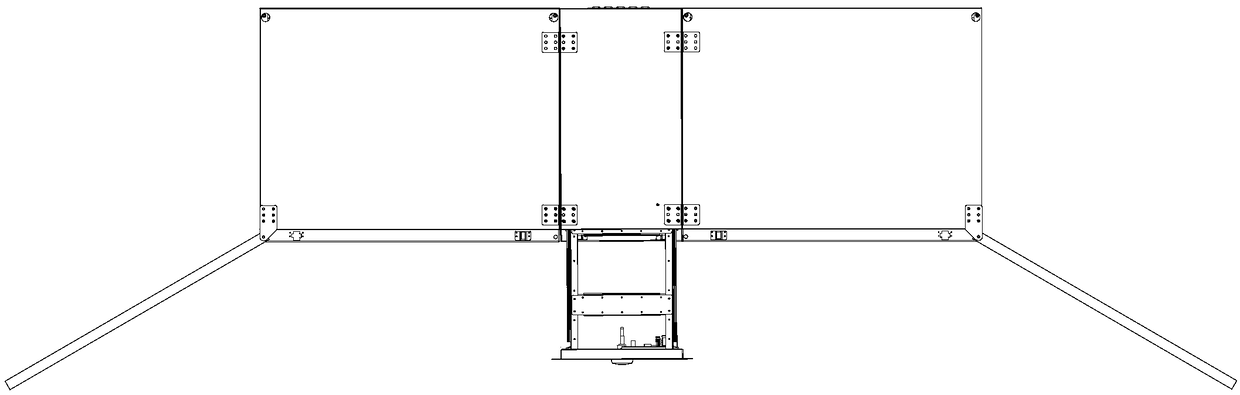

Integrated vending machine and working method thereof

InactiveCN109300235AIncrease productivityReduce thicknessCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringUltimate tensile strength

The invention relates to an integrated vending machine and a working method thereof, wherein a central control box controls two vending machines at the same time, so that the space for the vending machine can be saved and more goods can be sold. A motor is laterally fixed at one side of track-type goods passages, and according to the lateral fixation, the vertical space in the vending machine canbe saved, so that more track-type goods passages can be arranged inside the vending machine. A lifting platform is constructed by splicing a lateral plate and vertical plates on the inner and outer sides. A plurality of through holes are formed in the lateral plate, which can reduce the total weight of the lifting platform. A plurality of connecting rods are arranged from left to right between thevertical plates, which can increase the strength. The two vertical plates are respectively arranged with a mounting port near the outlet of the vending machine. A sensor can be fixed in the mountingport, which can sense that goods being moved to a tray of the central control box assembly through the outlet of the vending machine.

Owner:JIANGYIN WANYUAN ELECTRONICS TECH CO LTD

Water meter sealing performance detection device and detection method

ActiveCN114166423AAvoid damageGuaranteed air tightnessTesting/calibration for volume flowFluid-tightness measurement using fluid/vacuumComputer hardwarePilot light

The invention is suitable for the field of detection, and provides a water meter sealing performance detection device and method, and the device comprises a workbench and a limiting ring which is fixedly installed on the workbench. The indicating lamp is fixedly installed in a sealing box, the sealing box is hollow, a static contact is installed in the sealing box, the static contact is electrically connected with the indicating lamp, a movable contact is further movably arranged on the workbench, and the movable contact is electrically connected with the indicating lamp. The moving contact is connected with a trigger mechanism which is used for driving the moving contact to move towards the position of the static contact, and the trigger mechanism is movably arranged on the workbench; the elastic assembly is connected with the triggering mechanism and is movably arranged on the workbench; the air inflation assembly is movably arranged on the workbench and is connected with the elastic assembly; the clamping mechanisms are movably mounted on the working table and are symmetrically arranged; and the driving assembly is movably arranged on the working table.

Owner:湖南常德牌水表制造有限公司

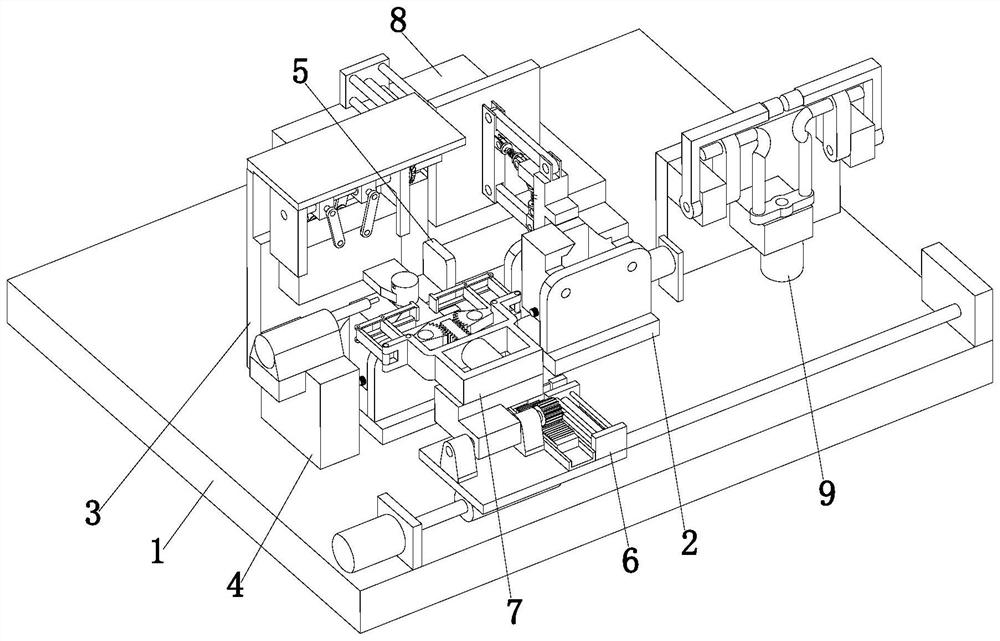

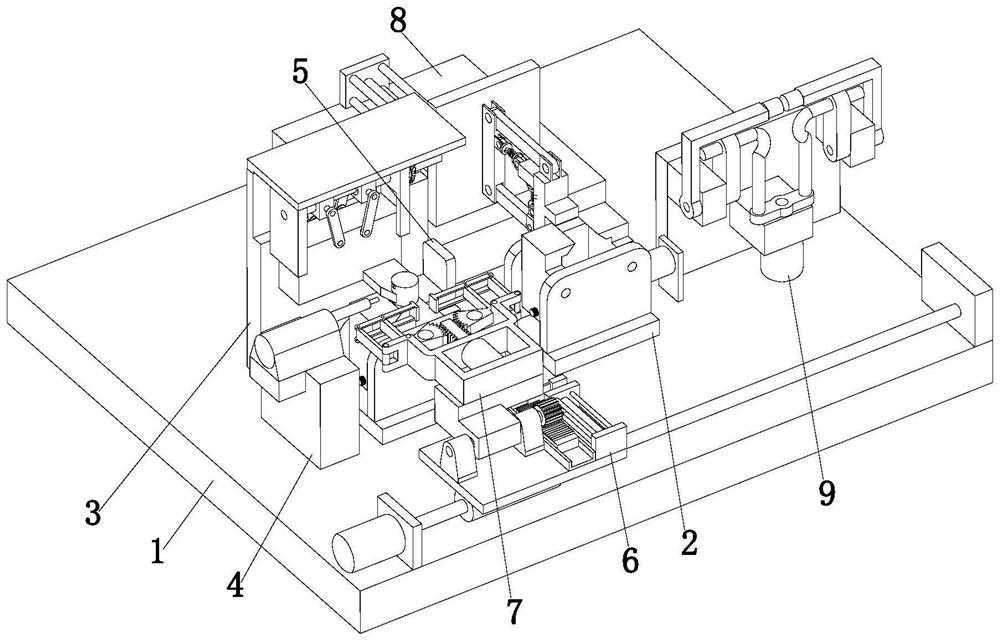

Detection process of special clamping forceps for endoscope

InactiveCN112539899AEasy to moveImprove smooth performanceMachine part testingFluid-tightness measurement using lightForcepsMechanical engineering

The invention discloses a detection process of special clamping forceps for an endoscope, and belongs to the technical field of special clamping forceps for endoscopes. The detection process comprisesthe following steps of: 1, clamping and fixing special clamping forceps for an endoscope; 2, covering the clamped special clamping forceps; 3, detecting the sealing degree of the special clamping forceps; 4, clamping the special clamping forceps for the endoscope; 5, turning over the special clamping forceps for the endoscope; 6, fixing the operation end of the special clamping forceps for the endoscope; 7, detecting the locking degree of the special clamping forceps for the endoscope; and 8, detecting the performance of the special clamping forceps for the endoscope after multiple times of opening and closing. According to the invention, the detection process is ingenious in process design, smooth in procedure connection and high in automation degree, achieves full-automatic detection ofthe sealing degree and the locking performance of the special clamping forceps for the endoscope, saves labor, greatly improves the production efficiency, is high in detection precision and has remarkable economic value.

Owner:谢三保

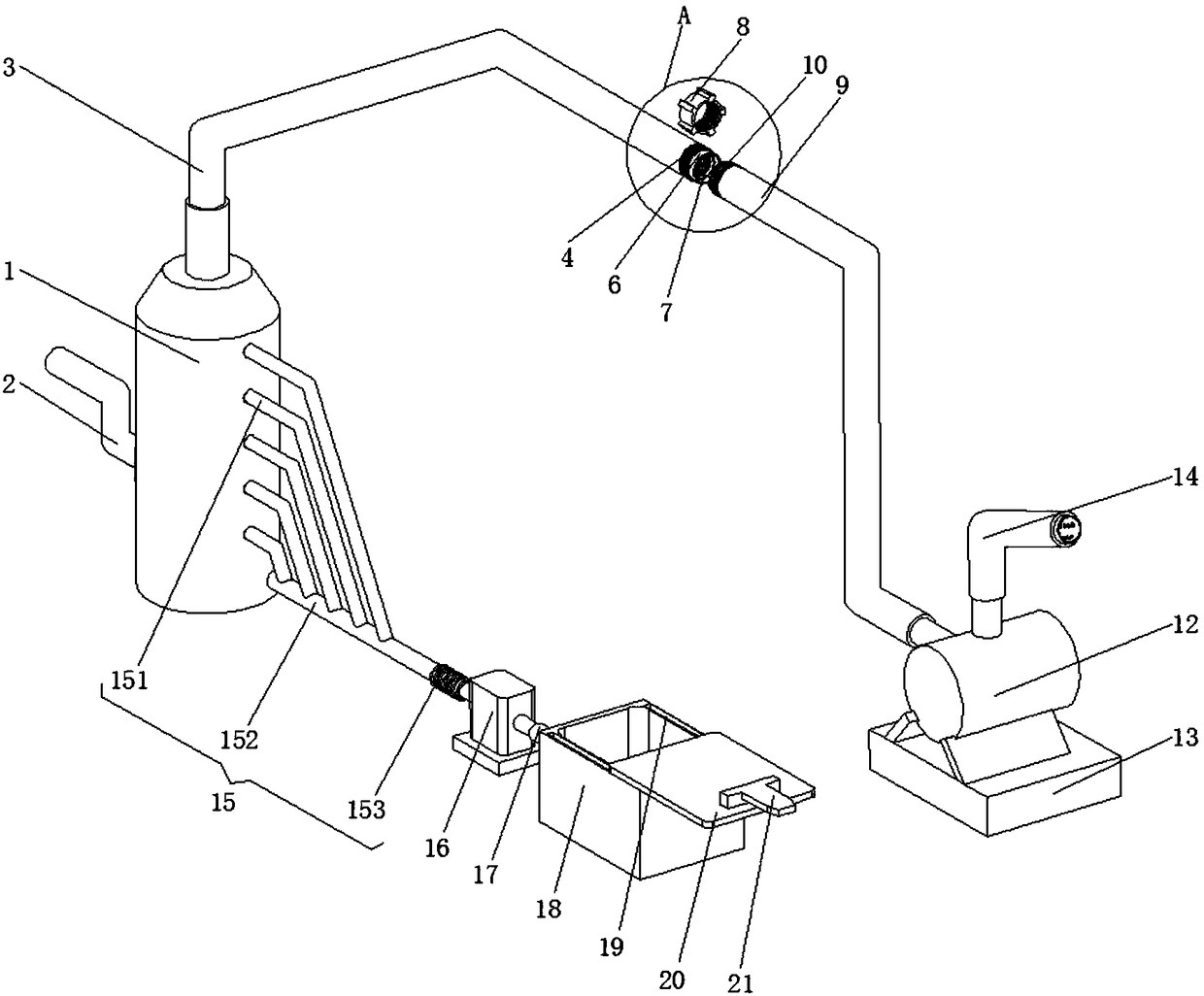

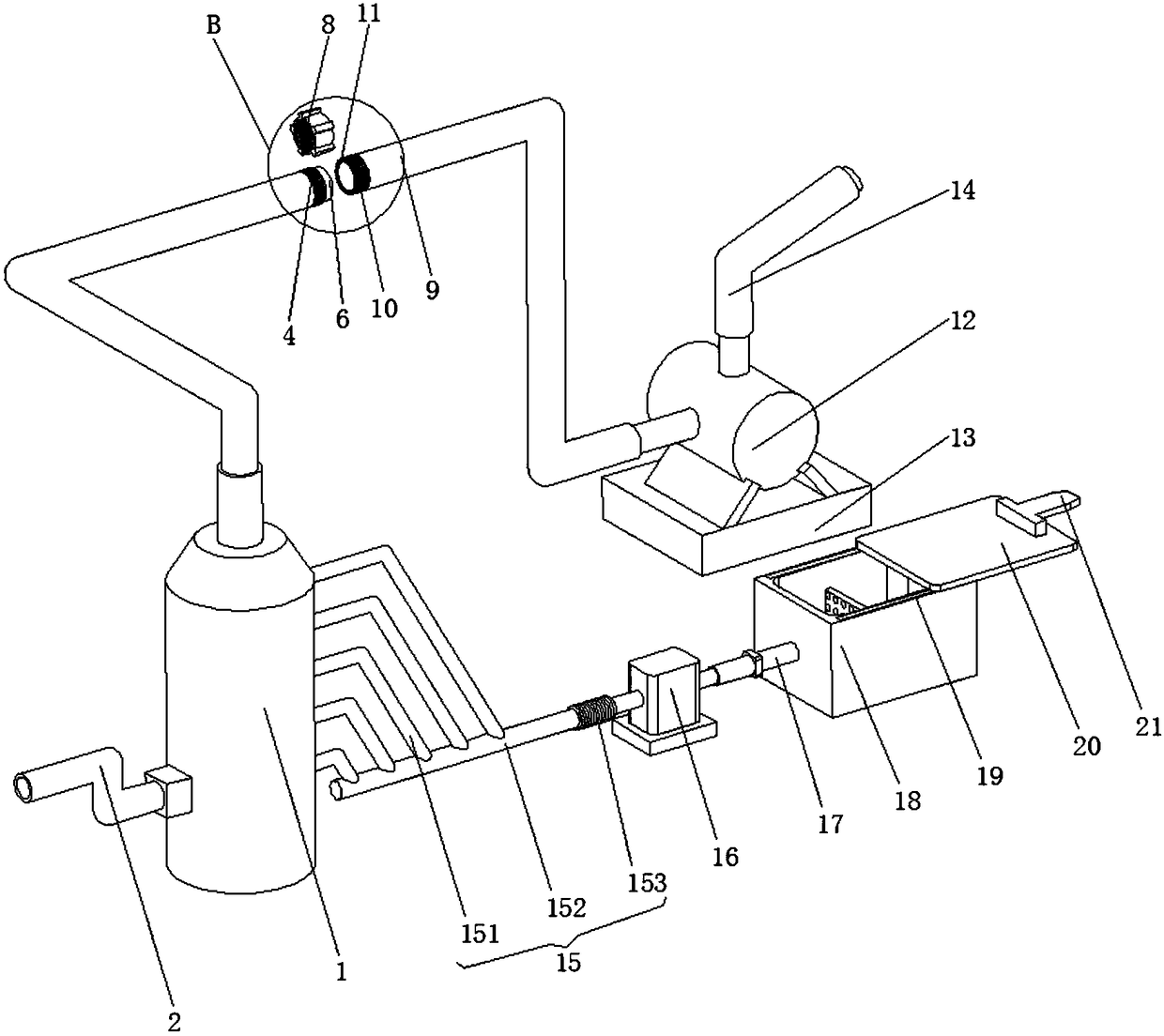

Environmental protection device for dedusting and desulfurizing smoke

InactiveCN108554072AImprove efficiencyEfficient diversion workGas treatmentUsing liquid separation agentSulfurEngineering

The invention relates to the technical field of environmental protection devices, and discloses an environmental protection device for dedusting and desulfurizing smoke. The device comprises a dedusting tower, the bottom end of one side of the dedusting tower is fixedly connected with a smoke introduction tube, an exporting tube is fixedly mounted at the top of the dedusting tower, a connecting threaded groove 1 is arranged on the external of one end, away from the dedusting tower, of the exporting tube, and a sealed connecting groove 1 positioned at one end, away from the dedusting tower, ofthe exporting tube is arranged at the inner side of the connecting threaded groove 1. The number of inner casings is same to the total number of pipelines in the environmental protection device for dedusting and desulfurizing smoke, so the inner casings can effectively protect the inner walls of the pipelines in the working process of the device to make scales formed by corrosion and condensationattached to the inner walls of the inner casings, and the inner casings have a detachable function, so the convenience and the high efficiency of pickling and cleaning of a pipeline assembly in the device are further improved.

Owner:李梦平

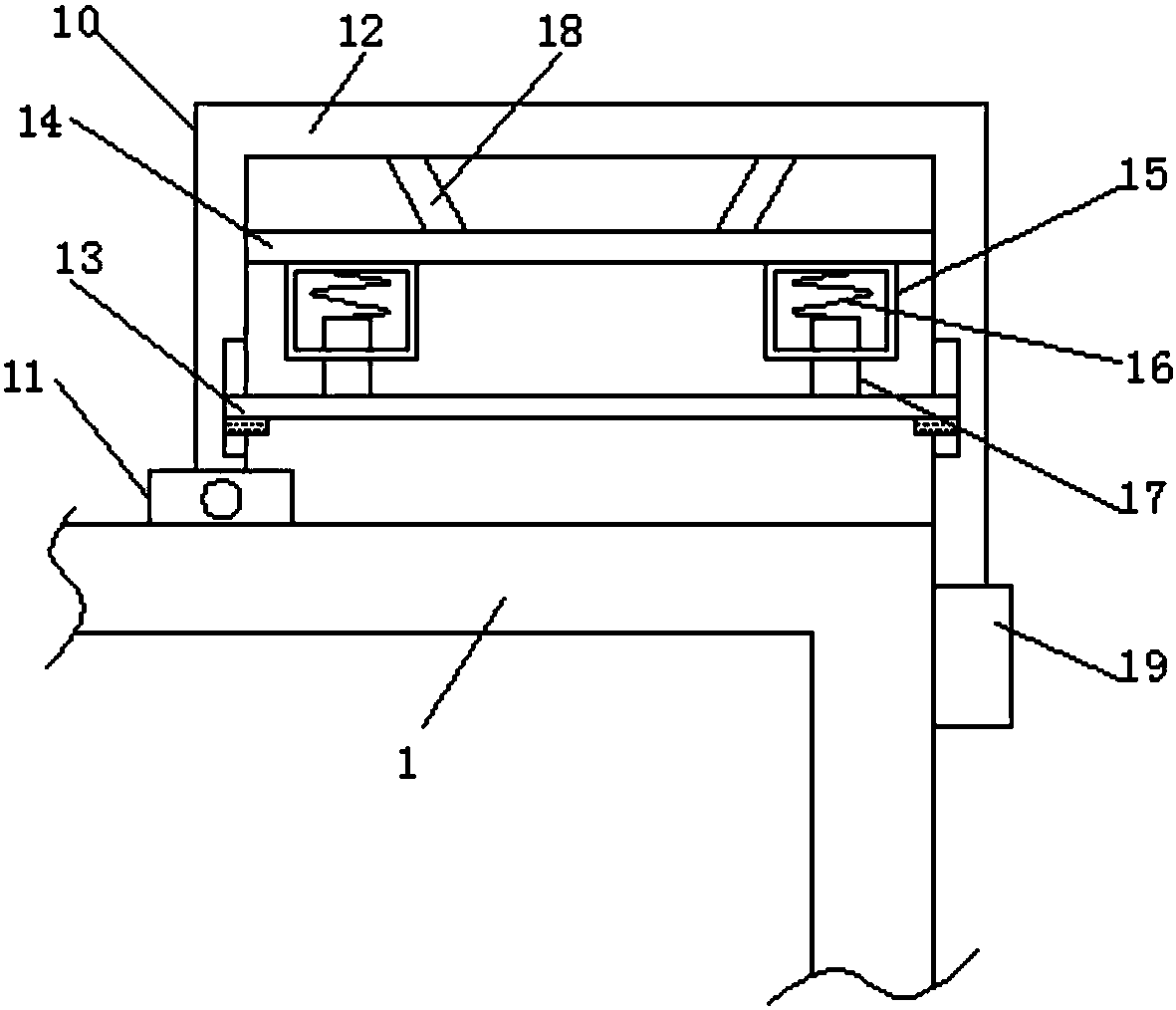

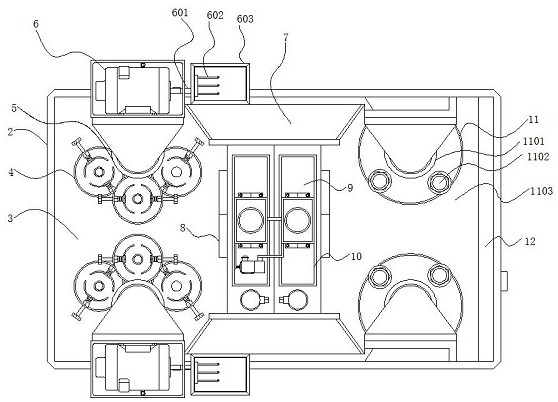

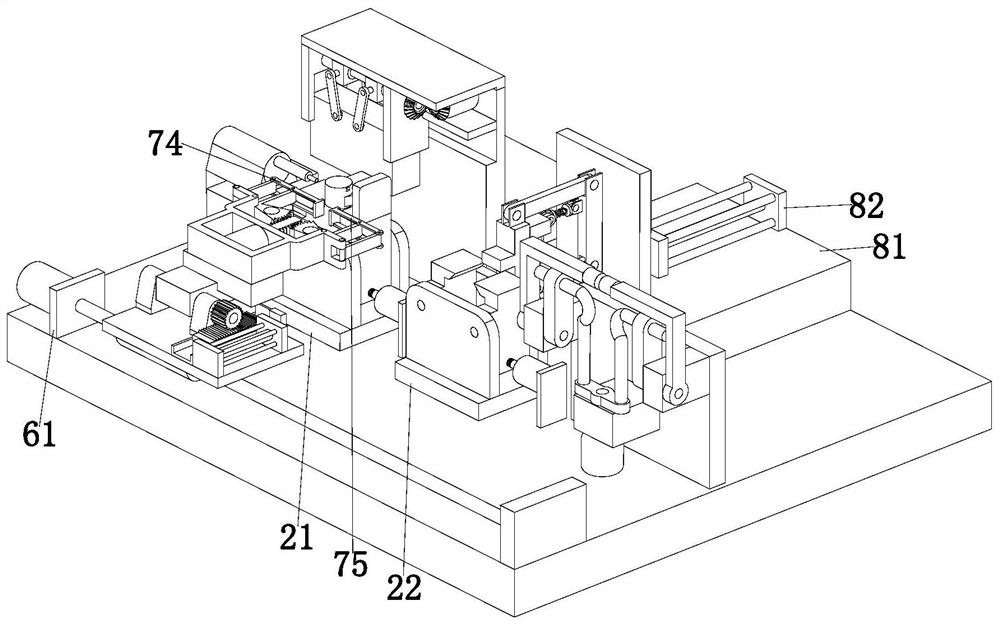

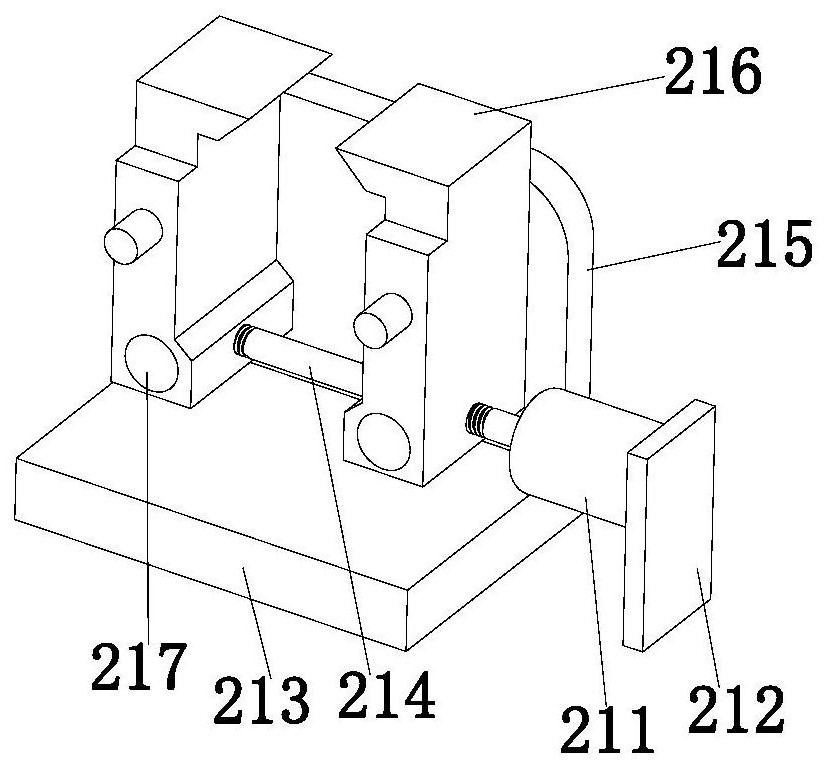

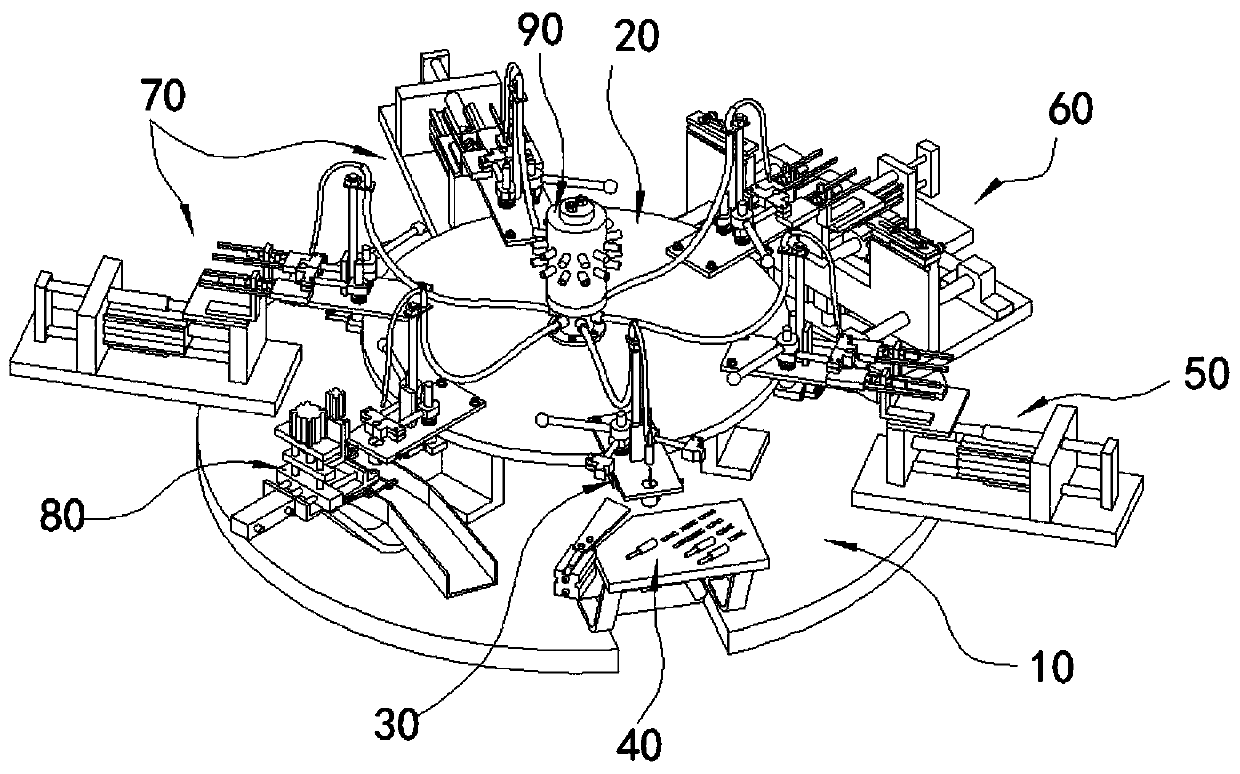

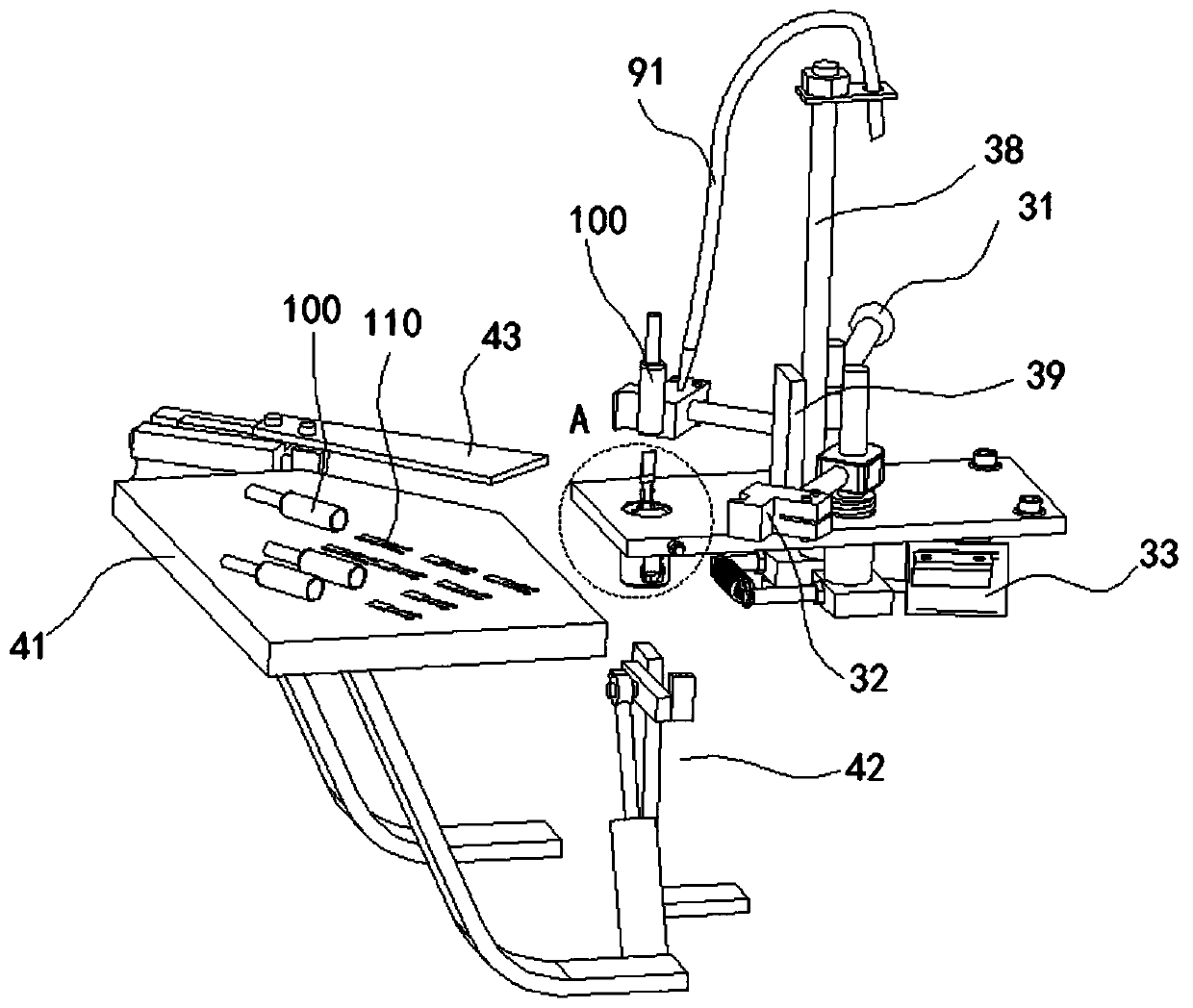

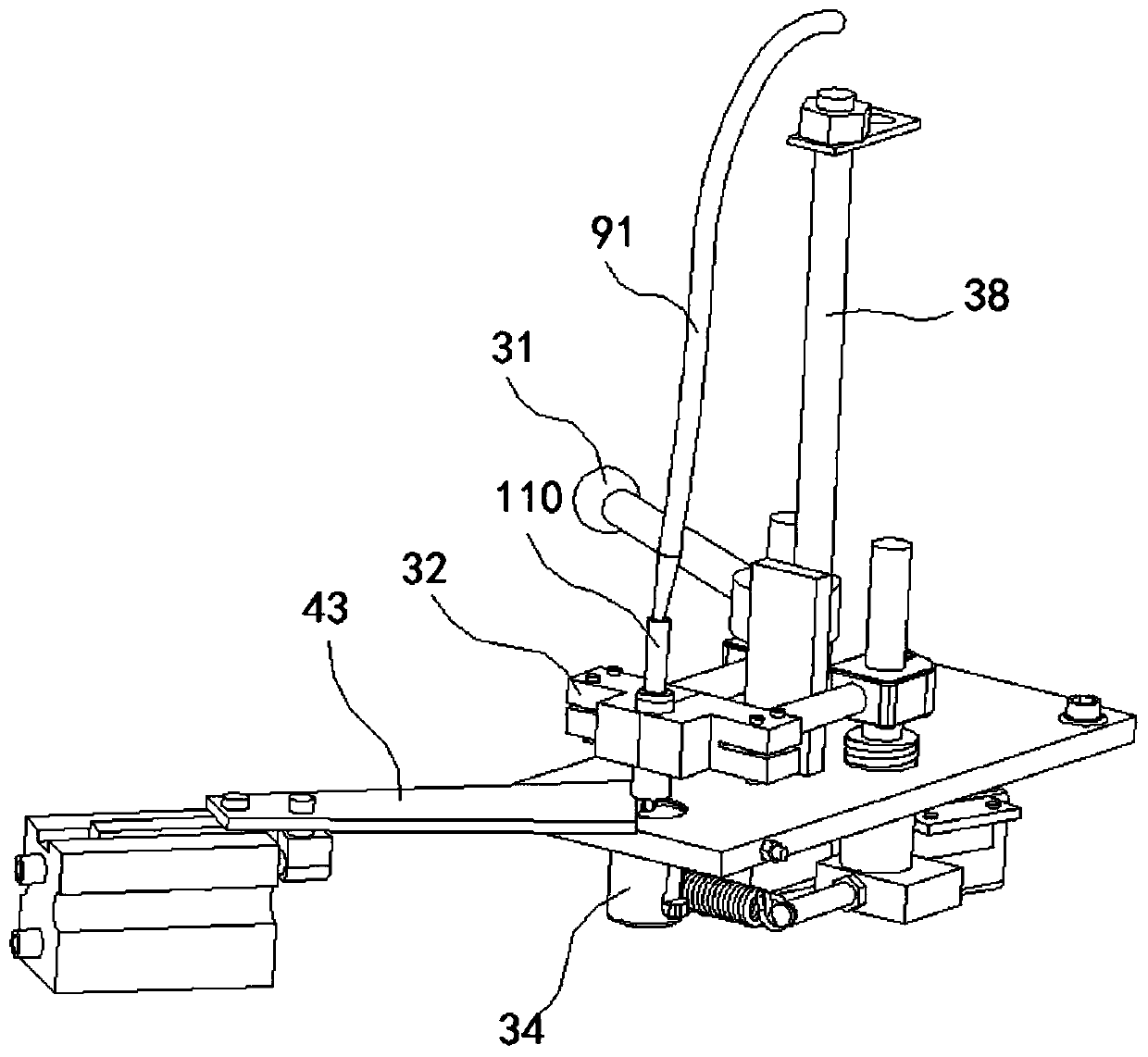

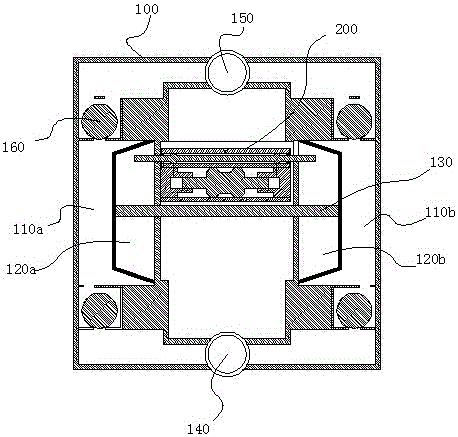

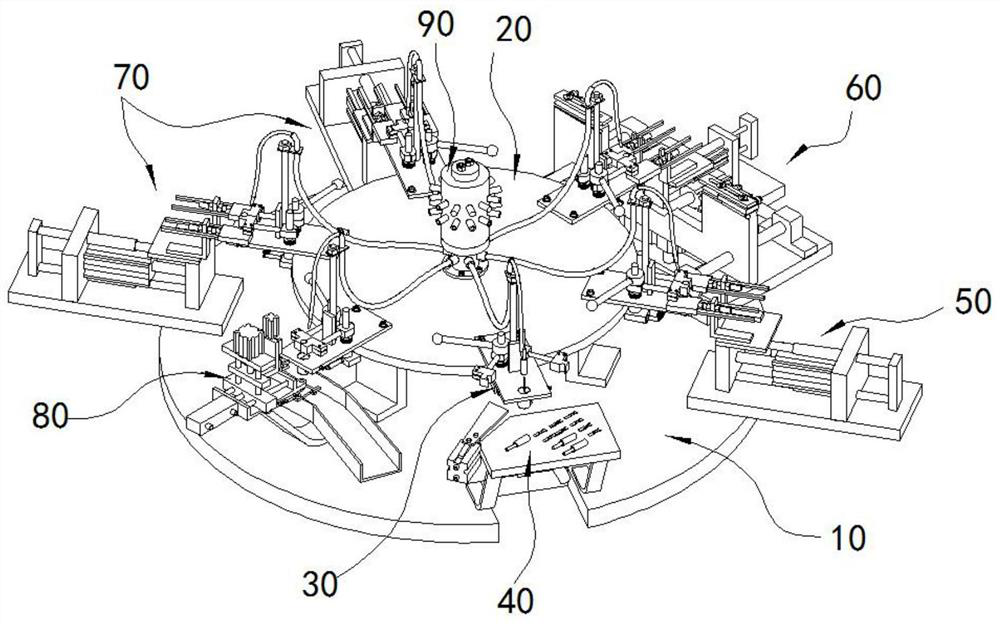

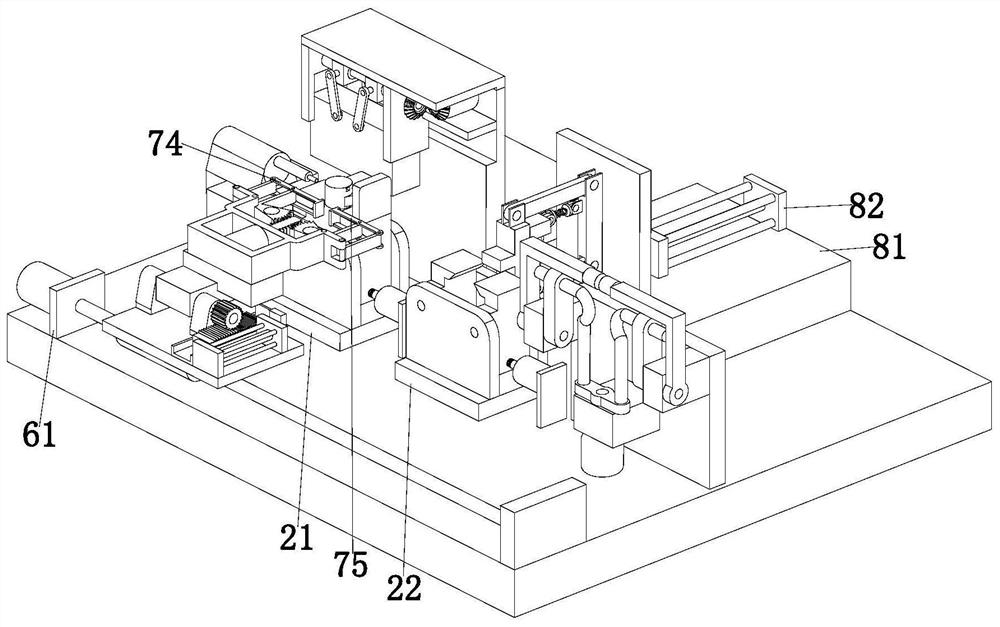

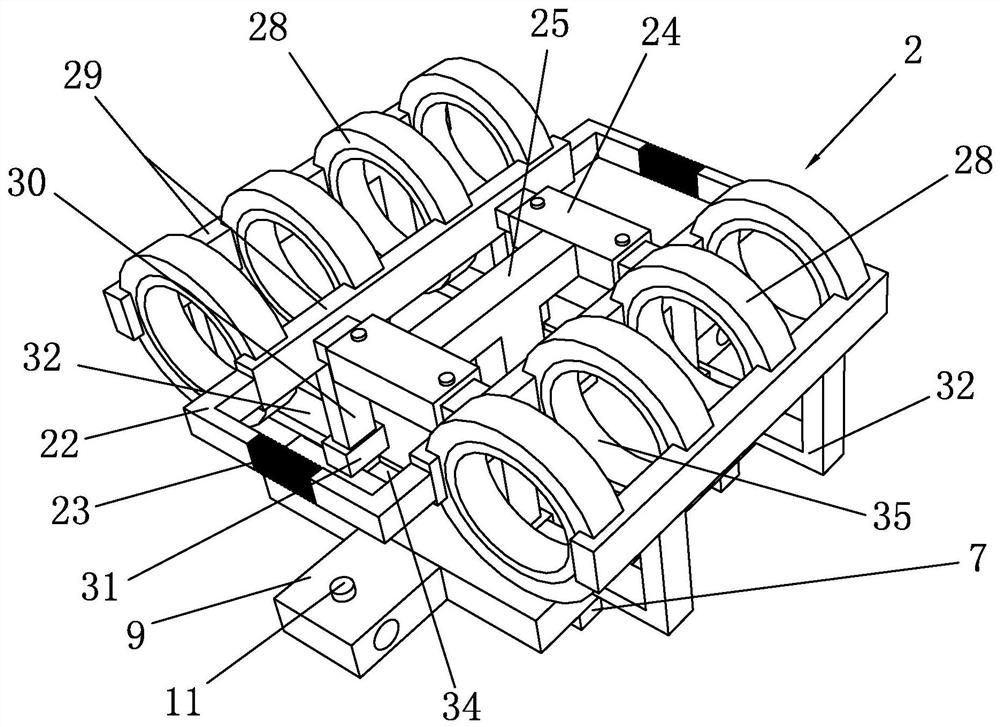

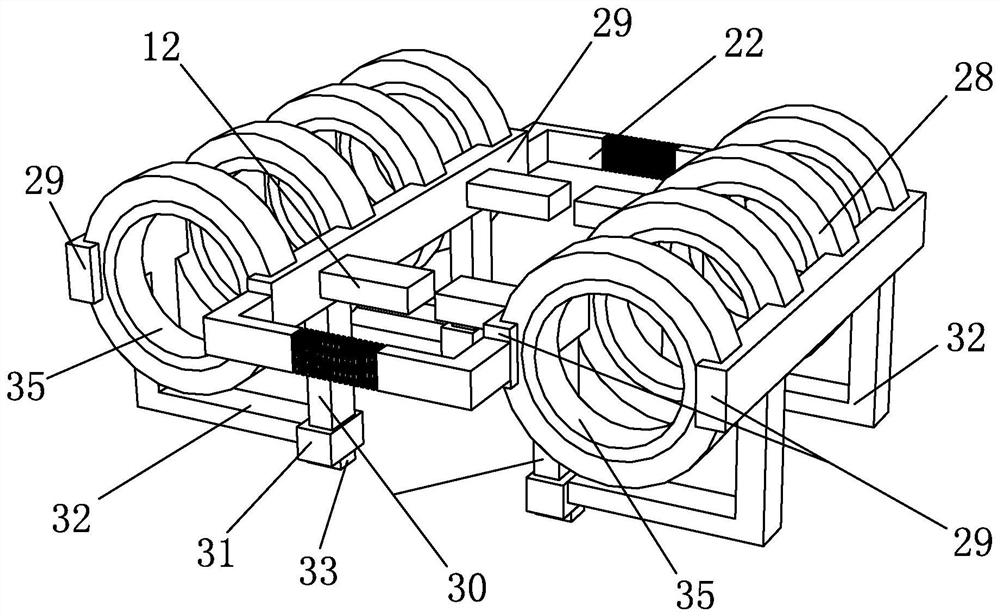

LED light source multi-station sealing and clamping machine

ActiveCN110645489APoor edge sealingPoor sealingSemiconductor devices for light sourcesProcess equipmentMechanical engineering

The invention discloses an LED light source multi-station sealing and clamping machine. The machine comprises a feeding mechanism, a preheating mechanism, a clamping and sealing mechanism, an annealing mechanism and a discharging mechanism, all of which are fixed to a rack and arranged right opposite to LED light source fixing mechanisms at a plurality of stations. The LED light source multi-station sealing and clamping machine aims to greatly improve the percent of pass and working efficiency by the adoption of improved sealing and clamping process equipment without being limited by existingtechnological knowledge.

Owner:贵州联尚科技有限公司

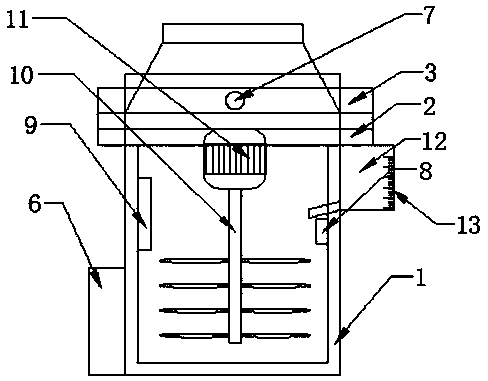

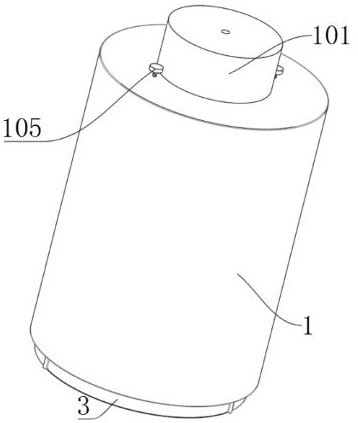

Initial fermenting barrel for enzyme

InactiveCN108485954AEasy to controlTimely processingBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholEngineering

The invention discloses an initial fermenting barrel for enzyme. The initial fermenting barrel comprises a barrel body, wherein the top end of the barrel body is fixedly connected with the bottom endof the sealing cover through an installation ring, a detection box is fixedly arranged outside of the sealing cover, an alcohol concentration detector probe is embedded at the lateral side of the bottom end of the sealing cover, a motor is fixedly arranged in the middle of the bottom end of the sealing cover, and a motor is in transmission connection with one end of a stirring paddle. The initialfermenting barrel disclosed by the invention can control a pipeline to be opened and closed through a control mechanism, a knob is rotated to drive a stopping plate to rotate in an arc sliding groove,and the pipeline can be controlled to be opened and closed; thus, the sugar feeding amount of a sugar storage box can be controlled; the detection box and the alcohol concentration detector probe areutilized to detect the alcohol concentration at the connection position; the alcohol concentration is displayed by the display end of an alcohol concentration detector; when the alcohol concentrationis too high, the airtightness is not good; the stirring paddle is driven by the motor to rotate to stir and mix fruits and sugar discontinuously, so that a contact area between the fruits and sugar is improved.

Owner:王岩

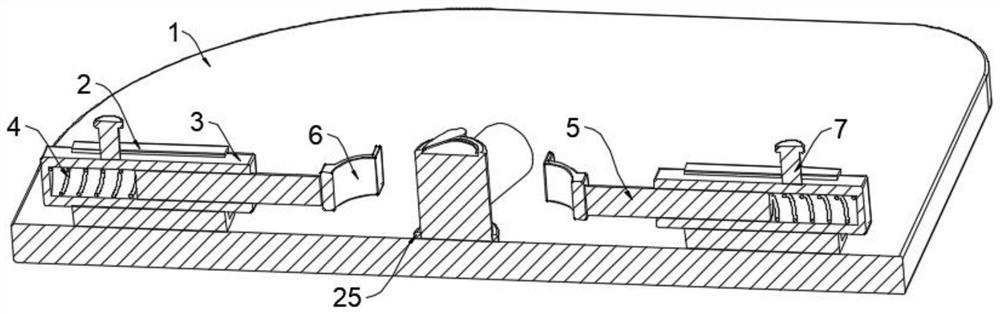

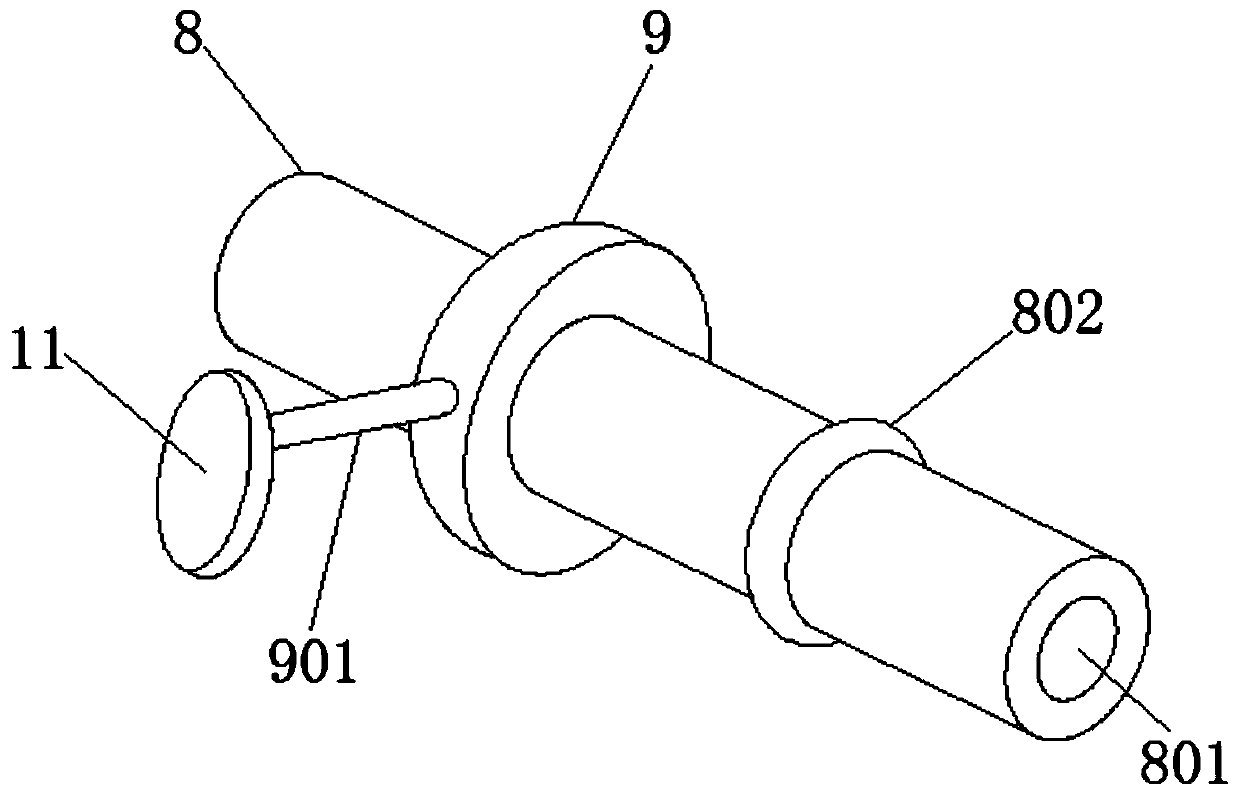

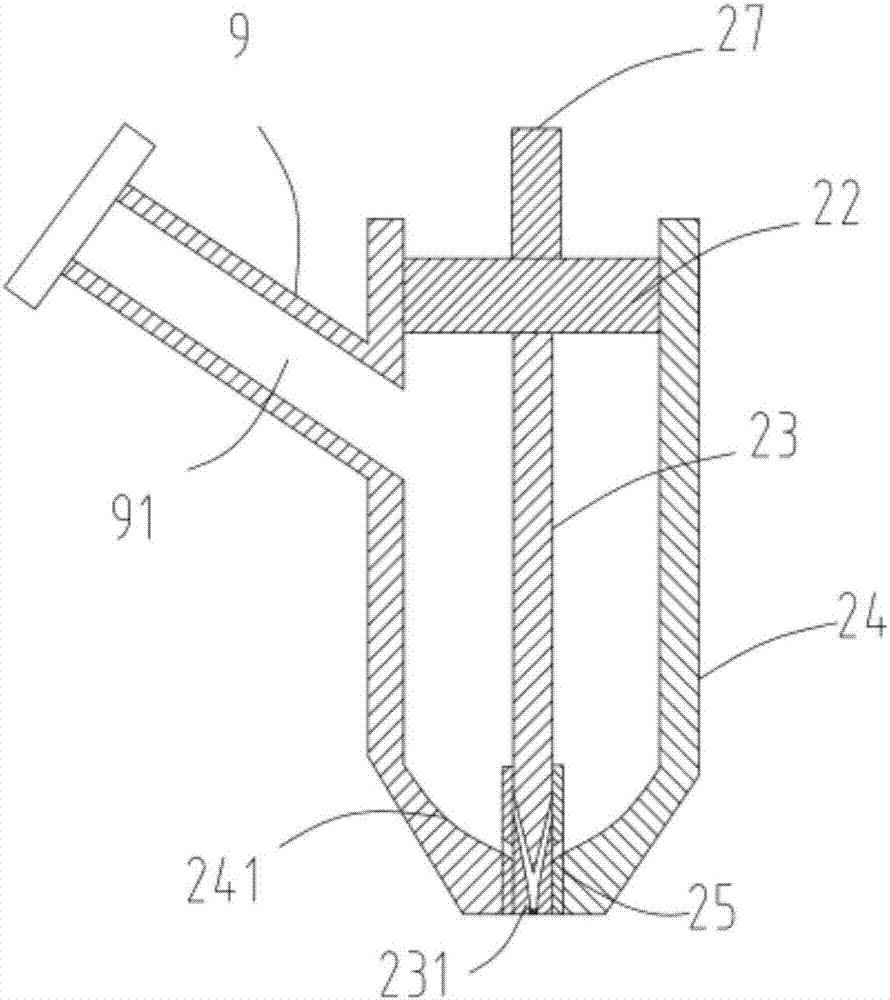

Blocking-prevention glue injection device of battery

ActiveCN105742726ACut off flowAvoid drippingFinal product manufactureCell sealing materialsColloidInjection device

The invention relates to a blocking-prevention glue injection device of a battery. The block-prevention glue injection device comprises a bearing table, a plurality of glue injection assemblies, a material tank and a supplied material assembly, wherein the plurality of glue injection assemblies are arranged in parallel at equal intervals, the material tank is used for storing colloid, a plurality of battery steel shells are carried in the supplied material assembly, the glue injection assemblies are in vertical correspondence to glue injection openings of the battery steel shells, each glue injection assembly comprises a power element, a press plate, a discharge rod, a glue injection barrel, and a material guide post, the press plate is arranged on a top rod of the power element, the discharge rod is arranged on the press plate, the material guide post sleeves the end part of the discharge rod, the discharge rod vertically slides relative to the inner wall of the material guide post, the material guide post is fixed on the glue injection barrel, a Y-shaped material guide hole is formed at the end part of the discharge rod, and a discharge hole is formed in the material guide post. By the blocking-prevention glue injection device, the problems that the mobility of the colloid is poor due to the influence of an external environment to further affect the tightness of the battery, generate a leakage phenomenon after injection completion and easily block an injection device during the glue injection process of the battery are solved.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

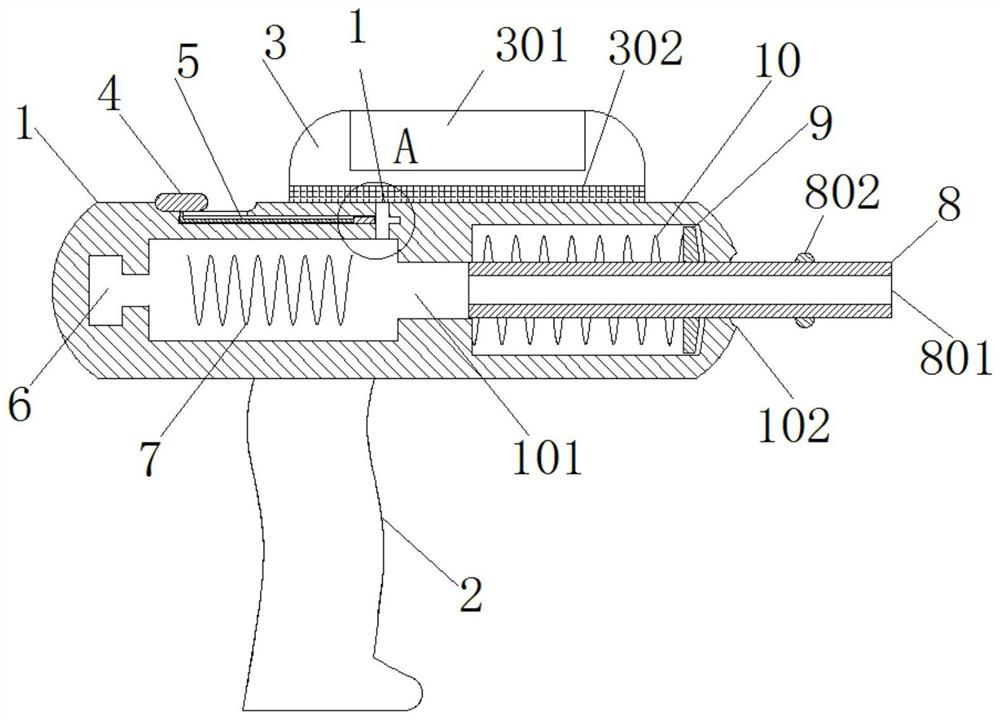

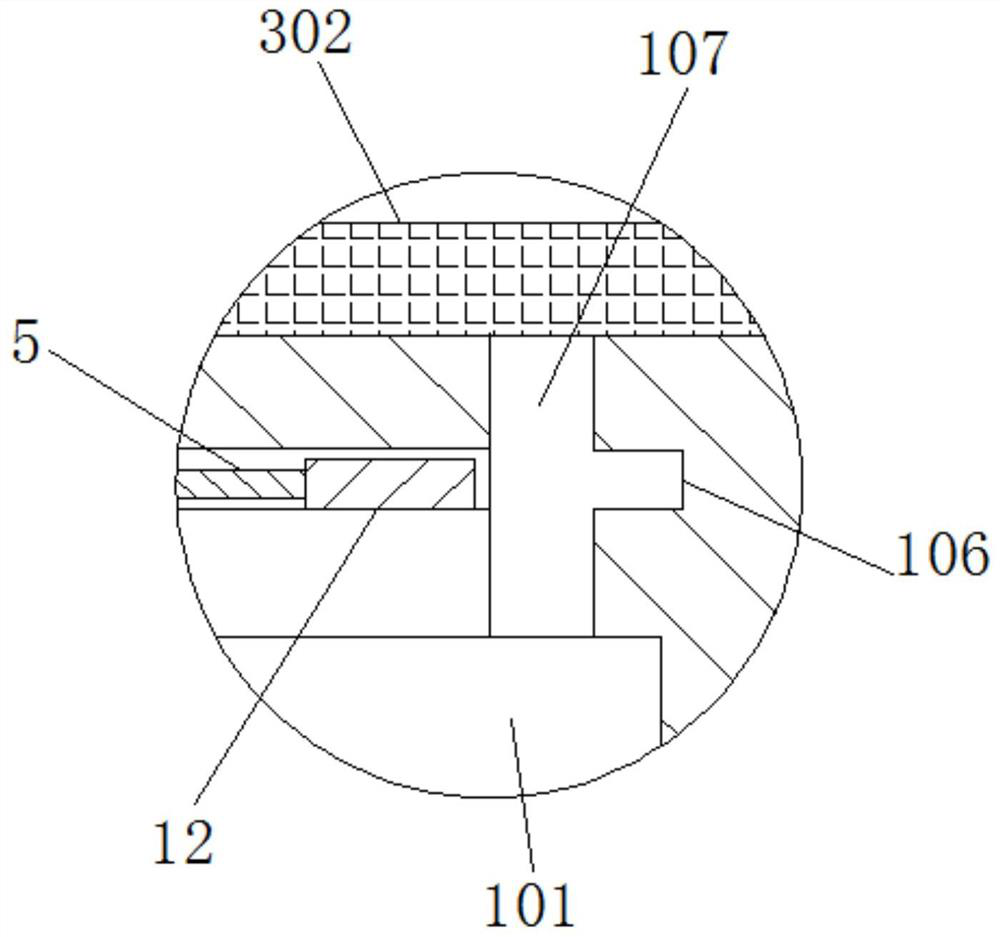

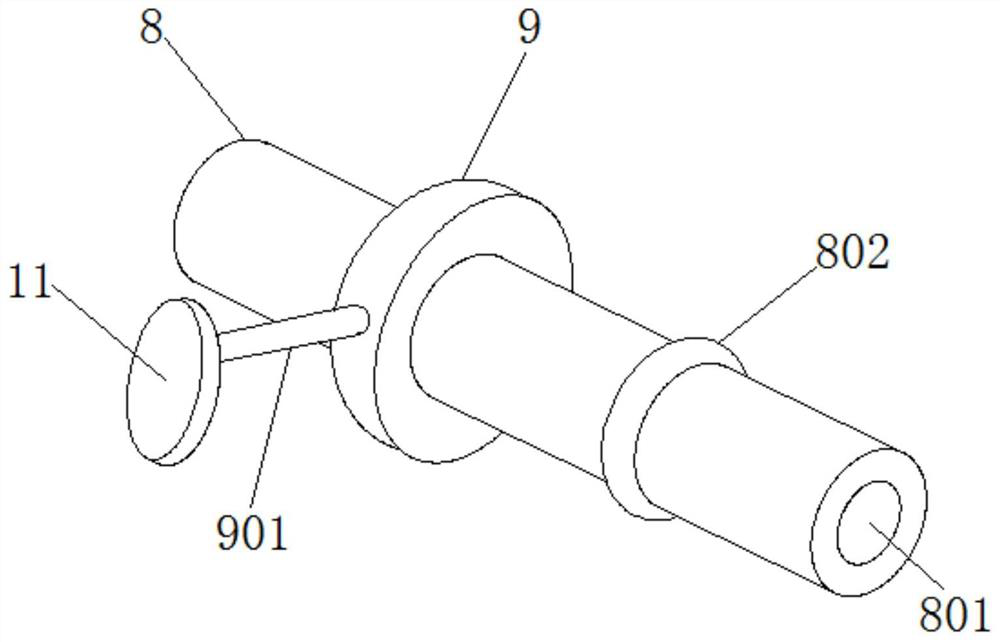

Pistol type welding gun equipment

The invention relates to the technical field of welding gun equipment, and discloses pistol type welding gun equipment. A gun body is included. The upper end of the gun body is connected with a preheating bin, the upper end of the gun body is connected with a sliding key, the lower end of the sliding key is connected with a push rod, and a fan is arranged in the gun body. The right side of the fanis provided with a heating metal wire, the right side of the heating metal wire is provided with a gun barrel, the left side of an arc circular stop block is connected with a compression spring, an indication disc is connected to one side of the arc circular stop block, and the right end of the push rod is connected with a sliding block. The heating metal wire is electrified and generates heat, the sliding key is moved to the left side of a second transverse arc groove, hot air can evenly heat plastics which are placed in a preheating bin and easily absorb moisture through a heat dissipationpad, the arc circular stop block drives the indication disc to leftwards slide in a first transverse arc groove through a connecting rod, a longitudinal line mark on the indication disc corresponds toa scale plate, and the structure solves the problems that since preheating is not conducted, the seal performance of a welding face is poor, and the pressure cannot be visually judged.

Owner:绍兴舟泽新材料股份有限公司

A battery uniform glue injection equipment

ActiveCN105789649BAvoid drippingReduce length of stayPrimary cell manufactureCell sealing materialsElectrical batteryInjection equipment

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

A new push-type faucet

InactiveCN104728490BExtended service lifeOpen quicklySpindle sealingsFluid-delivery valvesPilot holeEngineering

The invention belongs to the technical field of water faucet equipment, and in particular relates to a novel press type water faucet. The water faucet comprises a water faucet body, a water faucet body cover is fixedly connected with the water faucet body, a pilot rod is in clearance fit with the middle of the water faucet body, a threaded hole A is formed in the upper end face of the pilot rod, a press plate is arranged on the threaded hole A through a press plate fixing screw, and a reset spring is arranged between the lower surface of the press plate and the upper surface of the water faucet body cover; the pilot rod is fixedly connected with a pilot cylinder, a sealing cavity is formed inside the pilot cylinder, the interior of the sealing cavity is in clearance fit with a big piston, a big piston sealing ring is arranged between the big piston and a water outlet in a matched mode, the interior of the big piston is provided with a big piston inner cavity, and the big piston inner cavity is provided with a pilot hole; the lower end face of the pilot rod is provided with a threaded hole B, a pilot piston is arranged on the threaded hole B through a pilot piston fixing screw, and a pilot piston sealing ring is arranged between the pilot piston and the pilot hole in a matched mode.

Owner:UNIV OF JINAN

Distribution box sealing test device and test method

InactiveCN112683461APoor sealingImprove sealingDetection of fluid at leakage pointWater storageThermodynamics

The invention discloses a distribution box sealing test device and test method, and belongs to the field of distribution boxes. The distribution box sealing test device comprises: a sealing detection box; a water storage box, which is arranged at the upper end of the sealing detection box and used for spraying water into the sealing detection box; a mounting fixing frame, which is fixedly connected with the sealing detection box through a connecting shaft and is used for fixing a distribution box; a drive device; a slapping plate; a water collection tank; and a rotating shaft; the water storage box is arranged to perform spraying operation on the sealing detection box, the sealing performance of the distribution box in rainy days can be detected and simulated, meanwhile, the rotatable distribution box is arranged, the contact frequency of the distribution box and water is improved, the slapping plate is further arranged, water drops can be dispersed, and the sealing performance detection precision is improved; and the slidable water collection tank is further arranged, falling water can be collected, the sealing performance of the distribution box during soaking simulation is detected, the simulated detection environment is diversified, and the accuracy of the sealing performance detection result is improved.

Owner:杨慧中

Air flow through control valve

InactiveCN104806514BIncrease production costPoor sealingPositive displacement pump componentsFlexible member pumpsEngineeringAirflow

Owner:阜宁优越机械有限公司

A LED light source multi-station clamping machine

ActiveCN110645489BPoor edge sealingPoor sealingSemiconductor devices for light sourcesProcess equipmentMechanical engineering

The invention discloses an LED light source multi-station sealing and clamping machine. The machine comprises a feeding mechanism, a preheating mechanism, a clamping and sealing mechanism, an annealing mechanism and a discharging mechanism, all of which are fixed to a rack and arranged right opposite to LED light source fixing mechanisms at a plurality of stations. The LED light source multi-station sealing and clamping machine aims to greatly improve the percent of pass and working efficiency by the adoption of improved sealing and clamping process equipment without being limited by existingtechnological knowledge.

Owner:贵州联尚科技有限公司

Battery gluing device convenient to maintain

ActiveCN105789650ACut off flowAvoid drippingPrimary cell manufactureCell sealing materialsEngineeringInjection device

The invention relates to a battery gluing device convenient to maintain. The battery gluing device comprises a carrying platform, a plurality of gluing components, a storage tank and a feeding component. The gluing components are parallelly arrayed at equal intervals. The storage tank is used for storing glue. A plurality of steel battery shells are carried by the feeding component. Each gluing component comprises a power piece, a press plate, a discharge rod, a gluing barrel and a guide column. The press plates are arranged on ejection rods of the power pieces. The discharge rods are arranged on the press plates. The guide columns sleeve the ends of the discharge rods. The discharge rods slide up and down relative to the inner walls of the guide columns. The guide columns are fixed on the gluing barrels. Y-shaped guide holes are formed in the ends of the discharge rods. Discharge holes are formed in the guide columns. Ventilation pipelines communicated with the Y-shaped guide holes are arranged in the discharge rods. Electrical heating wires are arranged in hollow portions between the ventilation pipelines and the discharge rods. The battery gluing device has the advantages that the problems that during battery gluing, leakproofness of batteries is affected by low flowability caused by the fact that the glue is influenced by external environment, leakage exists after injection, injection devices are easy to block and injection channels are inconvenient to clean are solved.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

A battery glue injection equipment for convenient maintenance

ActiveCN105789650BCut off flowAvoid drippingPrimary cell manufactureCell sealing materialsElectrical batteryInjection equipment

The invention relates to a battery glue injection equipment for convenient maintenance, which includes a bearing table, several glue injection components arranged in parallel at equal intervals, a material tank for storing glue, and an incoming material component carrying several battery steel shells; the glue injection component includes Power part, pressure plate, discharge rod, glue injection barrel, material guide column; the pressure plate is set on the ejector rod of the power part; the discharge rod is set on the pressure plate; the material guide column is set on the end of the discharge rod, The rod slides up and down relative to the inner wall of the material guide column; the material guide column is fixed on the glue injection barrel; the end of the discharge rod is provided with a Y-shaped material guide hole; the material guide column is provided with a discharge hole; the inside of the discharge rod is provided with The ventilation pipe connected with the Y-shaped material guide hole; the hollow part between the ventilation pipe and the discharge rod is provided with a heating wire; the invention overcomes the problem that the flow of the colloid is affected by the external environment during the battery glue injection process and thus affects the battery. The tightness, leakage after injection, easy blockage of the injection device and inconvenient cleaning of the injection channel.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

Detection device of special clamping forceps for endoscope

InactiveCN112539898AEasy to check the tightnessImprove sealingMachine part testingFluid-tightness measurement using lightComputer hardwareMedicine

The invention discloses a detection device of special clamping pincers for an endoscope, and belongs to the field of special clamping pincers for endoscopes. The special clamping pincers comprises a detection table, a fixing device, a placing device, a light emitting machine, a photosensitive sensor, a turnover device, a clamping device, a locking performance detection device and a swing test device, the detection table is placed on the ground, the fixing device is installed on the detection table, the placing device is installed on the detection table, the light emitting machine is installedat the top of the detection table, the photosensitive sensor is installed on the fixing device, the turnover device is installed at the top of the detection table, the clamping device is installed onthe turnover device, the locking performance detection device is installed at the top of the detection table, the swing test device is installed at the top of the detection table, the fixing device isused for clamping to facilitate detection of special clamping pincers for an endoscope, the placing device is matched with the light emitting machine and the photosensitive sensor to perform tightness detection, the turnover device can turn over, the locking performance detection device can perform locking performance detection, and the swing test device can perform repeated opening and closing tests.

Owner:谢三保

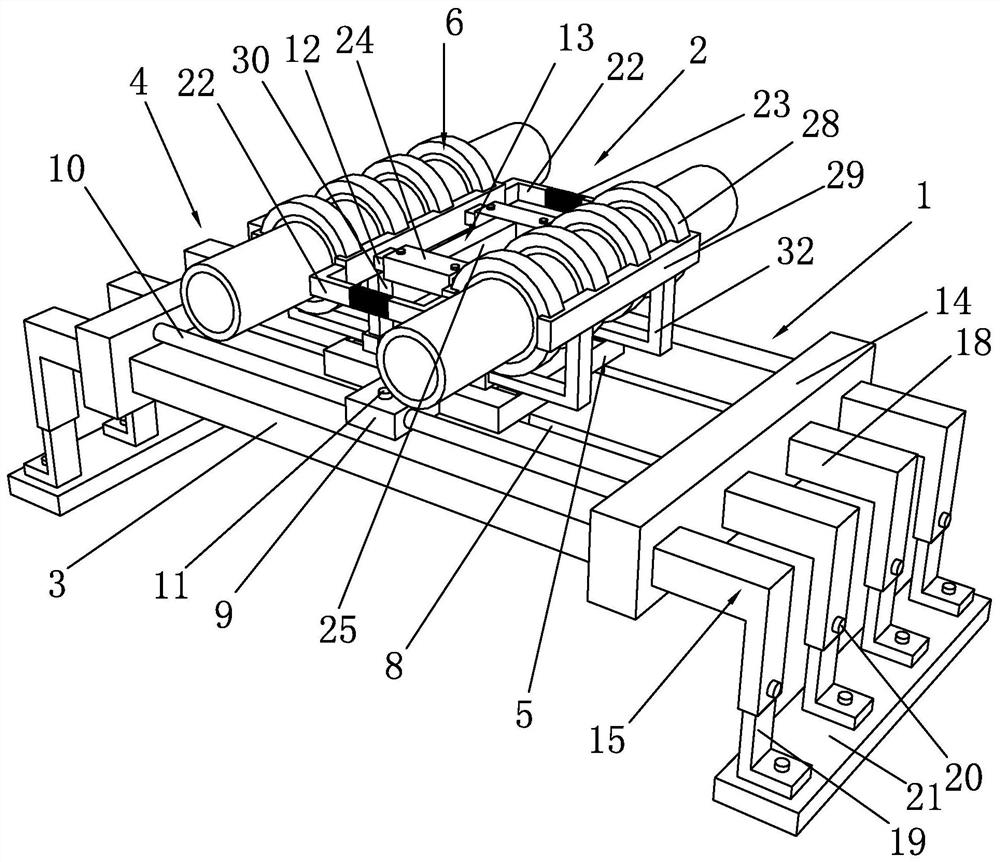

A pipe centering device for large-scale air purification equipment

ActiveCN109664226BHigh precisionEasy to dock and fixWork holdersMetal-working hand toolsButt jointAir purification

The invention discloses a pipeline centering device of a large-scale air purifying equipment. The pipeline centering device comprises a fixed support and a damping base, wherein the fixing support comprises a fixed bottom plate and side brackets; the damping base comprises a damping bottom plate and damping sleeve pipes, sliding blocks are arranged on the front side and the rear side of the damping bottom plate, and sliding rods are transversely arranged in the sliding blocks in a penetrating mode, an adjusting frame is arranged between the two damping sleeves, and the bottom of the adjustingframe is slidably clamped on the top surface of the damping bottom plate. According to the device, the centering accuracy between the two pipelines can be effectively ensured, so that the follow-up horizontal connection and fixation between the two pipelines are facilitated, the tightness property of the pipeline after being connected is improved, and meanwhile, the centering device can also playa damping effect, the mechanical vibration transmitted by the pipeline has a good isolation effect, and the effect of reducing noise inside the pipeline is greatly achieved, and the damping effect ofthe centering device can also be used for avoiding serious staggered edges of the pipeline butt joint due to shaking of the pipeline in the pipeline butt joint process, and the operation difficulty ofpipeline butt joint is lowered.

Owner:泰州市津达电子科技有限公司

A kind of pistol type welding torch equipment

Owner:绍兴舟泽新材料股份有限公司

A battery rapid injection equipment

ActiveCN105703020BCut off flowAvoid drippingPrimary cell manufactureFinal product manufactureColloidEngineering

The invention relates to a battery rapid glue injection equipment, which includes a bearing platform, several glue injection components arranged in parallel at equal intervals, a material tank for storing glue, and an incoming material component carrying several battery steel shells. The glue injection opening of the battery steel case corresponds vertically; the glue injection assembly includes a power part, a pressure plate, a discharge rod, a glue injection barrel, and a material guide column; the pressure plate is arranged on the ejector rod of the power part; The rod is set on the pressing plate; the material guide column is sleeved on the end of the discharge rod, and the discharge rod slides up and down relative to the inner wall of the material guide column; the material guide column is fixed on the glue injection barrel; the discharge rod The end of the Y-shaped material guide hole is provided; the material guide column is provided with a discharge hole; the invention overcomes the fact that the colloid is largely affected by the external environment during the battery glue injection process, which makes the flow worse and affects the battery life. Sealing, there is a problem of dripping after injection.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

Drip-proof battery gel-injection equipment

ActiveCN105870396AGood effectIncreased cross-sectional areaCell component detailsInjection equipmentEngineering

The invention relates to drip-proof battery gel-injection equipment, which comprises a bearing platform, a plurality of gel-injection assemblies, a charging bucket and a material feeding assembly, wherein the plurality of gel-injection assemblies are arranged in parallel at equal intervals; the charging bucket is used for storing gel; the material feeding assembly carries a plurality of steel battery shells; the gel-injection assemblies vertically correspond to gel-injection openings of the steel battery shells; each gel-injection assembly comprises a power part, a pressure plate, a discharge rod, a gel-injection barrel and a material guide post; each pressure plate is arranged on a push rod of the corresponding power part; each discharge rod is arranged on the corresponding pressure plate; each material guide post sleeves the end part of the corresponding discharge rod; each discharge rod slides up and down relative to the inner wall of the corresponding material guide post; each material guide post is fixed on the corresponding gel-injection barrel; a W-shaped guide hole is formed in the end part of the each discharge rod; and a discharge hole is formed in each material guide post. By the drip-proof battery gel-injection equipment, the problems that the mobility of the gel becomes poor to affect the air-tightness of a battery due to a relatively great influence from the external environment in the battery gel-injection process, the gel-injection process is slow, the residual gel in a gel-injection head leaks outside after injection is completed and an injection device is easily blocked are solved.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com