Integrated vending machine and working method thereof

A vending machine and cargo channel technology, applied in the field of integrated vending machines, can solve the problems of low strength, occupying the upper and lower space of the vending machine, and unable to place machines, etc., and achieves strong thermal insulation performance, thin box thickness, and improve production The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

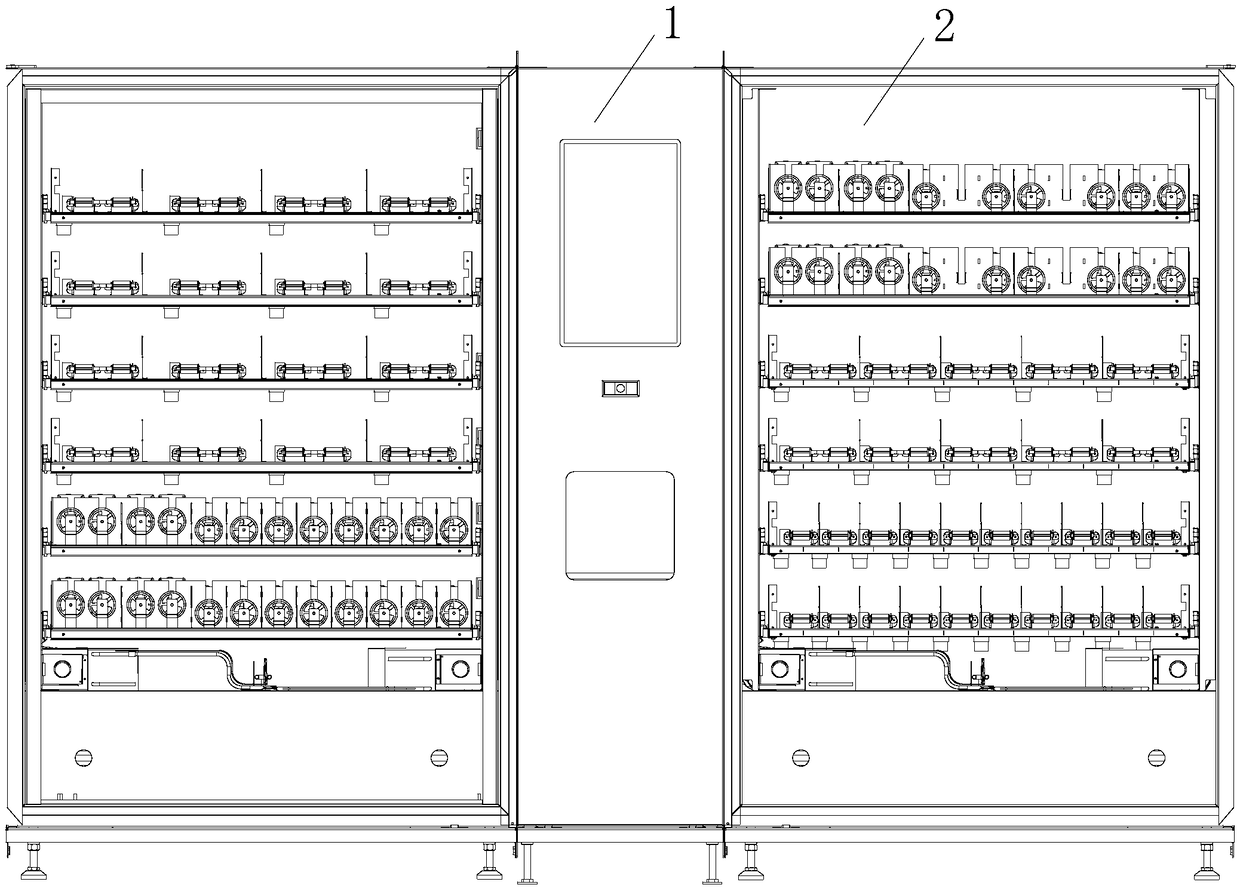

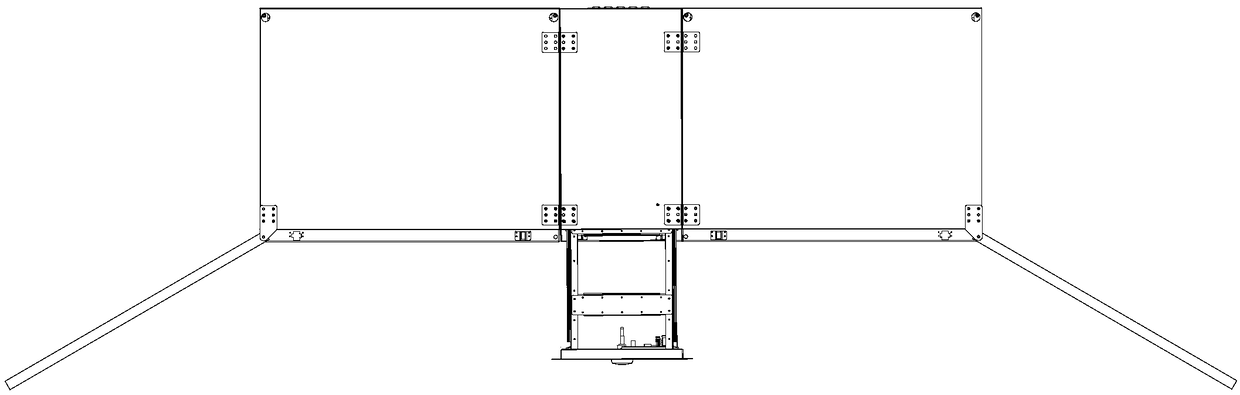

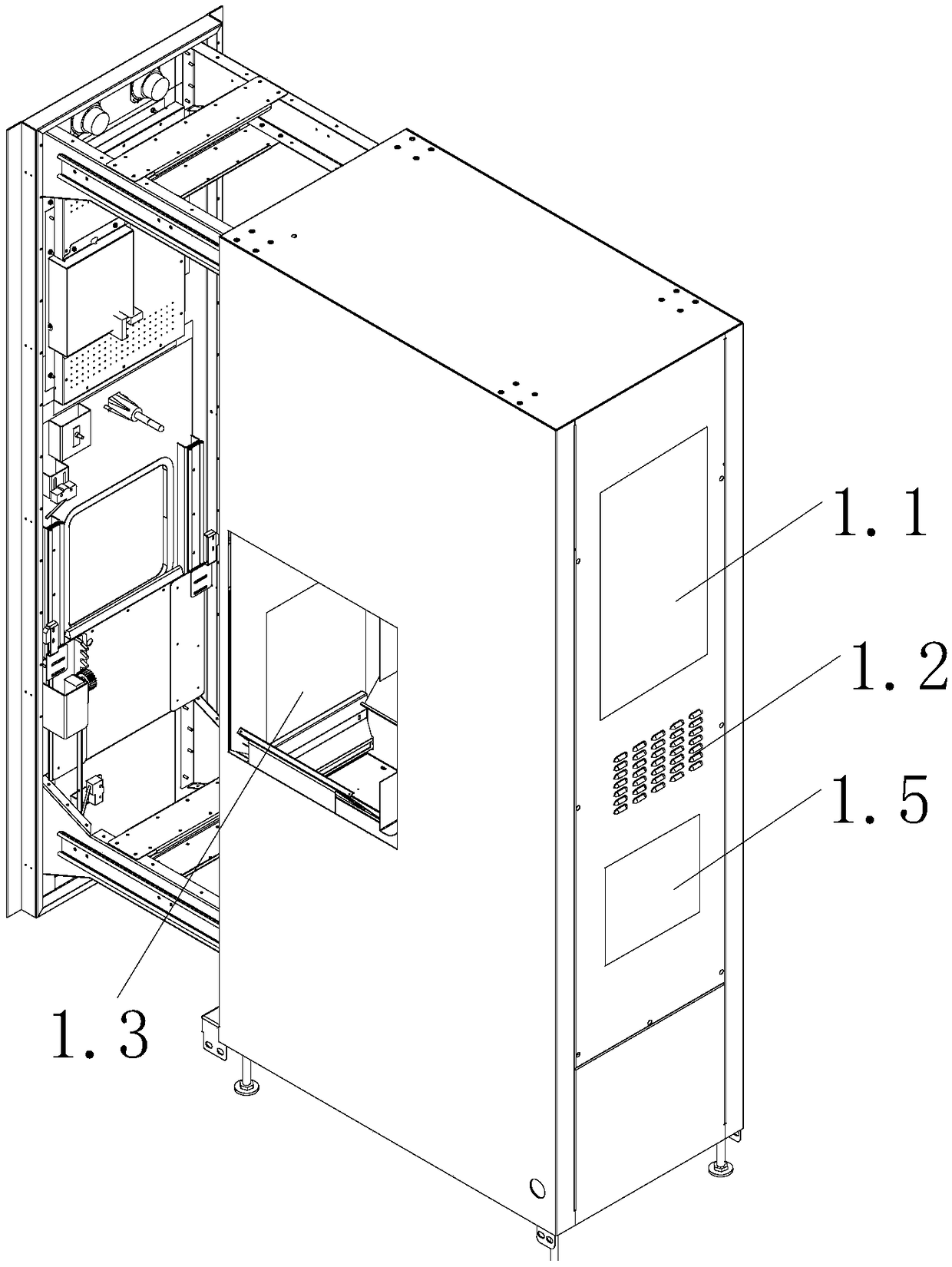

[0033] see Figure 1 to Figure 11 , The present invention relates to a comprehensive vending machine, comprising a central control box assembly 1 in the middle and a vending machine body 2 on the left and right sides.

[0034]The central control box assembly 1 is equipped with a control system inside, and the control system is used to obtain product information that customers need to purchase, and simultaneously control the shipment of vending machines on the left and right sides. The front side of the central control box assembly 1 is provided with Touch screen 1.1, and commodity button 1.2 can also be set under touch screen 1.1, and commodity button 1.2 can play the effect of standby selection commodity, and the left and right sides of described central control box component 1 are provided with a central control box inlet 1.3 respectively, and described The central control box inlet 1.3 is connected with the vending machine outlet 2.4 of the vending machine body 2, and is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com