Battery gluing device convenient to maintain

A technology of glue injection and battery, applied in the field of battery glue injection equipment, can solve the problems of affecting the sealing performance of the battery, easy blockage of the injection device, inconvenient cleaning of the injection channel, etc., so as to avoid the wire drawing phenomenon and achieve the effect of good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

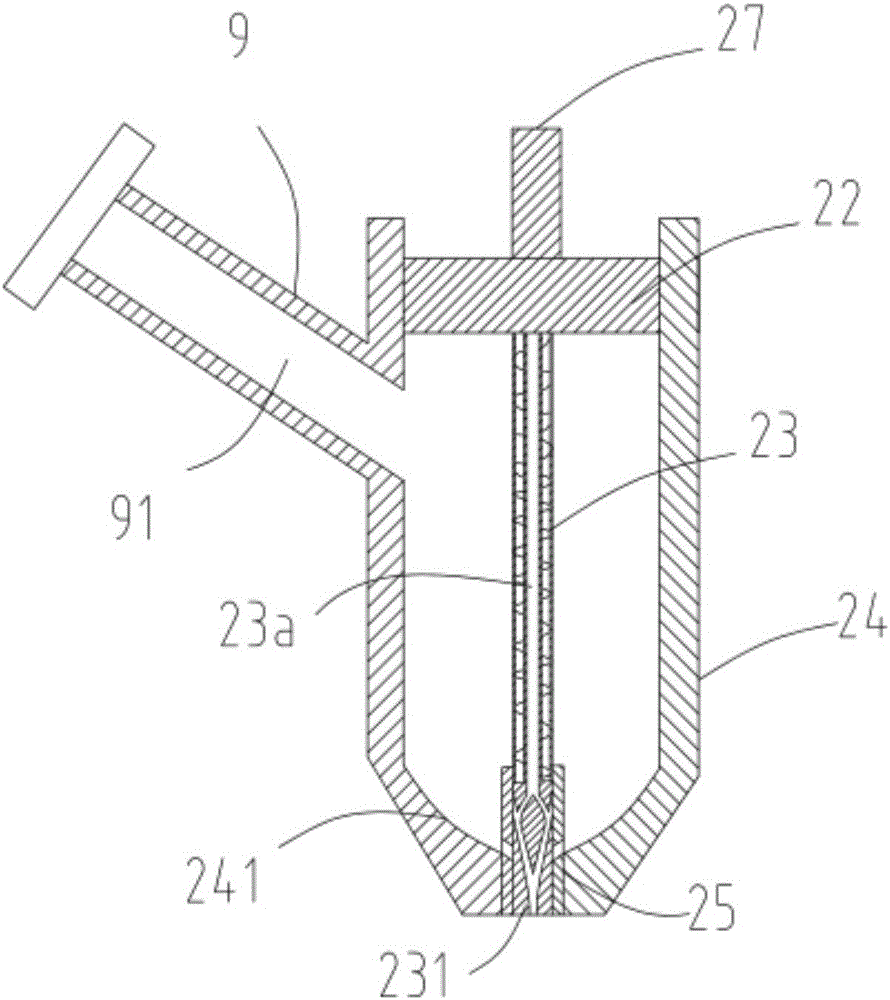

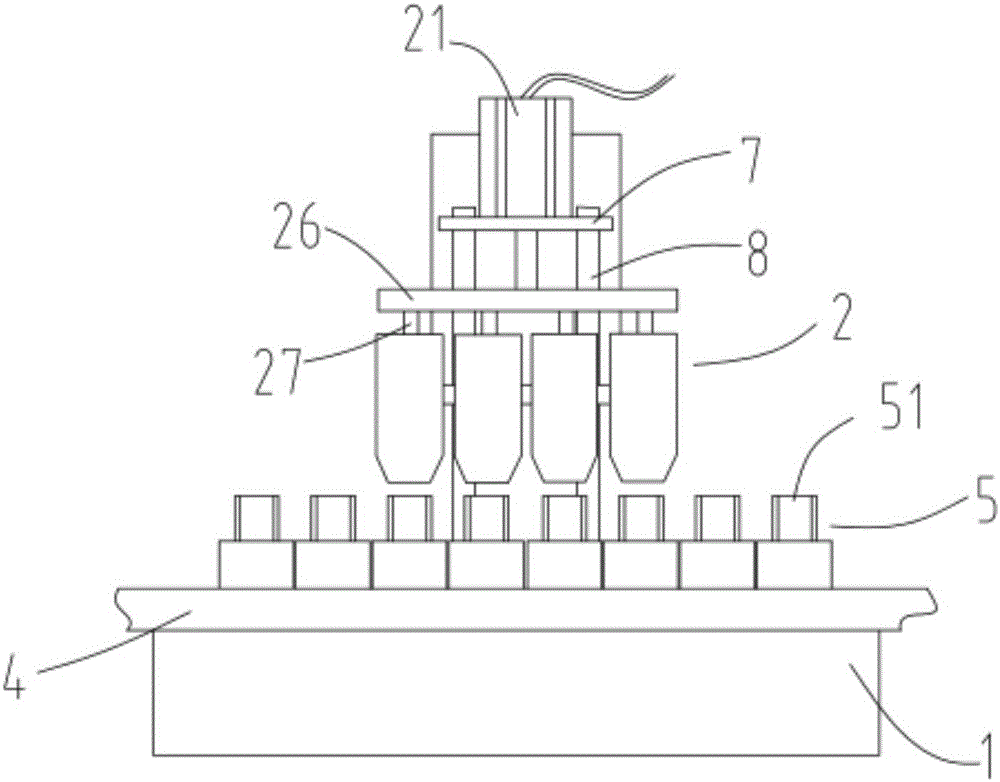

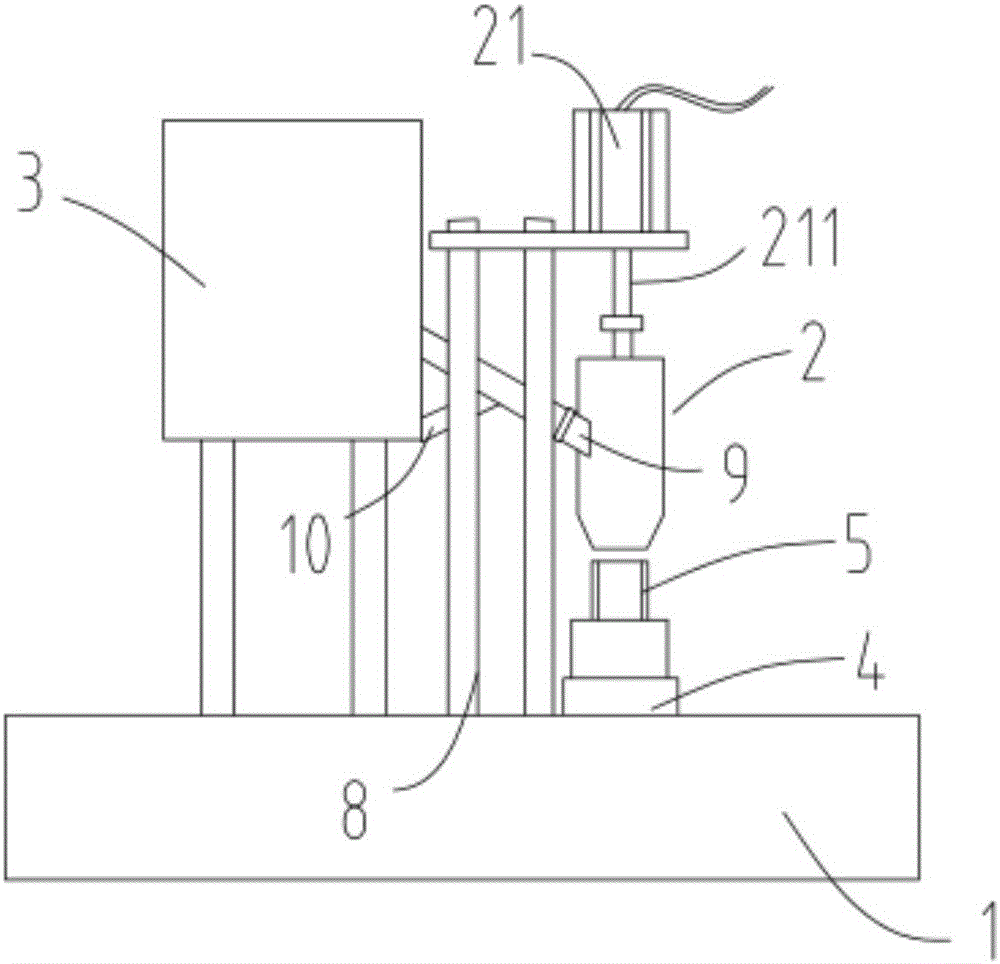

[0038] figure 1 It is a structural schematic diagram of the glue injection component part of a battery glue injection equipment for easy maintenance, figure 2 It is a schematic diagram of the front structure of a convenient maintenance battery glue injection equipment, image 3 It is a side-view structural schematic diagram of a battery glue injection equipment for easy maintenance, Figure 4 It is a structural schematic diagram of the end of the discharge rod and the guide column of a conveniently maintained battery glue injection equipment, Figure 5 A schematic diagram of the side section structure of the end of the discharge rod and the guide column of a conveniently maintained battery glue injection equipment, Image 6 It is a structural schematic diagram of the material tank of a convenient maintenance battery glue injection equipment. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6As shown, a battery glue injection equipment for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com