Blocking-prevention glue injection device of battery

An anti-clogging and glue injection technology, which is applied in the direction of alkaline batteries, battery pack parts, battery boxes/coats, etc., can solve the problems of affecting the sealing of batteries and easy clogging of injection devices, so as to avoid wire drawing and achieve good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

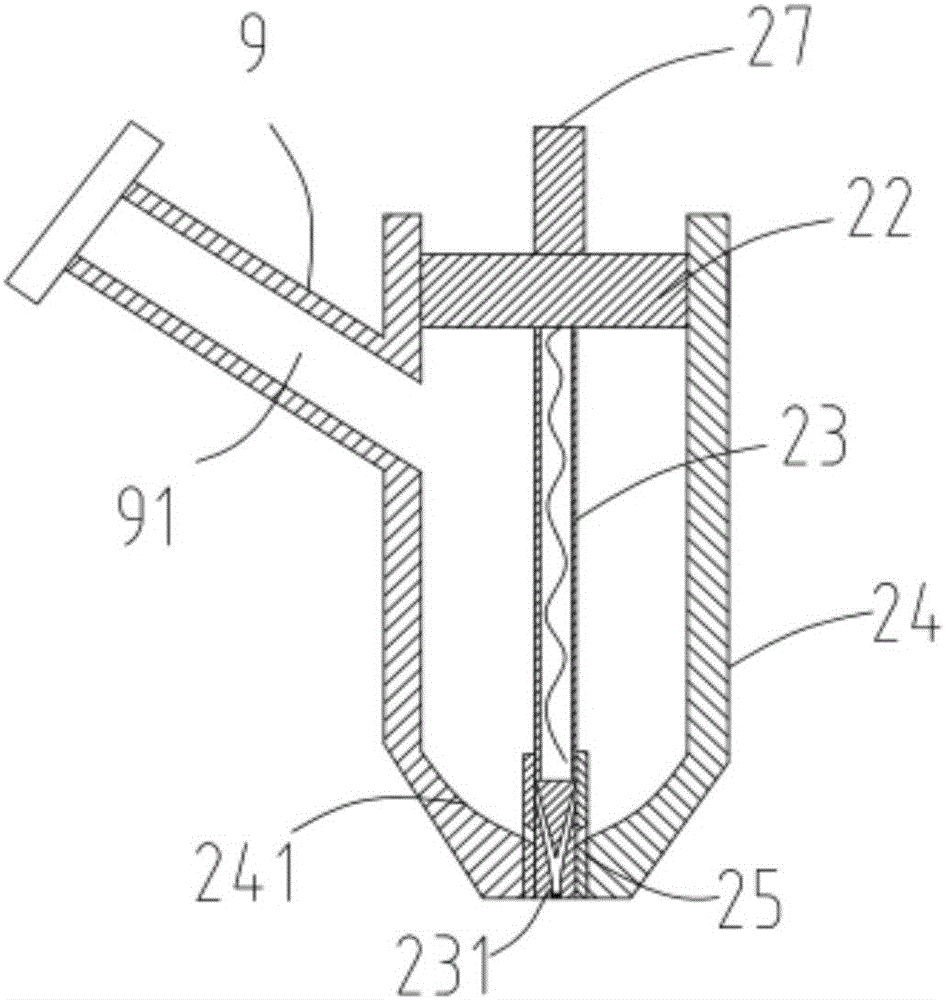

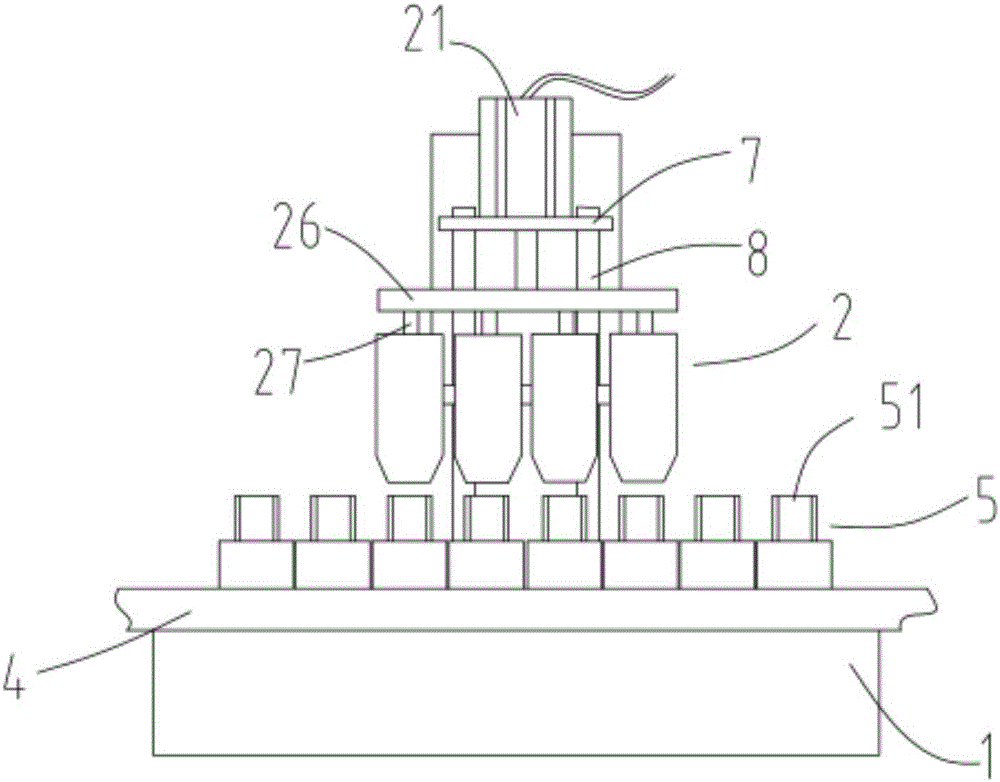

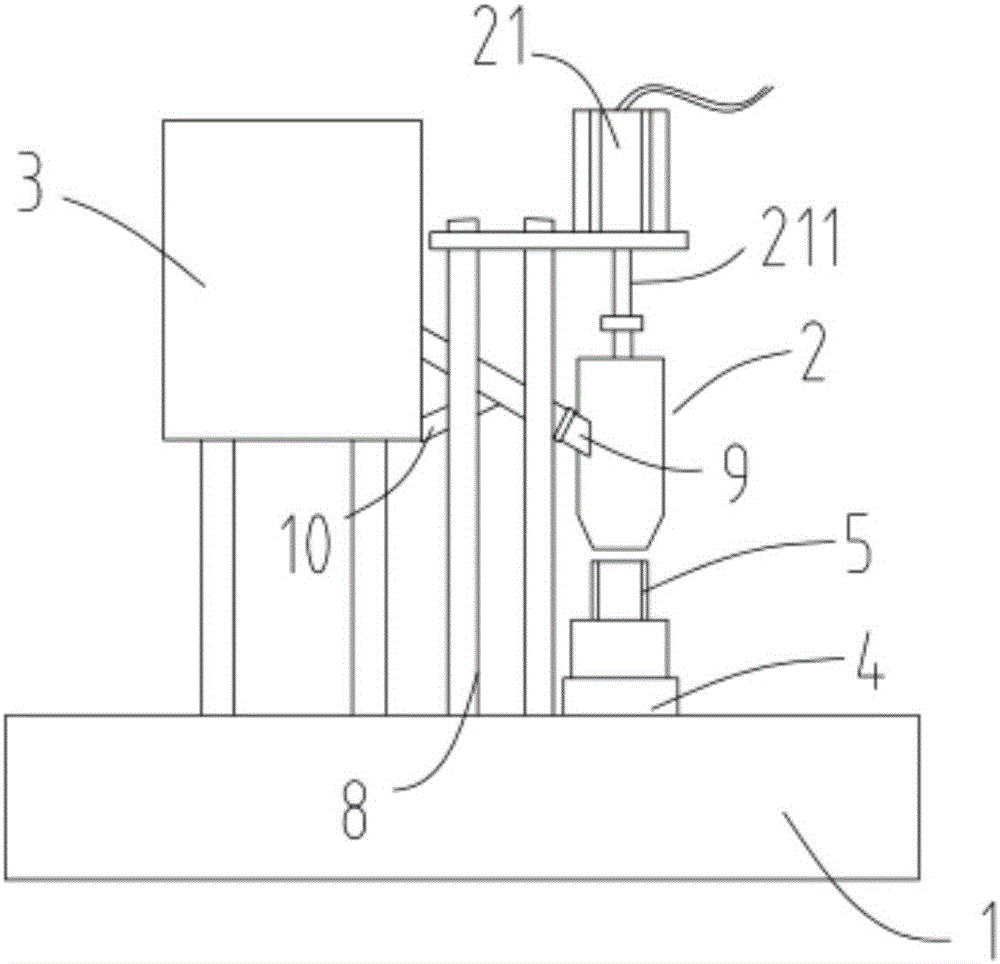

[0036] figure 1 It is a schematic diagram of the partial structure of the glue injection component of an anti-blocking battery glue injection equipment, figure 2 It is a front view structural schematic diagram of an anti-clogging battery glue injection equipment, image 3 It is a side view structural schematic diagram of an anti-clogging battery glue injection equipment, Figure 4 It is a structural schematic diagram of the end of the discharge rod and the material guide column of an anti-blocking battery glue injection equipment, Figure 5 It is a structural schematic diagram of a material tank of an anti-clogging battery glue injection equipment. Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown in the figure, an anti-clogging battery glue injection equipment includes a loading platform 1, several glue injection assemblies 2 arranged in parallel at equal intervals, a material tank 3 for storing glue, and an incoming material assembly 4 carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com