Drip-proof battery gel-injection equipment

An anti-drip and glue injection technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of slow glue injection process, dripping to the outside of injection devices, affecting battery sealing, etc. The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

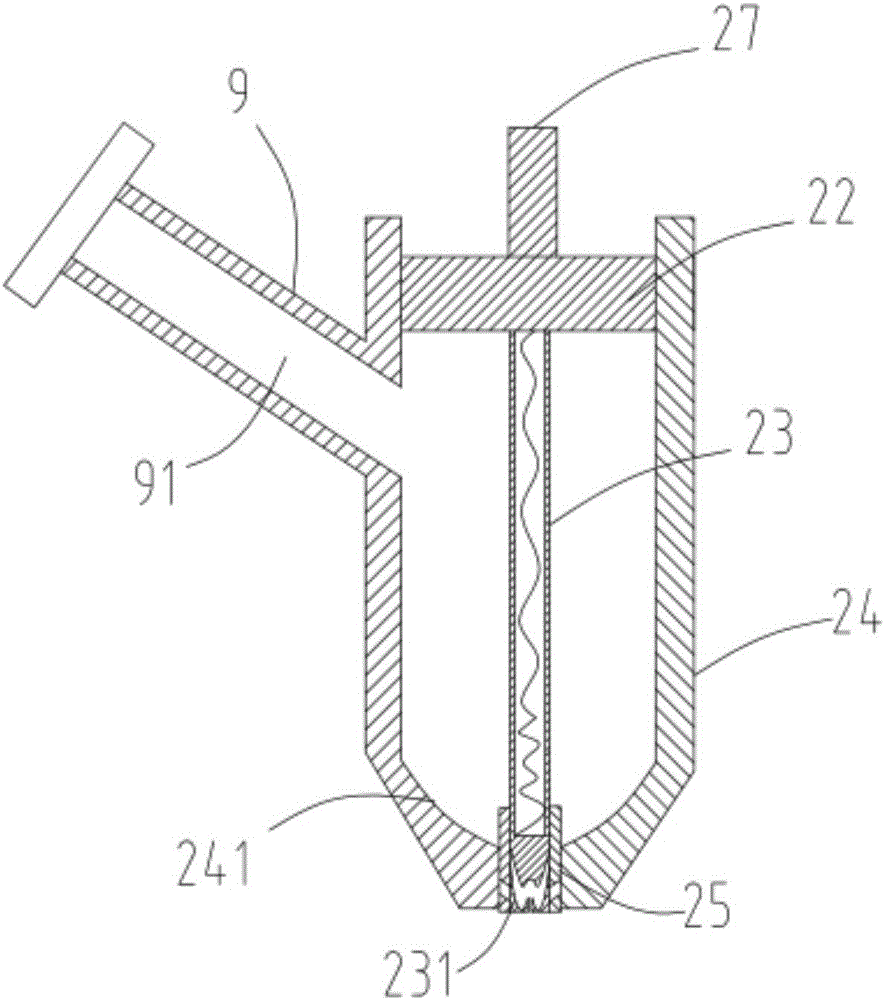

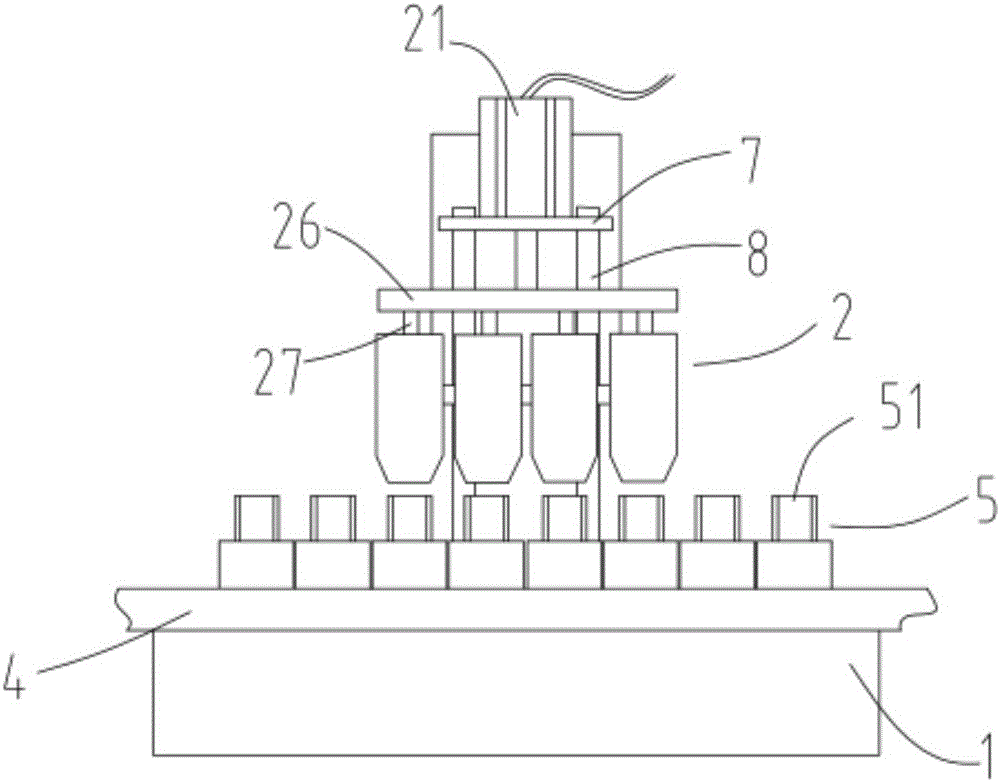

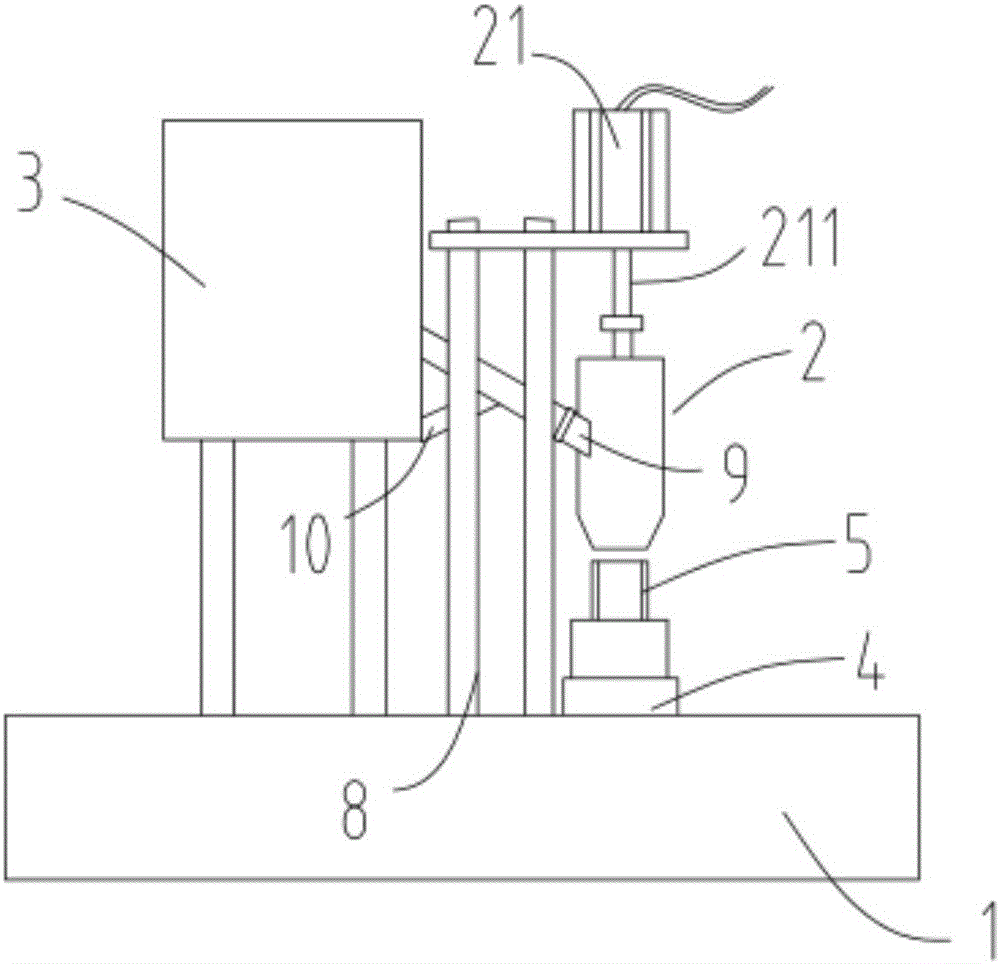

[0038] figure 1 It is a structural schematic diagram of the glue injection component part of an anti-drip battery glue injection equipment, figure 2 It is a schematic diagram of the front structure of an anti-drip battery glue injection equipment, image 3 It is a side-view structural schematic diagram of an anti-drip battery glue injection equipment, Figure 4 It is a structural schematic diagram of the end of the discharge rod and the guide column of an anti-drip battery glue injection equipment, Figure 5 It is a structural schematic diagram of a material tank of an anti-drip battery glue injection equipment. Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5As shown in the figure, an anti-drip battery glue injection equipment includes a loading platform 1, several glue injection assemblies 2 arranged in parallel at equal intervals, a material tank 3 for storing glue, and an incoming material assembly 4 carrying several battery steel shells 5, The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com