Heat exchanger for a motor vehicle

A technology for heat exchangers and automobiles, applied in heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

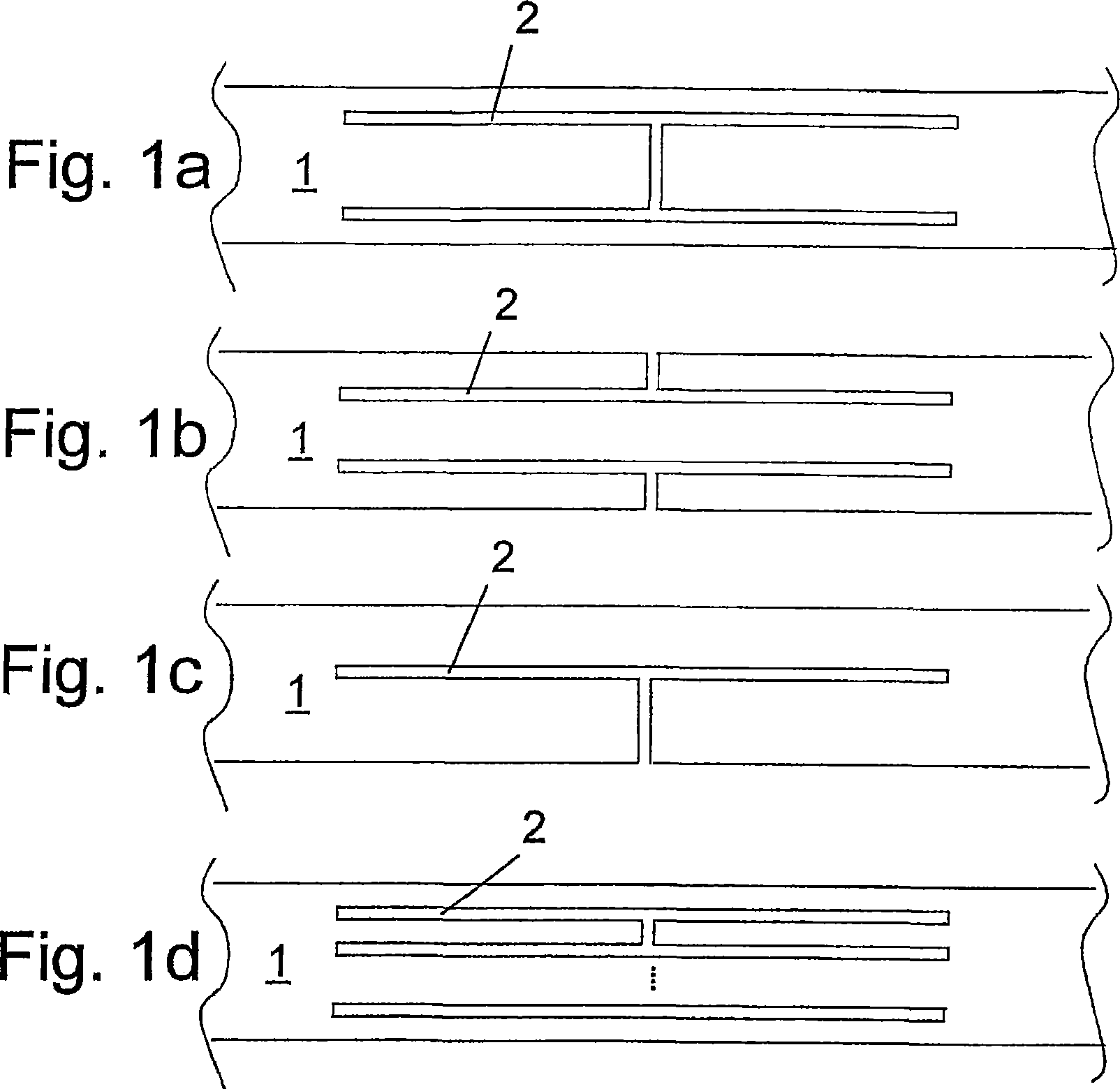

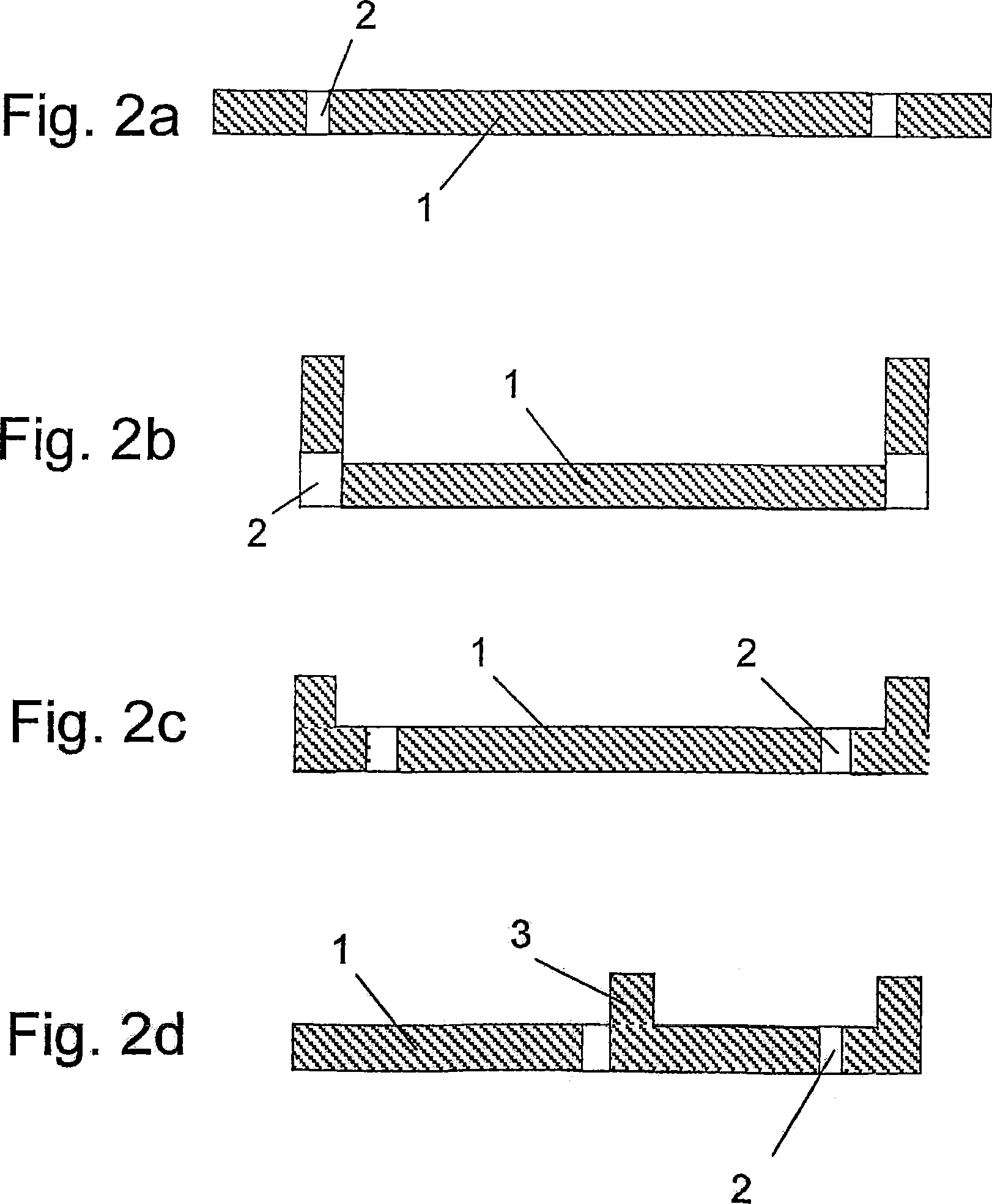

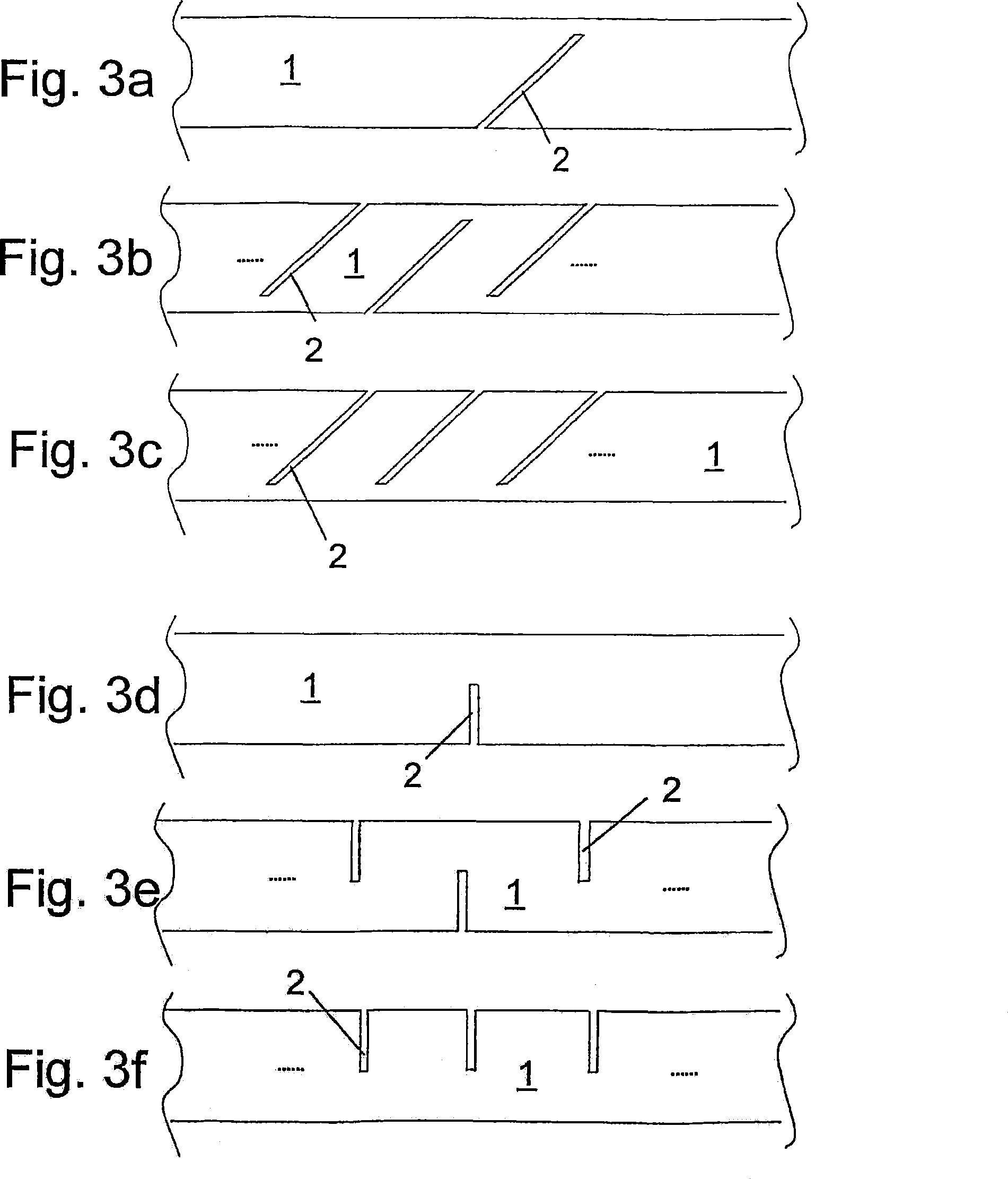

[0026] The heat exchanger, here the charge air cooler of the motor vehicle, only parts of the side plate 1 are shown in the figures. According to this embodiment, the heat exchanger has two collecting tanks formed by basin-shaped tank elements and tube sheets, a plurality of open tubes whose ends are inserted into the tube sheets, and corrugations arranged between the tubes. fins. The side plates 1 are arranged on the outside between the collecting tanks, for which purpose they are fixedly connected to the collecting tanks and not directly connected to tubes and / or corrugated fins. The individual parts of the heat exchanger are brazed to one another in a known manner, preferably in one brazing process, or are fixedly connected to one another in another way.

[0027] In order to keep the stresses between the tube plate and especially the outer tubes as low as possible at the start of operation or when the load on the charge air cooler starts to increase, corresponding springs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com