Distribution box sealing test device and test method

A technology of test device and distribution box, which can be used in the use of liquid/vacuum for liquid tightness measurement, by detecting the appearance of fluid at the leak point, etc. Problems such as damage to electrical components of the electric box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

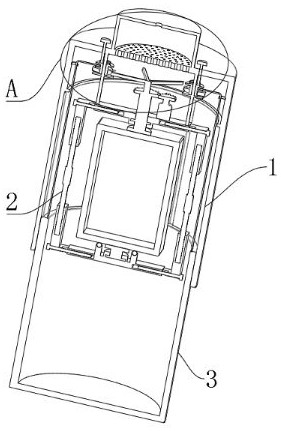

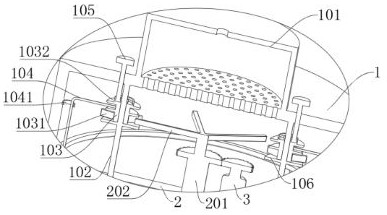

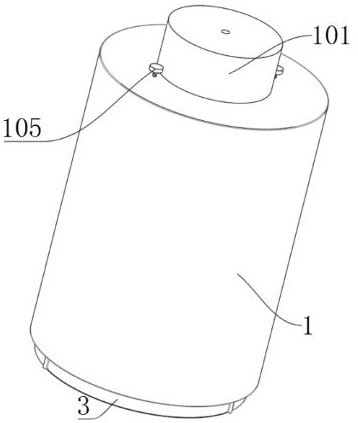

[0036] refer to Figure 1-6 , a distribution box leak test device, comprising: a seal detection box 1; a water storage tank 101, arranged on the upper end of the seal test box 1, for spraying water into the seal test box 1; The box 1 is fixedly connected through the connecting shaft 102, and is used to fix the distribution box; wherein, the installation fixture 2 is provided with a turret 201 that is adjacent to the distribution box, and the turret 201 is symmetrically arranged on the upper and lower sides of the distribution box, and The turret 201 is rotatably connected to the mounting bracket 2; the driving device is used to drive the turret 201 to rotate, and the driving device includes a driving motor 4, and the rotating end of the driving motor 4 is meshed with the connecting shaft 102 through a gear; the beating plate 202, There are five groups, all of which are fixedly connected to the upper turret 201 and are located at the lower end of the water storage tank 101; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com