Initial fermenting barrel for enzyme

A fermentation barrel and enzyme technology, applied in the field of fermentation barrels, can solve the problems of difficulty in controlling the amount of sugar added, fermentation failure, poor sealing, etc., and achieve the effects of convenient control, improved fermentation efficiency, and increased contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

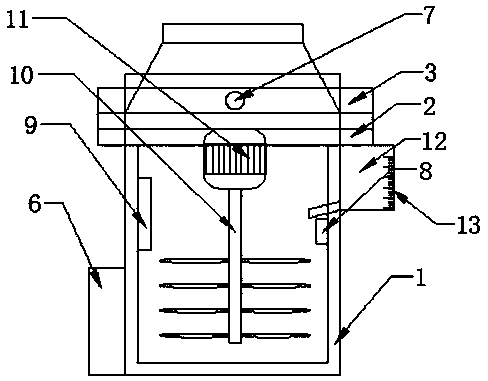

[0023] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

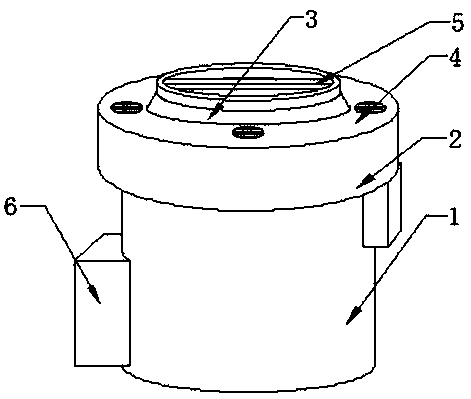

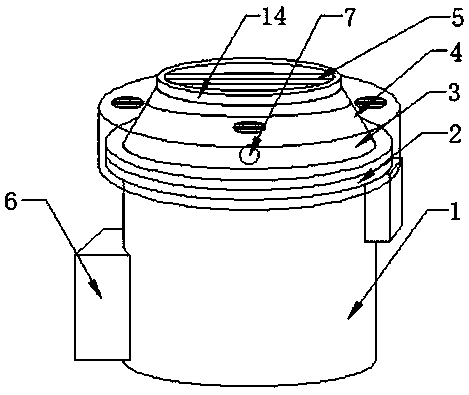

[0024] Such as Figure 1-4 Shown, a kind of ferment of the present invention is used initial stage fermenter, comprises barrel body 1, and the top of barrel body 1 is fixedly connected with the bottom end of sealing cover 3 by mounting ring 2, and the exterior of sealing cover 3 is fixedly provided with detection box 4, and sealing The side of the bottom end of the cover 3 is inlaid with an alcohol concentration detector probe 7, and the middle part of the bottom end of the sealing cover 3 is fixedly provided with a motor 11, which is connected to one end of the stirring paddle 10 by transmission, and the top of the sealing cover 3 is fixedly provided with a fixed ring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com