Main shaft lubricating mechanism of straight buttonhole machine

A technology of lubricating mechanism and buttonhole machine, which is used in lubrication/cooling devices, sewing machine components, textiles and papermaking, etc., can solve the problems of inability to reuse lubricating oil, increase maintenance costs, add lubricating oil, etc., and achieve enhanced deformation resistance. , good lubricating effect, increase the effect of lubricating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

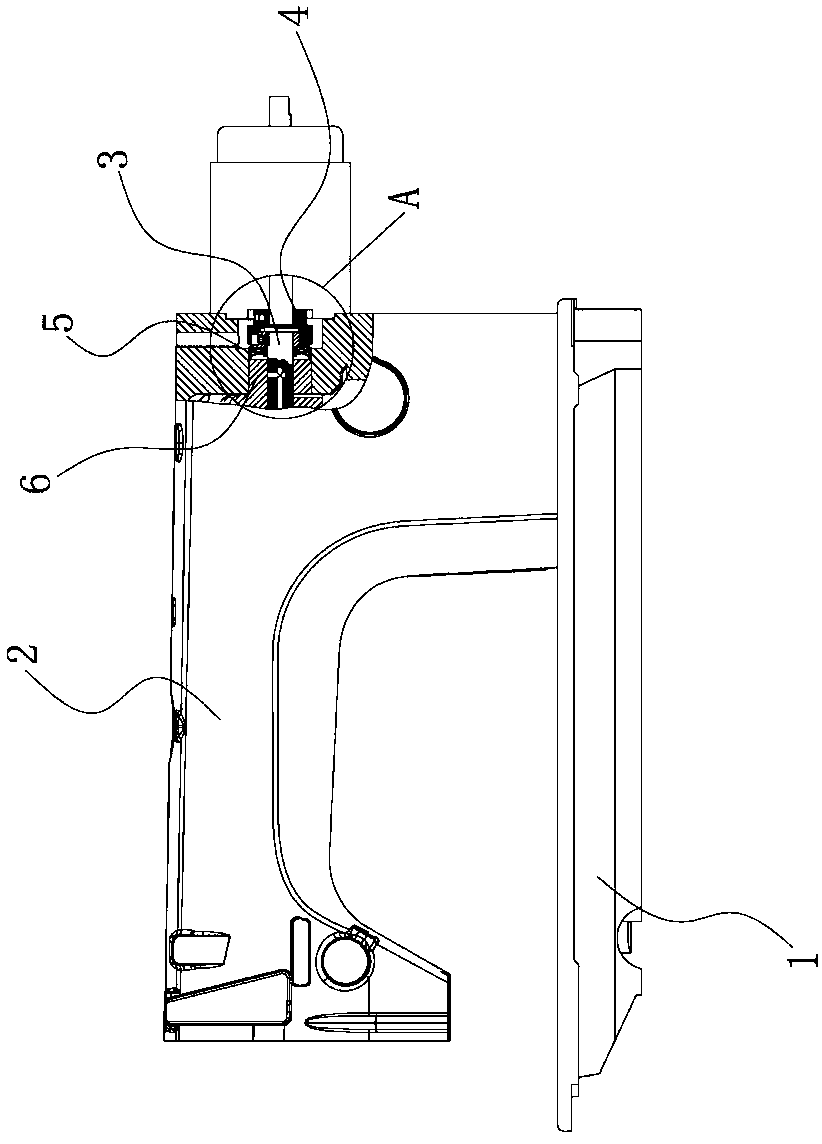

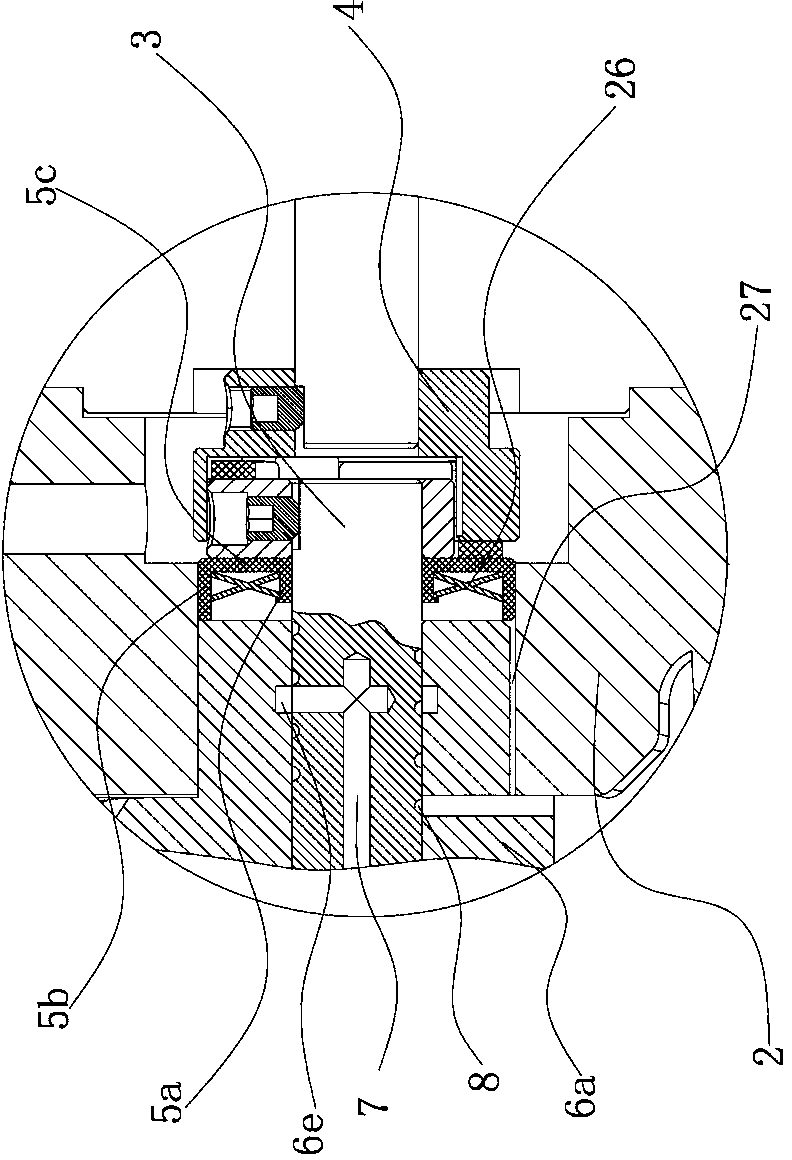

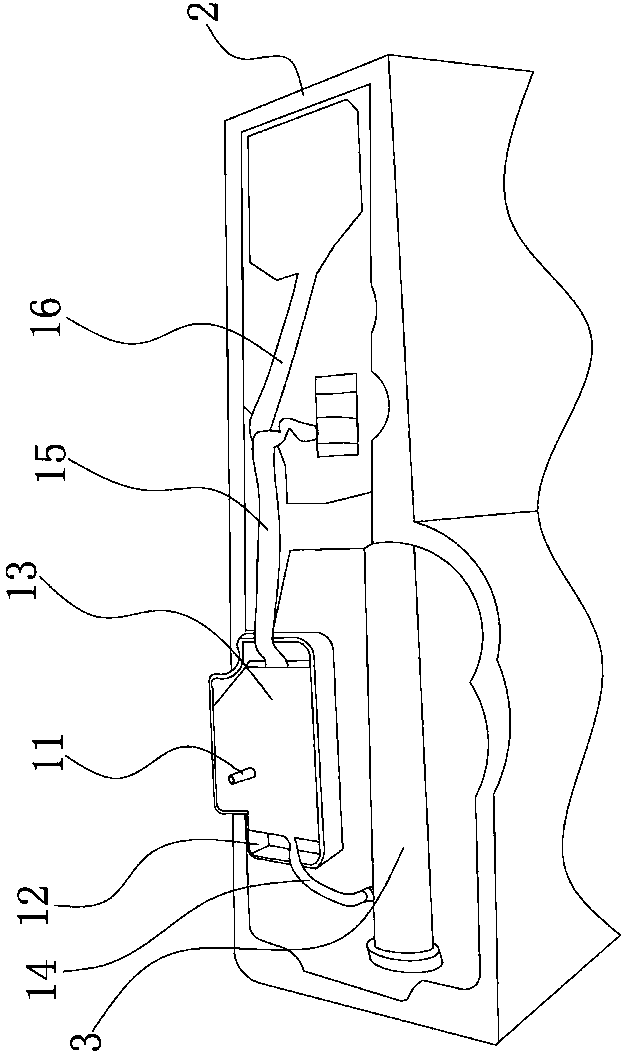

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 or Figure 5 As shown, the main shaft lubrication mechanism of the flat head buttonhole machine, the flat head buttonhole machine is mainly composed of a base 1, a machine head housing 2 is fixed on the base 1, and a main shaft 3 is fixed inside the machine head housing 2. One end of the main shaft 3 passes through the machine head housing 2 and the extended end of the main shaft 3 is directly connected with the motor rotor 4 and driven by the motor rotor 4 to rotate. There is an oil seal 5, and the preferred solution of the oil seal 5 is: the oil seal 5 includes an inner ring surface 5a, an outer ring surface 5b, and is connected to the inner ring surface 5a, the outer ring surface 5b and integrally formed with the inner ring surface 5a, the outer ring surface 5b The connection plate surface 5c, the inner ring surface 5a and the outer ring surface 5b are parallel to each other, and a set is provided between...

Embodiment 2

[0030] as shown in the picture Figure 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the elastic structure includes a U-shaped strip plate 23, a spring groove 24 is arranged on the U-shaped strip plate 23, and The outer end face of the plunger 18 is provided with a blind hole 21, the blind hole 21 is opposite to the notch of the spring groove 24 of the U-shaped strip plate 23, and a spring 25 is arranged in the blind hole 21, and one end of the spring 25 leans against the blind hole. In the hole 21 , the other end abuts against the aforementioned spring groove 24 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com