A LED light source multi-station clamping machine

A technology of LED light source and multi-station, which is applied in the direction of light source, semiconductor device of light-emitting element, lighting and heating equipment, etc. It can solve the problem of energy-saving LED light source pressure sealing, poor sealing of the edge of the sealing part, low pass rate, etc. problems, to achieve the effect of stabilizing the internal structure, weakening the residual stress, and compacting the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

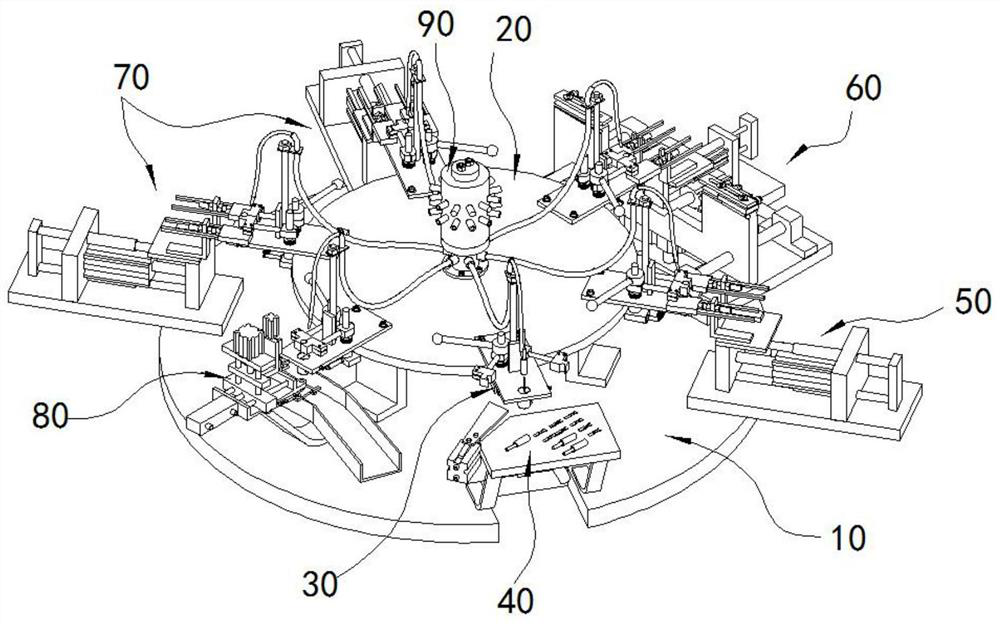

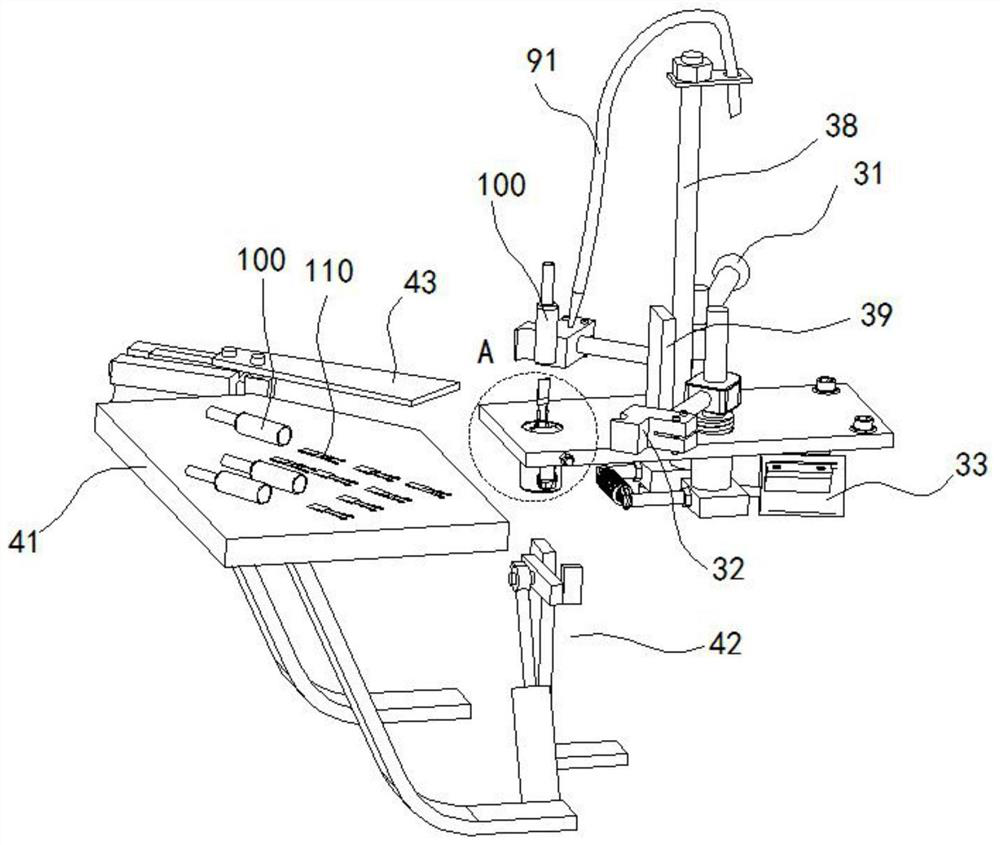

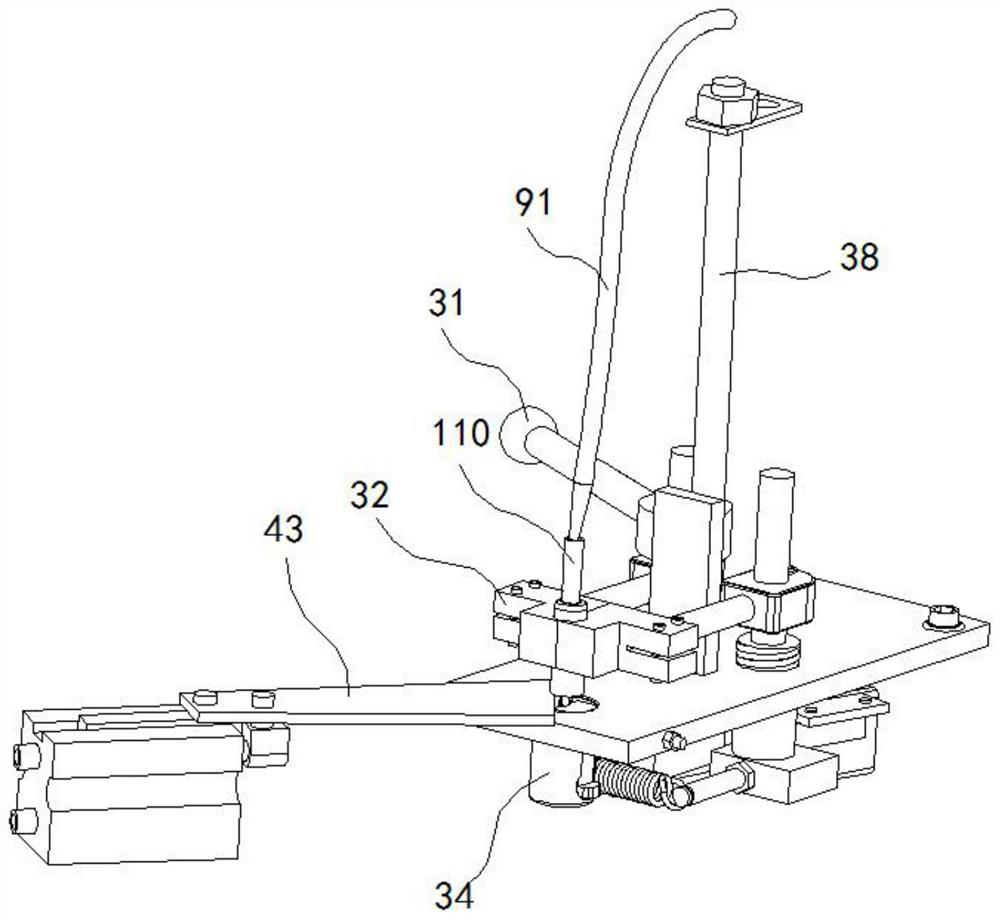

[0038] Please refer to figure 1 , shows the structure of the LED light source multi-station clamping machine of the present invention, which includes: a feeding mechanism 40, a preheating mechanism 50, a clamping Sealing mechanism 60. For LED lamps, the high temperature makes it impossible to seal the energy-saving LED light source in the quartz glass bulb. In order to solve the problem of sealing the LED light source in the glass bulb, high boron glass with lower sealing temperature is used material, but the expansion coefficient of high boron glass is relatively high. Therefore, in this scheme, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com