Thermospray feeding-flame atomizer for atomic spectrometry

A technology of atomizer and atomic spectrum, which is applied in the field of atomic spectrum analysis and testing, and can solve the problem of low detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

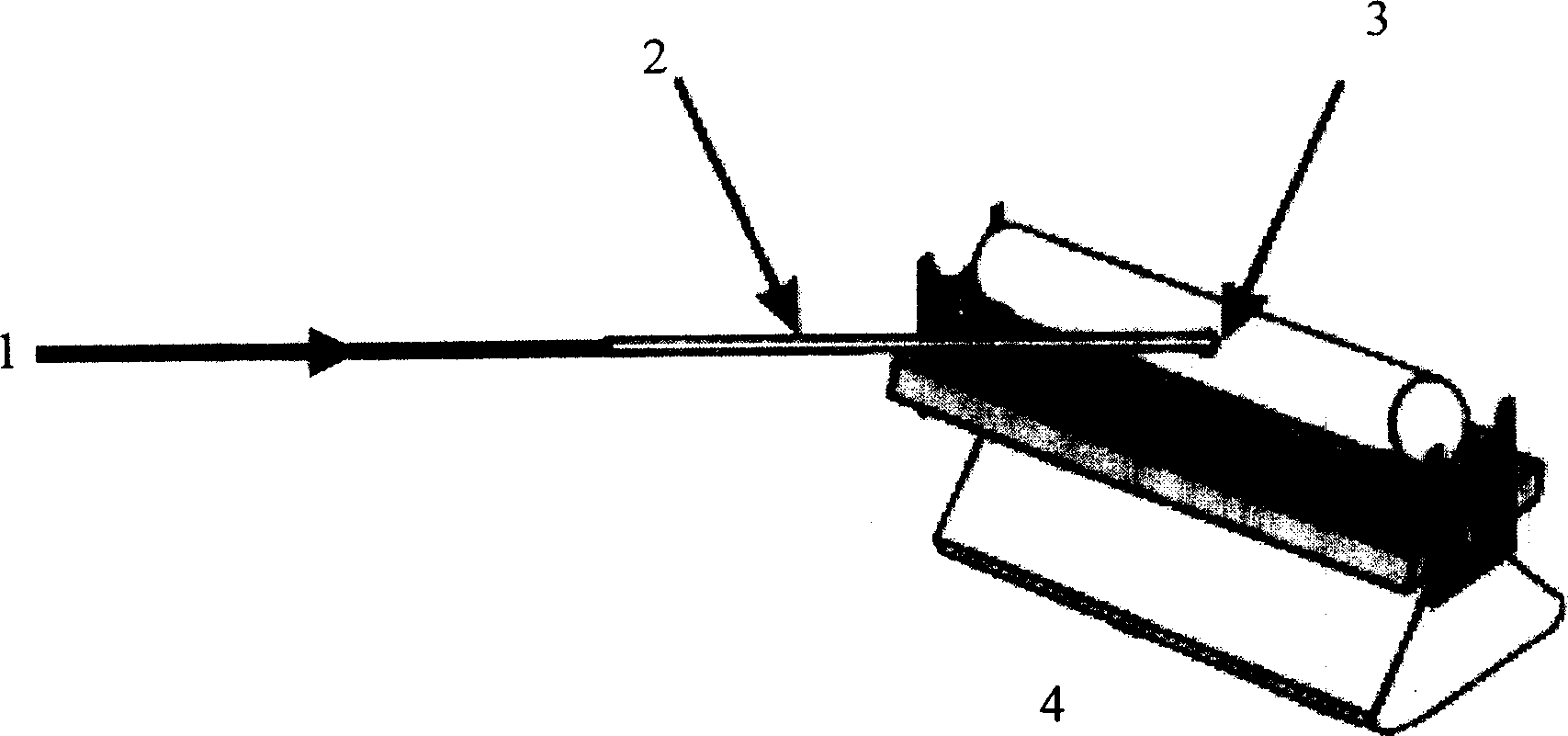

[0008] The example that the present invention is used for flame atomic absorption is as follows: first ignite the air-acetylene flame of flame atomic absorption instrument during work, flame furnace 3 (instrument figure is shown in the accompanying drawing of specification sheet) is placed on the stainless steel support on the combustion head 4, then Insert the thermal spray capillary 2 horizontally and vertically into the flame furnace. The sample solution 1 is lifted into the pipeline by the pump and enters the thermal spray capillary through the connector to be thermally atomized. The sample aerosol enters the flame furnace 3 at high speed and is atomized. The free atomic absorption light signal in the flame furnace is detected by the flame atomic absorption instrument. The software records, thus completes the working process of the present invention. See Table 1 for the detection limits of some elements when the present invention is applied to flame atomic absorption.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com