Electric heater for flask and similar container

A technology for electric heaters and containers, which is applied to flasks, heating or cooling equipment, laboratory appliances, etc., and can solve problems such as flask damage, user electric shock, and short circuit of electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

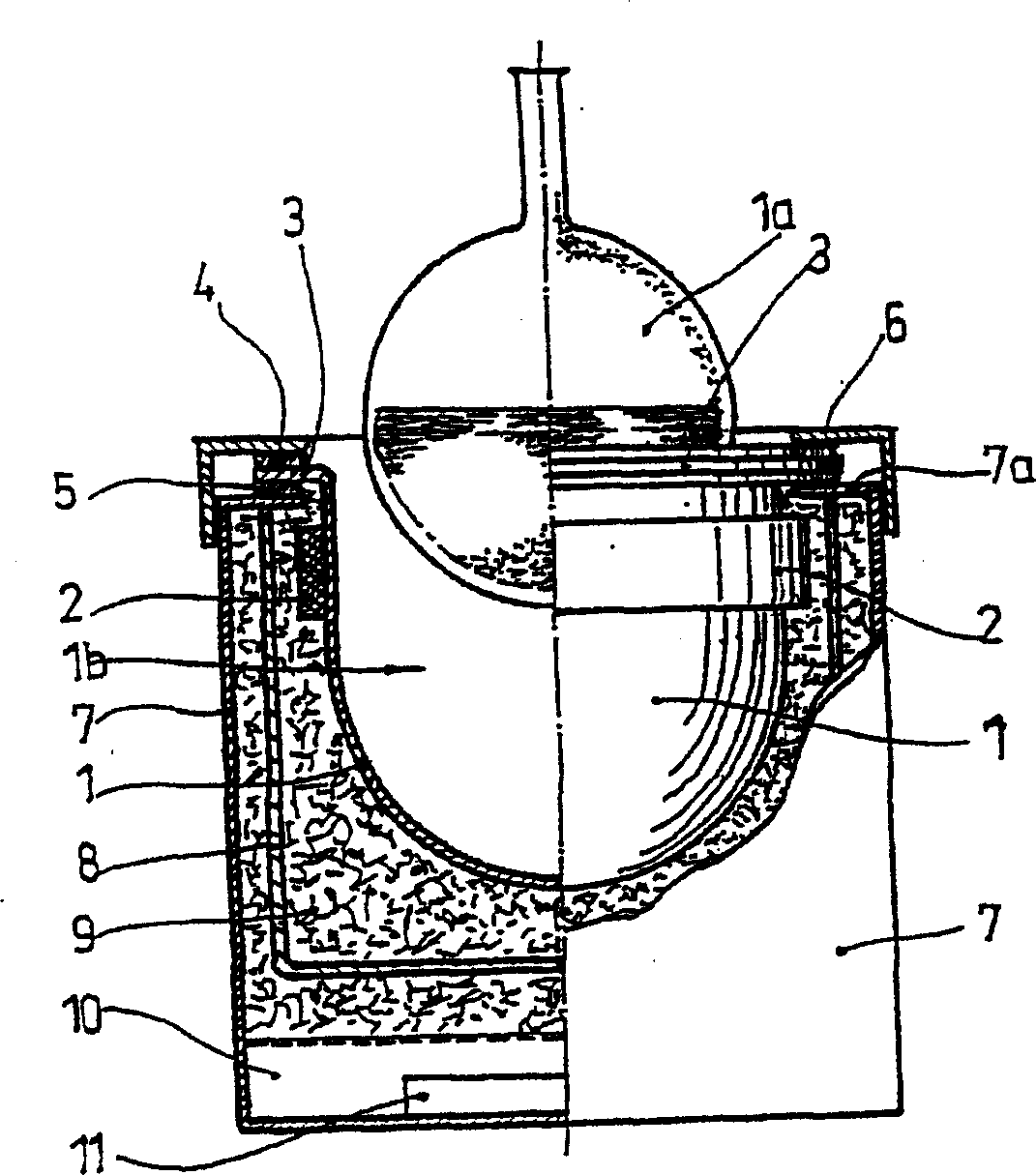

[0018] According to these figures, a heater for a flask or similar vessel consists of a heating housing (1) made of metallic material and coated with a layer of ceramic material or stainless steel as previously described, said heating housing having A cylindrical top and a spherical bottom shroud with a plated resistor or heating jacket (2) completely surrounding the outside of the top of the heating shell (1).

[0019] The housing (1) has an upper flange which is an annular hoop placed between two circular rings (4) and (5) made of a material with insulating capacity in the form of a "sandwich" ( 3).

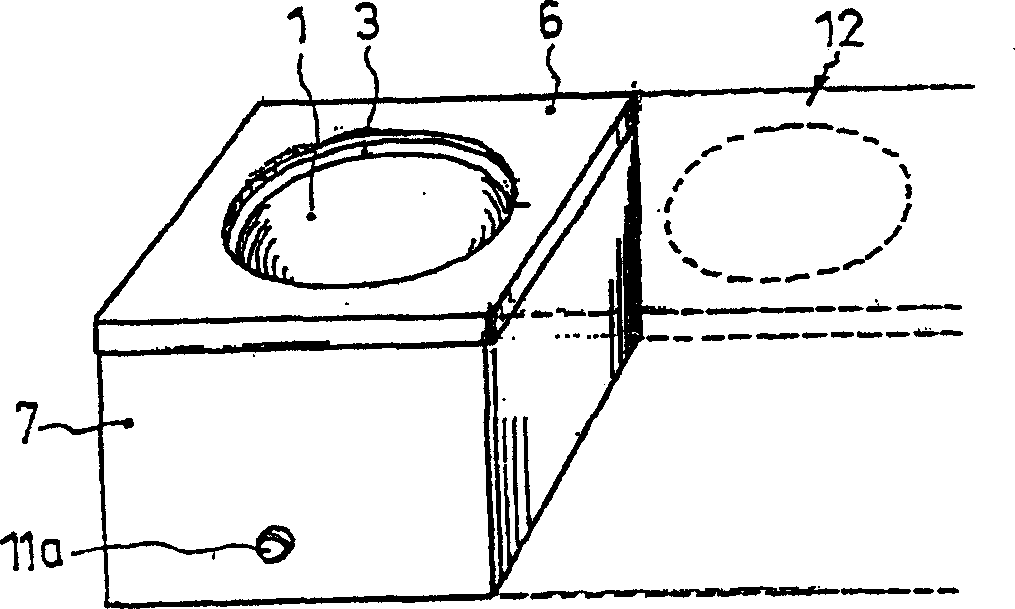

[0020] On these insulated rings (4) and (5) a suitable upper cover (6) is placed, equipped with a central opening which coincides exactly with the top of the heating shell (1) and with corresponding vertical The upper cover covers the upper contour of the base (7) constituting the outer or bottom outer part of the device.

[0021] The base (7) is completed by its horizontal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com