Connecting element

A technology for connecting splints and splints, used in elevators, transportation and packaging, etc., can solve the problems of small wall thickness, high cost, impossible to achieve, etc., and achieve the effects of good strength, low cost, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

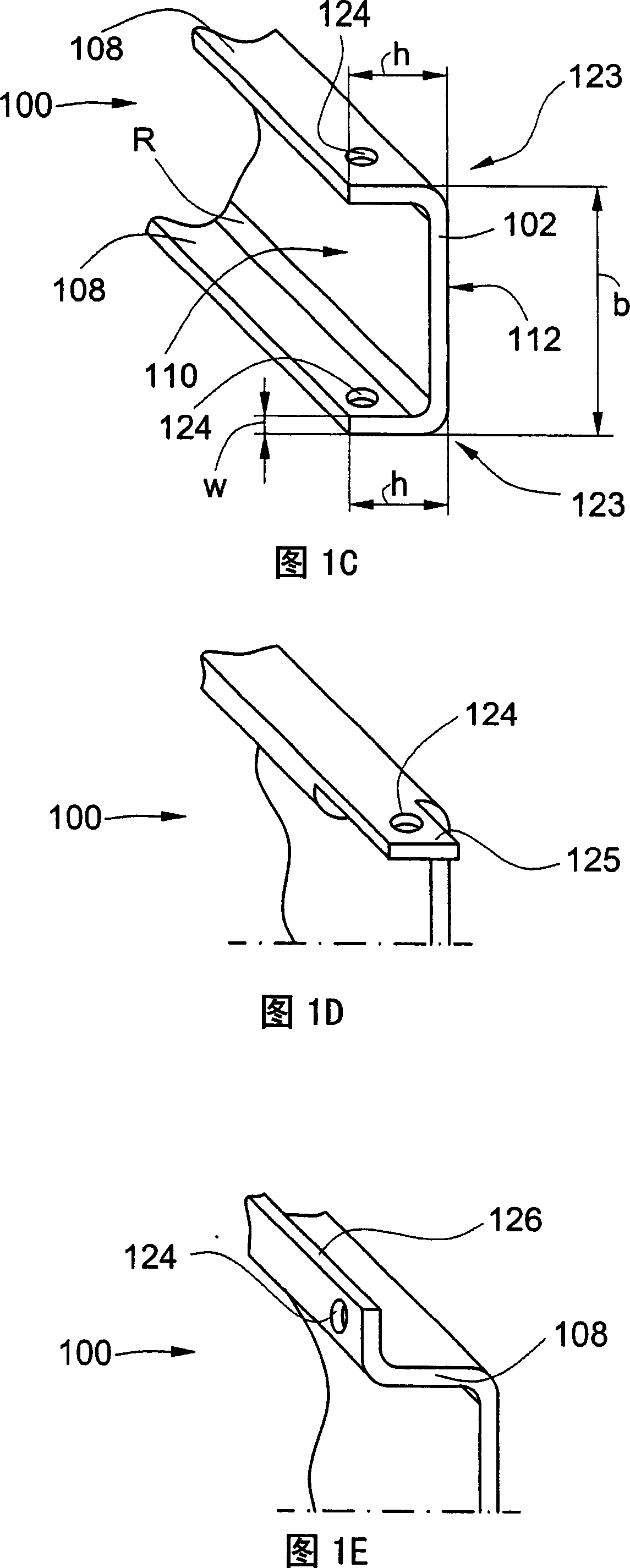

[0059] The flange height h of the two longitudinal flanges 108 can also be different, and said flange height of a longitudinal flange does not have to be constant.

[0060] In FIG. 1C , the difference from FIG. 1A is that the eyelets 124 are provided on the flange 108 . The holes can be utilized when shipping and / or installing the rail.

[0061] Additional embodiments are shown in Figures ID and IE. FIG. 1D shows a connecting lug 100 which has a plate 125 with a hole 124 . FIG. 1E shows a connecting bridge 100 which has a bridge 126 along at least one flange 18 . The bridge 126 can be used as a connection aid. In addition, the bridging elements can increase the rigidity of the connecting splint 100 .

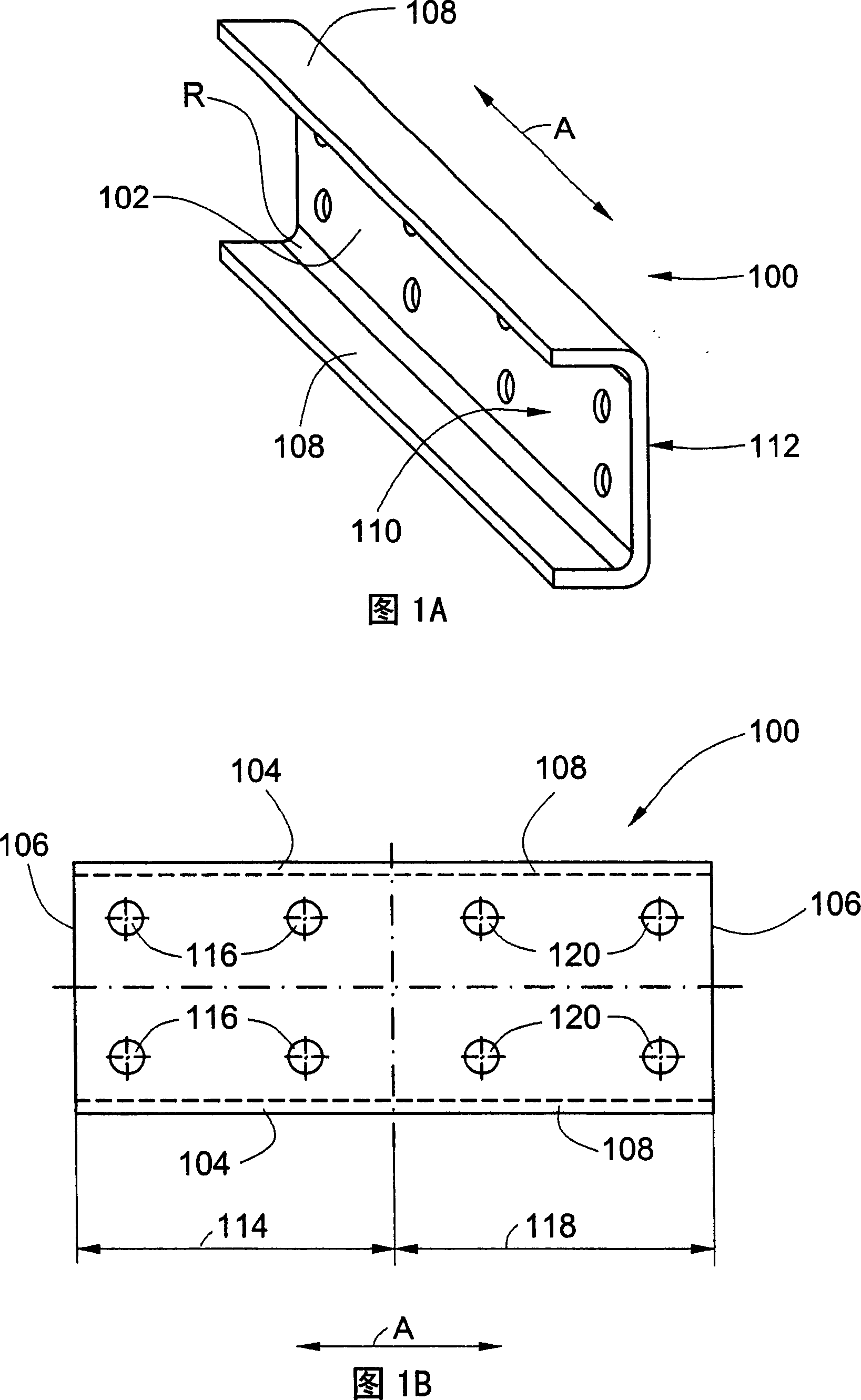

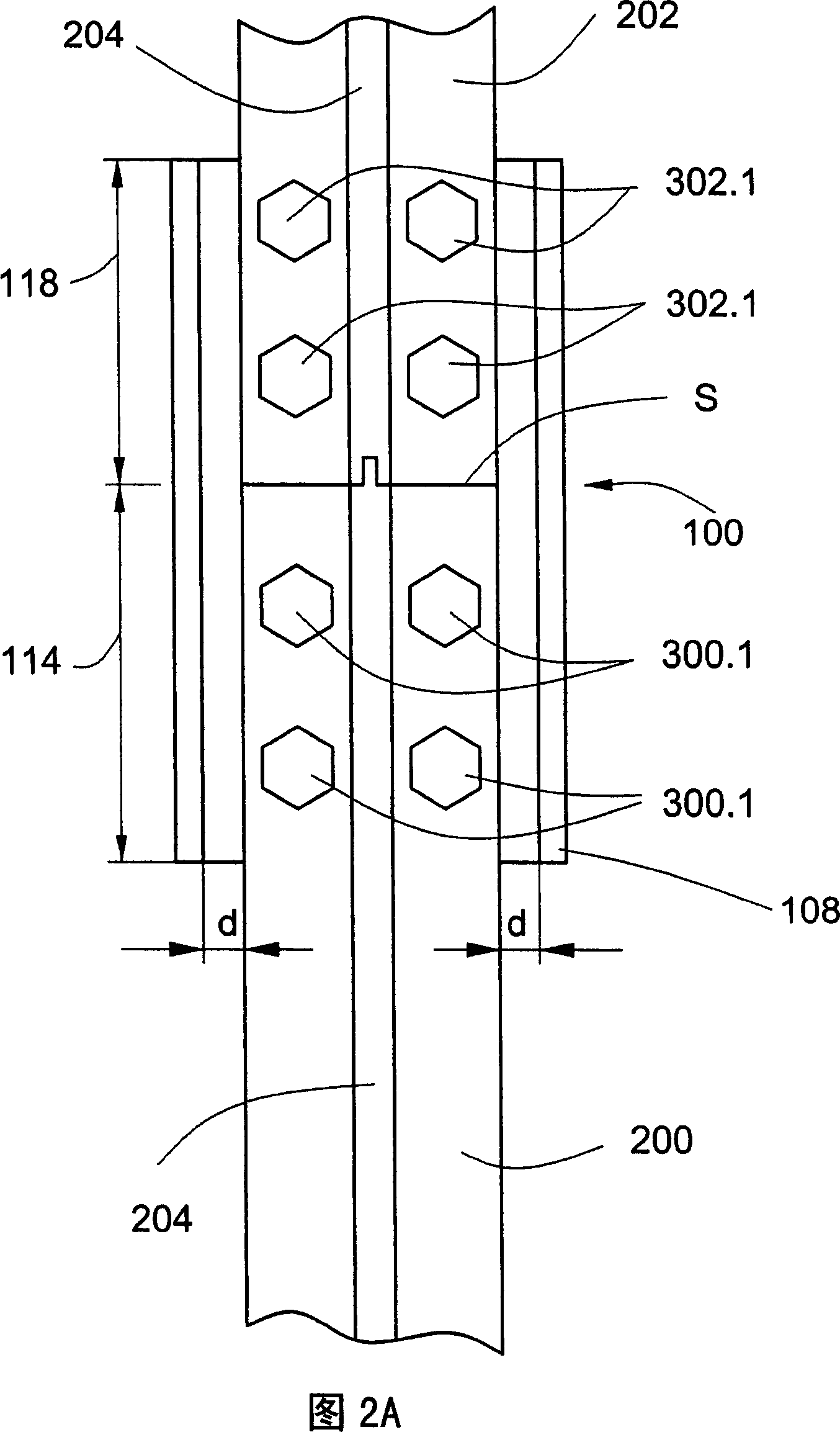

[0062] 2A and 2B show a connecting splint 100 having the structure of the connecting splint 100 shown in FIG. 1 . The connecting splint 100 is used to connect one guide rail part 200 with another guide rail part 202 . The structure of the connection clamp should make its l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com