Welding free biheading pressure plate

A pressing plate and spacing technology, applied in the direction of pipes/pipe joints/pipe fittings, passing components, mechanical equipment, etc., can solve the problem that the center of the heading head cannot be consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

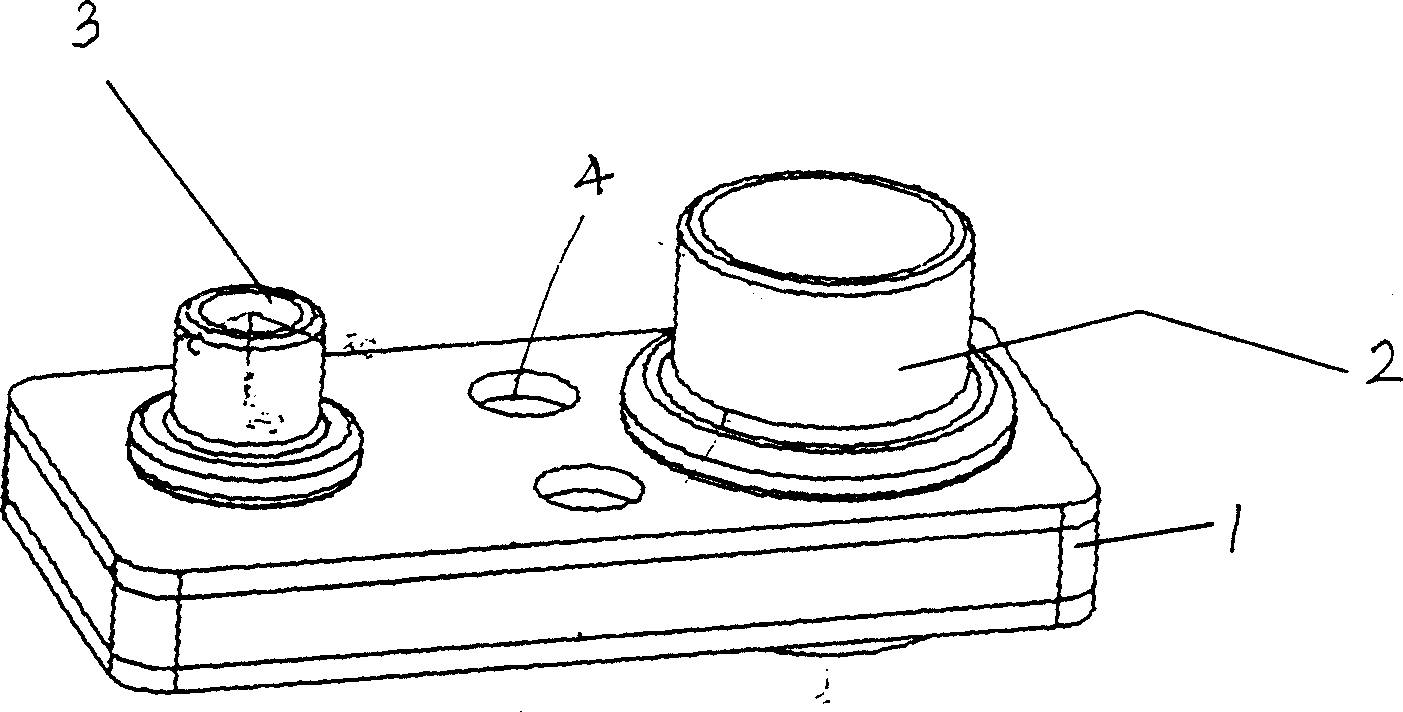

[0007] Below with reference to accompanying drawing, the present invention is further described

[0008] The present invention is a welding-free double-headed pressure plate, which mainly includes a pressure plate body 1, and a first joint 2 is arranged on the pressure plate body, and it is characterized in that: a second joint 3 is arranged on the pressure plate body on one side of the first joint, The distance between the first joint and the second joint is 2cm-40cm, and a mounting hole 4 is provided at the pressing plate body. In specific implementation, the joint of the pressure plate and the pipeline can be directly upset together, so as to ensure the assembly center distance of the two pipe joints.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com