Robot programming device

一种机器人、搬运机器人的技术,应用在程序控制、程序控制机械手、仪器等方向,能够解决花费时间、机器人系统多工时或者时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

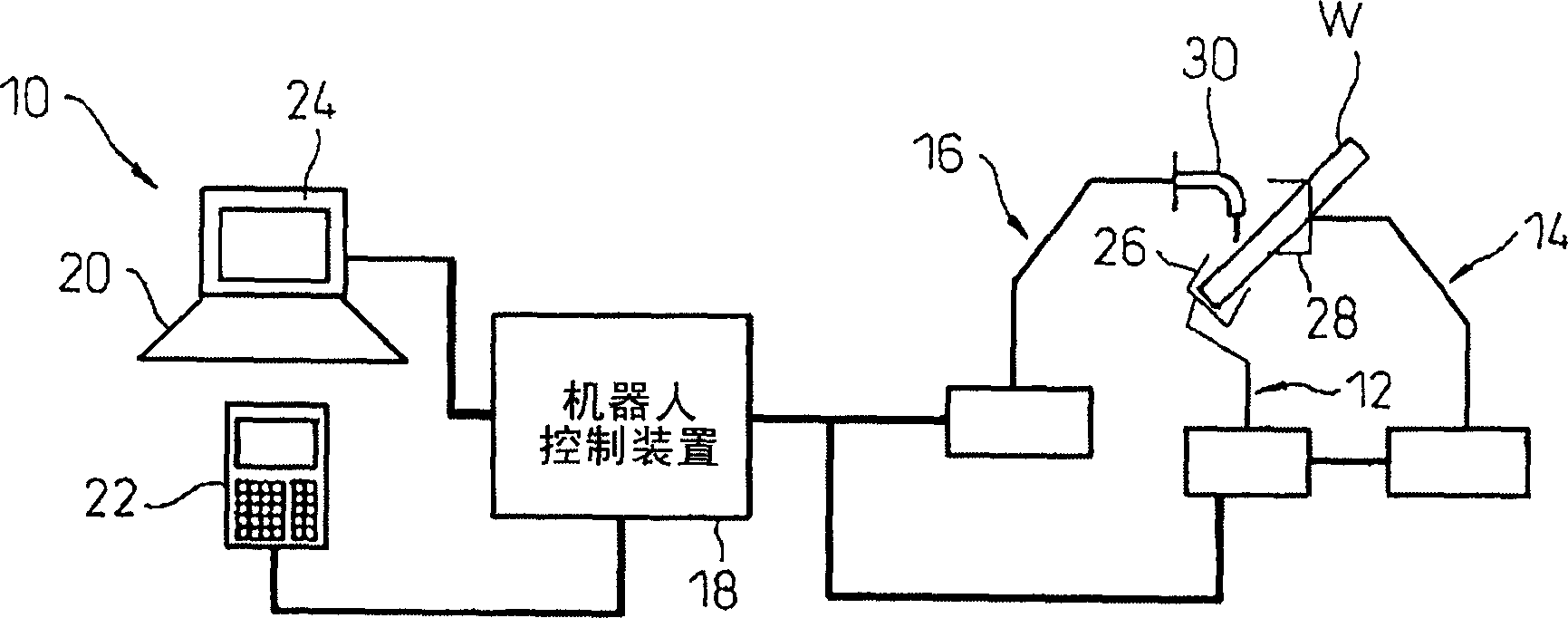

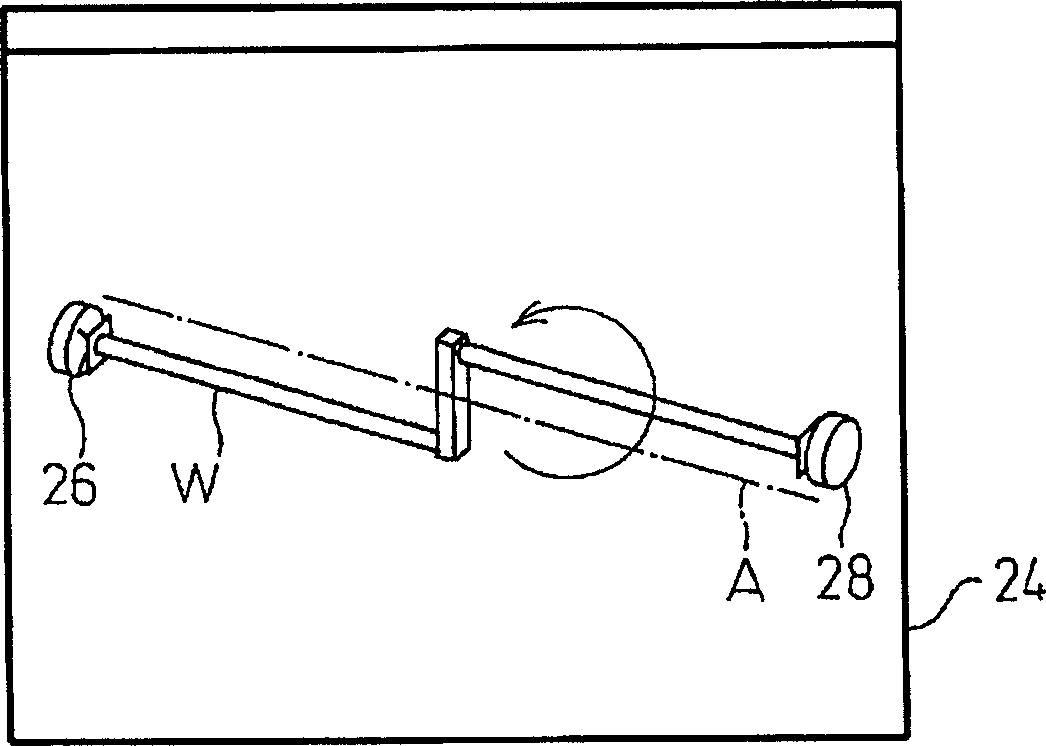

[0022] Refer to the attached Figure 1 The present invention will be described in detail. figure 1 It is a basic configuration diagram showing a robot system that can use the robot programming device of the present invention. The robot system 10 includes: two transfer robots 12 and 14 each having a manipulator for grasping a workpiece W which is a workpiece; a welding robot 16 for performing processing (welding processing in this embodiment) on the workpiece W; a control robot 12, 14 and 16 robot controllers 18; an input device 20 such as a personal computer connected to the robot controller 18; a teaching operation panel 22 connected to the robot controller 18 and used for teaching operations of the robots 12, 14, and 16 . In addition, in any of the present embodiments, the robot programming device of the present invention and each unit included in the device are incorporated in the personal computer 20, and other forms are also possible.

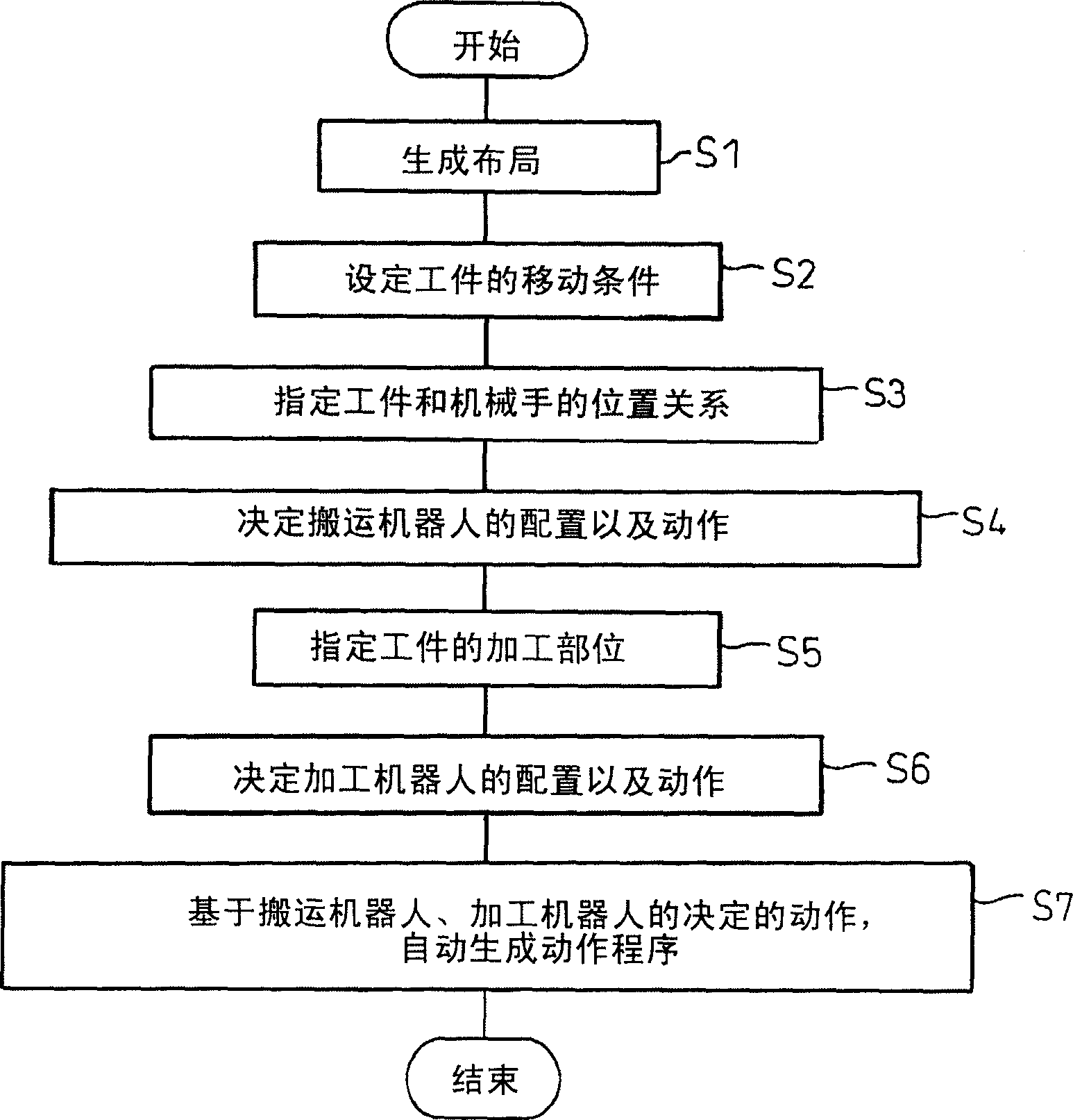

[0023] figure 2 It is a flowch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com