Rapid construction method for stone dam rolling asphalt concrete cutoff core wall

A technology of asphalt concrete and construction method, which is applied in dams, barrages, water conservancy projects, etc., can solve the problems of difficult to find anti-seepage core wall materials, poor dam construction conditions, and small engineering volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

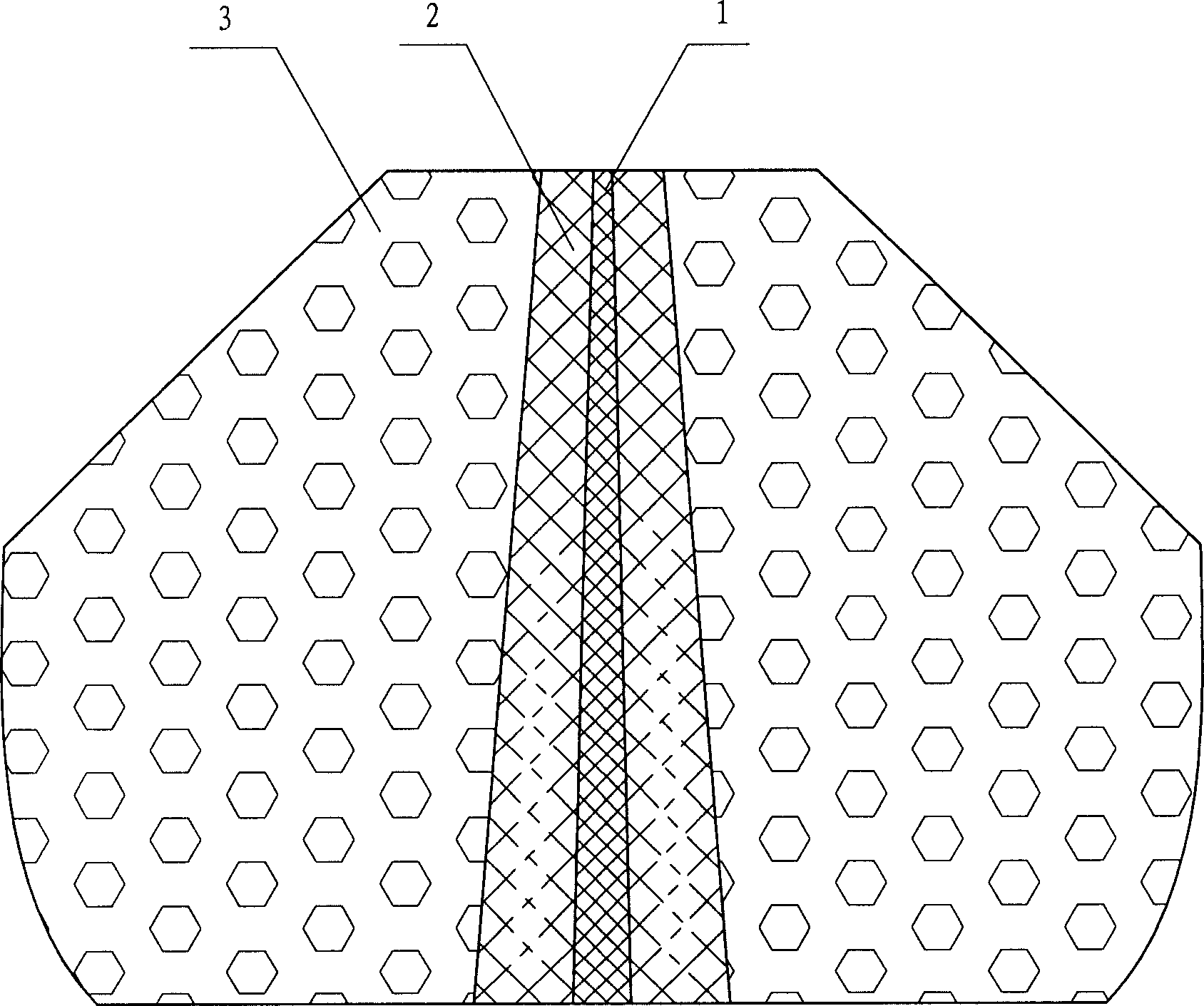

[0027] A rapid construction method for an earth-rock dam roller compacted asphalt concrete anti-seepage core wall, comprising the following steps:

[0028] 1. The foundation surface of the core wall of an earth-rock dam is set out, that is, the design center line of the anti-seepage core wall and the width of asphalt concrete paving are set after measurement. According to the steel formwork with a vertical height of 30cm set by the two side lines after the measurement, the core wall transition material is paved on the outside of the steel formwork, and the surface of the core wall foundation is heated to prepare for asphalt concrete paving;

[0029] 2. The asphalt mixture with a temperature of 165-175°C at the outlet of the mixing building is loaded into the insulated transport vehicle, and the mixture is transported to the construction site and unloaded into the insulated hopper of the vertical transportation equipment; the vertical transportation equipment directly unloads th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com