Bottom roll bearing block

A technology of bearing seat and lower roller, which is applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., to achieve the effect of solving the tension between the wire and mother, facilitating installation and maintenance, and improving the service life of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

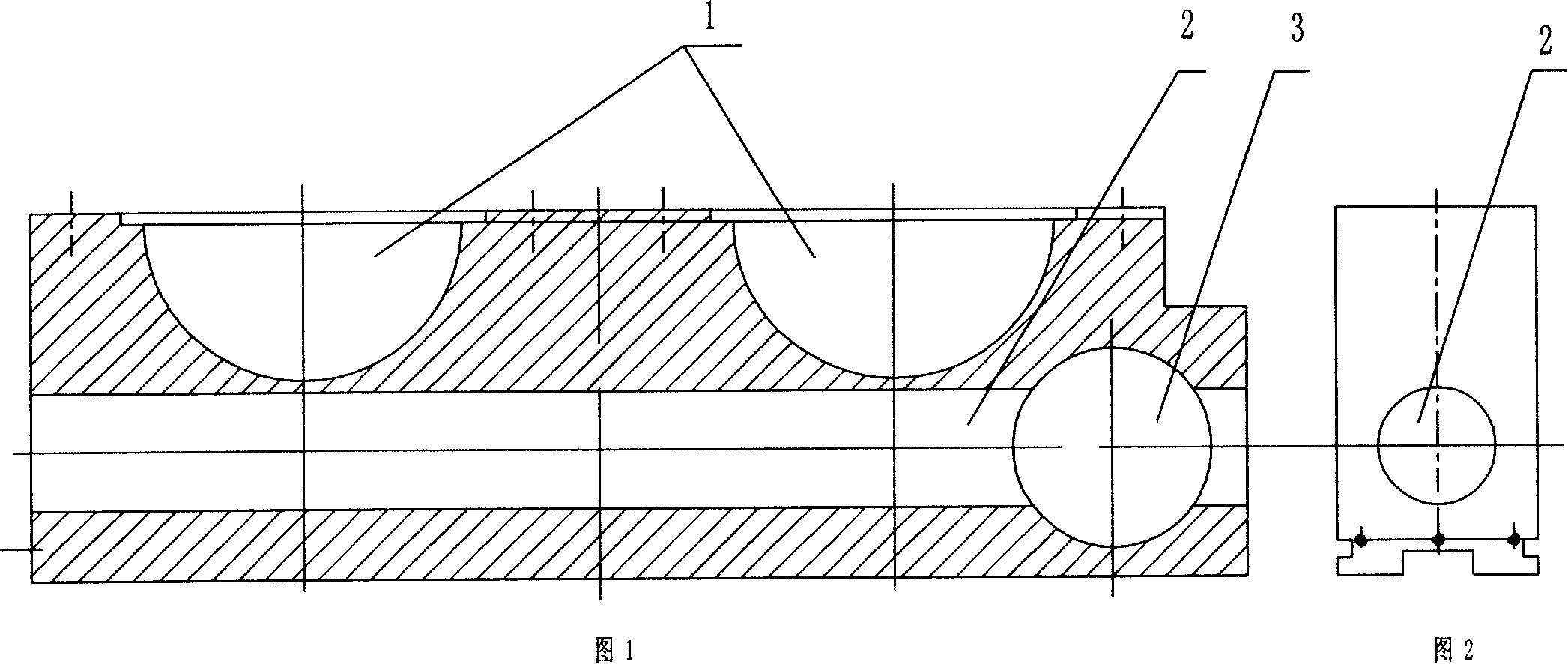

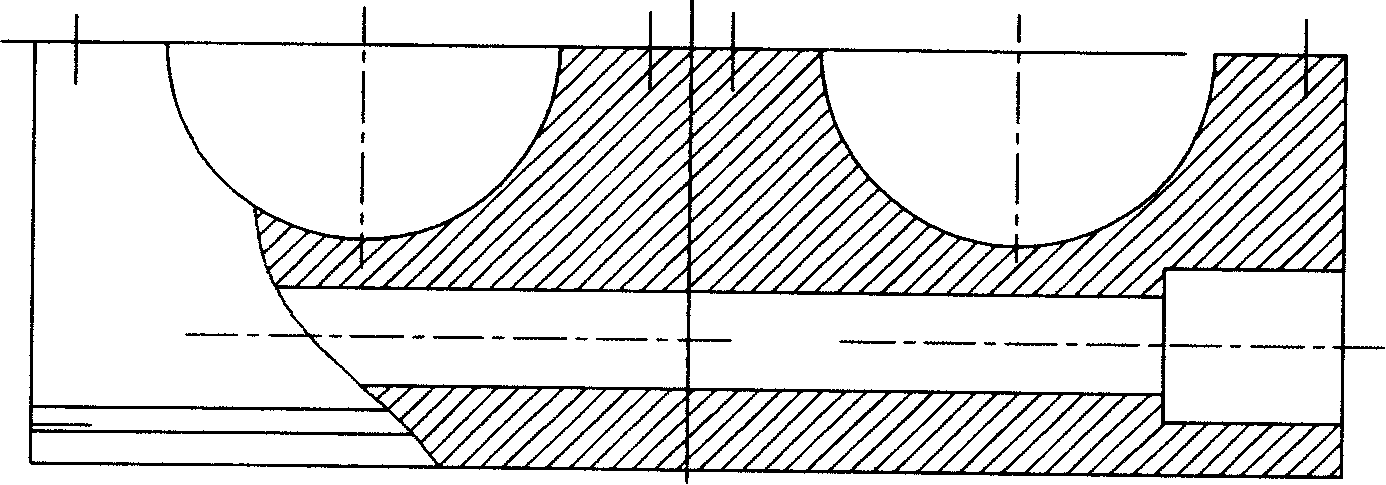

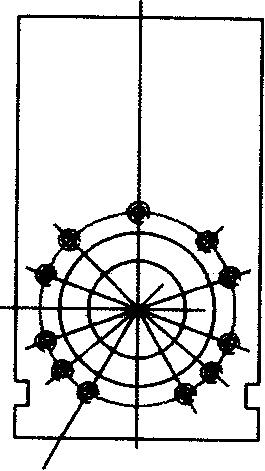

[0010] The present invention will be further described below in conjunction with the accompanying drawings. As shown in Fig. 1 and Fig. 2, the present invention discloses a lower roller bearing housing, the upper part of which is provided with a groove 1 or a round hole, and a tie bar perpendicular to the groove or round hole is arranged under the groove or round hole. Hole 2, one end or the middle of the tie rod hole is provided with a hole 3 perpendicular to it. The hole 3 and the tie rod hole 2 can be vertically intersected horizontally or vertically. There is a rod-shaped nut and a pull rod in the hole. Assembling, because there is a certain room for movement, there will be no tension in the pull rod nut during work, thereby improving the service life of the machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com