Axial-gap motor/generator

An axial gap, generator technology, applied in synchronous motors with static armatures and rotating magnets, electrical components, electromechanical devices, etc., can solve problems such as unsatisfactory, and achieve the effect of improving cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The most preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

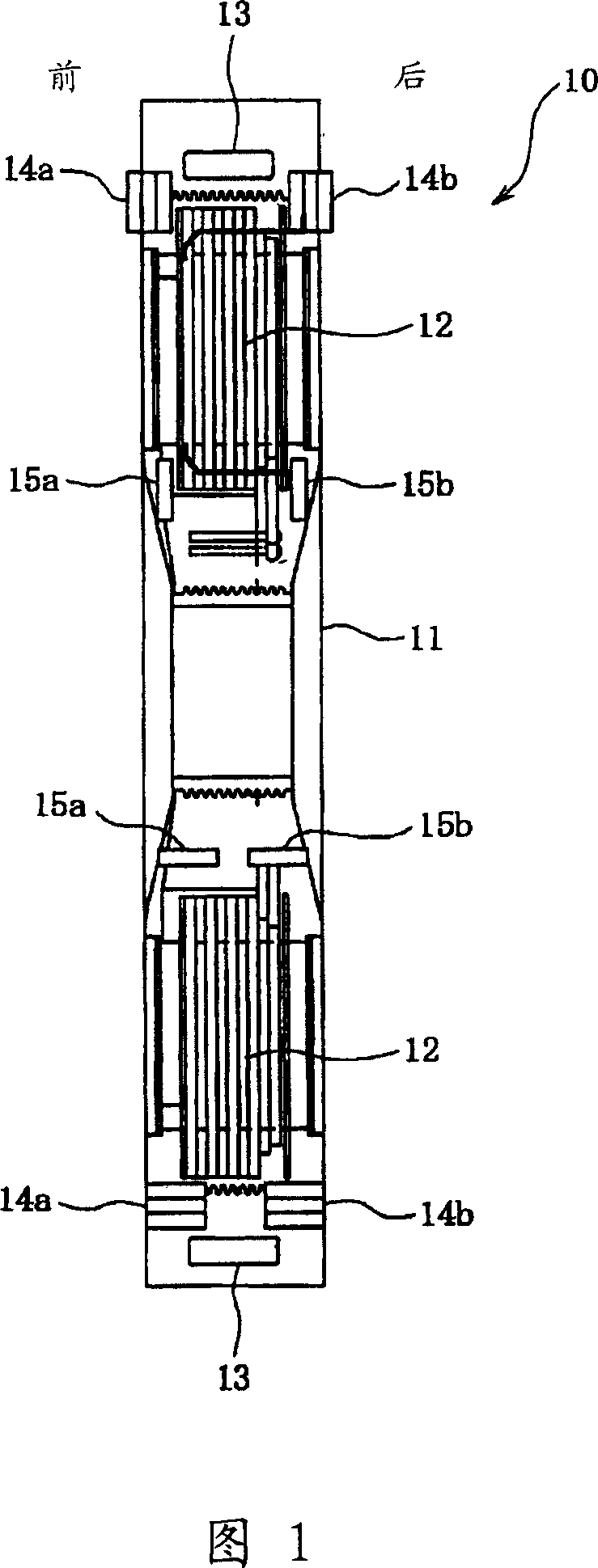

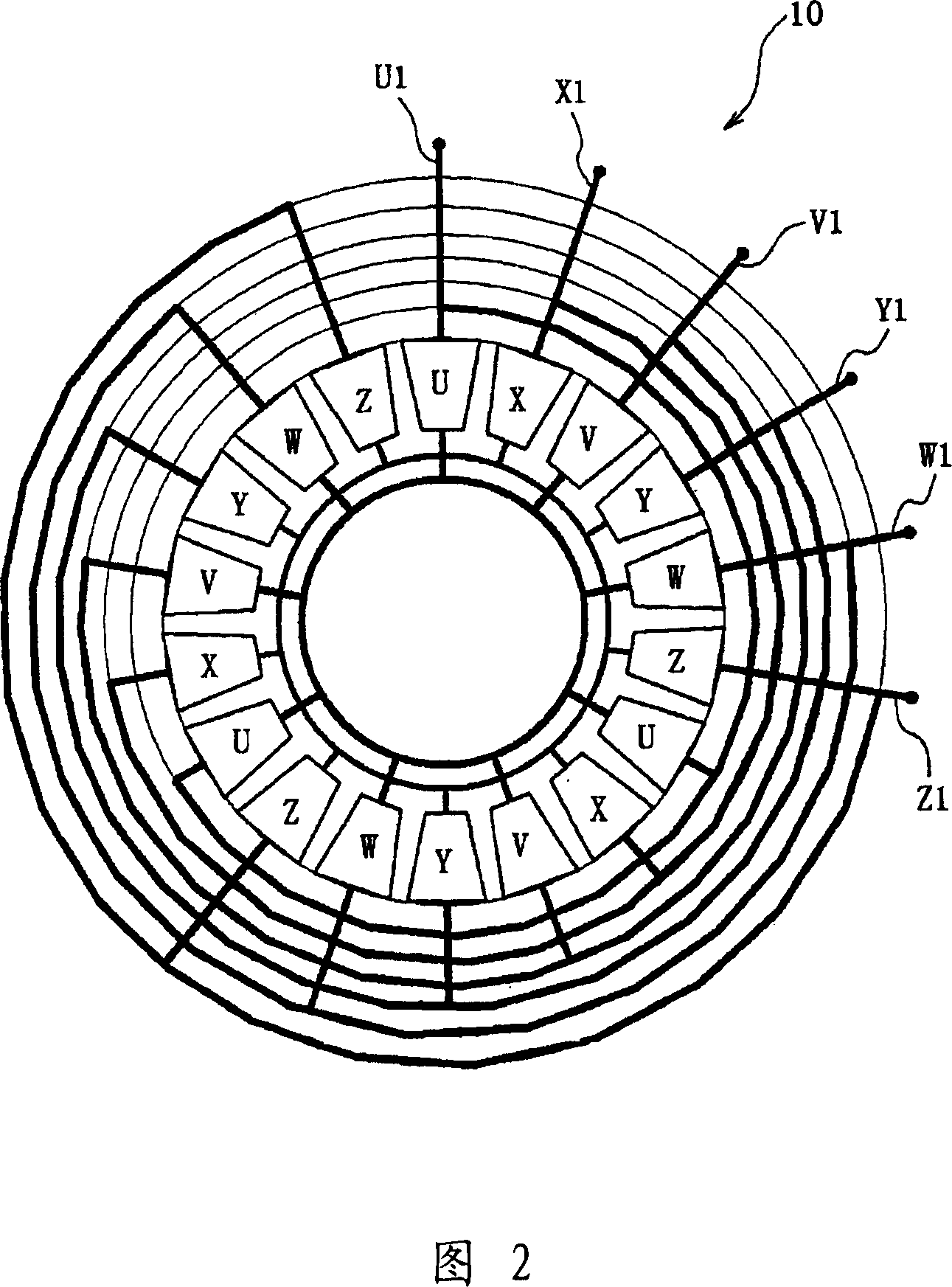

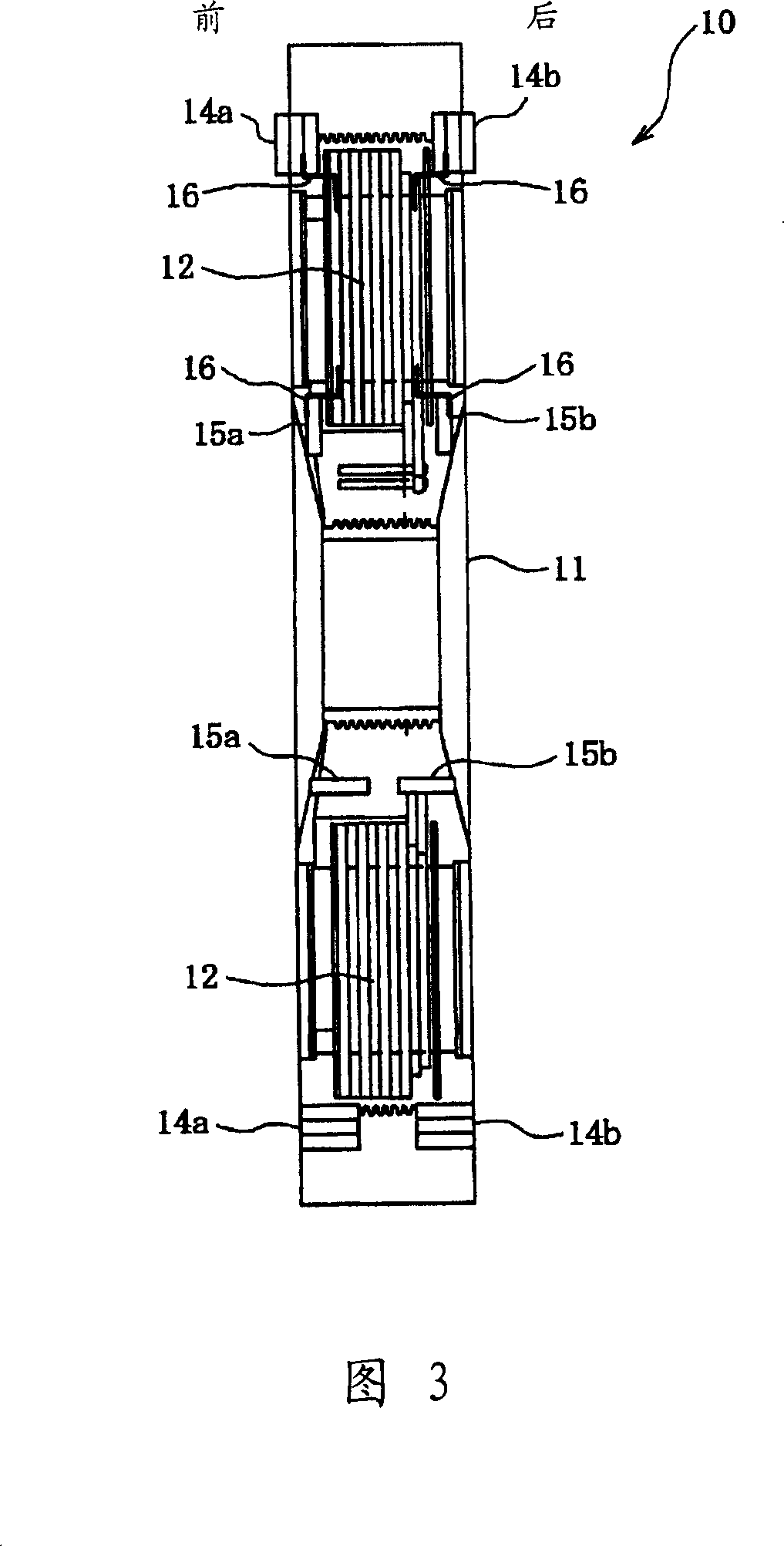

[0017] Fig. 1 shows a schematic cross-sectional view of a stator for an axial gap motor / generator according to an embodiment of the present invention, and Fig. 2 shows a wire joint structure for the axial gap motor / generator shown in Fig. 1 top view.

[0018] As shown in FIGS. 1 and 2, a stator 10 of an axial gap motor / generator includes a stator core 11 formed in a toric shape and positioned around a motor / generator rotation axis (not shown in the drawings), and includes a plurality of Coils 12 (see FIG. 1 ) of winding wires arranged in a row along the circumferential direction of the stator core 11, wherein the coils 12 are equipped with U-phase coils, V-phase coils, W-phase coils, X-phase coils, Y-phase coils, and Z-phase coils. 3 of each type of coil. Thus, the coil 12 consists of 6 phases and 18 slots (see FIG. 2 ). In addition, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com