Cooling plate and cooling system

A cooling system and cooling plate technology, which is applied in the direction of cooling devices, furnace cooling devices, furnace cooling, etc., can solve the problems of unsuitable fluid technology, costly processing technology of cooling plate parts or guard plates, etc., and achieve improved cooling performance and improved Cooling water flow performance and small pressure loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

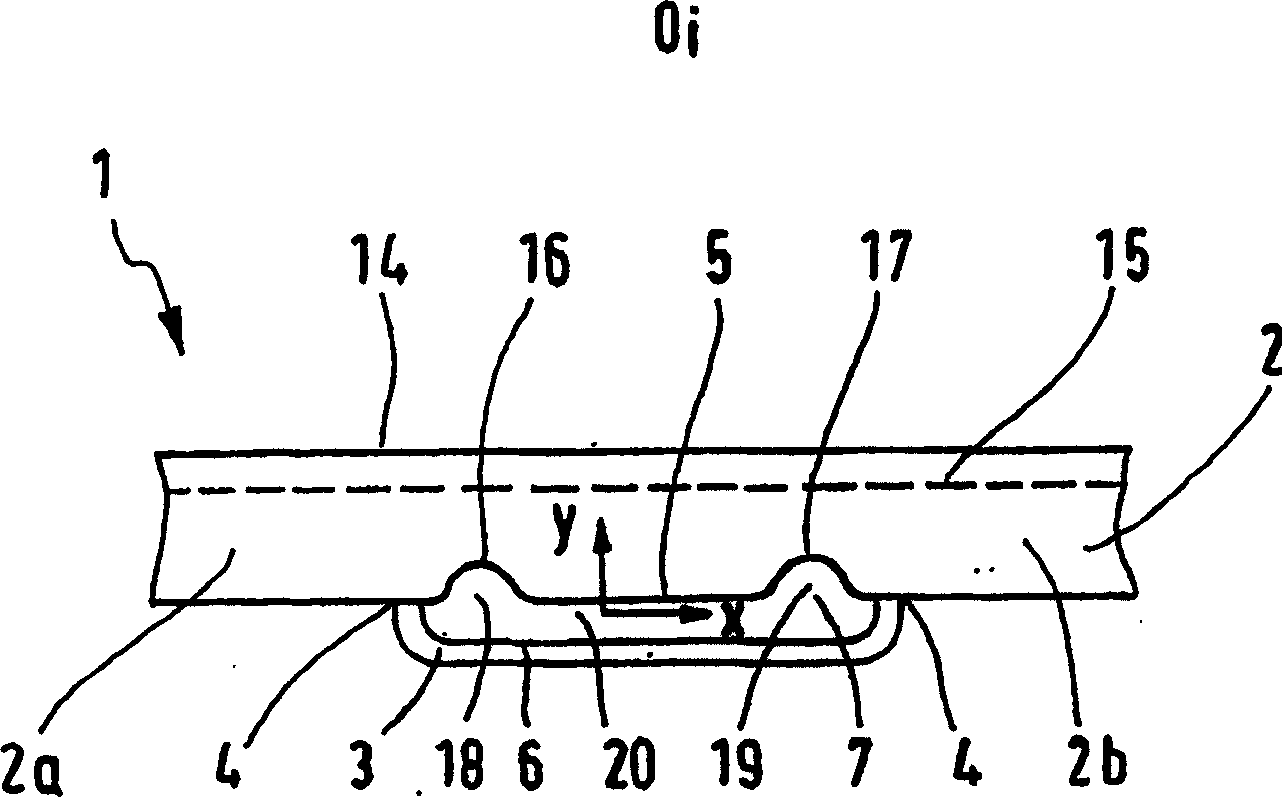

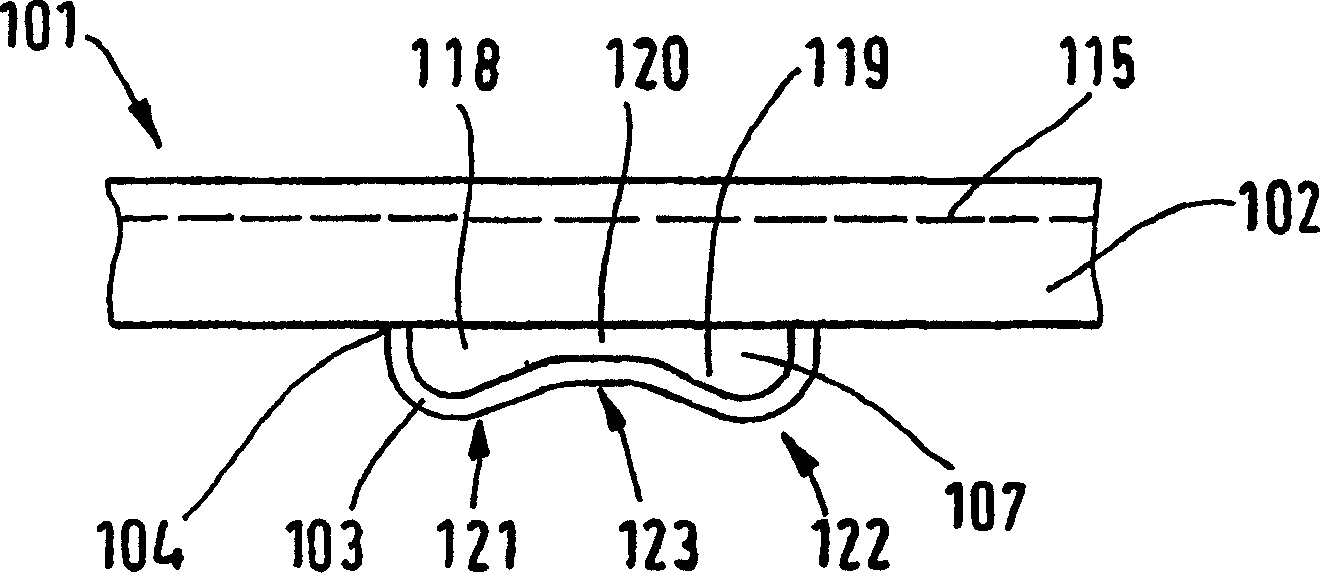

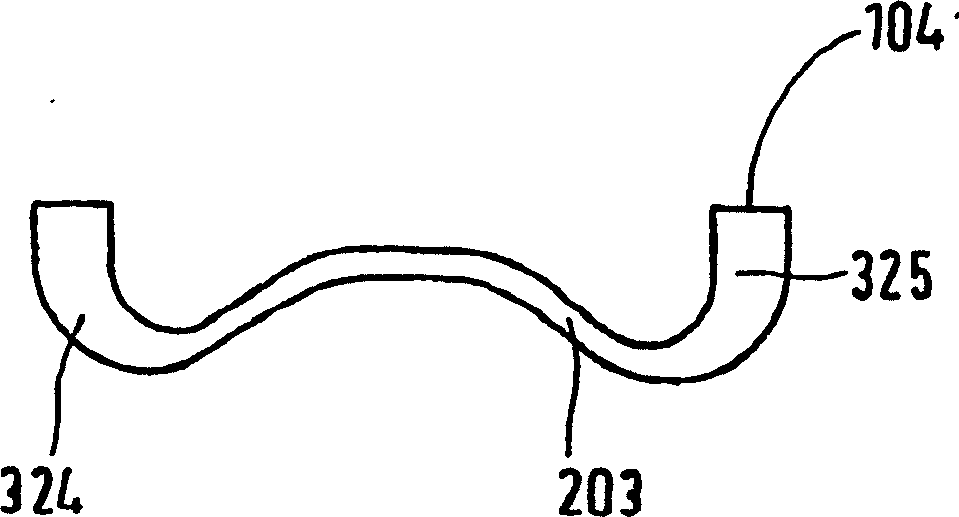

[0028] figure 1 represents a cooling plate 1 or furnace wall plate, which has a first pointing toward the furnace interior O i The first cooling plate part 2 and the second cooling plate part 3 are welded to each other on the back side. The weld seam 4 is located on the protected cold side of the cooling plate or furnace wall. Between the water side back of the first cooling plate part 2 as a rolled copper billet and the water side 6 of the second cooling plate part 3, a cooling channel 7 is formed, which leads to a cooling medium, preferably cooling water . The pipe sections 8 , 9 are fitted in holes in the second cooling plate part 3 for the inflow and outflow of water. The fixing of the cooling plate 1 on the furnace wall 10 is carried out, for example, by means of a connecting plate 11, which is inserted into a support 12 mounted on the furnace wall and braked by means of a pin 13 (see Figure 4 ). The first cooling plate part 2 is designed as a solid rolled blank wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com