Electrically heated water boiling vessels

A boiler, hot water technology, applied in electric heating devices, appliances for boiling water, electrical components, etc., can solve problems such as failure, lack of isolation between steam controllers and component safety controllers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

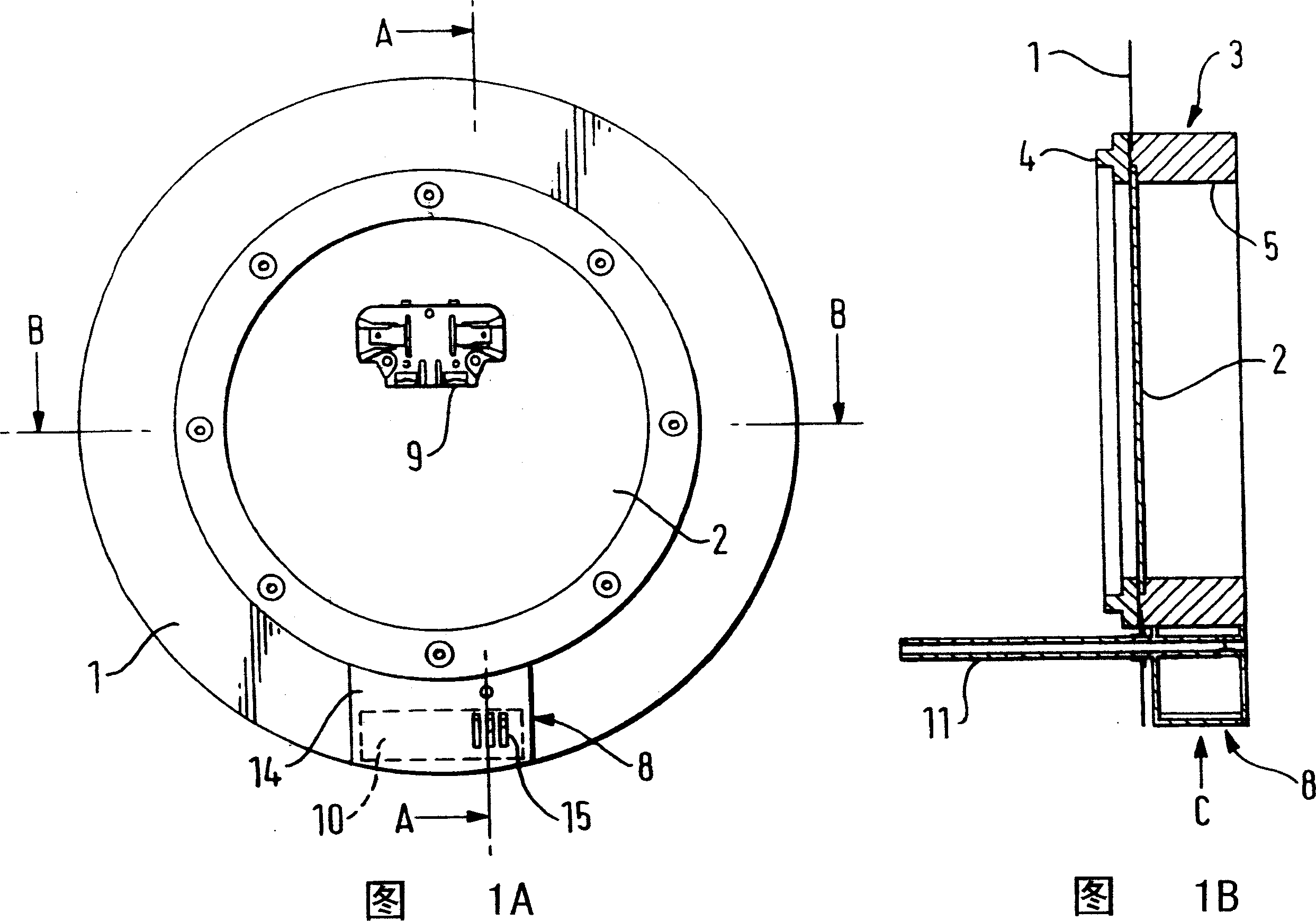

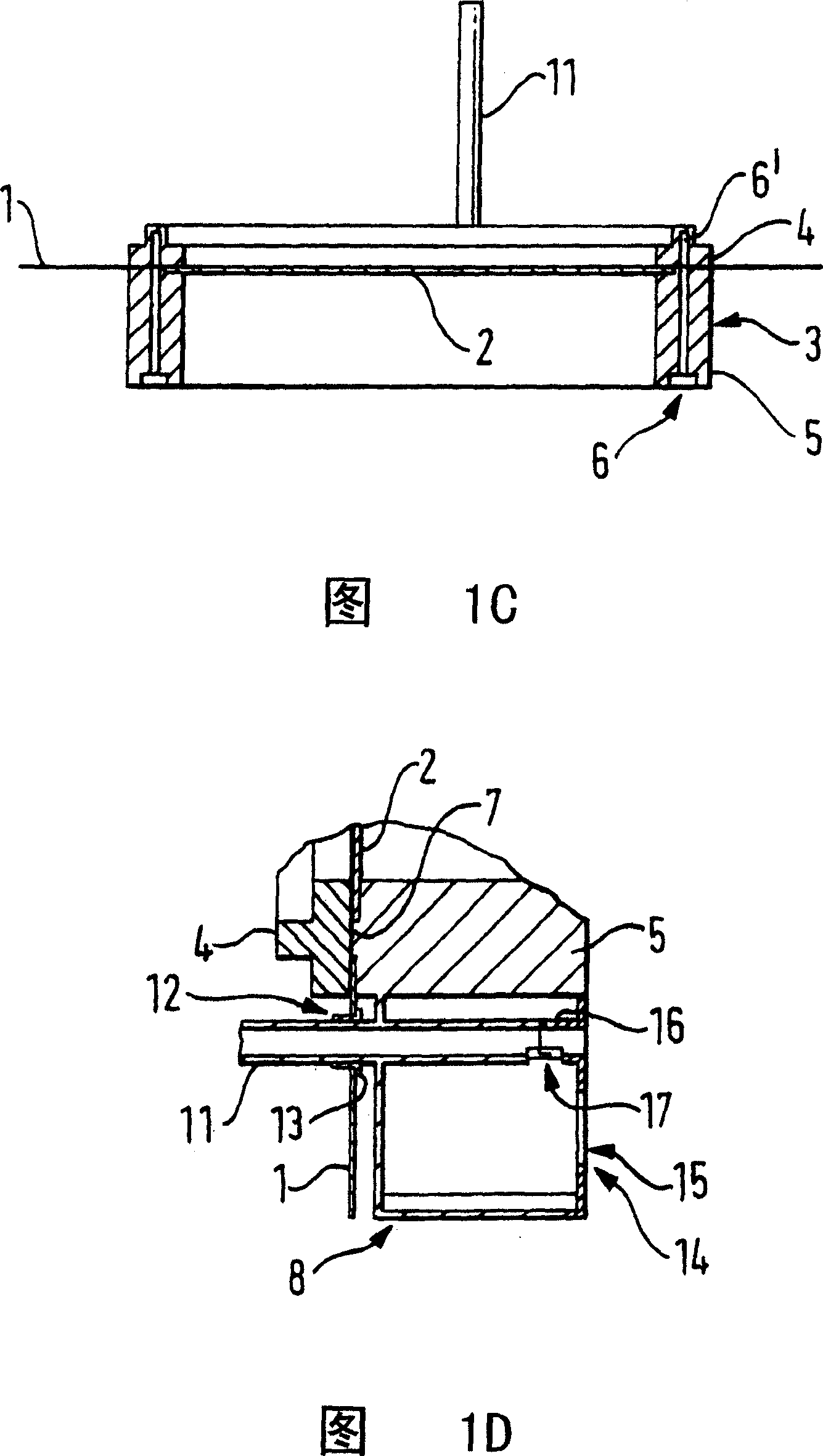

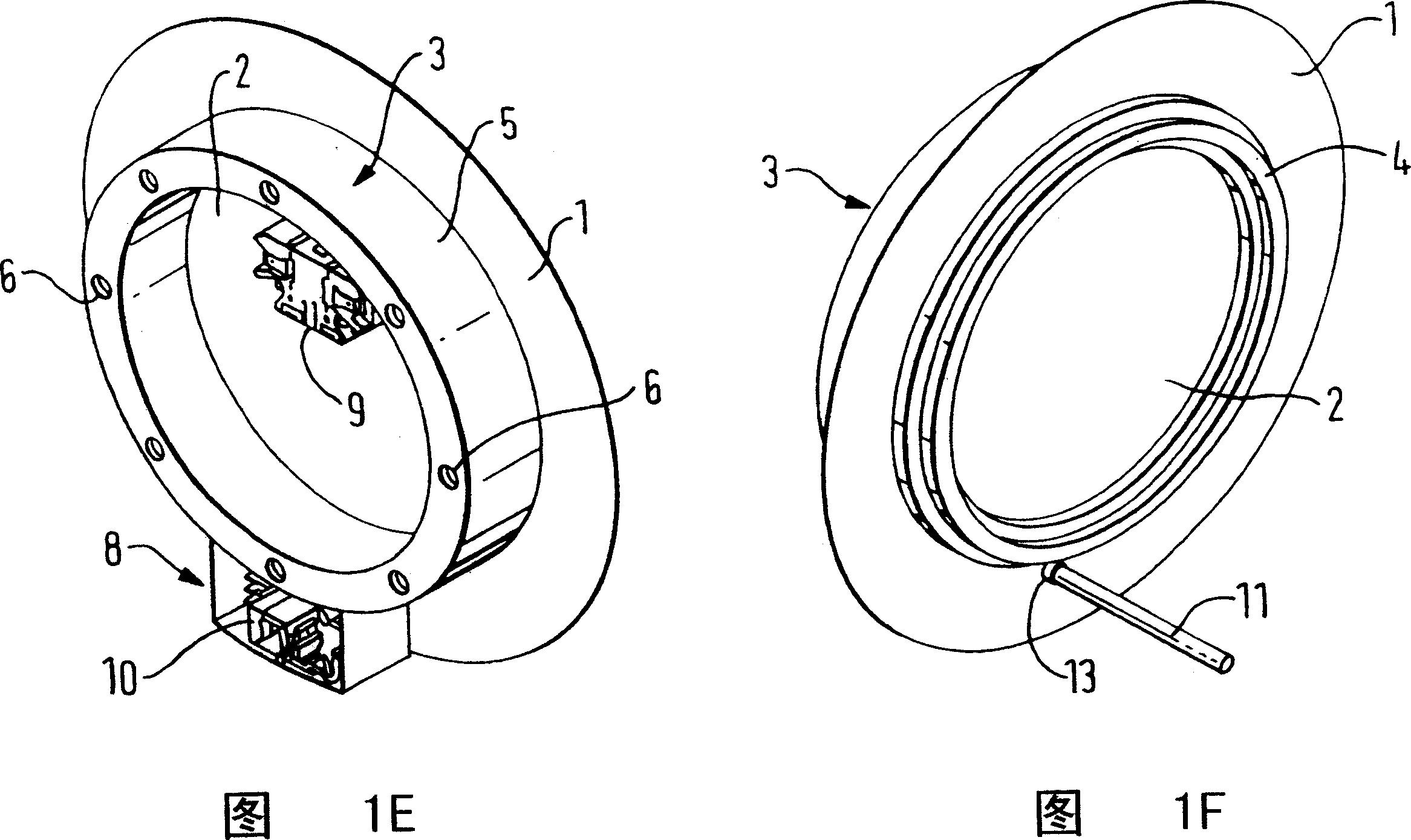

[0018] Referring first to Figures 1A to 1F, these figures show the shape of the base or bottom of an electrically heated water boiler shaped according to one embodiment of the present invention, the shape of which is only shown as part of the base or bottom wall 1 of the boiler, and should be It is understood that the rest of the boiler should be made by the device manufacturer.

[0019] A flat electric heating element 2 is fixed in a hole formed in the bottom 1 of the boiler by means of a chassis ring 3 of molded plastic material. The chassis ring 3 is made up of two parts, a top or upper chassis ring 4 and a bottom or lower chassis ring 5, which are adapted to be screwed by self-tapping screws into aligned holes 6 and 6' formed in these two parts. fixed together. As shown in Figure 1C, the holes in the top 4 are near their innermost ends. As shown more clearly in the enlarged detailed view in Fig. 1D, the top and bottom pan rings 4 and 5 form opposing surfaces which are us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com