External heating vacuum heat treatment tank

A vacuum heat treatment and external heat technology, applied in lighting and heating equipment, furnaces, muffle furnaces, etc., can solve problems such as unfavorable popularization and application of vacuum heat treatment technology, high cost of vacuum heat treatment of small parts, and easy to cause vacuum discharge. To achieve the effect of simple structure, easy vacuum sealing and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

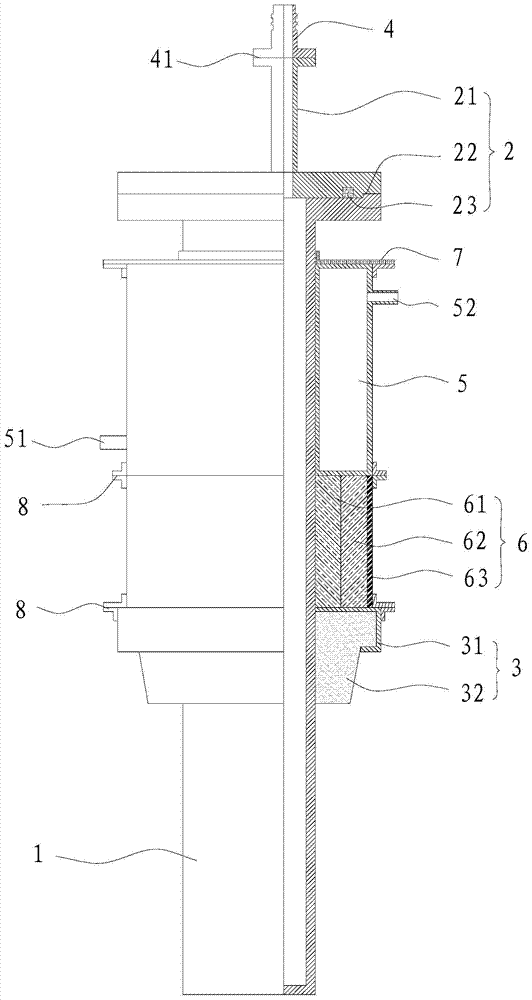

[0016] Such as figure 1 As shown, the present invention includes a tank body 1, the bottom of the tank body 1 is sealed, and the top is open. The opening at the top of the tank body 1 is provided with an air extraction assembly 2 that is sealingly connected with the tank body 1. The air extraction assembly 2 has a The inside of the tank body 1 is connected with an exhaust pipe 21, and the periphery of the middle part of the tank body 1 is provided with a heat-resistant chuck 3 for placing at the door of the resistance furnace. The tank body 1 can be formed by welding austenitic steel plates with argon arc, which is lower in cost than a cylindrical tank body formed at one time. The air extraction assembly 2 is flexibly connected with the tank body 1, and the air extraction assembly 2 can be taken off during use, and the parts to be processed can be put into it. The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com