Coupler mechanism

A buckle and tray technology, applied in the direction of record carrier structural parts, instruments, data recording, etc., can solve problems such as confusion and sound confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

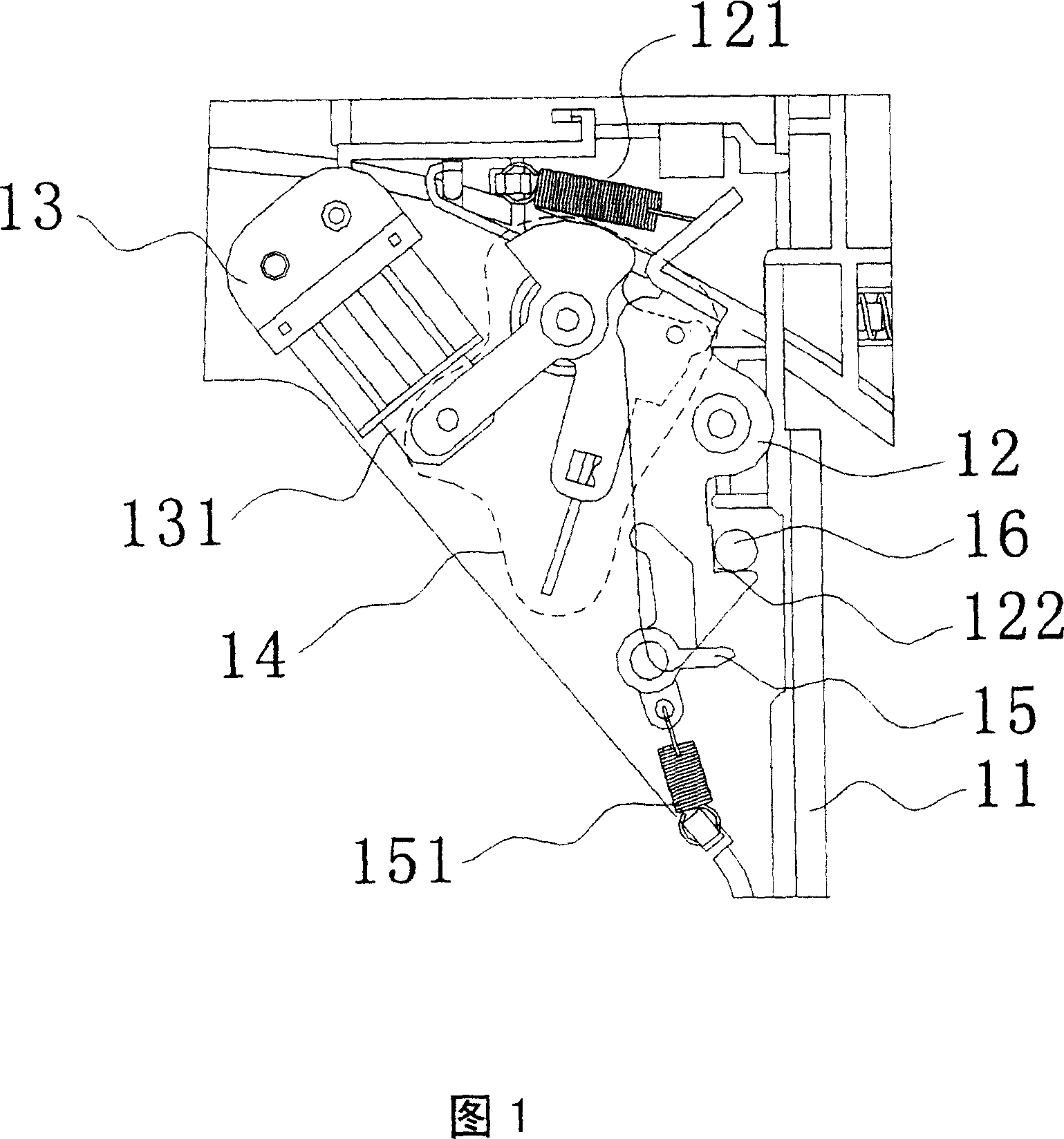

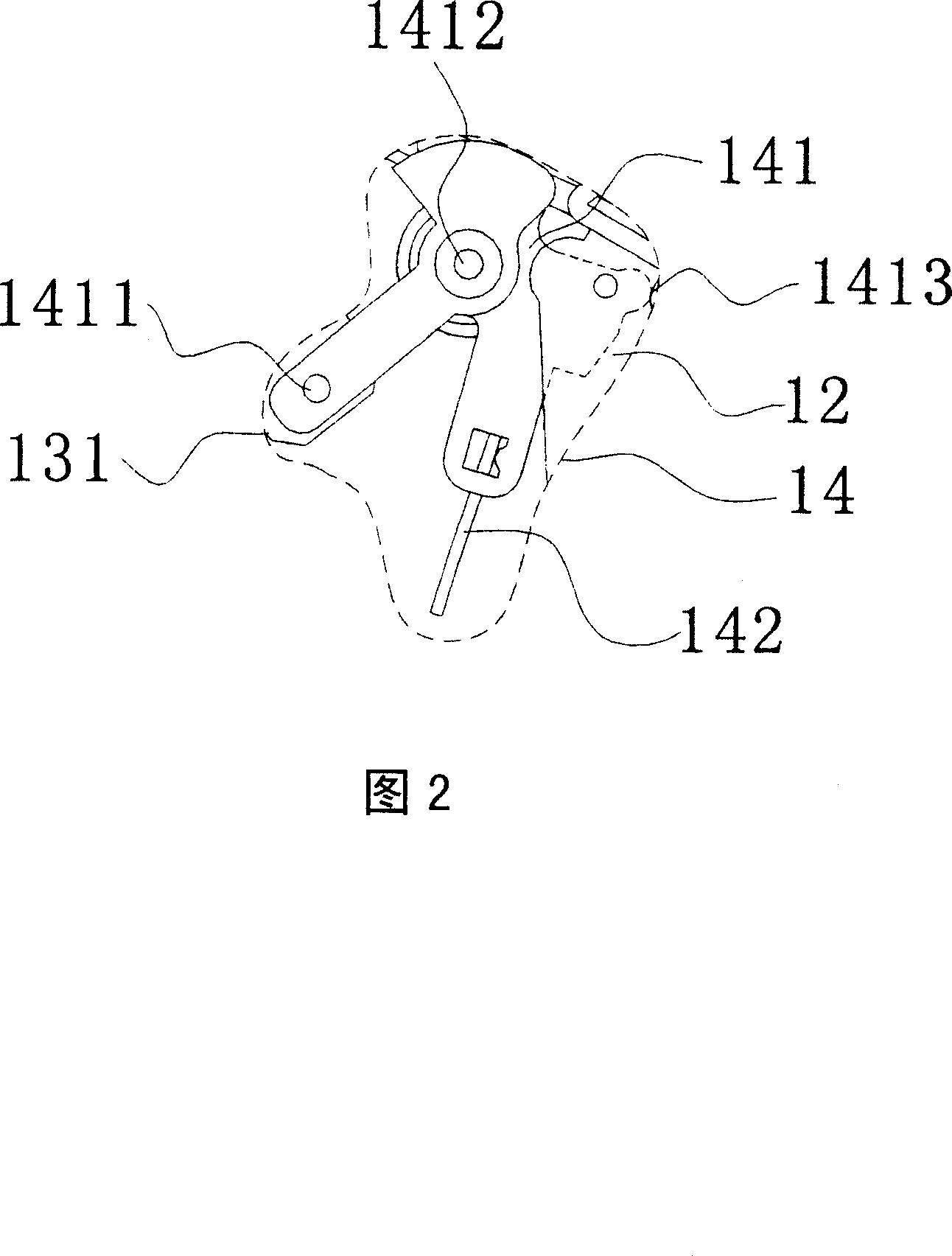

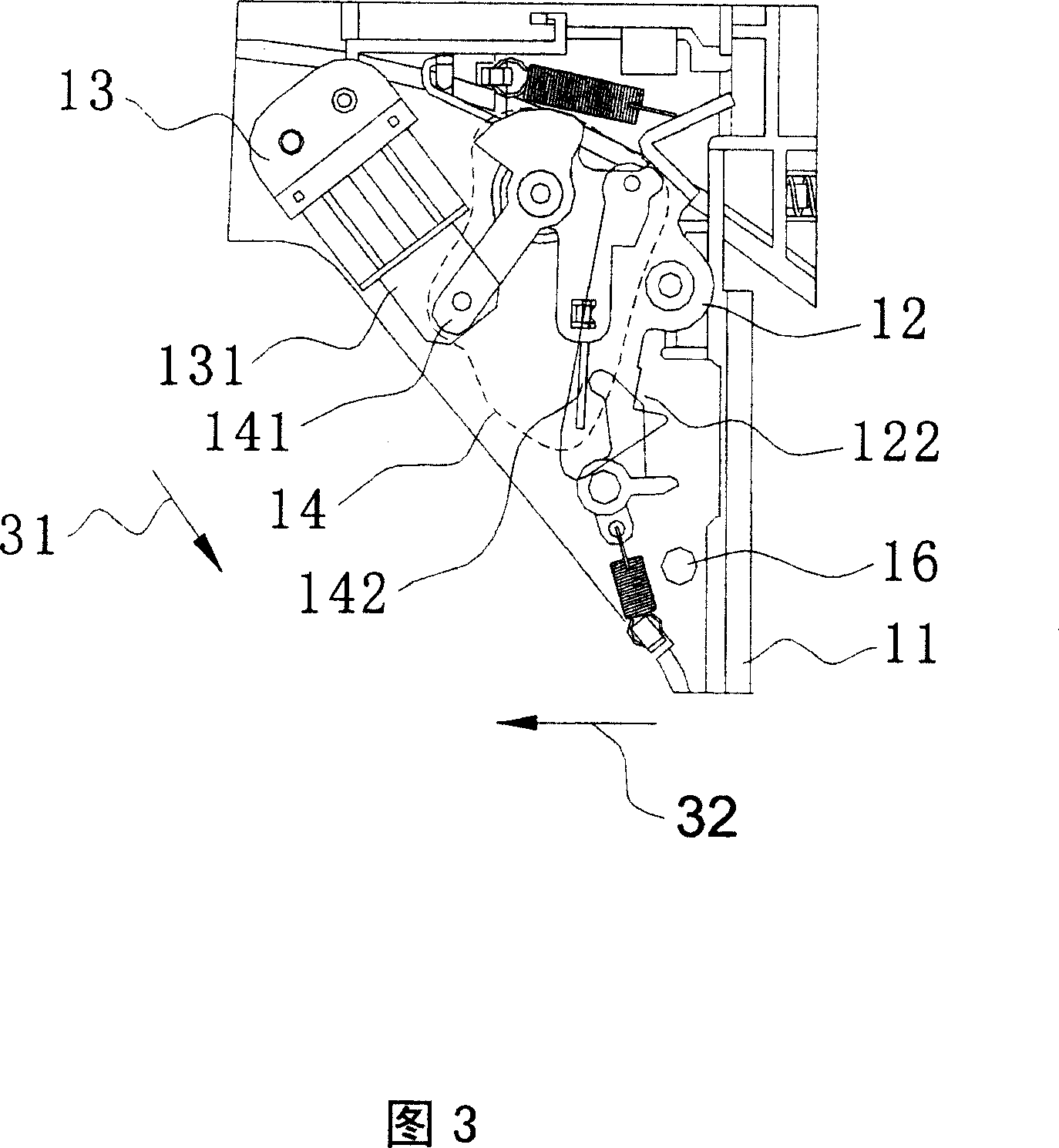

[0030] A hook mechanism according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols.

[0031] 6 to 10 are schematic diagrams of the hook mechanism and film feeding according to the first embodiment of the present invention. Referring to FIG. 6 and FIG. 7 , according to the first embodiment of the present invention, the hook mechanism at least includes a tray 11 , a hook 61 , a solenoid valve 13 , an interlocking device 14 , a first swing arm 62 and a pin 16 . Wherein, the structures of the hook 61 and the first swing arm 62 are different from the existing ones. The hook 61 is connected to the first elastic device 611 and is rotatably fixed on the tray 11 . The solenoid valve 13 is fixed on the tray 11 to provide magnetic force, and a movable block 131 is arranged on one side of the solenoid valve 13 . The linkage device 14 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com