Drive operation tool

A working tool and working technology, applied in nailing tools, manufacturing tools, etc., can solve problems such as hindering the removal of rotating bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

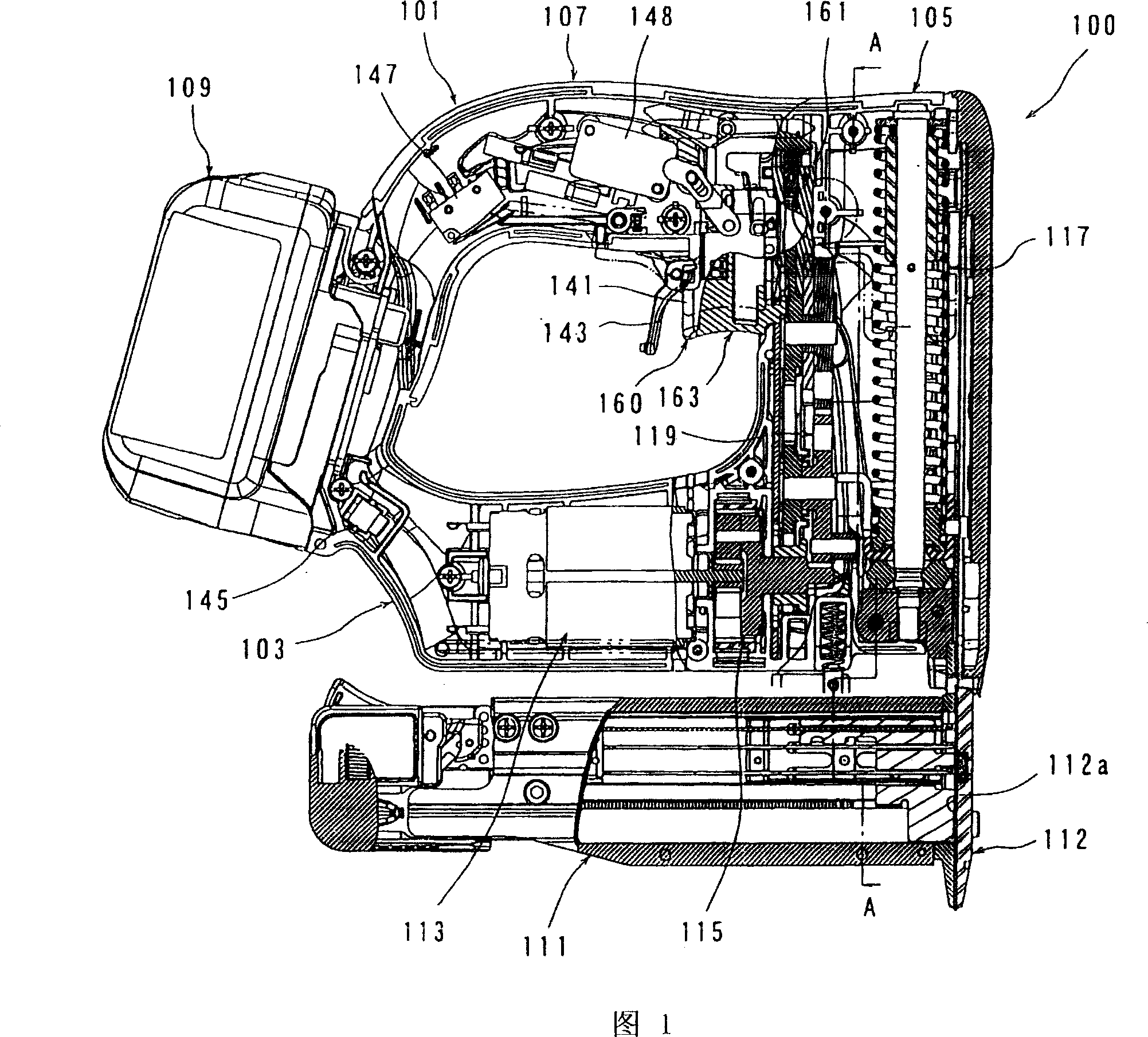

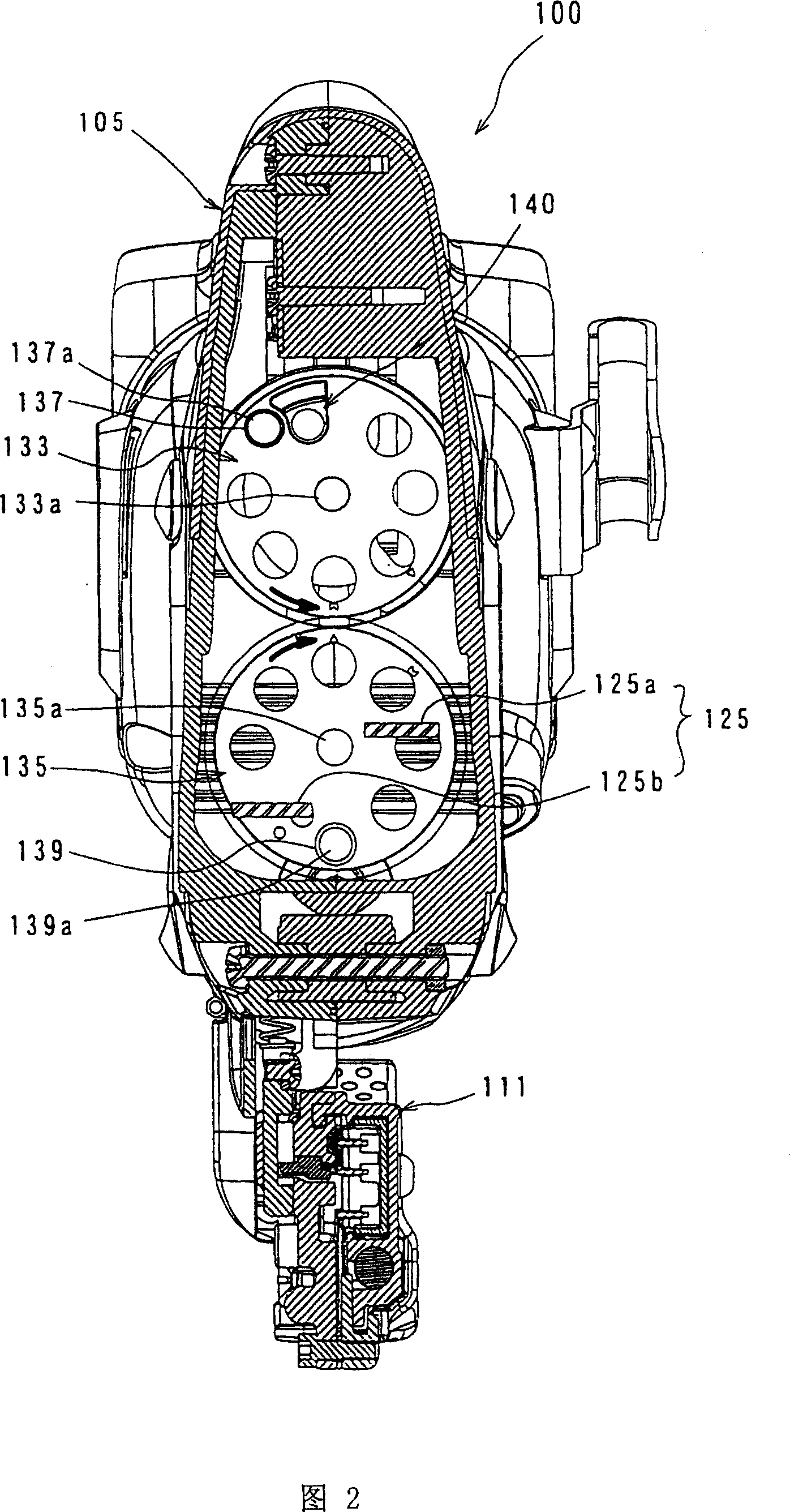

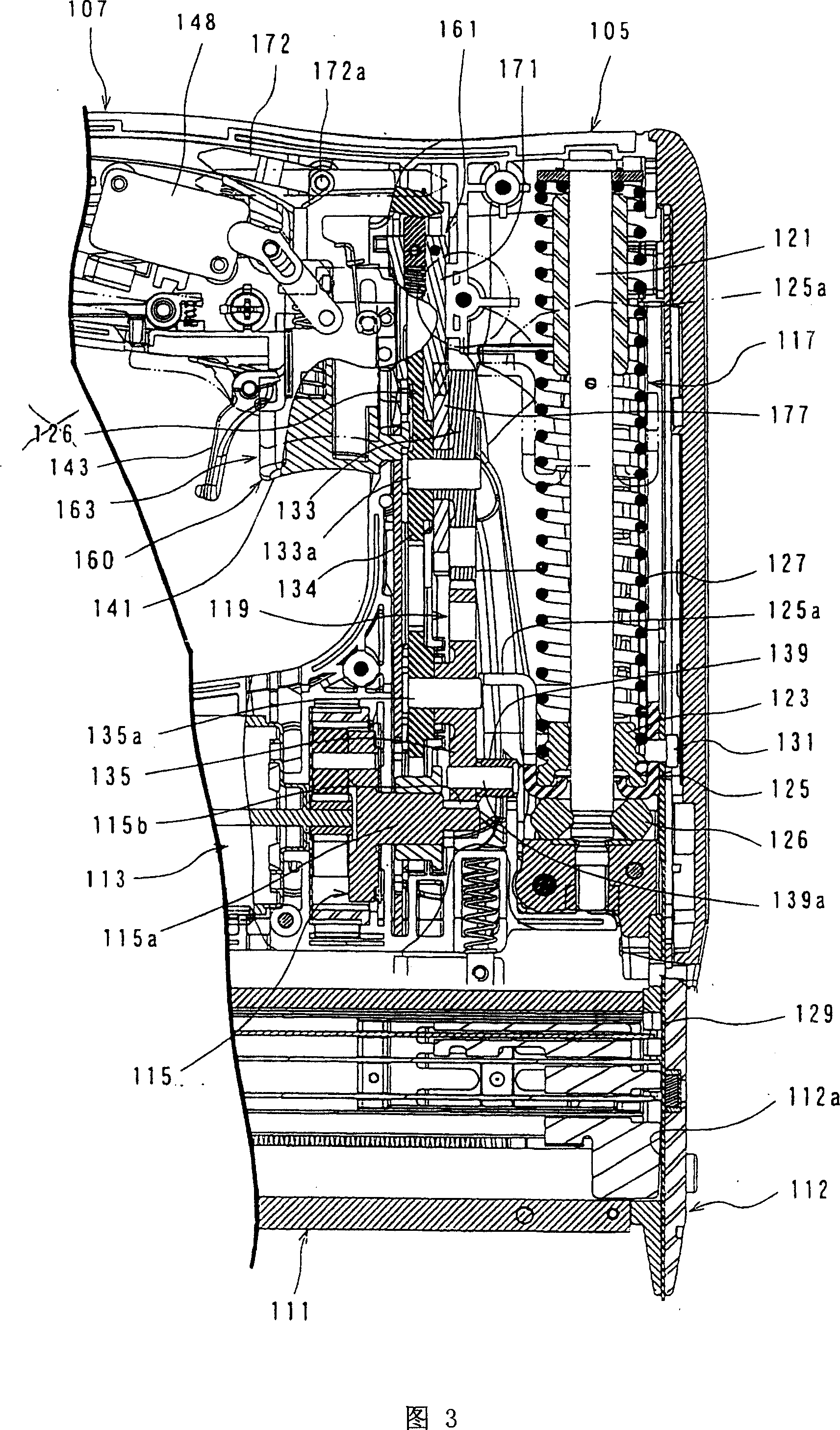

[0056] Hereinafter, an embodiment of the present invention will be described in detail with reference to FIGS. 1 to 9 . This embodiment will be described using a cordless nail gun as an example of the "driving tool" of the present invention. 1 is a side cross-sectional view showing the overall configuration of a cordless nail gun 100 according to the present embodiment, and FIG. 2 is a cross-sectional view taken along line A-A of the cordless nail gun 100 in FIG. 1 . FIG. 3 is an enlarged cross-sectional view illustrating a configuration of a main part of the cordless nail gun 100 of FIG. 1 .

[0057] As shown in FIG. 1 , regarding the rechargeable nail gun 100 involved in this embodiment, in general terms, its main body consists of: a body portion 101 forming the shell of the rechargeable nail gun 100; a battery box 109 for accommodating batteries; The staple magazine 111 is a nail as a driver that is driven into a workpiece.

[0058] The main body 101 includes: a motor hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com