Gas supply system for a pumping arrangement

A technology for purging gas and capillary tubes, which is applied to the components, pumps, and pump elements of pumping devices for elastic fluids, which can solve problems such as increasing costs and simplify installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

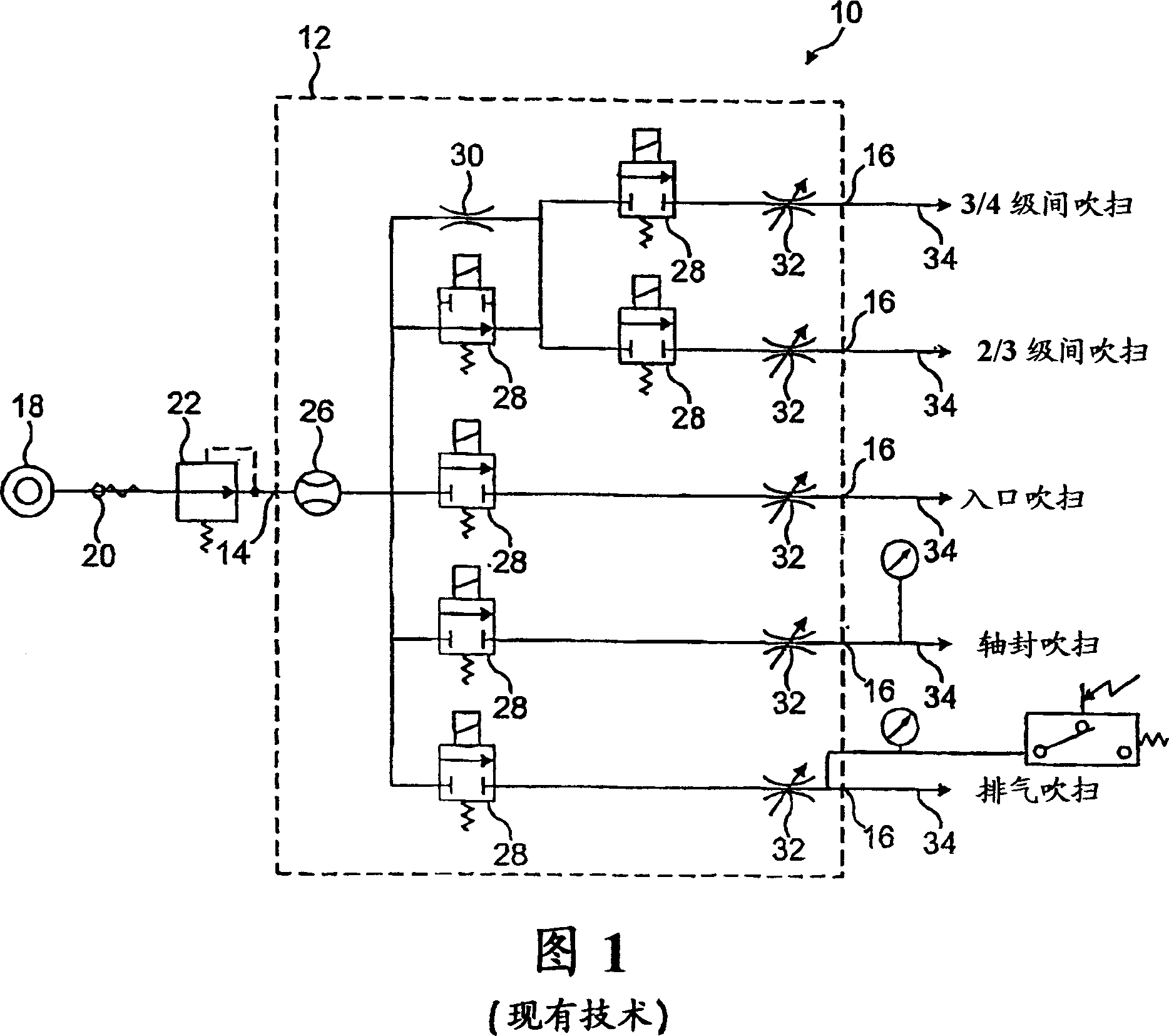

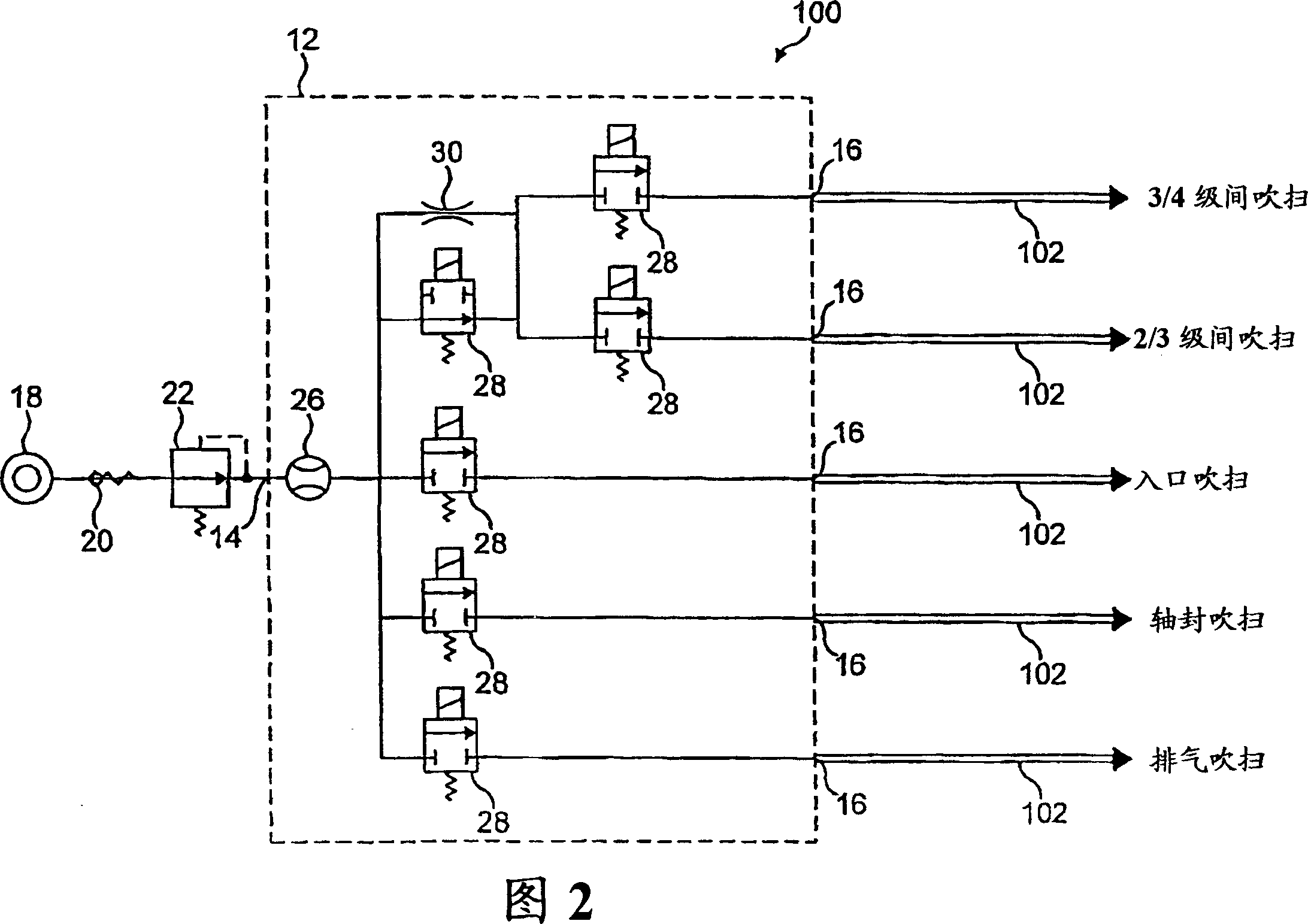

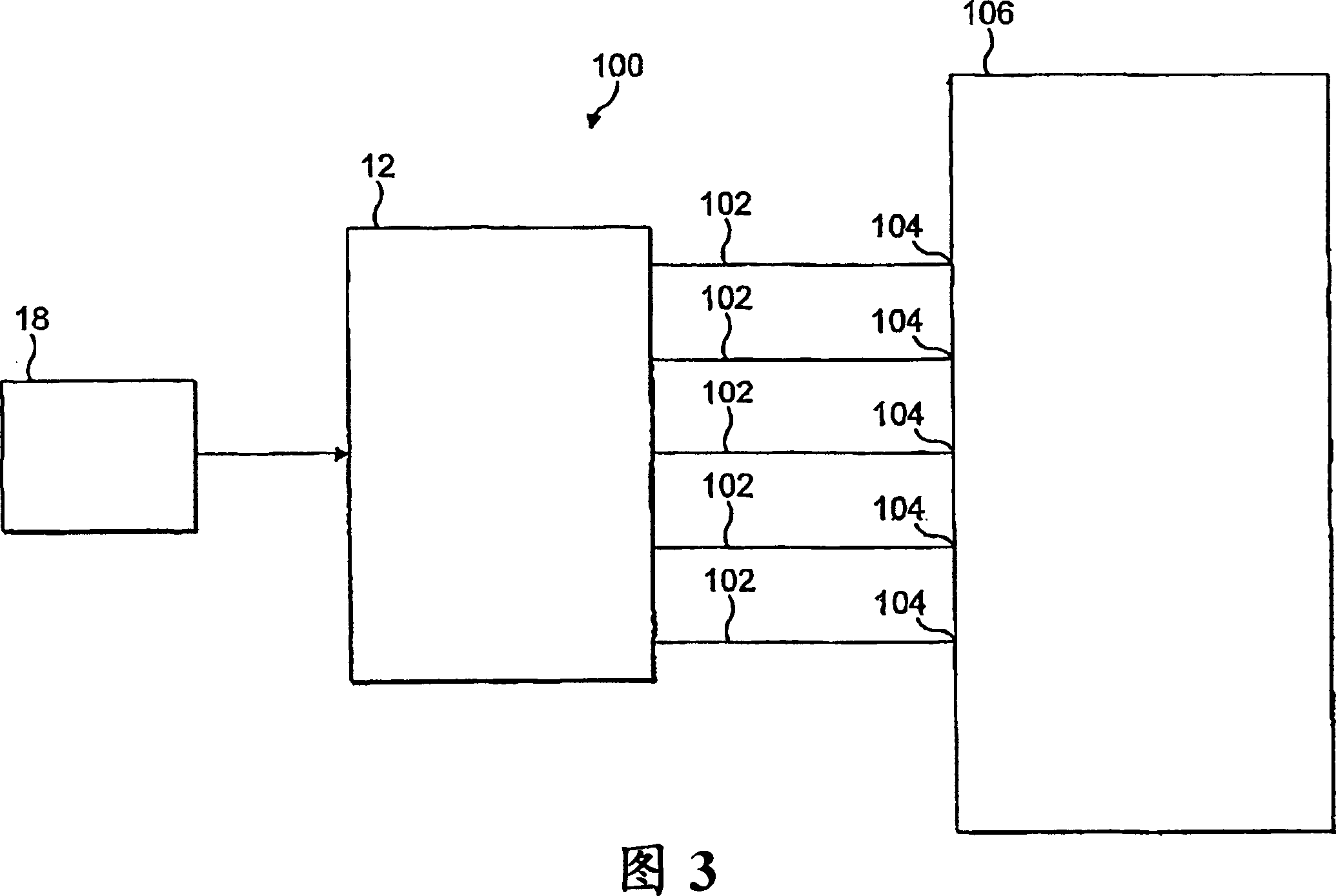

[0021] The gas supply system 100 of the embodiment shown in FIG. 2 differs from the known system previously described with reference to FIG. 1 in that a fixed flow restrictor 30 and The variable restrictor 32 is eliminated, and the rigid tube 34 is replaced by a flexible capillary 102 . As shown in FIG. 3 , each capillary 102 is connected to a corresponding purge port 104 of a pumping device 106 . As shown in Figure 2, these ports 104 may be located at various locations, for example near the inlet, exhaust, shaft seal, and / or at various locations between the suction stages of the pumping arrangement.

[0022] The inner diameter and length of capillary 102 determine the flow rate of purge gas to the purge port. The delivery system 100 may be equipped with a plurality of capillaries 102 of different diameters (eg, ranging from 1 mm to 5 mm). This may enable the user to select an appropriate diameter capillary 102 for connection to a particular purge port, where the capillary m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com