Curved curved composed of curved light duidance plates in use for lighting fixtures

A technology for lighting lamps and light guide plates, applied in the field of curved light sources, can solve the problem that the light source cannot meet the requirements, etc., and achieve the effects of flexible installation and use, beautiful appearance, and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

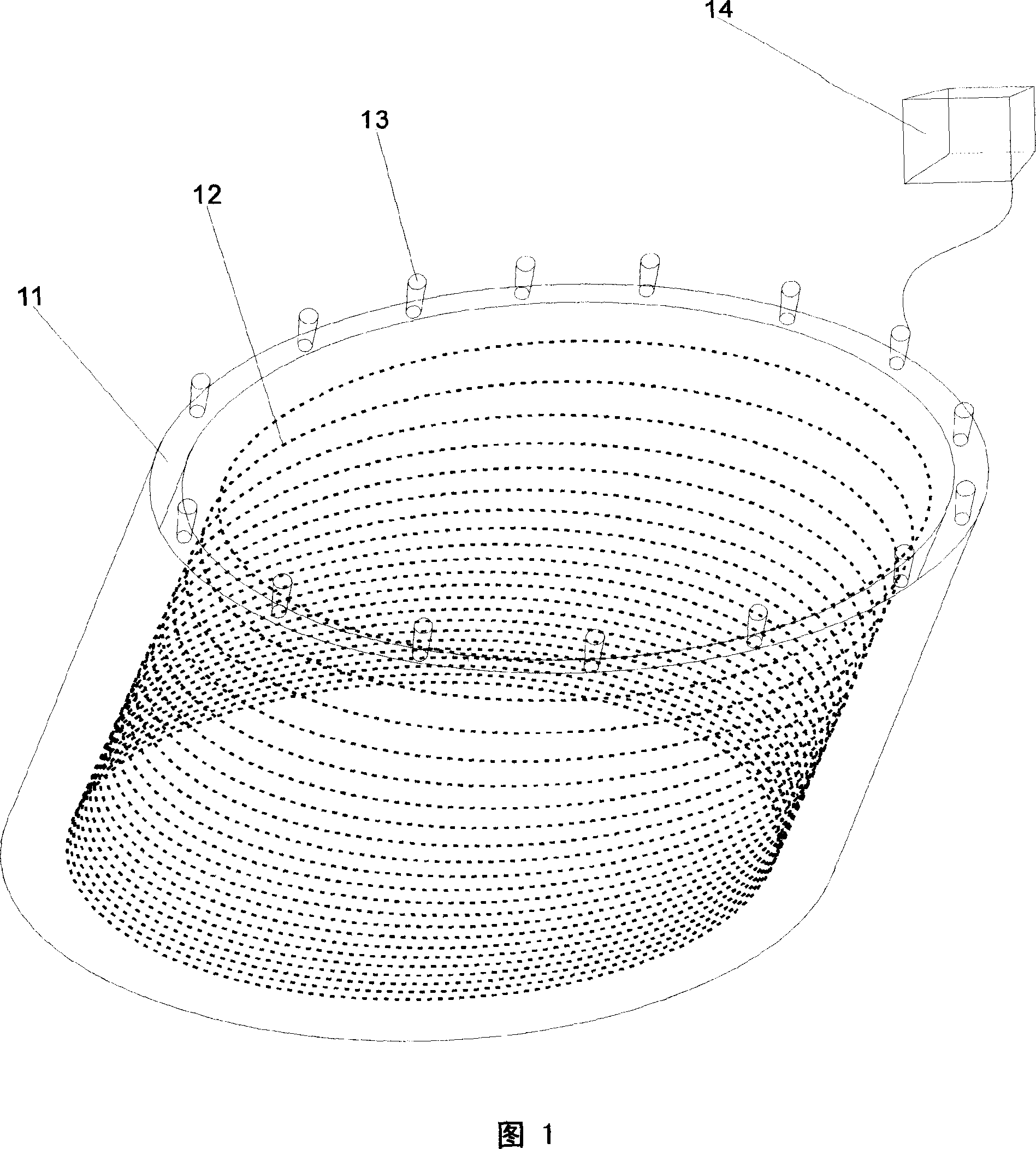

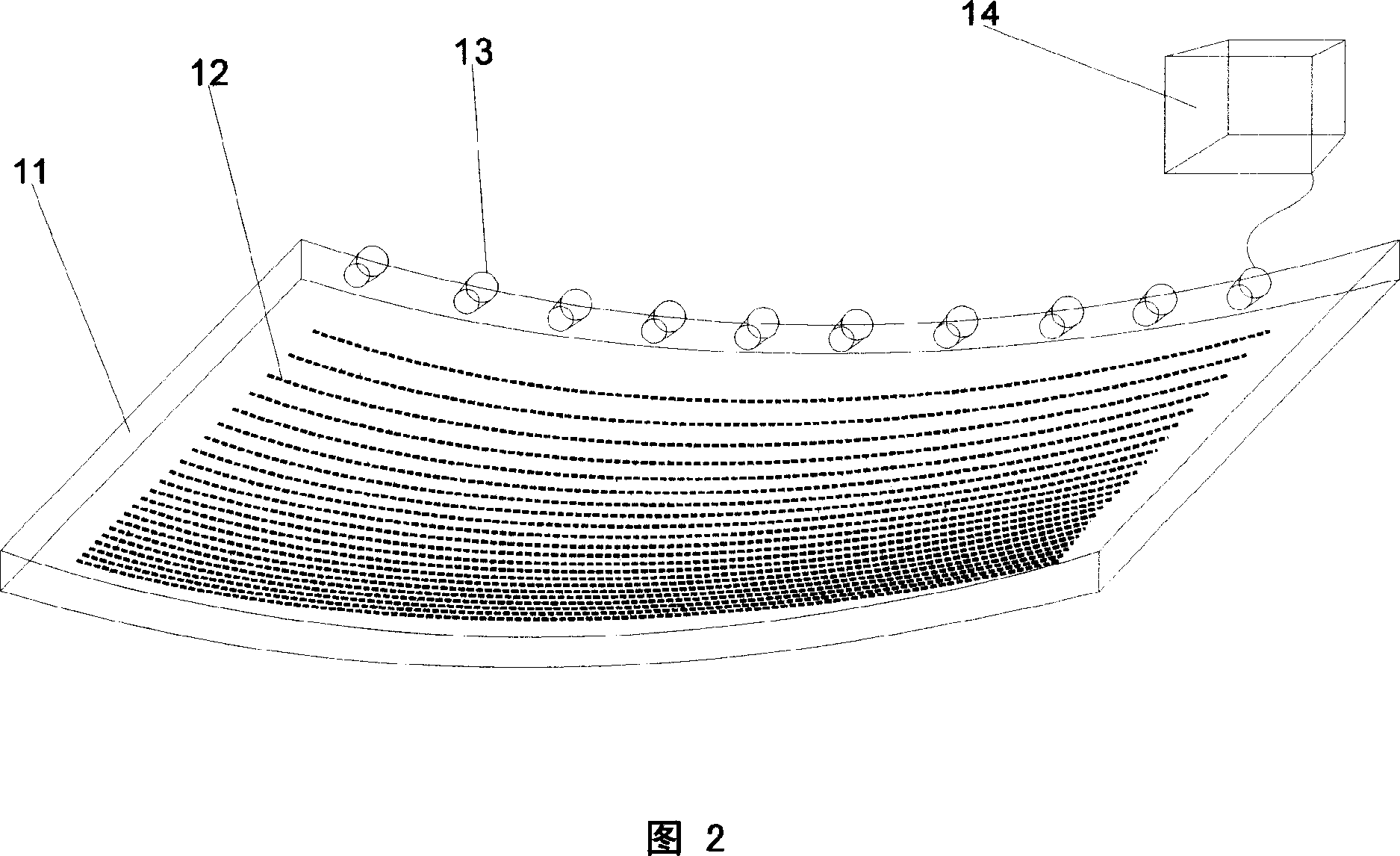

[0013] Fig. 1 is a schematic diagram of an exploded structure of the first embodiment of the present invention. What is shown in the figure is an embodiment of the present invention in which the light guide plate is a cylindrical surface, and the backlight pattern is a linear pattern, with light incident from one side.

[0014] As shown in FIG. 1 , the present invention includes a cylindrical light guide plate 11 on which a light guide pattern 12 is arranged. LED groups 13 are incident with light from the side of the light guide plate and connected to a power source 14 . When the present invention works, the LED group 13 incident light from the side of the light guide plate makes the light guide pattern on the cylindrical light guide plate emit light, forming a surface light source with two cylindrical light emitting surfaces inside and outside. Wherein, the inner l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com