Method for controlling content of salt and alkali in basin tidal flat

A tidal flat and watershed technology, applied in construction, application, soil drainage, etc., can solve problems such as shallow depth, easy silting, collapse, and salinity drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

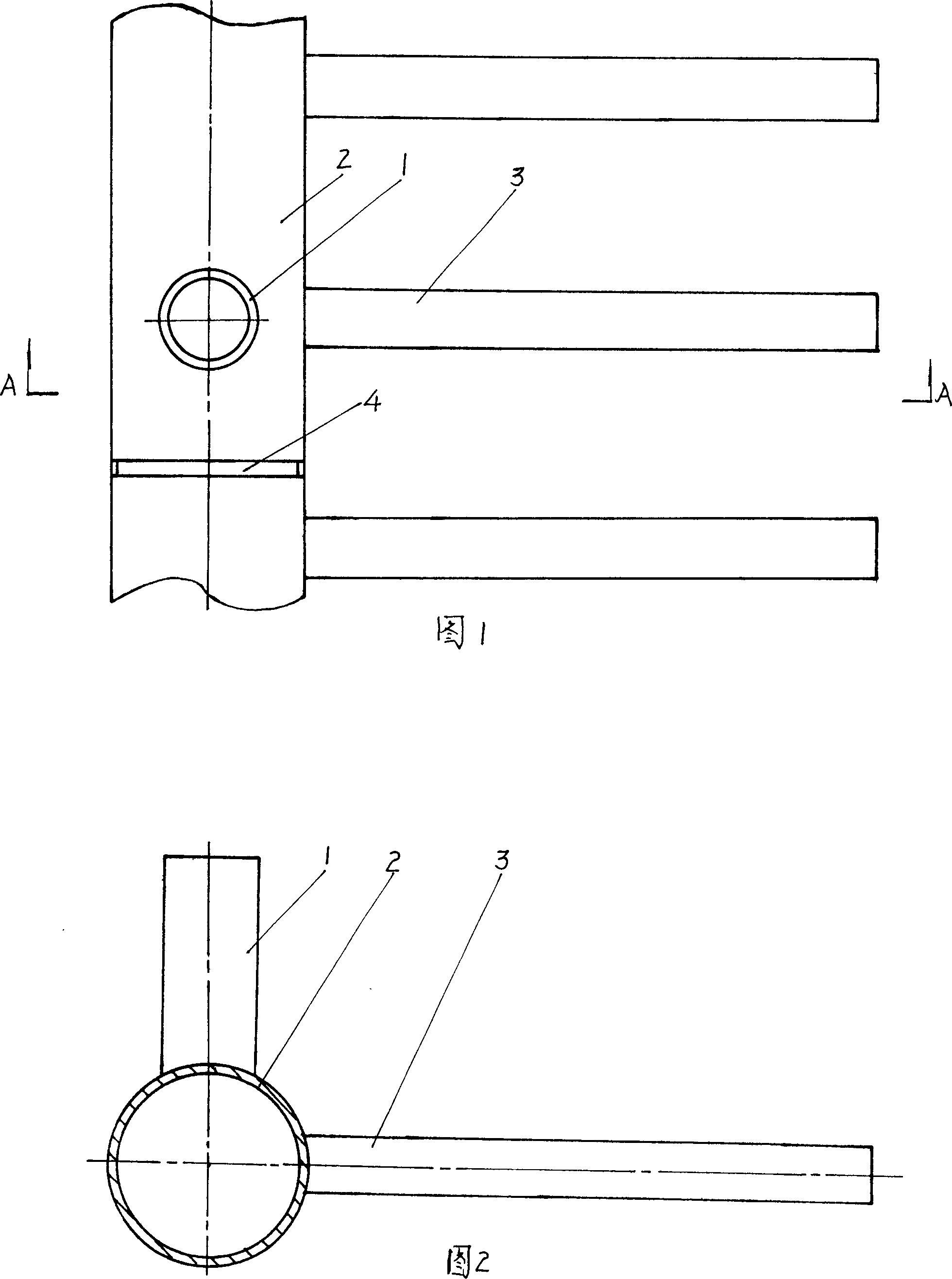

[0017] As shown in Fig. 1, Fig. 2 and Fig. 3, the method for controlling river basin tidal flat saline-alkali in the present embodiment, it comprises the following steps:

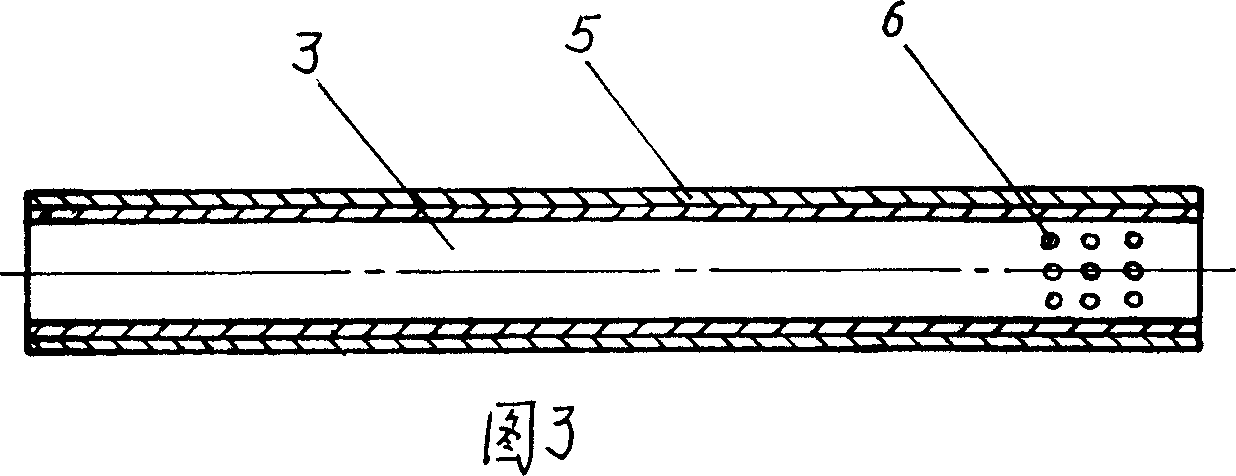

[0018] A, at first on the hollow branch pipe 3 that the diameter that PVC plastic is made is 2cm, process out some rows of sieve holes 6 that the diameter is 1mm, and the distance between every row of sieve holes 6 is 1cm;

[0019] B, wrapping 2 layers of mesh bags 5 on the outer surface of the hollow branch pipe 3 processed through the sieve holes;

[0020] c, burying a main pipeline 2 with a diameter of 1m in the tidal flats of the watershed, and its depth is 1.7m;

[0021] d. In the tidal flats of the watershed, dig a channel with a depth of 1.5m to bury the hollow branch pipe 3 every 5-10m, then put the hollow branch pipe 3 and lay 4mm thick fine sand around the hollow branch pipe 3 to wrap the hollow branch pipe 3 live, one end of each hollow branch pipe 3 is connected with the main pipe 2, and the ot...

Embodiment 2

[0024] As shown in Fig. 1, Fig. 2 and Fig. 3, the method for controlling river basin tidal flat saline-alkali in the present embodiment, it comprises the following steps:

[0025] A, at first on the hollow branch pipe 3 that the diameter that PVC plastic is made is 5cm, process out some row diameters and be the sieve holes 6 of 5mm, the distance between every row of sieve holes 6 is 2cm;

[0026] B, winding 3 layers of mesh bags 5 on the outer surface of the hollow branch pipe 3 with the sieve holes processed;

[0027] c. Embedding a main pipeline 2 with a diameter of 1.5m in the tidal flats of the river basin and a depth of 2.2m;

[0028] d. In the tidal flats of the river basin, dig a channel with a depth of 2.0m to bury the hollow branch pipe 3 every 5-10m, then put the hollow branch pipe 3 and lay 4mm thick fine sand around the hollow branch pipe 3 to wrap the hollow branch pipe 3 live, one end of each hollow branch pipe 3 is connected with the main pipe 2, and the other ...

Embodiment 3

[0031] As shown in Fig. 1, Fig. 2 and Fig. 3, the method for controlling river basin tidal flat saline-alkali in the present embodiment, it comprises the following steps:

[0032] A, at first on the hollow branch pipe 3 that the diameter that PVC plastic is made is 4cm, process out some row diameters and be the sieve holes 6 of 3mm, the distance between every row of sieve holes 6 is 1.5cm;

[0033] B, wrap 3 layers of mesh bags 5 on the outer surface of the hollow branch pipe 3 with the sieve holes processed;

[0034] c, burying the main pipeline 2 with a diameter of 1.3m in the tidal flats of the watershed, and its depth is 1.9m;

[0035] d. In the tidal flats of the river basin, dig a channel with a depth of 1.7m to bury the hollow branch pipe 3 every 5-10m, then put the hollow branch pipe 3 and lay 4mm thick fine sand around the hollow branch pipe 3 to wrap the hollow branch pipe 3 live, one end of each hollow branch pipe 3 is connected with the main pipe 2, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com