Stretching water level transducer of washing machine

A water level sensor, washing machine technology, applied to other washing machines, control devices of washing machines, liquid level indicators for physical variable measurement, etc., can solve problems such as inability to use, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

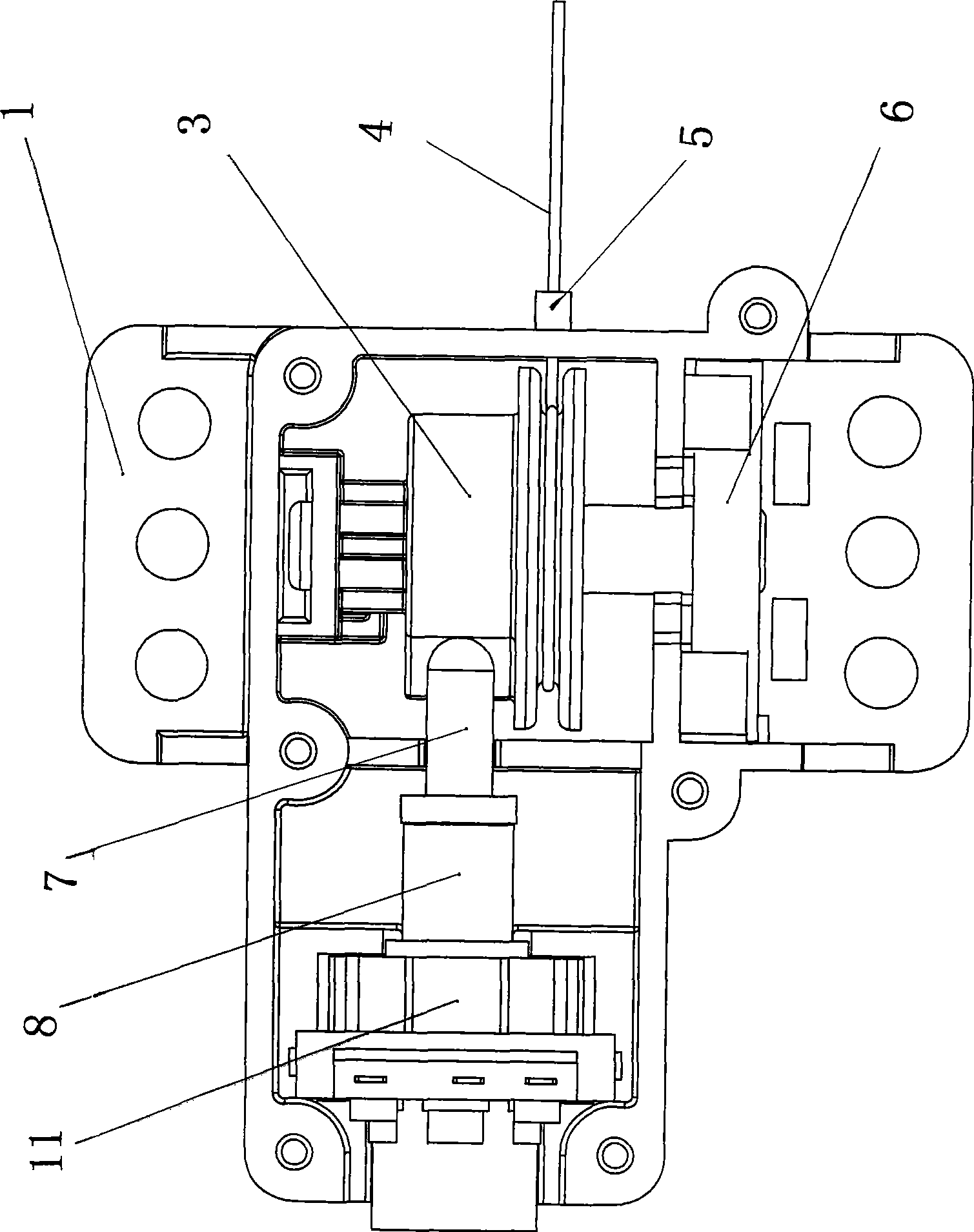

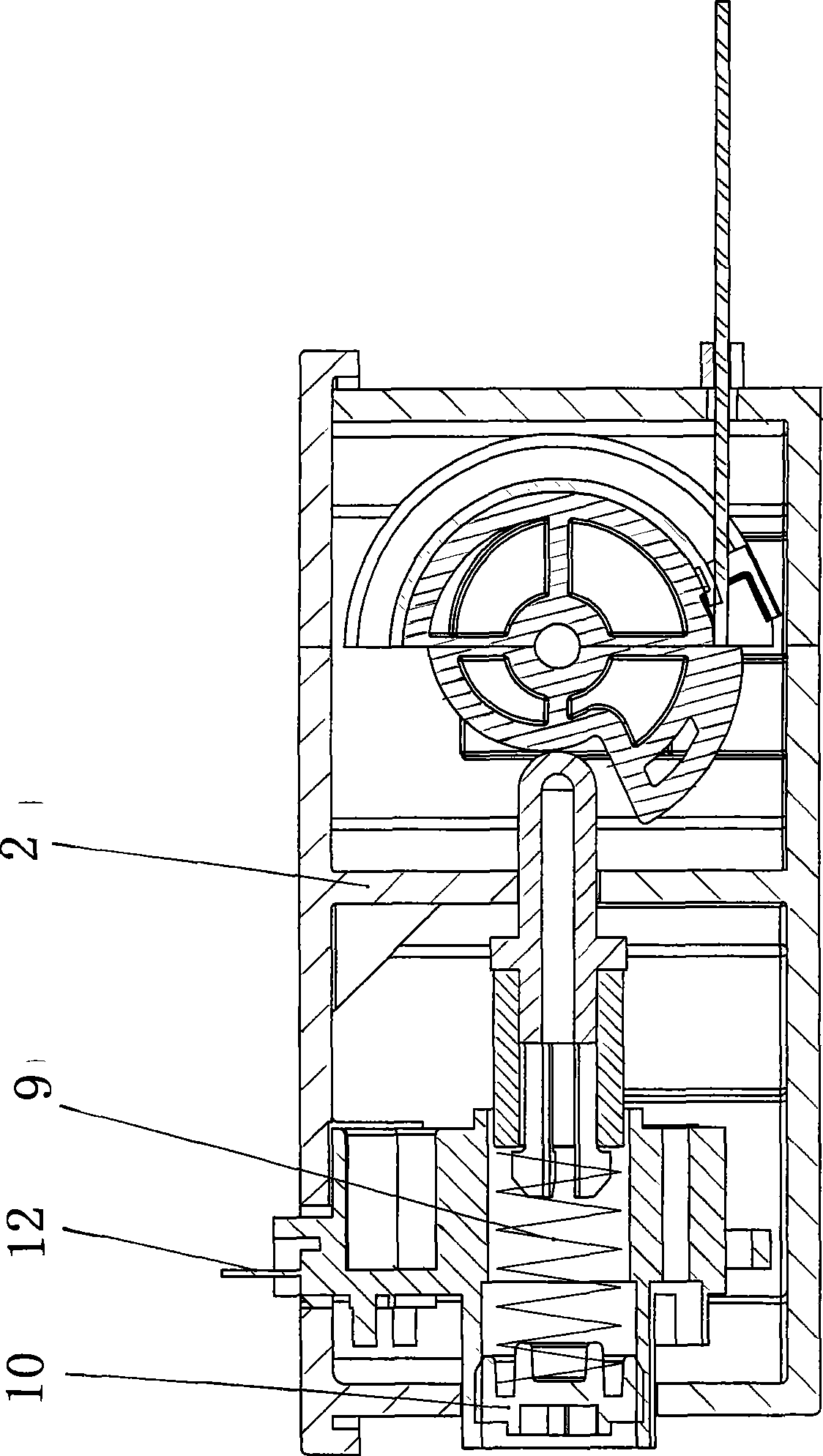

[0009] Such as figure 1 , 2 As shown, a tensile water level sensor for a washing machine includes a housing 1 and an upper cover 2. There is a shaft 3 in the housing 1, and a steel wire rope 4 wound on the shaft 3 is used to give rotation power to the shaft 3, and one end of the steel wire rope 4 is fixed. On the shaft 3, the other end passes through the housing 1 and is limited by a riveting joint 5; the reverse return power of the shaft 3 relative to the wire rope is provided by a clockwork spring 6; during the rotation of the shaft 3, through the shaft 3 The vortex structure cam on the top converts the rotary motion into a linear motion through a transmission rod 7. There is a magnetic core 8 on the transmission rod 7. The left side of the magnetic core 8 is a spring 9 that allows the magnetic core 8 to compress the shaft 3. The spring 9 of the spring 9 On the left is an adjusting screw 10 that compresses the spring. The magnetic core 8 is covered with a plastic-encapsulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com