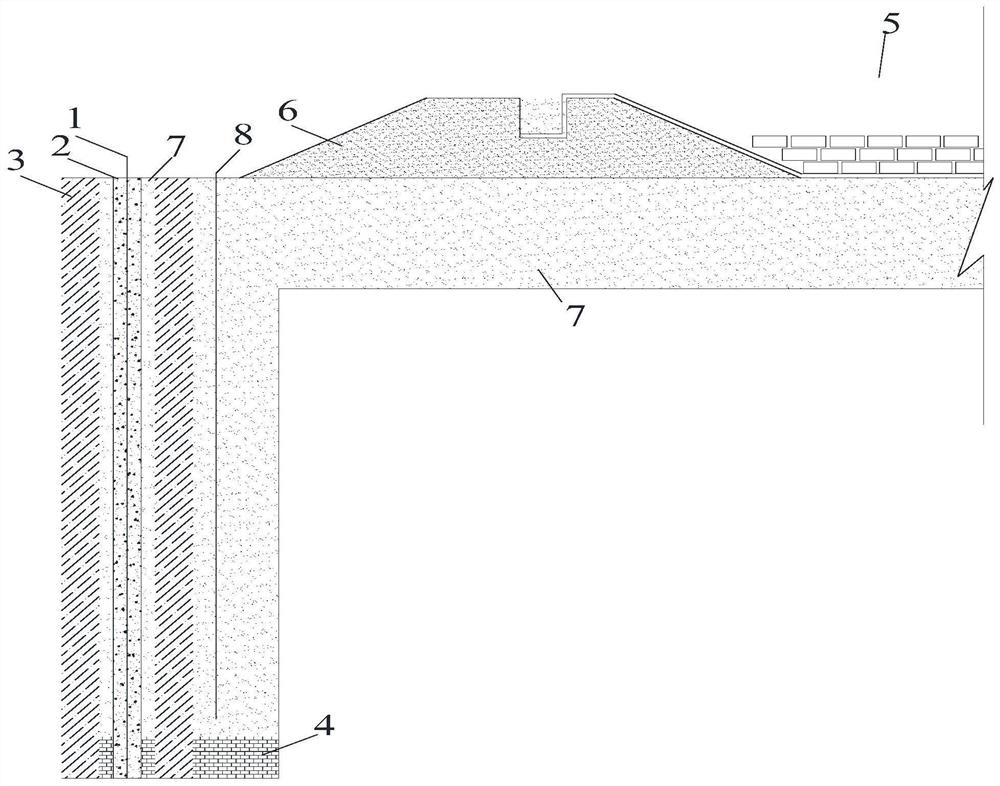

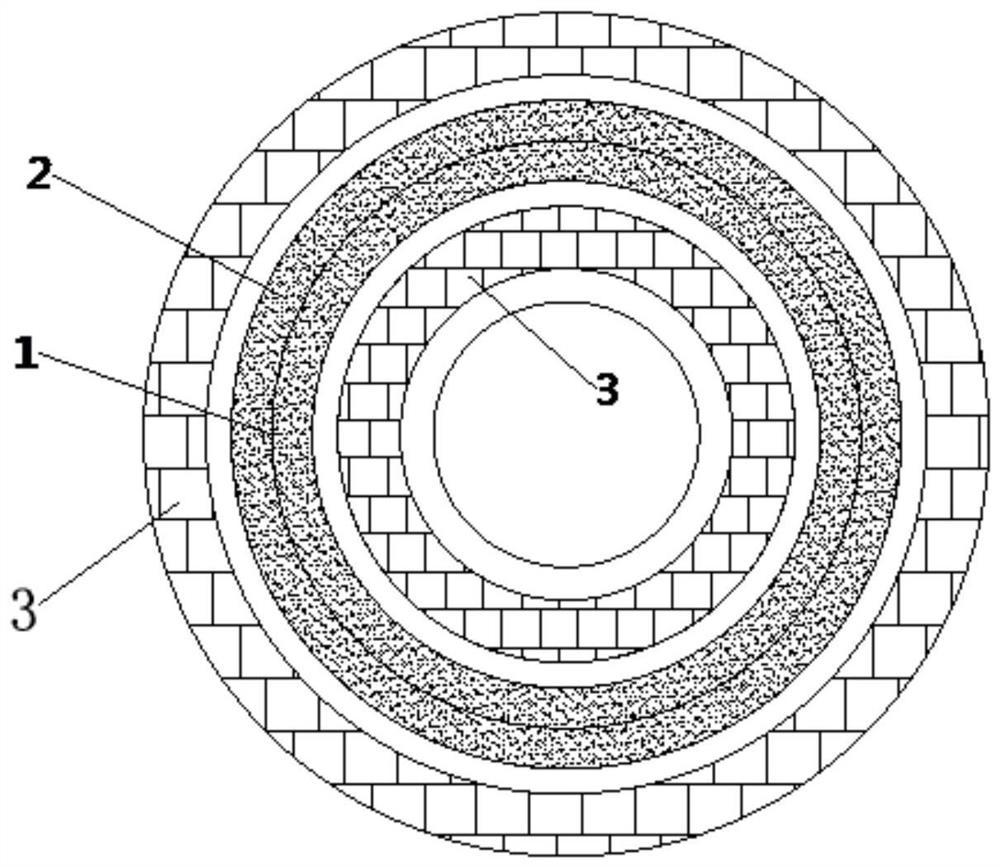

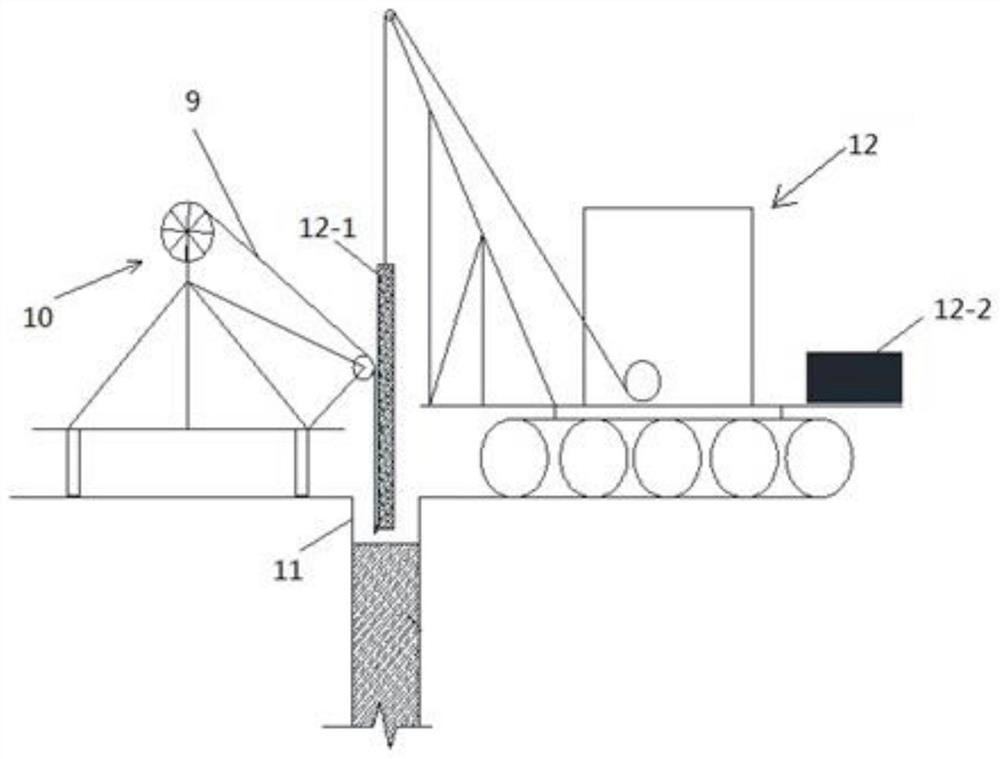

Composite anti-seepage wall and its construction method for environmental protection of landfill in soft soil area

A technology for environmental protection and landfills, applied in protection devices, infrastructure engineering, construction, etc., can solve the problems affecting the effect of bentonite, reducing the strength of plastic concrete and anti-seepage performance, so as to improve cohesion, stability, and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] The composition of the plastic concrete provided by the present embodiment is as follows: on the basis of every cubic plastic concrete, 150kg cement (42.5 ordinary Portland cement), 40kg sodium bentonite (grain size meets 400 mesh sieves below 10%), 75kg clay (water-containing 513kg coarse sand (0.5~3mm), 513kg rice sand (3~5mm), 513kg melon seed slices (5~10mm), 0.6kg alcohol ether sulfuric acid Salt (fatty alcohol polyoxyethylene ether sodium sulfate), 0.1kg polyethylene glycol hydrophilic non-ionic fluorocarbon surfactant (wherein polyethylene glycol molecular weight is 1.8k, fluorocarbon is perfluoro(2-methyl-3 -Oxahexyl) fluoride), 0.5kg polypropylene glycol adduct of ethylene oxide (wherein the number of oxirane groups is 45), 0.0002kg nonionic polyacrylamide, 300kg water. The plastic concrete is prepared according to the preparation method of the present invention.

Embodiment 2

[0119] The composition of the plastic concrete provided by the present embodiment is as follows: in every cubic plastic concrete, with 160kg cement (42.5 ordinary Portland cement), 50kg nano-bentonite (model is the same as embodiment 1), 80kg clay (model is the same as embodiment 1) ), 487kg coarse sand (model is the same as embodiment 1), 487kg rice sand (the model is the same as embodiment 1), 487kg melon seed slices (the model is the same as embodiment 1), 0.7kg alcohol ether sulfate (the model is the same as embodiment 1), 0.4 kg polyethylene glycol hydrophilic nonionic fluorocarbon surfactant (model is the same as embodiment 1), the adduct (model is the same as embodiment 1) of the ethylene oxide of 0.7kg polypropylene glycol, 0.005kg nonionic poly Acrylamide, 320kg water. The plastic concrete is prepared according to the preparation method of the present invention.

Embodiment 3

[0121] The composition of the plastic concrete provided by the present embodiment is as follows: in every cubic plastic concrete, with 180kg cement (42.5 ordinary Portland cement), 60kg nano-bentonite (model is the same as embodiment 1), 90kg clay (model is the same as embodiment 1) ), 465kg coarse sand (model is the same as embodiment 1), 465kg rice sand (the model is the same as embodiment 1), 465kg melon seed slices (the model is the same as embodiment 1), 0.8kg alcohol ether sulfate (the model is the same as embodiment 1), 1kg Polyethylene glycol hydrophilic nonionic fluorocarbon surfactant (model is the same as embodiment 1), the adduct (model is the same as embodiment 1) of the ethylene oxide of 1kg polypropylene glycol, 0.01kg nonionic polyacrylamide , 330kg of water. The plastic concrete is prepared according to the preparation method of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com